Magnetic powder core material with stable magnetic permeability and low loss and preparation method thereof

A magnetic powder core and magnetic permeability technology, which is applied in the direction of magnetic materials, inorganic materials, magnetic objects, etc., can solve the problems of reducing the magnetic permeability of soft magnetic composite materials, high production environment requirements, and low uniformity of insulating layers. To achieve the effect of ensuring high saturation magnetization, ensuring thickness and reducing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

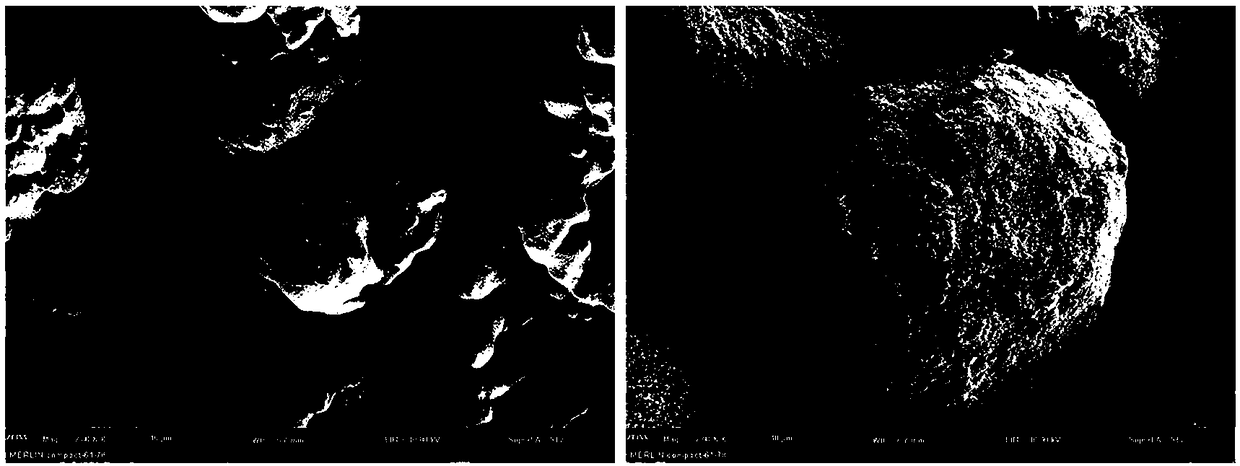

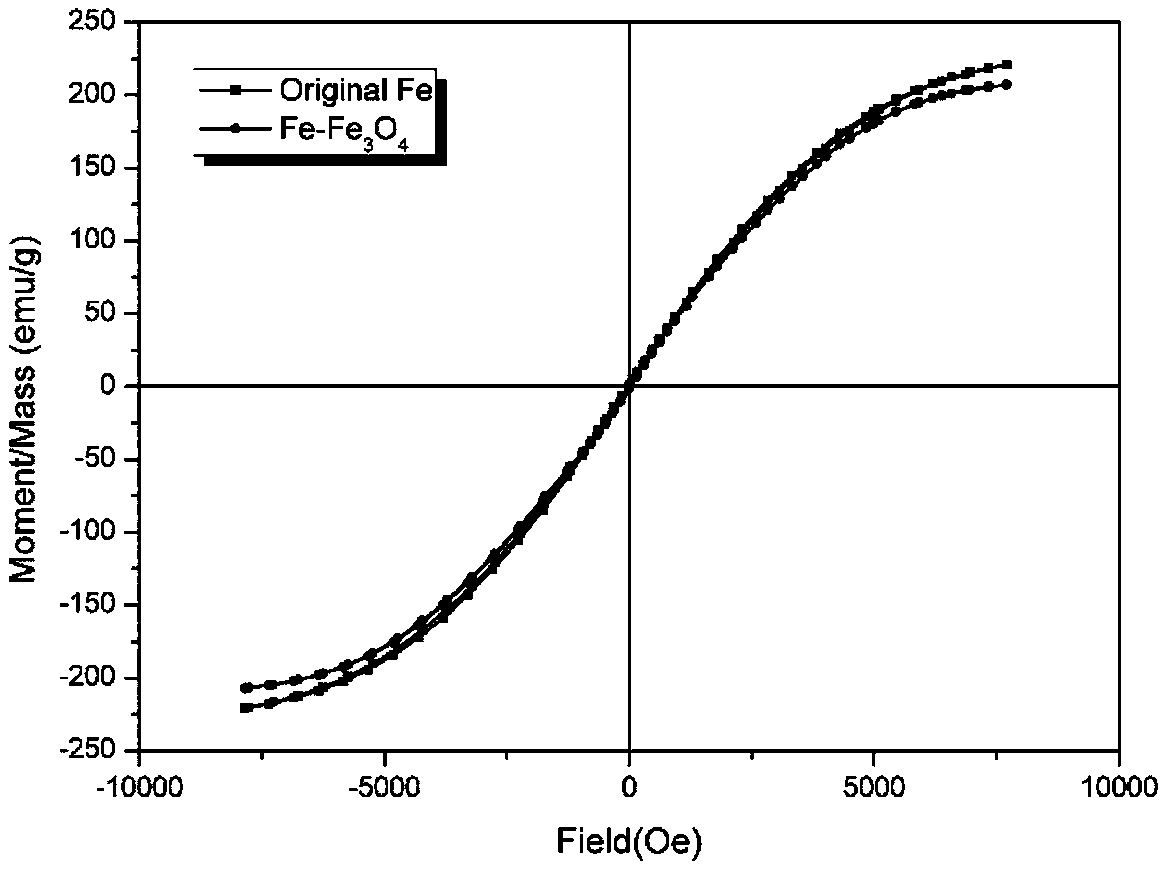

[0039] Weigh 47g of water-atomized pure Fe powder with an average particle size of 75μm in a beaker, add ammonia water that can wet the iron powder, stir clockwise with a glass rod for 20min, and then weigh 3g of Fe powder with a particle size of 20nm 3o 4 Powder, premixed in a V-blender. Use a planetary ball mill to carry out dry ball milling, and take the Fe / Fe prepared by dry ball milling 3 o 4 Core-shell structure coated powder 4g, the scanning electron microscope picture of the prepared coated powder is as follows figure 1 As shown, comparing the powder surface morphology before and after ball milling, it can be seen that the smooth water atomized pure Fe powder surface is compounded in situ under the action of ball milling to obtain soft magnetic composite powder. Using VSM equipment to test the saturation magnetic induction of composite powder, such as image 3 As shown, it can be known that its saturation magnetic induction is 207emu / g, which is only 5.9% lower tha...

Embodiment 2

[0043] Weigh 47g of water-atomized pure Fe powder with an average particle size of 300μm in a beaker, add ammonia water that can wet the iron powder, stir clockwise with a glass rod for 20min, and then weigh 3g of Fe powder with a particle size of 20nm 3 o 4 Powder, premixed in a V-blender. Use a planetary ball mill to carry out dry ball milling, and take the Fe / Fe prepared by dry ball milling 3 o 4 Core-shell structure coating powder 4g, add epoxy-modified silicone resin with a mass fraction of 1% soft magnetic powder, fully mechanically stir at 80°C, and then put the dry powder into a ring-shaped alloy steel mold for room temperature pressing , pressed at a pressurization rate of 5MPa / s, and held at 800Mpa for 3min to obtain an iron / ferric oxide block composite material with an outer diameter of 20mm, an inner diameter of 12mm, and a height of 3mm. The block is subjected to vacuum heat treatment at 450°C for 1h, and the vacuum degree is ≤10 -3 Pa. Utilize the B-H analyz...

Embodiment 3

[0047] Weigh 47g of water-atomized pure Fe powder with an average particle size of 75μm in a beaker, add ammonia water that can wet the iron powder, stir clockwise with a glass rod for 20min, and then weigh 3g of Mn powder with a particle size of 50nm 0.6 Zn 0.4 Fe 2 o 4 Powder, premixed in a V-blender. Using planetary ball mill for dry ball milling, Figure 5 Fe / Mn obtained after high energy ball milling 0.6 Zn 0.4 Fe 2 o 4 From the scanning electron microscope image of the composite powder, it can be seen that the ball milling process has the same effect on oxides of different compositions or particle sizes, and can obtain soft magnetic composite powder with uniform oxide coating on the surface. Fe / Mn prepared by dry ball milling 0.6 Zn 0.4 Fe 2 o 4 Core-shell structure coating powder 4g, add epoxy-modified silicone resin with a mass fraction of 1% soft magnetic powder, add amorphous iron silicon boron powder 0.5g, fully mechanically stir at 80°C, and then put the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Saturation magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com