Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

94results about How to "Guaranteed manufacturing cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

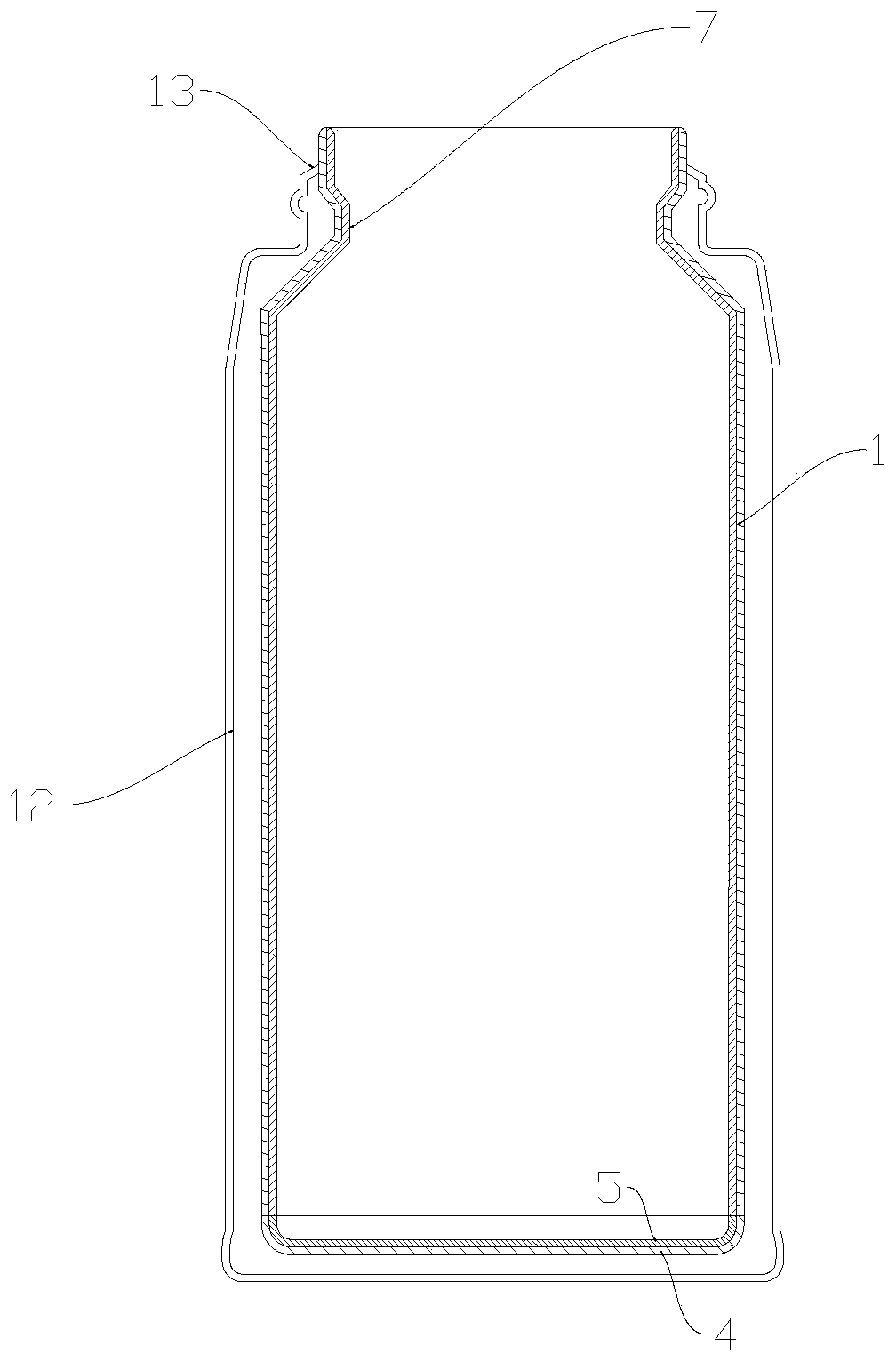

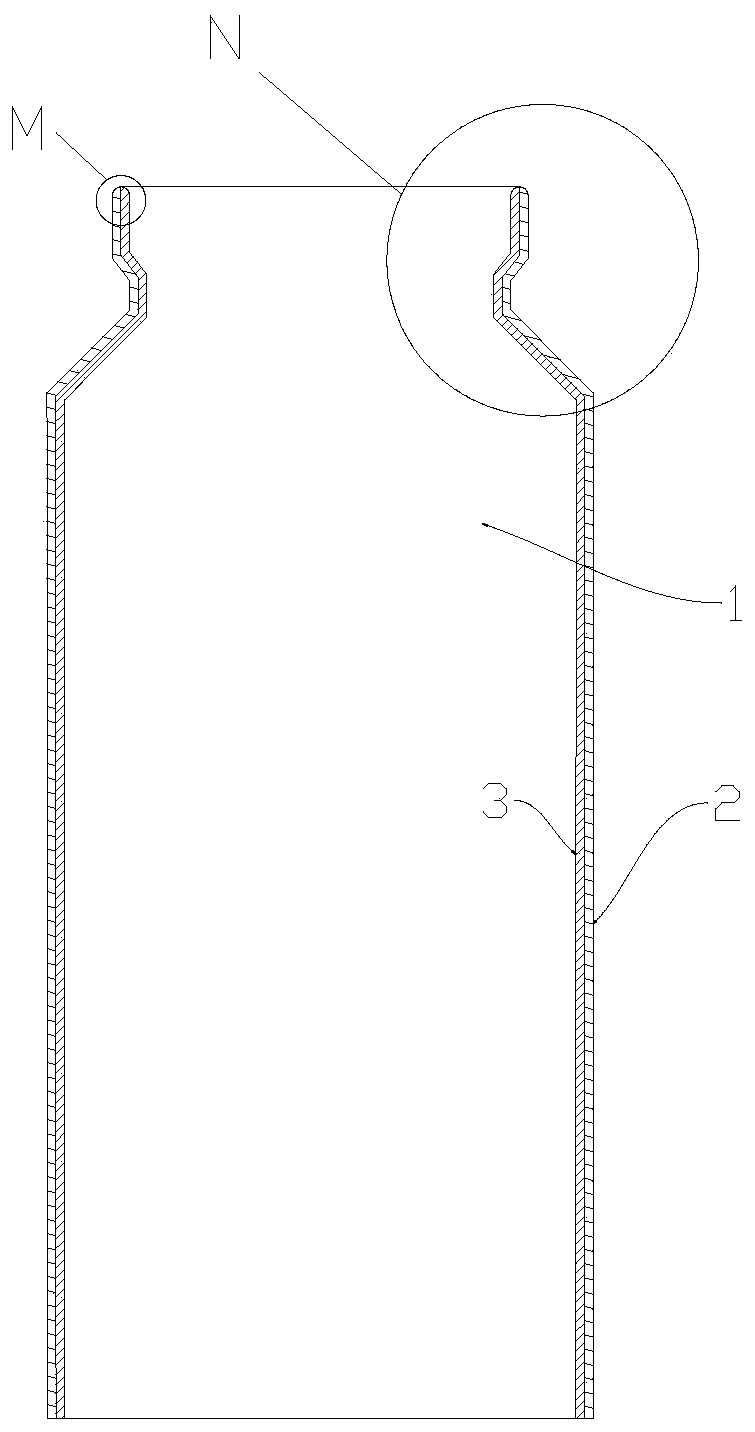

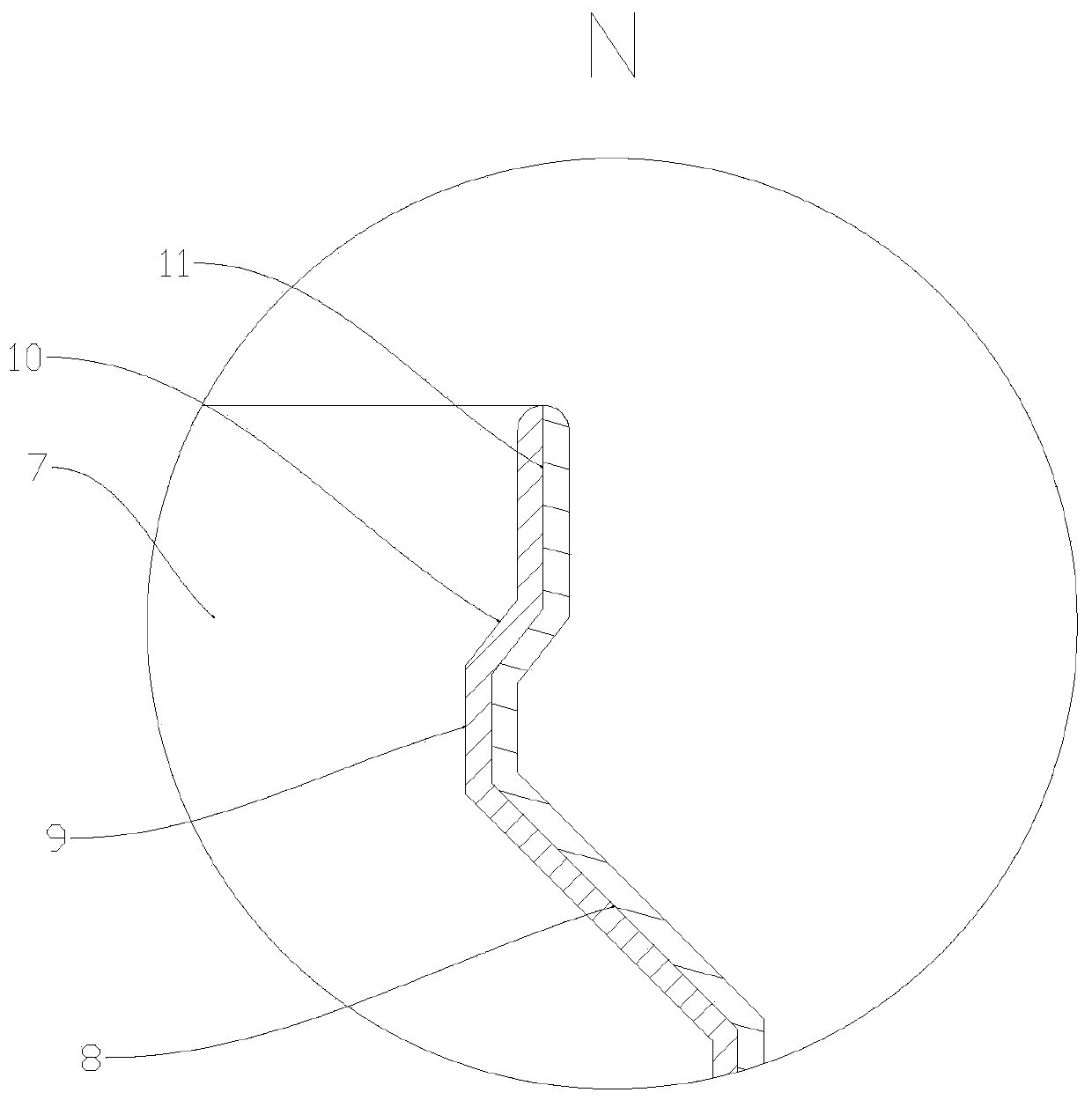

Insulation cup with titanium composite inner tank and manufacturing process thereof

ActiveCN111250620AReduce manufacturing costGuaranteed manufacturing costDwelling equipmentDrinking vesselsTitaniumStainless steel material

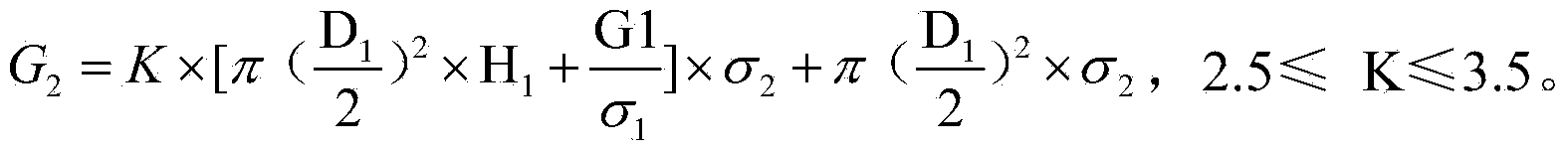

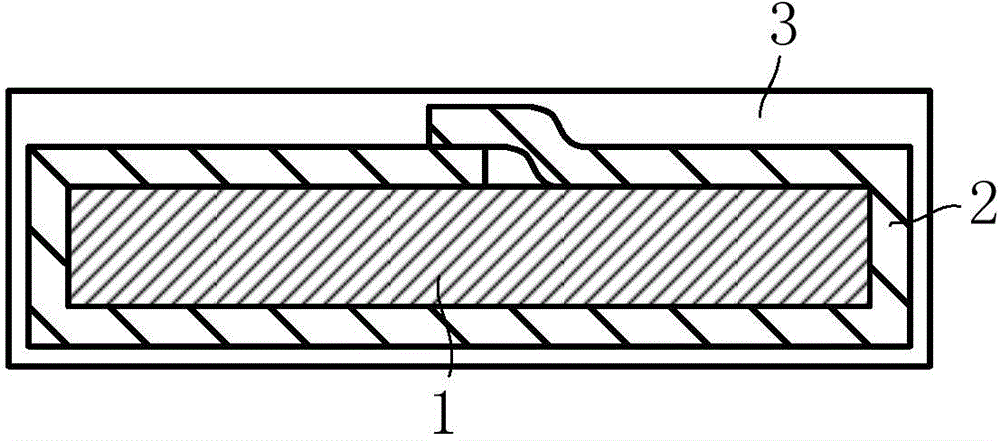

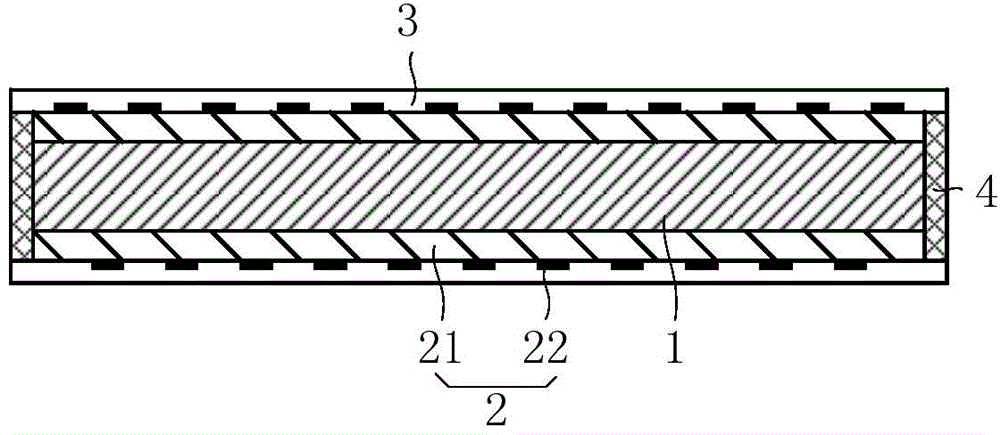

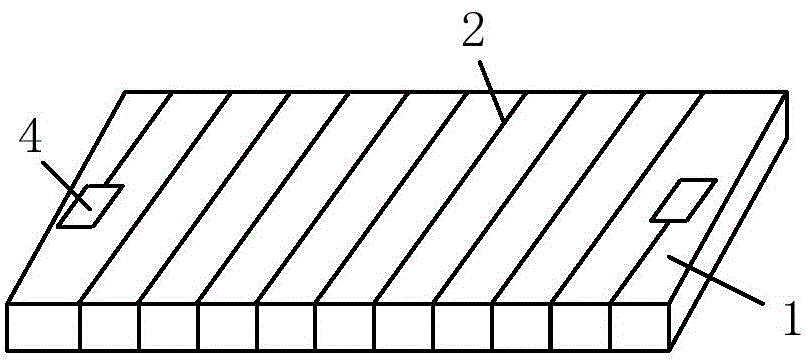

The invention relates to the technical field of insulation cups, and discloses an insulation cup with a titanium composite inner tank and a manufacturing process thereof. The insulation cup with the titanium composite liner includes an inner tank body (1); the inner tank body (1) includes a first inner tank layer (2) and a second inner tank layer (3); the first inner tank layer (2) and the secondinner tank layer (3) are arranged concentrically; the first inner tank layer (2) is made of a stainless steel material, a copper material, an iron material or an aluminum material; the second inner tank layer (3) is made of a titanium material; the lower end of the inner tank body (1) is provided with a first bottom layer (4) and a second bottom layer (5); the first bottom layer (4) is made of thestainless steel material; the second bottom layer (5) is made of the titanium material; the first bottom layer (4) is fixedly connected to the lower end of the first inner tank layer (2); and the second bottom layer (5) is fixedly connected to the lower end of the second inner tank layer (3). The invention reduces the consumption of the precious metal titanium material, reduces the manufacturingcost of the inner tank body, and ensures the health of the water quality.

Owner:ZHEJIANG SUNTRUE TITANIUM TECHNOLOGY CO LTD

Powder metallurgy component and production method of powder metallurgy component with through hole

The invention discloses a powder metallurgy component which is compressed by powder materials. The powder materials includes, by weight, 100 parts of iron powder, 1.8-2.2 parts of copper powder, 0.-1.0 part of graphite powder, 2.0-3.0 parts of nickel powder, 0.4-0.8 part of molybdenum powder, 0.5-1.0 part of micro powder wax, and 0.5-1.0 part of calcium fluoride. The invention further disposed a production method of the powder metallurgy component with a through hole. The method includes: well mixing the powder materials, placing the mixed alloy iron-based powder in a die for compressing forming, sintering, mechanically drilling, thermally processing, and surface vibration grinding to obtain the powder metallurgy component. The produced powder metallurgy component is high in precision, strength and hardness, good in wear resistance, widely applicable to manufacturing of various bevel gears, and the like.

Owner:江苏宏创精密制造有限公司

Dispensing device and automatic analysis device

InactiveCN101473230ASustaining manufacturing costGuaranteed manufacturing costSamplingSyringeBiomedical engineering

A dispensing apparatus in which, while the manufacturing cost is maintained, dispensing abnormality can be detected with high accuracy regardless of the characteristics of the dispensing apparatus, and an automatic analyzer including the dispensing apparatus are provided. The dispensing apparatus includes a probe (2) that directly sucks or discharges a liquid; a syringe (4) that generates a pressure necessary for the probe (2) to suck or discharge the liquid; a pressure measuring unit (6) that detects the pressure applied to the probe (2); a setting unit (14) that sets a correction coefficient used when correcting a physical amount based on characteristics of the dispensing apparatus; a storage unit (15) that stores therein information including the correction coefficient set by the setting unit (14), and a correcting unit (16) that corrects the physical amount using the correction coefficient stored in the storage unit (15).

Owner:BECKMAN COULTER INC

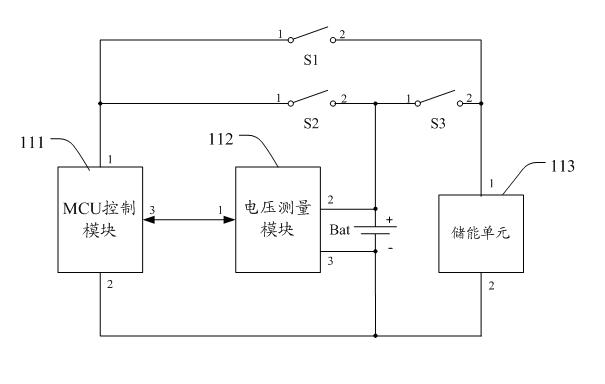

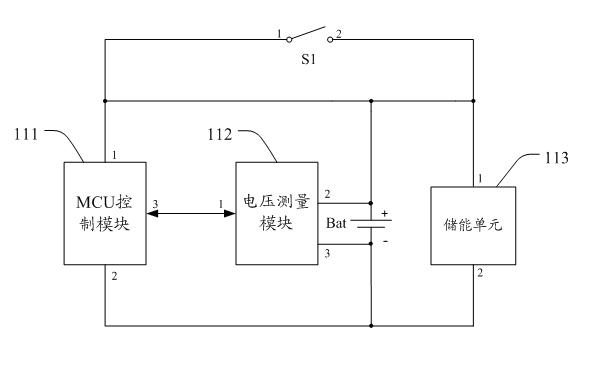

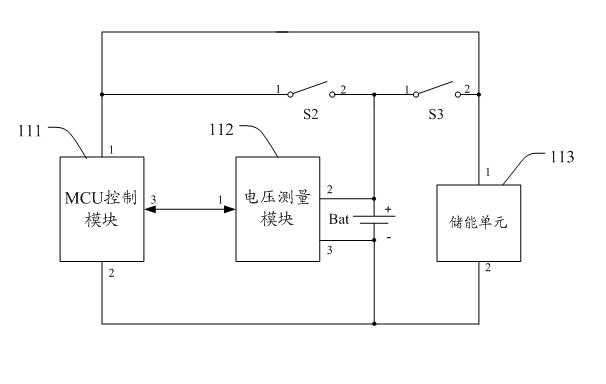

Mobile terminal for detecting electric quantity of battery on line and detection method thereof

ActiveCN102074984AAccurate detectionHigh precisionElectrical storage systemBatteries circuit arrangementsElectrical batteryEngineering

The invention discloses a mobile terminal for detecting the electric quantity of a battery on line and a detection method thereof. The mobile terminal comprises a voltage measuring module, an energy storage unit, an MCU (Micro Control Unit) control module and the battery, wherein the MCU control module, the battery and the energy storage unit are mutually connected in parallel; the voltage measuring module and the MCU control module are connected with the anode and the cathode of the battery; the MCU control module is used for controlling a power supply circuit of the battery, the voltage measuring module and the MCU control module and a power supply circuit of the battery and the energy storage unit to be conducted and controlling a power supply circuit of the energy storage unit and theMCU control module to be broken off when the mobile terminal normally works; and when the mobile terminal is positioned in the electric quantity detection state of the battery, the MCU control moduleis used for controlling the power supply circuit of the energy storage unit and the MCU control module to be conducted and controlling the power supply circuit of the battery, the voltage measuring module and the MCU control module and the power supply circuit of the battery and the energy storage unit to be broken off. According to the invention, on the premise of ensuring the manufacturing costof the mobile terminal, the accurate detection of the electric quantity of the battery can be realized.

Owner:TCL CORPORATION

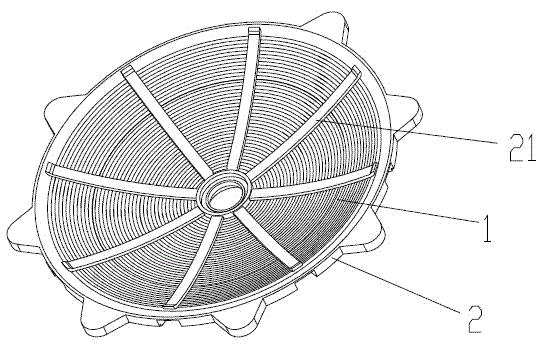

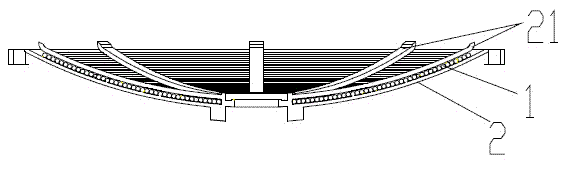

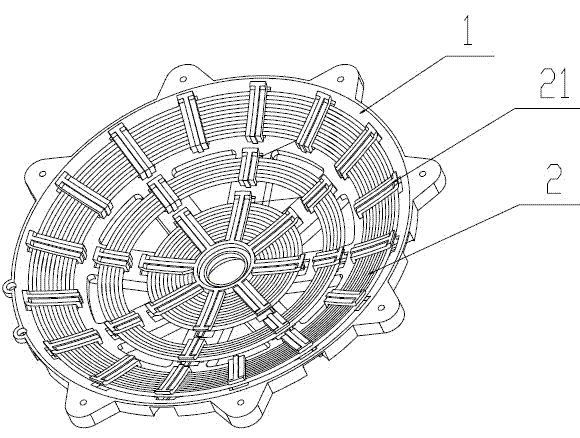

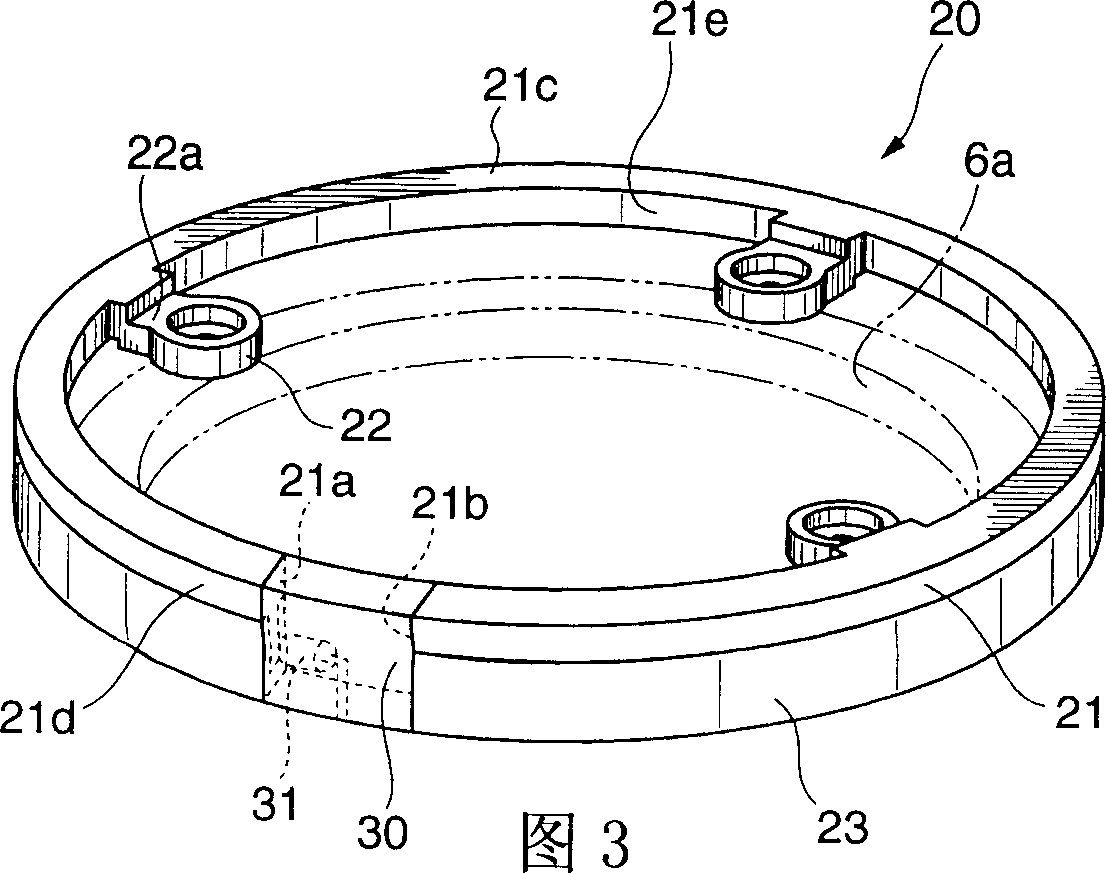

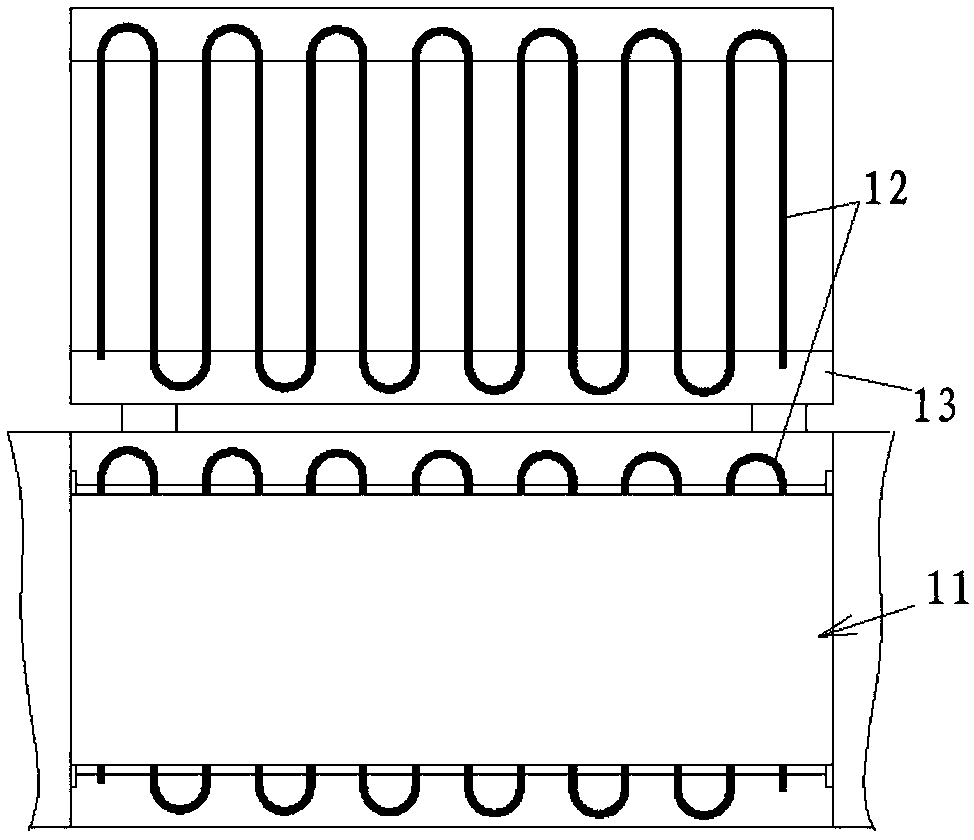

Coil disc of electromagnetic oven

ActiveCN102523643AGuaranteed performance and stabilityImprove performanceCoil arrangementsCoil procedureEngineering

The invention discloses a coil disc of an electromagnetic oven, comprising a coiling bracket and coil windings arranged on the coiling bracket, wherein the coiling bracket is provided with a plurality of wire buckles which are distributed in a ring shape and are convenient for winding fixed enamelled wires; and the coil windings are formed by winding of the enamelled wires which penetrate through the wire buckles distributed in a ring shape. The coil disc is characterized in that due to adoption of the structure with wire buckles, adhesive-less winding on the coiling bracket can be realized, and no matching of a coiling mold is needed, so that the coiling procedure is greatly simplified, the safe and convenient effects are achieved, the production efficiency is improved and the manufacturing cost is saved. Especially for multiple circles of windings, the coil disc can realize accurate coiling of multiple windings and ensures that the distance among wire rings is constant all the time, thus ensuring the performance stability of the coil disc in batch production. According to the coil disc, not only can the manual fast and accurate coiling be realized and is the operation simple and convenient, but also the high-speed coiling also can be realized by matching of simple mechanical equipment, and the requirement for corresponding equipment is lower, the production efficiency is greatly improved and the manufacturing cost is reduced. The coil disc is ingenious in design and is convenient and practical.

Owner:MIDEA GRP CO LTD

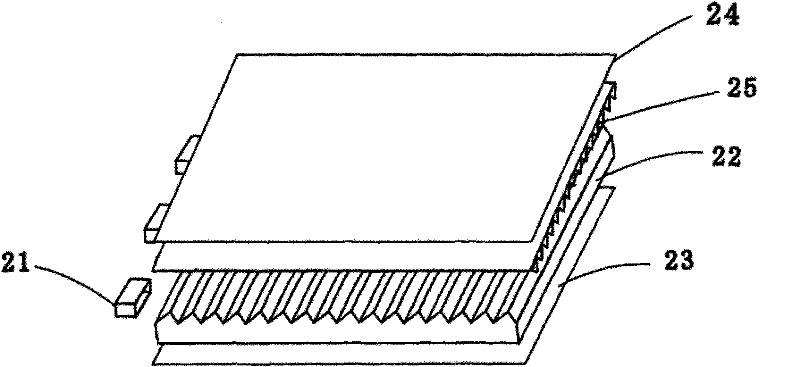

Integrated micro-optics backlight module

InactiveCN102537762AImprove coupling efficiencyRealize the structureMechanical apparatusLight guides for lighting systemsLight guideRadiance

The invention provides an integrated micro-optics backlight module, which comprises an integrated micro-optics light-guiding plate and at least one light source. The light-guiding plate comprises a light incidence surface, a light emitting surface, a bottom surface opposite to the light emitting surface and three side faces, wherein the three side faces are connected with the light emitting surface and the bottom surface, a micro-optics light condensing structure designed by utilizing micro-optics and binary optic iterative algorithm is arranged on the light emitting surface, and a micro-optics reflection structure matched with the micro-optics light condensing structure on the light emitting surface is arranged on the bottom surface. The micro-optics reflection structure on the bottom surface can reflect and diffract light beams, and the micro-optics light condensing structure on the light emitting surface is matched with the micro-optics reflection structure on the bottom surface so that the light beams can be concentrated in an ideal view field to be emitted, and radiance and uniformity of emitted light are improved. The integrated micro-optics backlight module does not use a flat surface reflective sheet, a diffusing sheet and a double-layer crossed-prism lens in a typical backlight module but exceeds a typical multiple-layer structure in effect, the backlight module is highly integrated, utility rate of luminous energy is improved, and cost is reduced.

Owner:徐平 +1

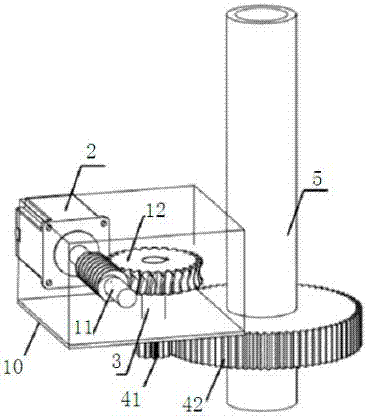

Heliostat transmission system capable of increasing transmission precision

ActiveCN102734437AOvercoming complex processing and assembly problemsIncrease production capacityGearboxesToothed gearingsHeliostatEmbedded system

The invention relates to a heliostat transmission system capable of increasing transmission precision, which comprises a decelerator, a motor, an input shaft, a gear pair and an output shaft, wherein a transmission group is arranged in the decelerator; a first-stage transmission force of the transmission group is worm and gear transmission; the input shaft is mounted on the decelerator is connected with the transmission group in a transmission manner; the motor is connected with the transmission group so as to drive the input shaft to rotate; the input shaft is connected with the output shaft in a transmission manner through the gear pair; the heliostat transmission system also comprises at least backlash elastic piece; and the backlash elastic piece is connected with the input shaft or / and the output shaft so as to eliminate a gap between the gear pair. According to the invention, the heliostat transmission system is independent of gear processing precision and worm and gear transmission precision; reasonable layout is processed through a transmission stage; in addition, the heliostat transmission system solves technical problems of lower heliostat transmission precision and efficiency, insufficient sensitivity, poor reliability, complex processing assembly, high manufacture cost and the like.

Owner:ZHEJIANG SUPCON SOLAR TECHNOLOGY CO LTD

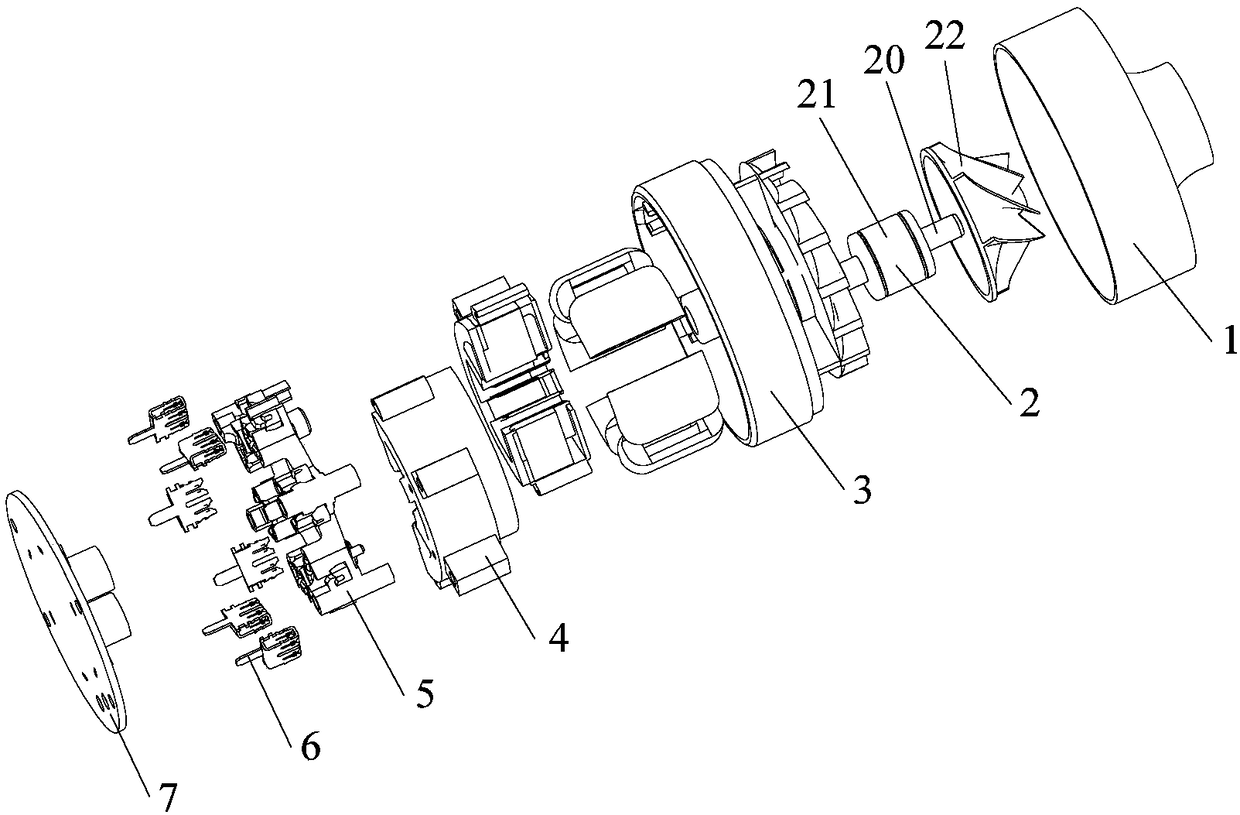

Electric fan

ActiveCN109185196AReduced parts countAssembly accuracy is lowPump componentsWorking fluid for enginesImpellerEngineering

The invention provides an electric fan which comprises a rotor component and a machine shell, wherein the rotor component comprises a bearing, a moving impeller and a magnetic ring; the magnetic ringand the moving impeller are correspondingly mounted at two ends of the bearing; the machine shell is equipped with a bearing chamber; the diameter of the magnetic ring is less than that of the bearingchamber; the magnetic ring is capable of penetrating through the bearing chamber; and after the mounting operation is completed, the moving impeller and the magnetic ring are correspondingly positioned at two ends of the bearing chamber. According to the electric fan provided by the invention, only one bearing is utilized, and the utilized bearing is positioned between the moving impeller and themagnetic ring which are mounted on a rotating shaft; during the assembling process, the magnetic ring penetrates through the bearing chamber; after the mounting operation is completed, the moving impeller and the magnetic ring are correspondingly positioned at the two ends of the bearing chamber; by the adoption of such a rotor component and machine shell assembling mode, the assembling operationcan be facilitated and the assembling process can be simplified; due to the use of only one bearing, the rotor component and machine shell assembling precision requirements are low, and the improvement of the assembling efficiency can be facilitated; and furthermore, the quantity of parts of the electric fan is reduced, so that the reduction of the product cost can be facilitated and the assembling efficiency can be further improved.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

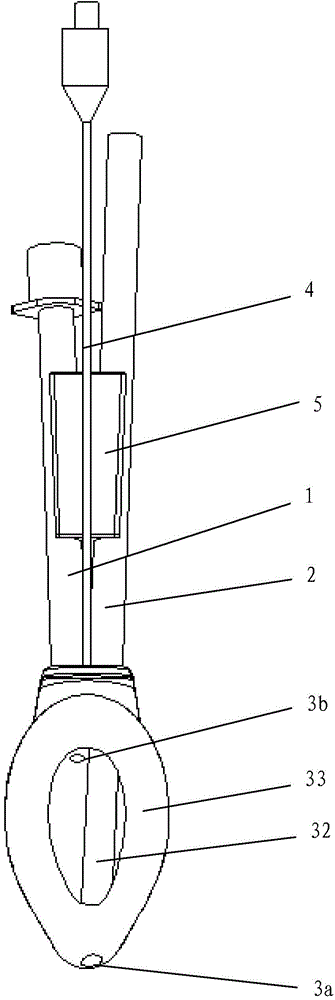

Laryngeal mask breather tube device and manufacturing method thereof

ActiveCN103432670BRaise the level of quality assuranceReduce in quantityTracheal tubesLaryngeal MasksDrainage tubes

Owner:GUANGZHOU WELLLEAD MEDICAL EQUIP CO LTD

Embedded folding wing mechanism

PendingCN112319768ACompact structureQuick responseFuselagesAir-flow influencersFlight vehicleShock resistance

The invention provides an embedded folding wing mechanism which comprises a wing piece or a rudder piece, a seat body, a torsional spring, a screw pin, a plate spring and a cylindrical pin, and the seat body is connected with an aircraft cabin; the wing pieces or the rudder pieces are hinged to the base body through cylindrical pins, rotate around the axes of the cylindrical pins and retract intoaxial grooves in the outer wall of the aircraft cabin body or are unfolded in the radial direction of the aircraft cabin body. One end of the torsional spring is connected with the seat body through ascrew pin, and the other end is connected with a cylindrical pin to provide power for outward rotation of the wing or rudder from the aircraft cabin; the plate spring is installed on the seat body, the plate spring is located between the wing piece or the rudder piece and the seat body when the wing piece or the rudder piece retracts into the outer wall of the aircraft cabin body, the wing pieceor the rudder piece extrudes the warping face of the plate spring to deform, the plate spring rebounds after the wing piece or the rudder piece is unfolded and abuts against the side face of the wingpiece or the rudder piece, and in-place unfolding is guaranteed. A longitudinal folding scheme is adopted, the structure is exquisite, the response speed is high, and good strength, rigidity, shock resistance and installation precision are achieved.

Owner:西安长峰机电研究所

Novel spraying manufacturing process of glass bottles

InactiveCN105252946AHigh degree of simulationSensory grade improvementDecorative surface effectsIron contentMaterials science

A novel spraying manufacturing process of glass bottles comprises the steps of (1), carrying out preparation before spraying, wherein the transparent semi-finished glass bottles with the iron content smaller than or equal to 0.055% are selected, dirt on the glass bottles are removed, water containing 5% of hydrofluoric acid is used for cleaning the glass bottles and the glass bottles continue being cleaned after the treatment; (2), spraying semi-finished products, wherein milky-white glazes and green glazes are selected, the milky-white glazes are used for priming, the green glazes are sprayed as finish paint, and the double-spraying process is adopted in spraying; (3), drying the glass bottles, wherein the glass bottles are dried in drying equipment; (4), sticking decorations to the glass bottles, wherein the decorations are stuck to the glass bottles at appropriate temperature; (5), firing the decorations, after the decorations are stuck, film combining and decoration firing are carried out on the products. By applying the novel spraying manufacturing process to white spirit bottle production, the produced products are high in simulation degree and can simulate jade, stone, wood, copper and the like, and the appearance grade of the products is obviously improved compared with existing common products. In addition, the produced glass bottles are high-value-added products, and the economic benefit of each bottle can be increased by 0.5-1.5 yuan.

Owner:SHANDONG JINGFENG GLASS TECH CO LTD

Laryngeal mask breather tube device and manufacturing method thereof

ActiveCN103432670ARaise the level of quality assuranceReduce in quantityTracheal tubesLaryngeal MasksEngineering

The invention discloses a laryngeal mask breather tube device, comprising a breather tube, a drainage tube and a hollow mask bag with an opening at the bottom, wherein the bottom end of the hollow mask bag is connected with the breather tube and the drainage tube; a drainage port which is in fluid communication with the drainage tube is formed in the front end of the hollow mask bag; a ventilation port which is in gas communication with the breather tube is formed in the hollow mask bag; the hollow mask bag is in an integrated structure which is formed by one-time operation and comprises an inflatable back mask, a drainage tube in the mask and an inflatable sleeve bag sealing piece; the drainage port is in fluid communication with the drainage tube through the drainage tube in the mask. The invention also discloses a manufacturing method of the laryngeal mask breather tube device. According to the laryngeal mask breather tube device and the manufacturing method thereof, rugged burrs can be reduced to the maximum degree, the production process can be simplified and production efficiency can be improved.

Owner:GUANGZHOU WELLLEAD MEDICAL EQUIP CO LTD

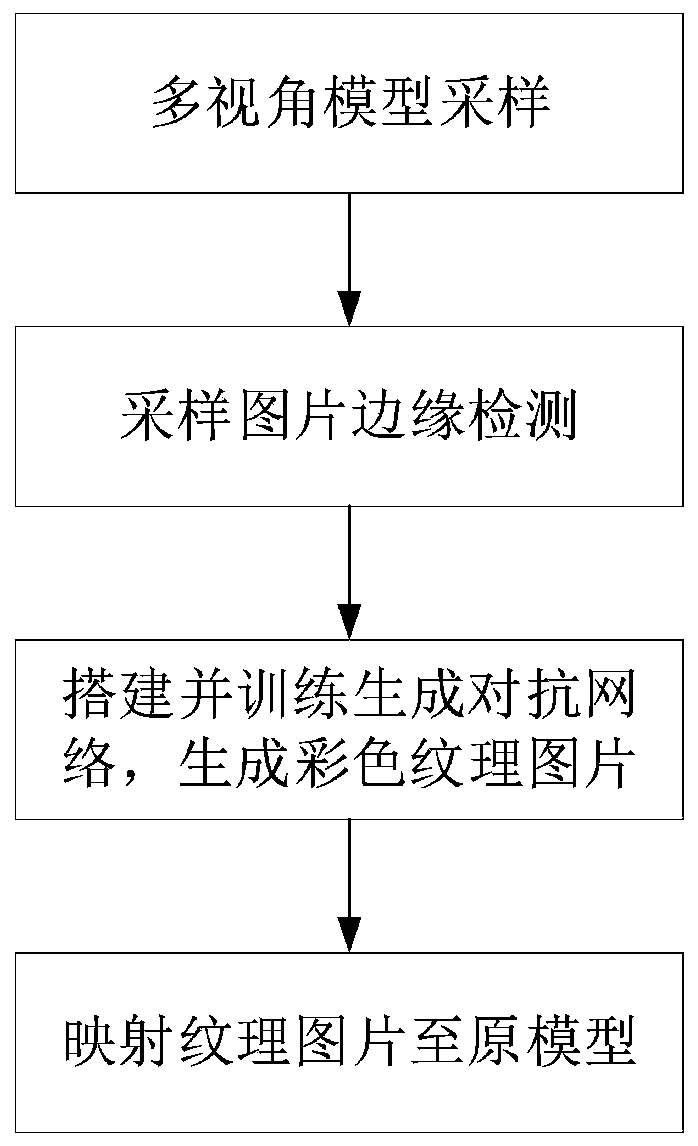

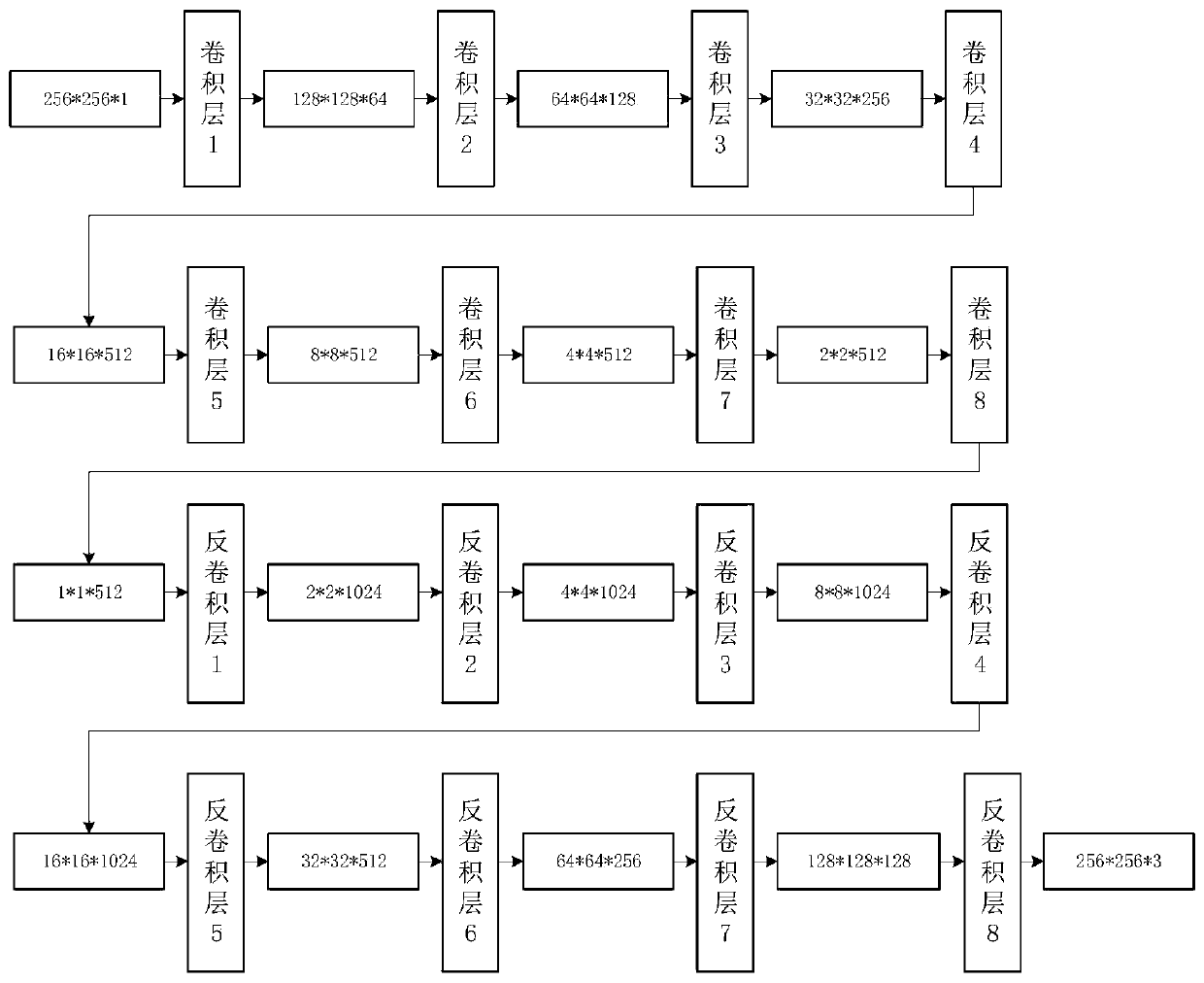

Model texture generation method based on generative adversarial network

PendingCN110060326ALow production costDiversity guaranteedImage analysis3D-image renderingGenerative adversarial networkThree dimensional model

The invention discloses a model texture generation method based on a generative adversarial network. The method comprises the following steps: (1) for an input model, namely a three-dimensional modelof a texture-free map, acquiring sampling pictures of the model from a plurality of visual angles according to a given sampling rule; (2) carrying out edge detection processing on the sampling picture, and converting the sampling picture into a line frame picture; (3) establishing and training a generative adversarial network for generating color textures, taking the line frame diagram as the input of the network, and outputting a color texture diagram through the processing of the generative adversarial network; and (4) mapping the plurality of color texture images output by the network to the original model to realize texture coloring and obtain the three-dimensional model with the texture map. According to the method, the texture picture can be generated by building and training the deep convolution-based generative adversarial network, the manufacturing efficiency of the texture map is improved, the cost is saved, meanwhile, the environmental factors of texture generation are alsounified, and the consistency of final texture coloring is ensured.

Owner:HANGZHOU DIANZI UNIV

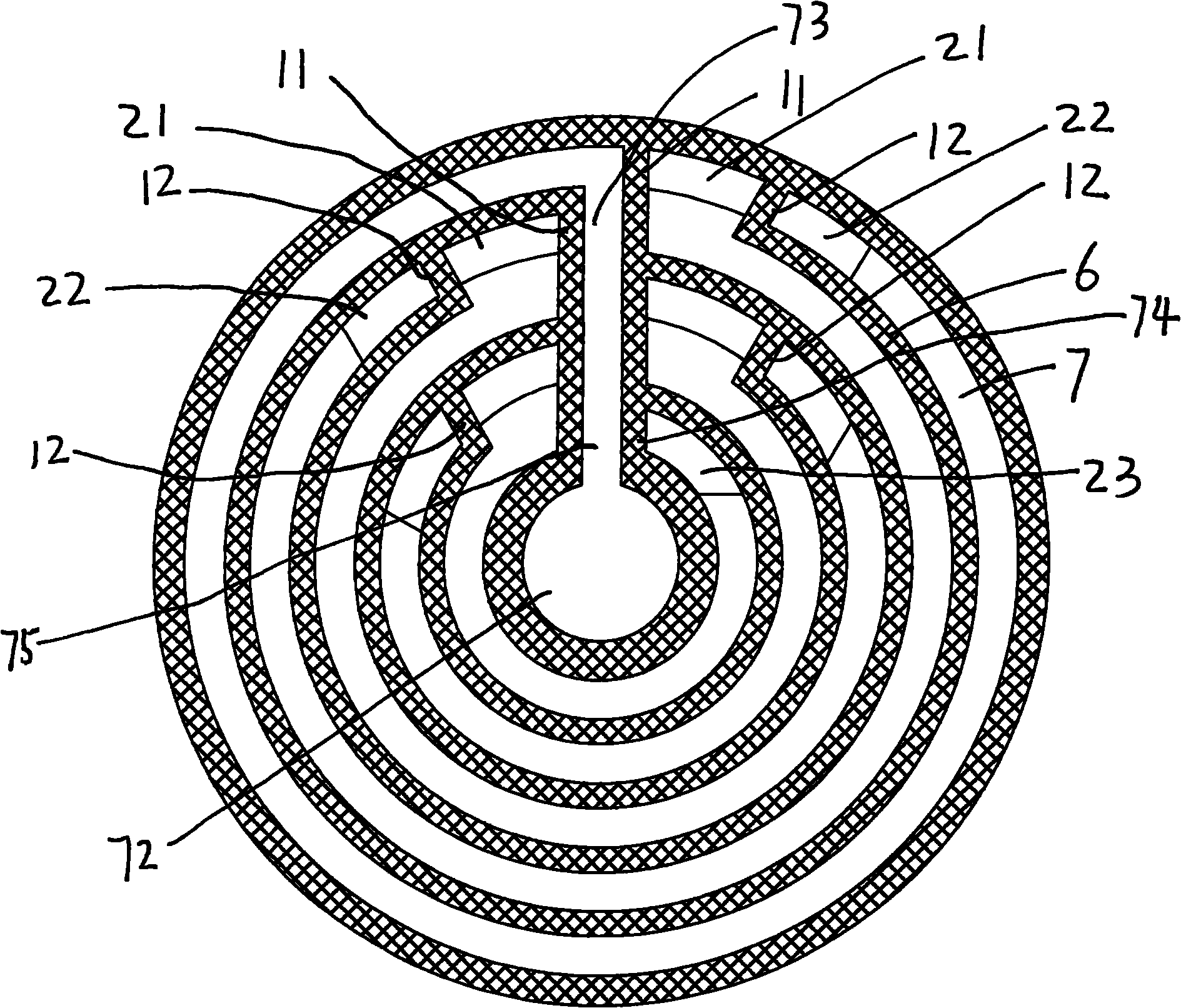

Electric shock preventing protector of electric water heater

The invention discloses an electric shock preventing protector of an electric water heater, which comprises an upper insulating cover, a lower insulating cover and an insulating trough disc. The upper insulating cover and lower insulating cover are sealed on the upper and lower end surfaces of the insulating trough disc, respectively. A water inlet pipe and a water outlet pipe are formed on the upper insulating cover and lower insulating cover, respectively. A plurality of circles of independent water channel walls in one-to-one correspondence are arranged on both upper and lower end surfaces of the insulating trough disc. A groove type waterflow channel is formed between two adjacent water channel walls. The waterflow channel in the outermost circle of the end surface of the insulating trough disc is communicated with the water outlet of the water inlet pipe in a sealing mode, and the space in the innermost circle of water channel wall on the lower end surface of the insulating trough disc is communicated with the water inlet of the water outlet pipe in the sealing mode. The waterflow flows from the water inlet pipe and flows in the waterflow channel on the upper and lower end surfaces of the insulating trough disc to increase the length of the current so as to realize the function of electric shock prevention. The invention has the advantages of ensuring hermeticity of the waterflow channels effectively with good anticreep function and ensuring life safety of people effectively with stable quality and low manufacturing cost.

Owner:SAKURA BATH & KITCHEN PRODS CHINA

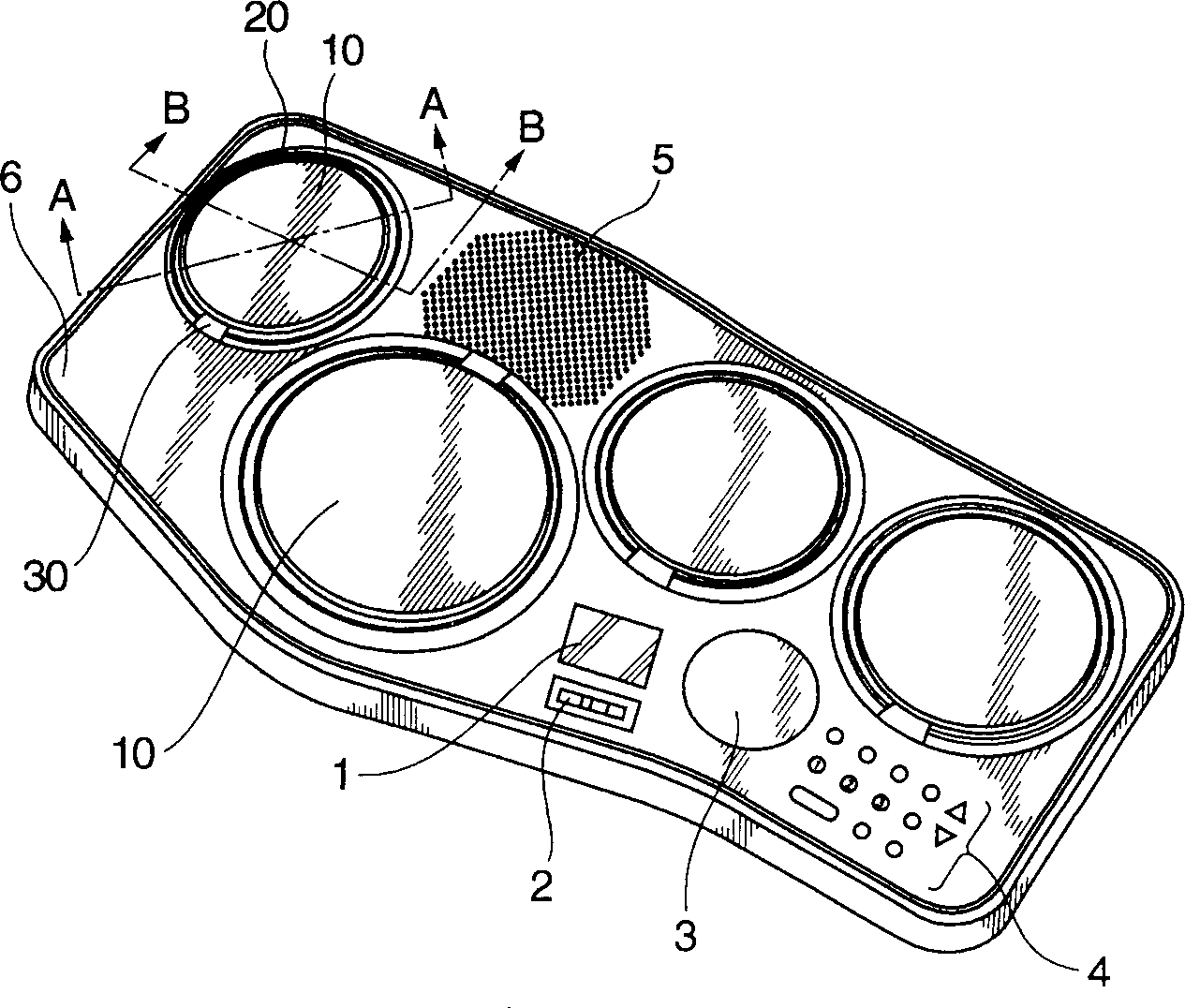

Electronic music instrument

InactiveCN1356684AReduce manufacturing costSolution to short lifeElectrophonic musical instrumentsElectronic instrumentEngineering

There is provided an electronic musical instrument which enables the whole periphery of at least one pad member to shine by a simple construction, and at the same time maintain durability and low costs, and a shining method therefor. An electronic musical instrument of a drum type detects beats on a surface to be beaten of the pad member, and generates a musical tone signal in response to an output indicative of the detected beats. A light transmitter in a linear form is arranged along the periphery of the pad member and guides light which has been emitted from a light source arranged in the vicinity of one end of the light transmitter and entering the light transmitter via the one end, by utilizing principles of light propagation of an optical fiber, toward the other end of the light transmitter, and at the same time causes at least part of the light entering via the one end to emit out of the light transmitter via a light emitting surface formed by roughening part of an exposed surface of the light transmitter.

Owner:YAMAHA CORP

Electroplated tin steel plate for beverage can and production method of electroplated tin steel plate

ActiveCN107541663AImprove mechanical propertiesImprove product qualityChemical compositionUltimate tensile strength

The invention relates to an electroplated tinned steel plate for beverage cans and a production method thereof, which mainly solves the technical problems of high strength, poor strength stability, low elongation after breaking and easy cracking in the can making process of existing electroplated tinned steel plates used for beverage cans . An electroplated tin-plated steel plate for beverage cans provided by the present invention, the weight percentage of the chemical composition of the substrate: C: 0.01% to 0.03%, Si≤0.03%, Mn: 0.25% to 0.35%, P≤0.025%, S≤0.015 %, Alt: 0.045% to 0.065%, Cr: 0.11% to 0.16%, and the balance is Fe and unavoidable impurity elements. The yield strength of the steel plate is 300MPa-330MPa, the tensile strength is 400MPa-430MPa, the hardness value is 55‑58HR30Tm, and the elongation after fracture is A50≥28%. The invention is mainly used in the field of beverage can packaging.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

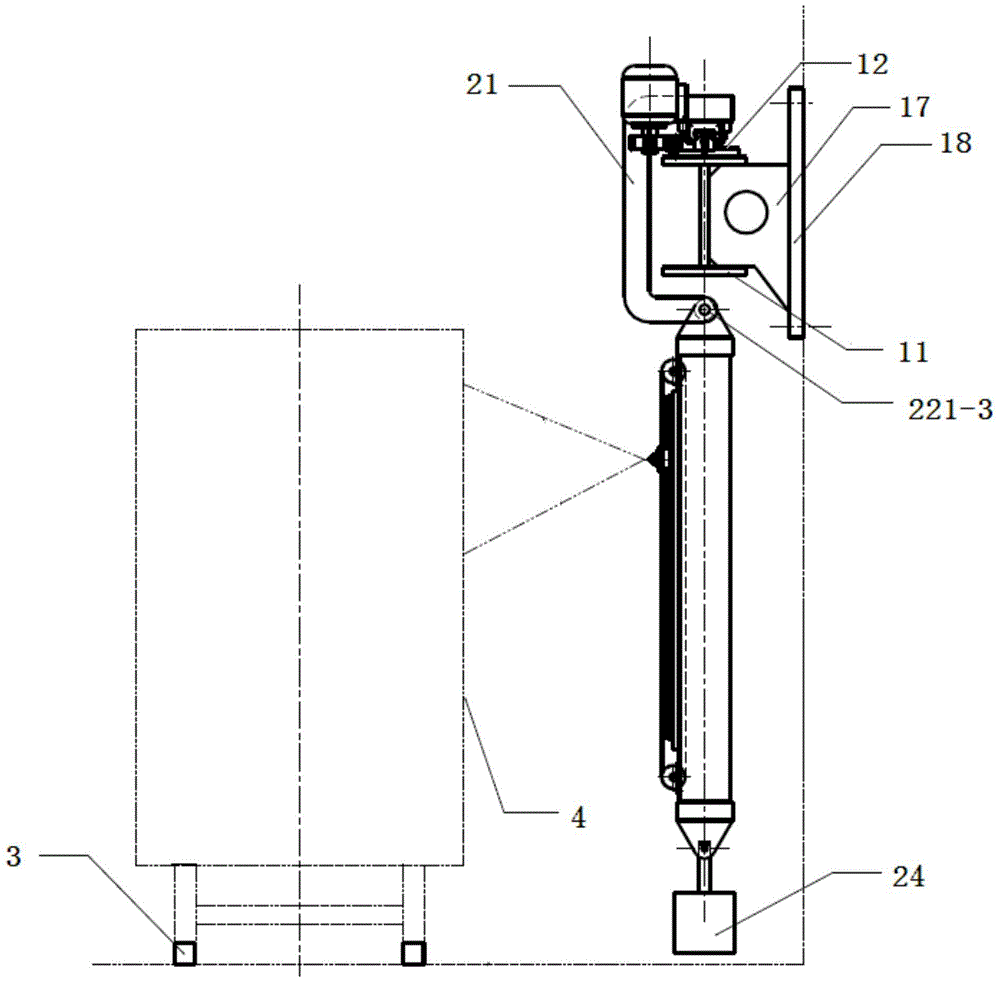

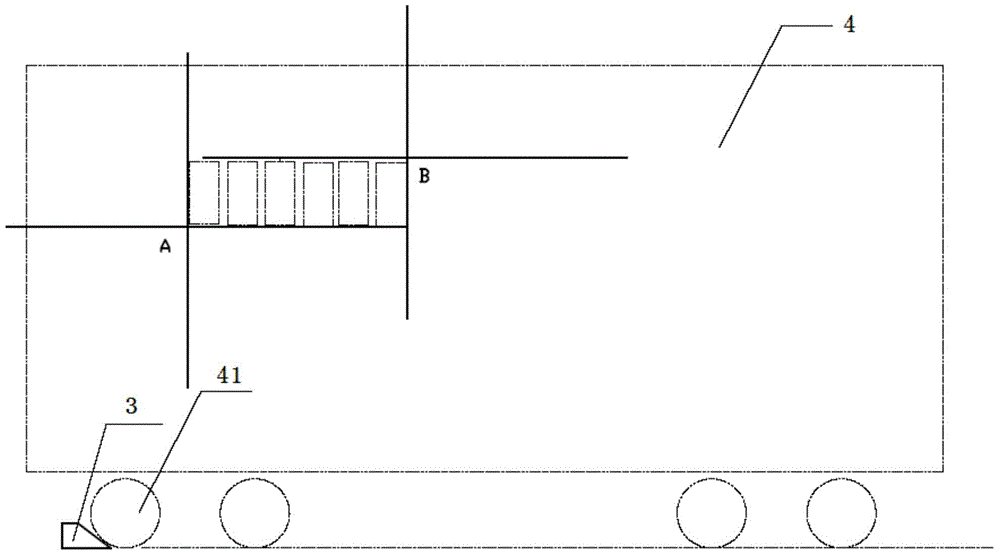

Automatic wagon oil paint marking position positioning device

ActiveCN104368470ALow manufacturing costEasy to install and adjustSpraying apparatusTruckVertical motion

The invention relates to an automatic wagon oil paint marking position positioning device which is characterized in that the positioning device comprises a side hanging guide rail assembly, two digital control cross curve semi-conductor laser positioning mechanisms and a plurality of vehicle positioning blocks for fixing wagon wheels on the workshop ground; each digital control cross curve semi-conductor laser positioning mechanism comprises a longitudinal motion trolley assembly, a vertical motion mechanism assembly, a crossing curve semi-conductor laser assembly and a balance weight; the side hanging guide rail assembly is fixedly arranged on the workshop wall face or the workshop column face, and the two longitudinal motion trolley assemblies are arranged on the side hanging guide assembly at an interval in a sliding mode; the bottoms of all the longitudinal motion trolley assemblies are connected with the vertical motion mechanism assemblies in a rotating mode; the outer side faces of all the vertical motion mechanism assemblies are fixedly arranged on the crossing curve semi-conductor laser assemblies, and the balance weights are hung on the bottoms of all the vertical motion mechanism assemblies. The automatic wagon oil paint marking position positioning device can be widely applied to the wagon side wall oil paint marking process.

Owner:CRRC QIQIHAR ROLLING CO LTD

Preparation method of high-lignin content phenolic foam

Owner:TIANJIN UNIV OF SCI & TECH

Container corner fitting and heat treatment process thereof

ActiveCN110055470AImprove low temperature toughnessPromote improvementLarge containersSolid state diffusion coatingAlloy compositionHeat treated

The invention discloses a container corner fitting, and belongs to the field of container materials. The alloy compositions of the container corner fitting are composed of the following elements, by the mass percent, of 0.09-0.15% of C, 0.95-1.40% of Mn, 0.27-0.36% of Si, 0.19-0.26% of Ni, 0.15-0.22% of Cr, 0.0007-0.015% of Al, being no more than 0.03.% of P, being no more than 0.03% of S, being no more than 0.08% of Mo, being no more than 0.17% of Cu, being no more than 0.01% of V, and the balance Fe and inevitable impurities, wherein Ni / Cr=1.00-1.25, Mn / Si=3.0-3.8, and Ni + Cr + Mo +Cu is equal to or less than 0.72% by the mass percent. The alloy compositions of the container corner fitting are improved, on the premise of guaranteeing the production cost, the strength of the corner fitting is improved, the toughness is greatly improved at the low temperature, and the corner fitting also has good welding performance.

Owner:MAANSHAN SHENGLEI WEAR RESISTANT ALLOY MFG

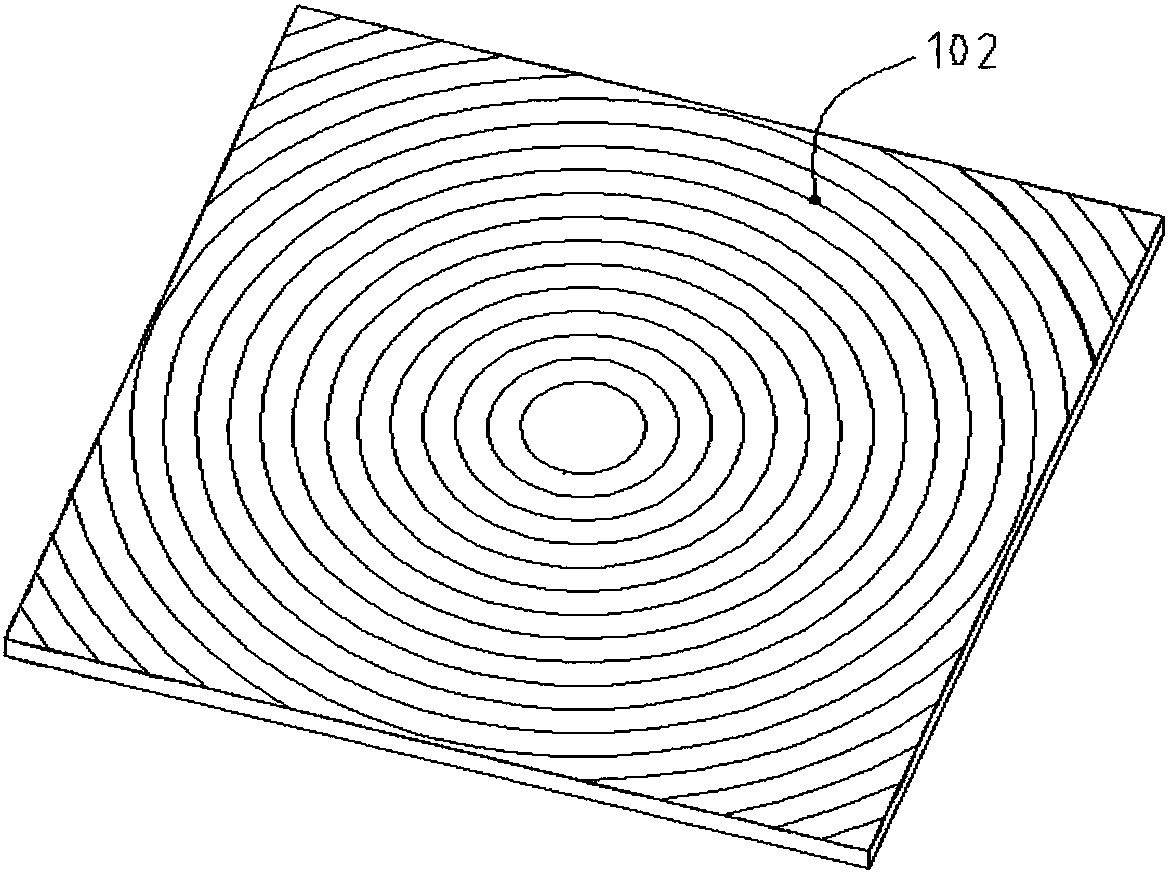

OCM Fresnel Lens and moulding technology thereof

InactiveCN108802868AImprove thermal stabilityHigh precisionOptical articlesLensFresnel lensReflection loss

The invention relates to a lens and a moulding technology thereof, and specifically relates to an OCM Fresnel Lens and a moulding technology thereof; the OCM Fresnel Lens comprises an lens main body;the lens body comprises a substrate; an lens body is arranged one side of the substrate; a reflection reducing coating is arranged on the other side of the substrate; the lens body is provided with aplurality of annular insection rings; the advantages are that 1, the lens thermal stability and optically focused precision can be improved; 2, lens reflection losses are reduced, and the lens surfaceis protected from being eroded by sands; 3, the method ensures OCM Fresnel Lens technology performance, production efficiency and manufacture costs, thus realizing target technology performance and manufacture cost desired values.

Owner:北京首耀科技有限公司

Miniature inductor and manufacturing method thereof

InactiveCN104616859ALow costGuaranteed performanceTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureBiochemical engineeringBarrel Shaped

The invention provides a miniature inductor. The miniature inductor comprises a magnetic core and a coil, wherein the coil comprises a supporting body and a distribution line, the supporting body is of a barrel-shaped structure, the distribution line is spirally arranged on the supporting body, and the magnetic core is arranged on the inner side of the supporting body. The miniature inductor is excellent in comprehensive performance, easy to manufacture and low in cost. The invention further provides a manufacturing method of the miniature inductor.

Owner:BEIJING JIAYUE TONGLEJI ELECTRONICS

Undaria pinnatifida stem and leaf separator

The invention discloses a undaria pinnatifida stem and leaf separator, which comprises a machine frame, a shell is supported at the top of the machine frame, a transverse moving cylinder is arranged at one end of the interior of the shell; the working end of the transverse moving cylinder is connected with the side wall of the transverse moving box body; the transverse moving box body is connectedinto the shell in a sliding manner; the transverse moving box body can reciprocate in the length direction of the shell; an upper transverse moving motor and a lower transverse moving motor are arranged in the transverse moving box body; a transverse stem moving roller is connected to the working end of the upper transverse moving motor; the working end of the lower transverse moving motor is connected with a transverse moving leaf roller; long grooves matched with working shafts of the upper transverse moving motor and the lower transverse moving motor are further formed in the side wall ofthe shell, a fixed box body is further arranged in the shell, an upper fixed motor and a lower fixed motor are arranged in the fixed box body, a fixed stem roller is connected to the working end of the upper fixed motor, and a fixed leaf roller is connected to the working end of the lower fixed motor.

Owner:DALIAN OCEAN UNIV

Near infrared spectrum brain function imaging system and imaging signal sampling method

PendingCN113633262AGood battery performanceReduce power consumptionMedical imagingDiagnostics using spectroscopyLight sourceImaging Signal

The invention provides a near infrared spectrum brain function imaging system. The near infrared spectrum brain function imaging system comprises a signal transmitting end module, a signal receiving end module and a signal control end module, wherein the signal transmitting end module is used for generating a near-infrared light source signal; the signal receiving end module is used for converting a near-infrared light signal reflected by the cerebral cortex into a digital signal to realize imaging; and the signal control end module adaptively adjusts working arrays in the signal transmitting end module and the signal receiving end module. Meanwhile, the invention provides a near-infrared spectrum brain function imaging signal acquisition method which comprises the step of adaptively adjusting the working arrays in the signal transmitting end module and the signal receiving end module through the signal control end to obtain a digital signal output by the signal receiving end. On the premise that the imaging precision and the manufacturing cost are guaranteed, meanwhile, the advantages of good battery performance, low power consumption and high data imaging precision are achieved.

Owner:嘉兴知芯电子科技有限公司 +3

Catalyst for toluene disproportionation and transalkylation, and preparation method thereof

ActiveCN108499596AGuaranteed manufacturing costReduce sizeMolecular sieve catalystsMolecular sieve catalystMolecular sieveToluene

The invention relates to a catalyst for toluene disproportionation and transalkylation, and a preparation method thereof. A purpose of the present invention is mainly to solve the technical problems of high aromatic ring loss rate and high reaction hydrogen consumption caused by excessive hydrogenation activity in the noble metal modified catalyst in the prior art. According to the present invention, the catalyst comprises a Group VIII metal, a silicon-aluminum molecular sieve and an inorganic alumina binder, the metal content is 0.005-0.5 wt%, the metal nanoparticles are positioned on the surface of the inorganic alumina, and the metal and the molecular sieve have good synergistic catalysis effect; and with the technical scheme, the technical problems of high aromatic ring loss rate and high reaction hydrogen consumption can be well solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

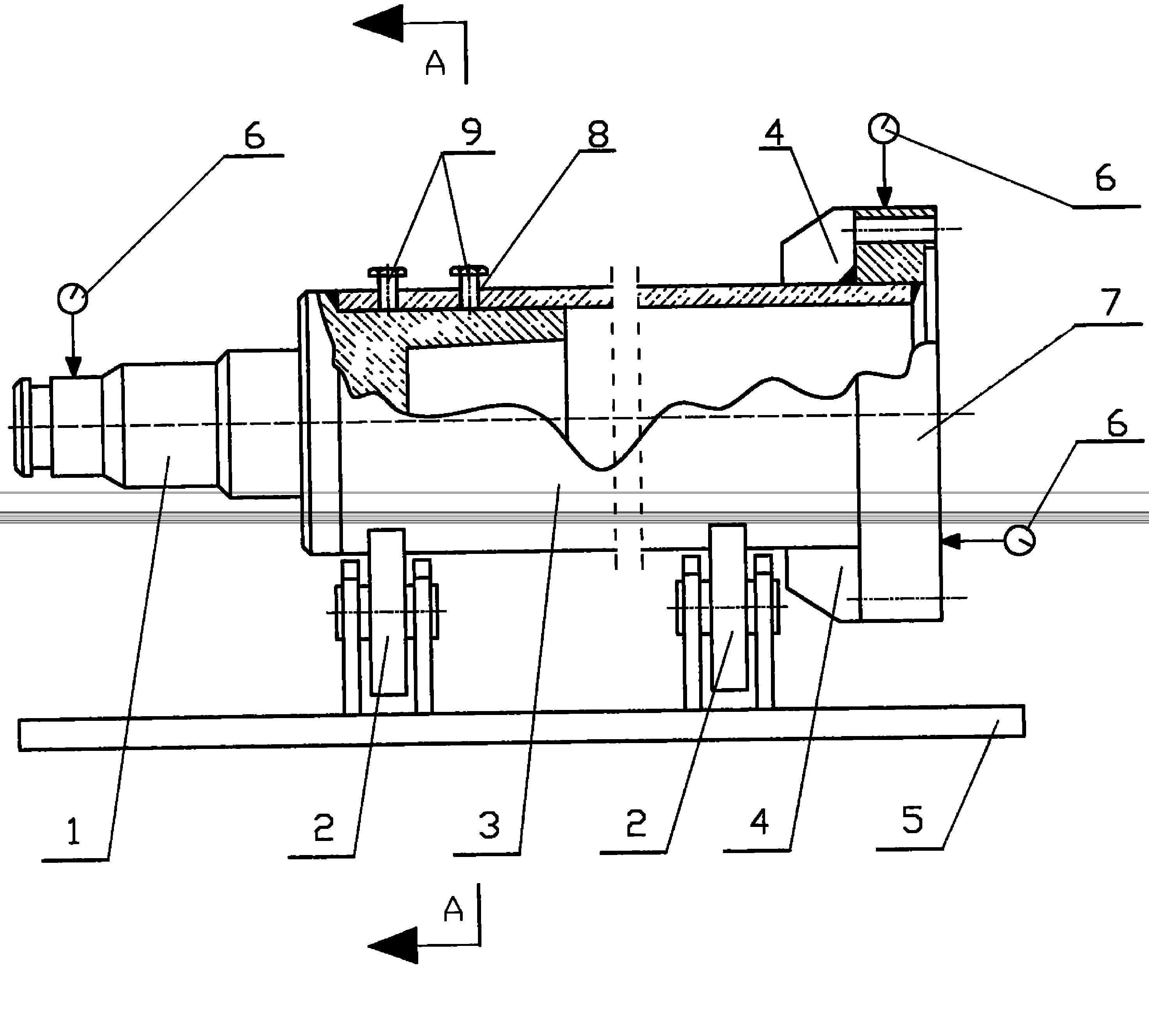

Novel assembling and welding process of spiral shaft of high-weir type double-spiral classifier

InactiveCN103433632AReduce manufacturing costGuaranteed manufacturing costWelding apparatusHelixWelding process

The invention relates to a novel welding process in machine manufacturing and solves the problems of high coaxiality requirement of each component after assembling and welding in the process of manufacturing by using a traditional method and difficulty of a traditional manufacturing process in meeting the requirement. By using the novel assembling and welding process of the spiral shaft of the high-weir type double-spiral classifier, the traditional manufacturing process for producing long-shaft assembling and welding parts is changed, the production process is simplified, the production cost is reduced, and the product quality is improved. Thus, when the spiral-shaft type classifier is operated, the vibration is less, the noise is low, the rotating speed can be increased, so as to increase the production efficiency, the service life of a bearing can be prolonged, and the service life of the spiral classifier is greatly prolonged.

Owner:王艳宜

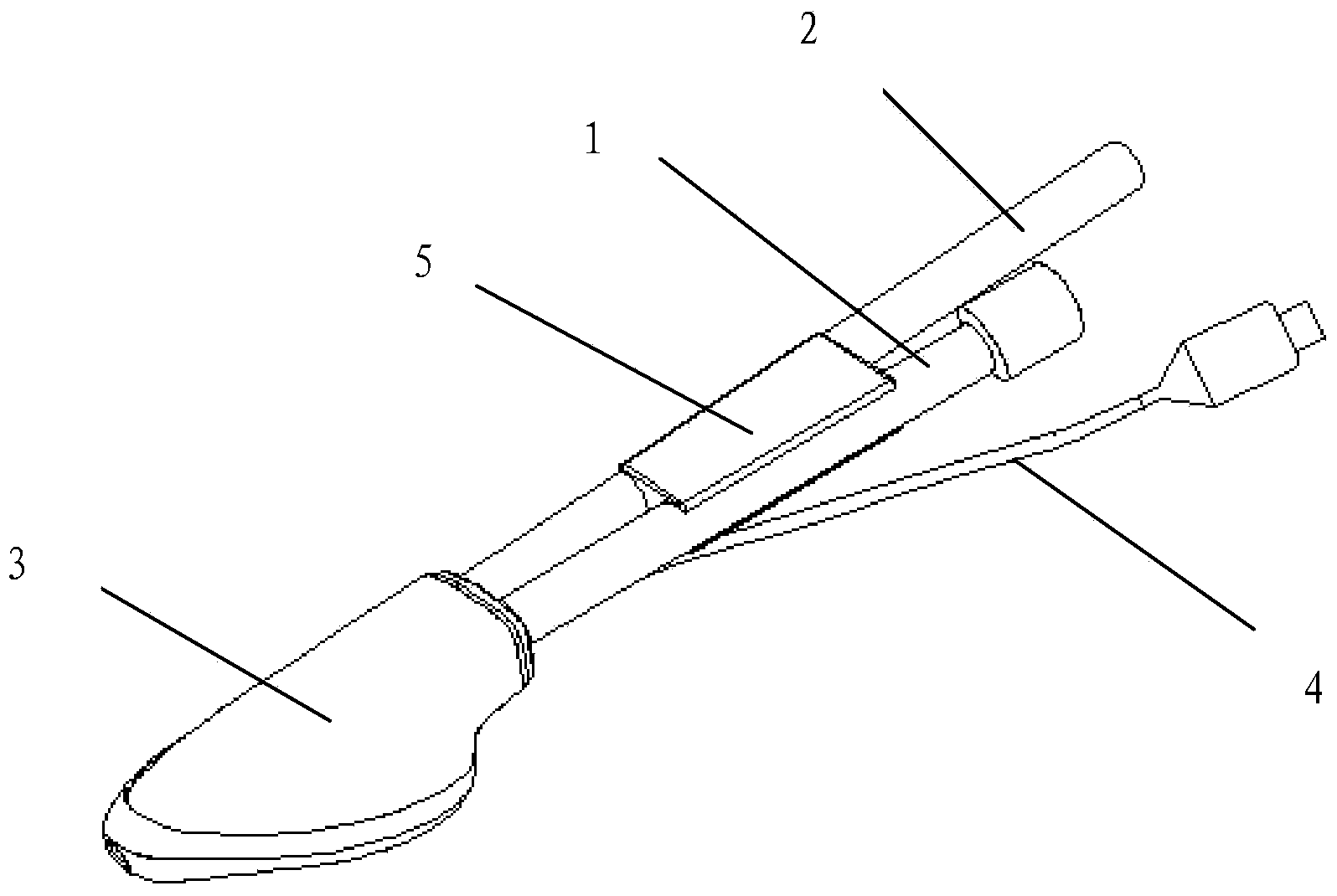

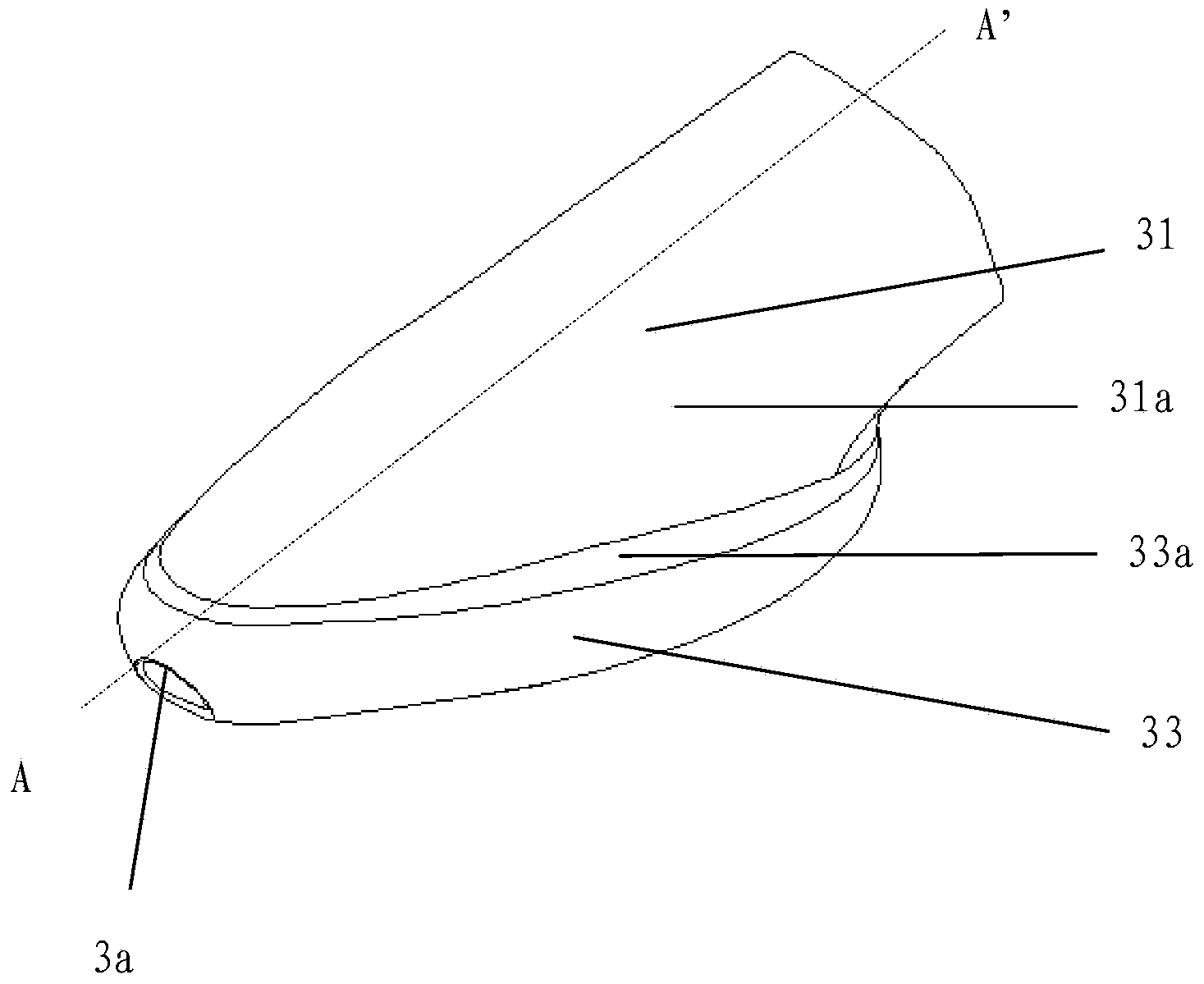

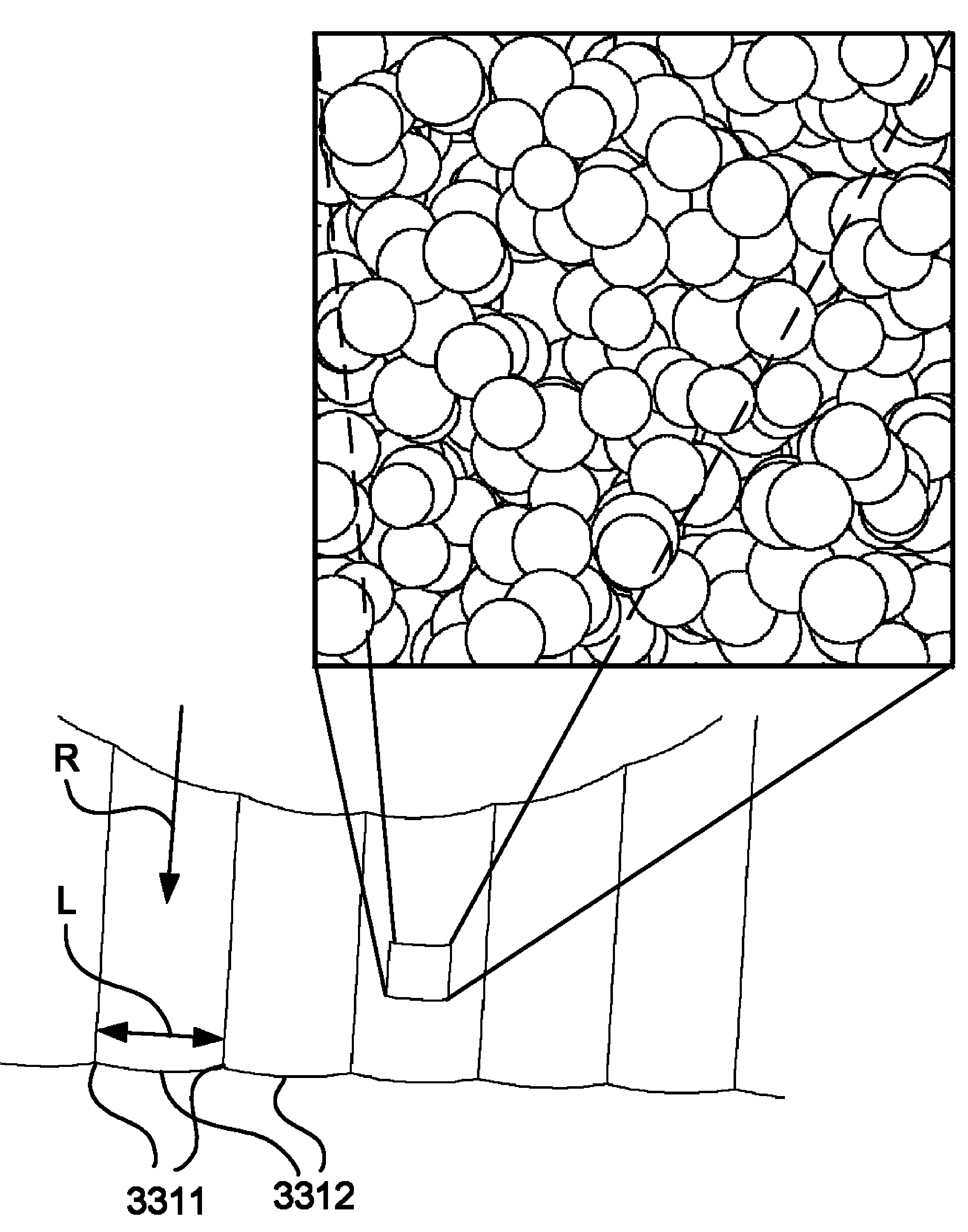

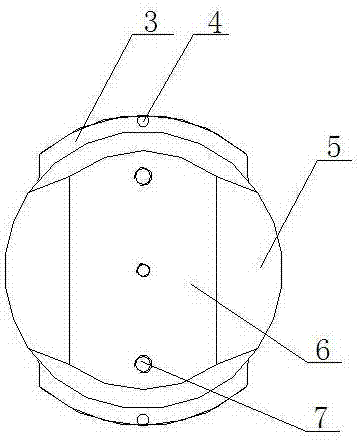

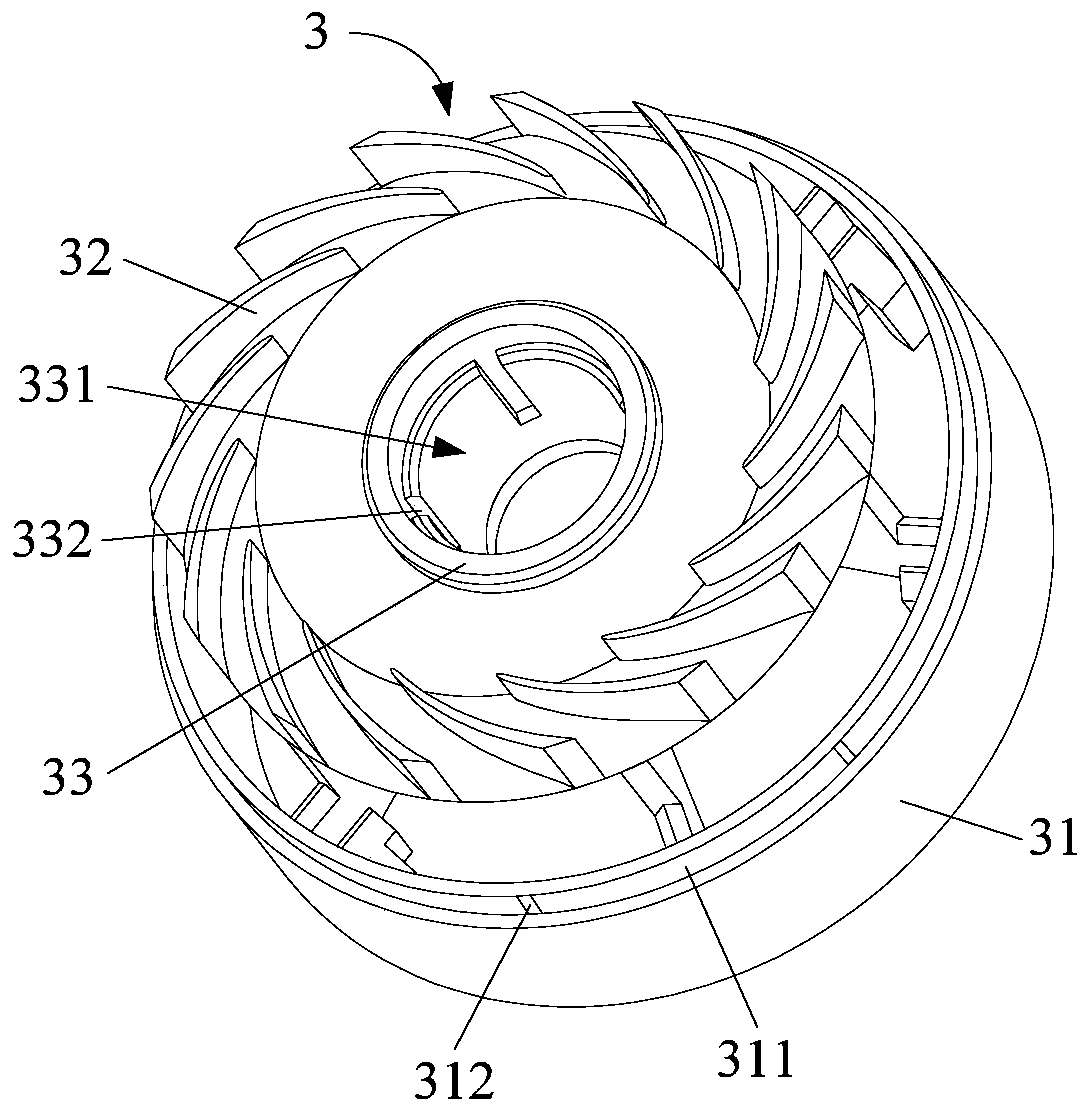

Piston for large sized internal combustion engine

ActiveCN104204485AImprove fatigue resistanceGuaranteed manufacturing costMachines/enginesPistonsCombustion chamberSurface roughness

A piston (1) for internal combustion diesel engine having a piston diameter (D) of 180 to 650 mm, the piston (1) comprising a top part (2) and a body part (3) connectable to each others, - the top part (2) defining, when installed in a cylinder of the engine, the piston (1) side of a combustion chamber, and - the body part (3) having an aperture (30) for a gudgeon pin (4), bosses (32) for distributing forces, when in use, between the piston (1) and the gudgeon pin (4), the body part (3) having an interior (33), an outer surface (34) and operable connecting surfaces (35). The interior (33) of the body part (3) comprises an interior wall (or surface) (330) having a macro geometry of wavy (331) surface, where a length (L) of a wave (331) is 3 to 25 mm and a height (h) of a wave (331) is 0,3 to 3 mm, the wavy surface having a micro geometry measurable as a surface roughness of 5 to 9 mum.

Owner:COMPONENTA FINLAND

Packaging box used for conical cylinder with small end provided with fin

The invention provides a packaging box used for conical cylinder with the small end provided with a fin and relates to a packaging box. By the adoption of the packaging box, the problem that currently, a packaging box special for a conical cylinder product with the tail end provided with a fin is unavailable, and accordingly packaging and transportation of the conical cylinder product with the tail end provided with the fin are inconvenient is solved. The packaging box comprises a packaging box frame assembly, an upper guard beam assembly, a tail end fixing assembly and a front end fixing assembly. The upper guard beam assembly is installed at the upper end of the interior of the packaging box frame assembly. The tail end fixing assembly and the front end fixing assembly are installed on the left side and the right side of the interior of the packaging box frame assembly correspondingly. According to the packaging box, the packaging box is provided with lifting rings and forklift holes, the function of lifting through a crane can be achieved, and the function of forking through a forklift can also be achieved, so that stacking and transportation are convenient; and due to the fact that a steel frame structure is adopted, crushing and deformation after the packaging box fall from a high position are avoided. The packaging box is used for packaging and transportation of the conical cylinder with the small end provided with the fin.

Owner:HARBIN JIANCHENG GRP

Improved end cover for universal joint pin type universal coupler

InactiveCN103573840ASimple structureReduce manufacturing costYielding couplingUniversal jointEngineering

The invention discloses an improved end cover for a universal joint pin type universal coupler. The end cover body takes the shape of a round disc; arced flanges are symmetrically arranged on the outer side surface of the end cover body; a flat column is arranged on one side of the end cover body; the diameter of the column is the same as that of the round-disc-shaped end cover body; an inclined surface is arranged from the top surface to each of the two sides of the column; the two inclined surfaces are arranged symmetrically. The improved end cover is simple in structure, reasonable in design, low in manufacturing cost, and capable of eliminating a gap between the end cover body and a flange fork, internal space of the end cover body is effectively utilized, and the overall rigidity of the end cover body is improved.

Owner:HENAN SANWEI HEAVY IND

electric fan

ActiveCN109185196BImprove reliabilityAchieve pre-positioningPump componentsWorking fluid for enginesImpellerEngineering

The invention provides an electric fan, comprising: a rotor assembly and a casing, the rotor assembly includes a bearing, a moving impeller and a magnetic ring, and the magnetic ring and the moving impeller are respectively installed at two ends of the bearing; the casing has a bearing chamber, and the magnetic ring The diameter is smaller than the diameter of the bearing chamber, and the magnetic ring can pass through the bearing chamber. After the installation is completed, the moving impeller and the magnetic ring are respectively located at both ends of the bearing chamber. The electric fan provided by the present invention only uses one bearing, and the bearing is located between the moving impeller and the magnetic ring of the rotating shaft. When assembling, the magnetic ring passes through the bearing chamber. After the installation is completed, the moving impeller and the magnetic ring are respectively located At the end, this assembly method of the rotor assembly and the casing is convenient for assembly and simplifies the assembly process; since only one bearing is used, the assembly accuracy requirements for the rotor assembly and the casing are low, which is conducive to improving assembly efficiency; The number of parts is beneficial to reduce product cost and further improve assembly efficiency.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

Boiler furnace, furnace pipe of rotary furnace, rotary cylinder and rotary kiln

PendingCN109442982AIncreased precision and adjustabilityIncrease production capacityRotary drum furnacesElectric heating for furnacesBoiler furnaceEngineering

The invention relates to a boiler furnace, a furnace pipe of a rotary furnace, a rotary furnace and a rotary kiln. The boiler furnace comprises a hollow cylindrical cannular body (1111) and a continuous spiral protrusion (1112) which is arranged on the inner wall of the cannular body (1111) and is integrally formed with the cannular body (1111). The continuous and spiral protrusion is integrally pressed in the boiler furnace, in the process that the furnace pipe of the rotary furnace is used for sintering a high-nickel ternary anode material, the protrusion rotates along with the rotation of the boiler furnace, due to the action of the protrusion, functions of stirring and pushing the material are achieved, the effect that the material is heated evenly in the sintering reaction process canbe achieved, the material makes sufficient contact with oxygen, and the product quality is effectively guaranteed.

Owner:宜兴精新粉体设备科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com