Red mud and fly ash fireproof insulation brick

A technology for refractory thermal insulation bricks and fly ash is applied in the field of refractory thermal insulation bricks, which can solve the problems of construction and maintenance costs of multiple storage yards, damage to the ecological environment, waste of resources, etc.

Inactive Publication Date: 2009-08-26

阮克胜

View PDF0 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Stacking is currently the main treatment method for red mud and fly ash. The stacking of red mud and fly ash not only occupies land resources, but also consumes more yard construction and maintenance costs, and damages the ecological environment, causing serious pollution and endangering nature. environment and human health, but also a waste of resources

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0029]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

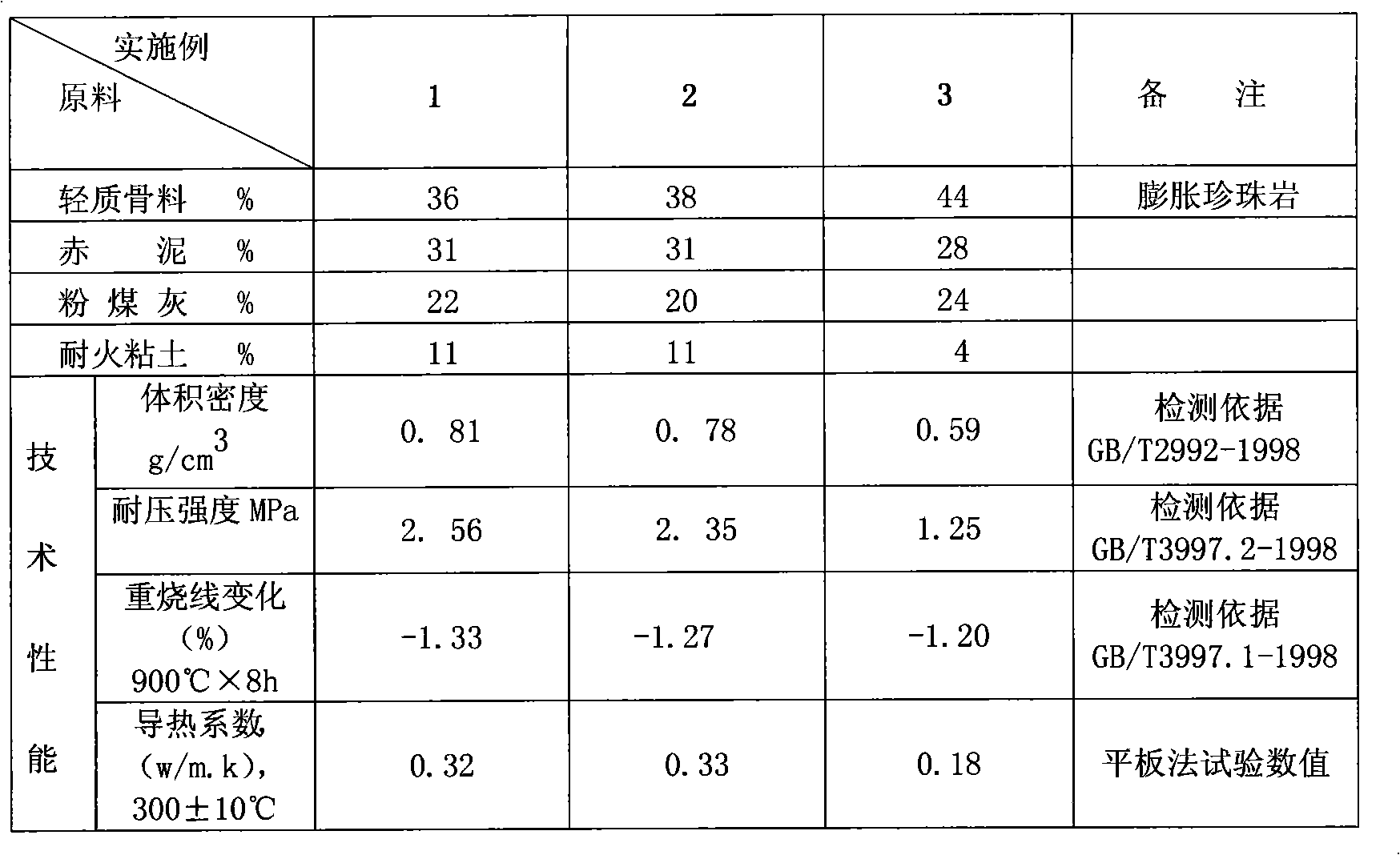

The invention provides red mud and fly ash fireproof insulation brick which use solid waste red mud produced by alumina industry and solid waste fly ash in fuel electric plant as main raw materials and uses lightweight aggregate and fireproof clay as auxiliary materials. The weight percentage of each component is 10-60 of red mud, 10-50 of fly ash, 15-48 of lightweight aggregate, 4-18 of fireproof clay and 12-25 of water. The used lightweight aggregate is lightweight ceramsite, floating bead, vermiculite, expansion perlite or other lightweight fireproof raw material. The red mud and the fly ash fireproof insulation brick of the present invention have advantages of small volume density and low heat conduction coefficient, can be used for heat-insulation layer of industrial high temperature kiln in industries such as metallurgy, machinery, non-ferrous metal, power, chemical industry and building material, can insulate heat for thermal source, can prevent heat loss in with temperature higher than ambient temperature, and reaches purpose of utilizing industrial waste material, saving resource and energy and reducing emission.

Description

Technical field: [0001] The invention belongs to refractory and thermal insulation materials, in particular to a refractory and thermal insulation brick used for lining a thermal insulation layer of a high-temperature kiln. Background technique: [0002] Red mud is industrial solid waste that is discharged after refining alumina from bauxite. To produce one ton of alumina, 1.0-2.0 tons of red mud must be discharged. With the continuous increase of alumina production, the discharge of red mud continues to increase. At present, the world produces about 70 million tons of red mud every year, and our country produces more than 20 million tons of red mud every year. [0003] Fly ash is one of the largest industrial wastes in my country. It is a solid waste discharged from coal combustion in thermal power plants and urban heating boilers. With the continuous increase of thermal power plants and urban heating projects, the discharge of fly ash is also increasing. At this stage, th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B35/66

Inventor 阮克胜

Owner 阮克胜

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com