Boiler furnace, furnace pipe of rotary furnace, rotary cylinder and rotary kiln

A rotary drum and rotary kiln technology, which is applied in the field of material forming and manufacturing, can solve problems such as poor product quality, and achieve the effects of increasing productivity, saving production costs, and improving pressing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

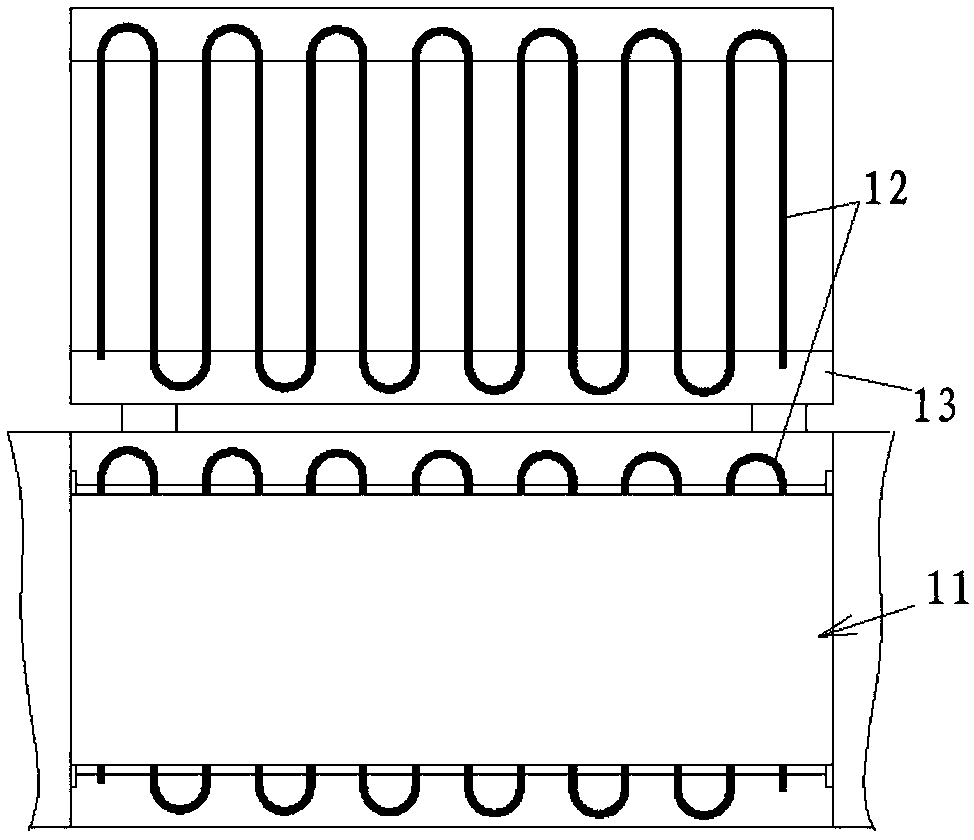

[0046] Such as figure 2 As shown, according to an embodiment of the present invention, the rotary furnace tube of the present invention includes: a furnace chamber 111 , an outer shell 112 , and a filling layer 113 between the furnace chamber 111 and the outer shell 112 . In this embodiment, the shell 112 is also a hollow cylindrical body, and is sheathed on the outside of the furnace 111. The outer diameter of the shell 112 is larger than the outer diameter of the furnace 111, so a ring is formed between the shell 112 and the furnace 111. shaped accommodating space, the filling layer 113 is located in the accommodating space between the shell 112 and the furnace 111.

[0047] Such as figure 2 As shown, according to an embodiment of the present invention, the filling layer 113 includes a first filling portion 1131 and a second filling portion 1132 at opposite ends of the first filling portion 1131 . In this embodiment, the expansion coefficient of the second filling part 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature tolerance | aaaaa | aaaaa |

| Temperature tolerance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com