Stator coil for rotating electric machine, method for manufacturing said stator coil, and rotating electrical machine

A technology for stator coils and rotating electrical machines, used in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve problems such as reduced withstand voltage characteristics, deterioration of enameled wires, poor insulation, etc. The effect of high fixing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0024] The stator coil of the rotating electrical machine according to the present embodiment includes a stator core and a coil formed by winding an enameled wire around a slot of the stator core. Here, the stator core and the enameled wire are not particularly limited, and stator cores and enameled wires known in the technical field can be used. Among them, the enameled wire is preferably an enameled wire covered with a polyamide-imide coating film.

[0025] In addition, the enameled wire is covered with a polyester resin film containing a cured product of the first insulating varnish containing a polyester resin, and the coil is covered with an epoxy acrylate resin film that is a cured product of a second insulating varnish containing an epoxy acrylate resin. Further cladding.

[0026] The polyester resin film covering the enameled wire has effects as a stress relaxation layer and an adhesiveness imparting layer. That is, since the polyester resin coating has lower hardnes...

Embodiment approach 2

[0057] In the stator coil of the rotating electric machine according to this embodiment, the coil formed by winding an enameled wire is coated with a polyester resin film which is a cured product of a first insulating varnish containing a polyester resin, and is coated with an epoxy-containing varnish. The epoxy acrylate resin film of the cured product of the second insulating varnish of acrylate resin is different from the stator coil of the rotating electrical machine according to the first embodiment in that the epoxy acrylate resin film is further coated with the polyester resin film to form an insulating layer. Even in the case where such an insulating layer is formed, not only the fixing force of the insulating layer but also the withstand voltage characteristics over a long period of time can be improved.

[0058] The polyester resin film covering the coil has effects as a stress relaxation layer and an adhesiveness imparting layer. That is, since the hardness of the po...

Embodiment 1

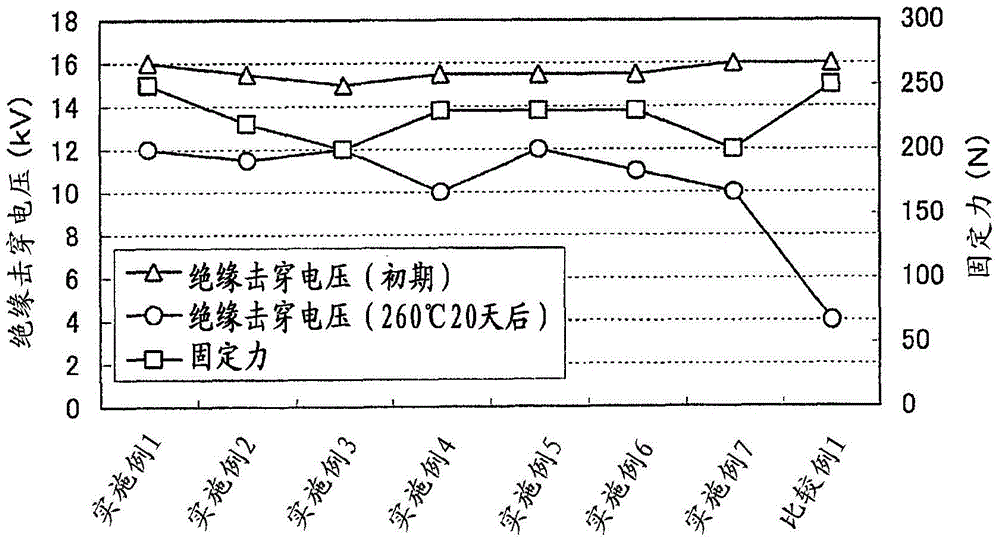

[0075] The following tests were performed using the first insulating varnish containing epoxy-modified polyester and the second insulating varnish containing bisphenol A type epoxy acrylate.

[0076] In accordance with JIS C2103, twisted pair wires and helical coils are manufactured using enameled wires covered with polyamide-imide film as enamel. Next, each of the twisted pair wire and the spiral coil was impregnated with the first insulating varnish, and then heated at 130° C. for 2 hours to form a polyester resin film. Next, after impregnating the twisted pair wire and the spiral coil in the second insulating varnish, the epoxy acrylate resin film was formed by heating at 160° C. for 2 hours.

[0077] The fixing force of the helical coil obtained above was measured using an autograph (AG-5000D manufactured by Shimadzu Corporation) according to JIS C2103. As a result, it was confirmed that the fixing force was 250N, and the fixing force of the insulating layer was high.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com