Glaze and preparation of embossment phantom glazed brick

A glazed tile and phantom technology, which is applied in the field of glaze and preparation of embossed phantom glazed tiles, can solve the problems of limitations, single plane pattern decoration, etc., achieve high refractive index and surface tension, ensure clarity, and have high refractive index effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in further detail below in conjunction with embodiment.

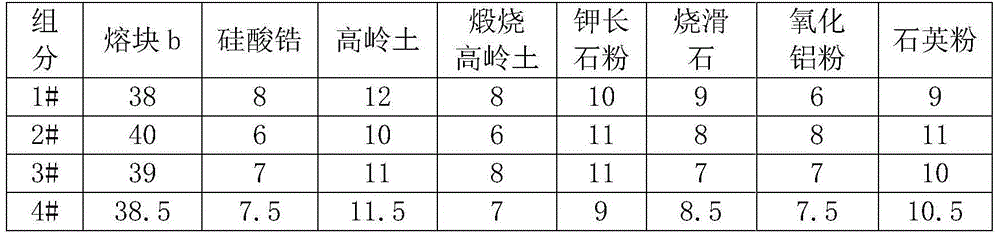

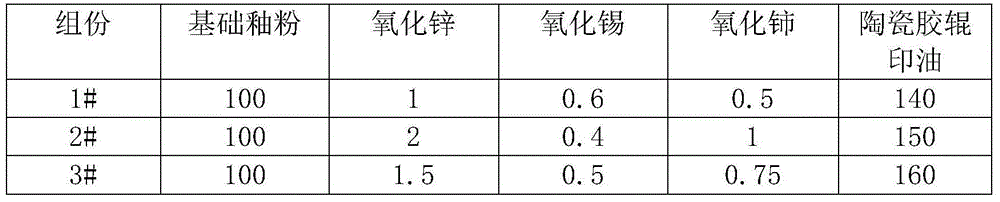

[0030] The glaze and preparation of a kind of embossed phantom glazed tile of the present invention firstly prepare the frit of bottom glaze, surface glaze and basic glaze powder.

[0031] Preparation of frit a: according to the chemical composition in Table 1, select the raw materials of quartz powder, potassium albite feldspar powder, talc powder, calcium carbonate, potassium carbonate, zinc oxide, zircon powder, and boric acid in corresponding proportions with a particle size of less than 150 mesh, and carry out The ingredients are mixed in a mixer for 30 minutes, melted in a frit furnace at a melting temperature of 1520°C to 1540°C, quenched with water to form frit particles and dried to obtain frit a.

[0032] Table 1, the chemical composition list of frit a (weight percent, %)

[0033] components

SiO 2

AL 2 o 3

CaO

MgO

K 2 o

Na 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com