Miniature inductor and manufacturing method thereof

A technology of micro-inductance and manufacturing method, which is applied in the field of inductance, can solve the problems of inability to take into account the comprehensive performance and processing cost of micro-inductors, the high manufacturing cost of deposition process, and the increase in the cost of micro-inductors, etc., to achieve low processing costs, superior comprehensive performance, and convenience The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to enable those skilled in the art to better understand the technical solution of the present invention, the micro-inductor provided by the present invention and its manufacturing method will be described in detail below with reference to the accompanying drawings.

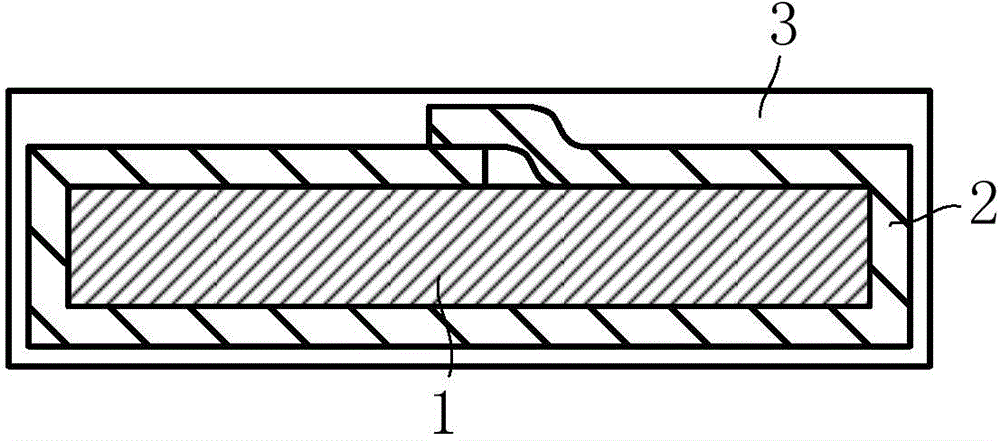

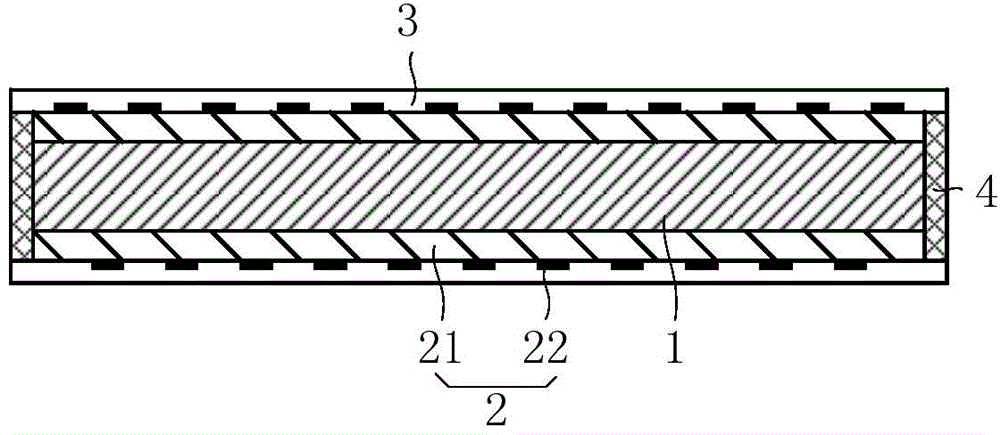

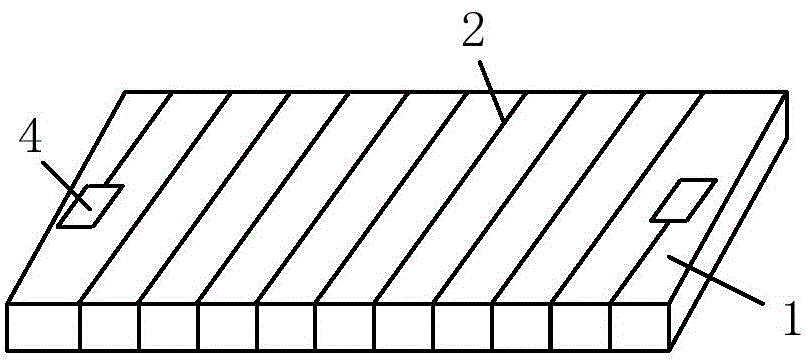

[0049] Such as figure 1 and Figure 2a As shown, the miniature inductor includes a magnetic core 1 , a coil 2 , an encapsulation layer 3 and pads 4 , and the coil 2 is arranged outside the magnetic core 1 . The encapsulation layer 3 is used for encapsulating the magnetic core 1 and the coil 2 , and a soldering pad 4 is respectively provided at the two ends of the wiring 22 for electrical connection between the coil 2 and other external devices.

[0050] Such as Figure 2a As shown, the coil 2 includes a support body 21 and wiring 22 . Wherein, the support body 21 is a hollow columnar structure, such as a square cylindrical structure. Of course, the support body 21 may also be a circular cylindri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com