Surface mount coil component

A coil component, surface mount technology, applied in coil manufacturing, transformer/inductor parts, electrical components, etc., can solve problems such as low bonding strength, thermal degradation of the adhesive 26, peeling, etc., to achieve high reliability, Effect of preventing thermal deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

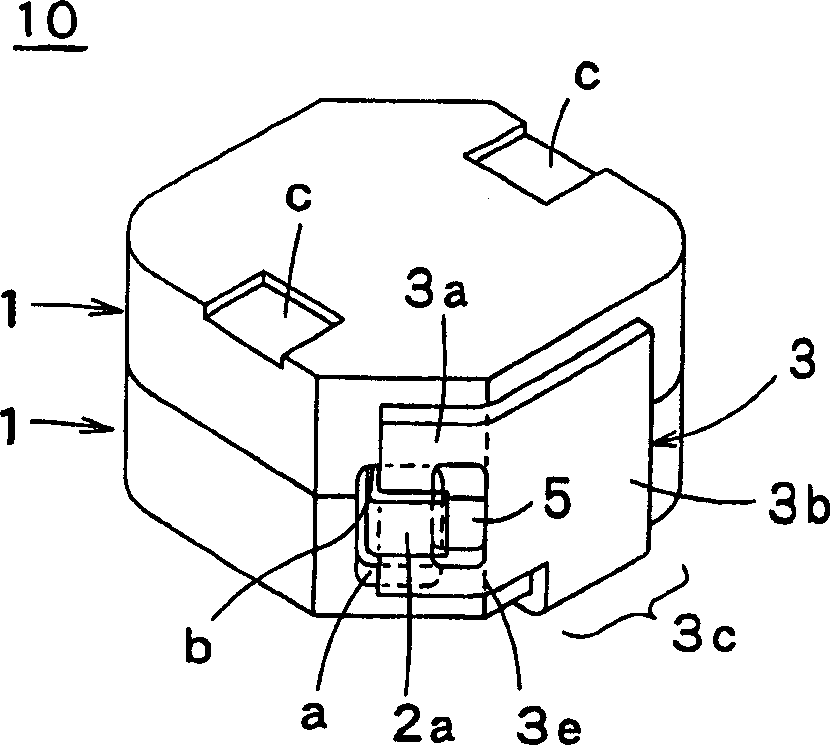

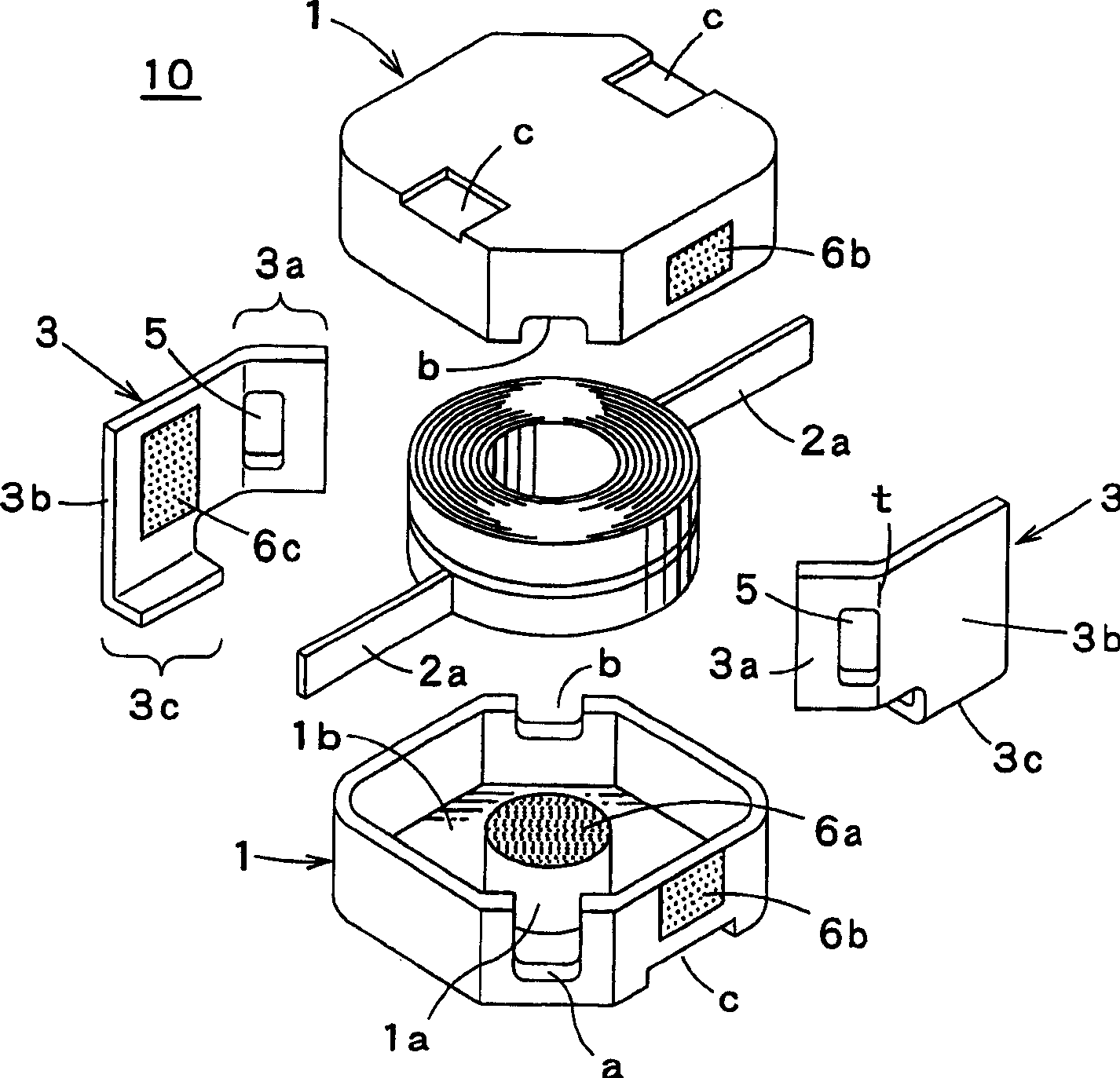

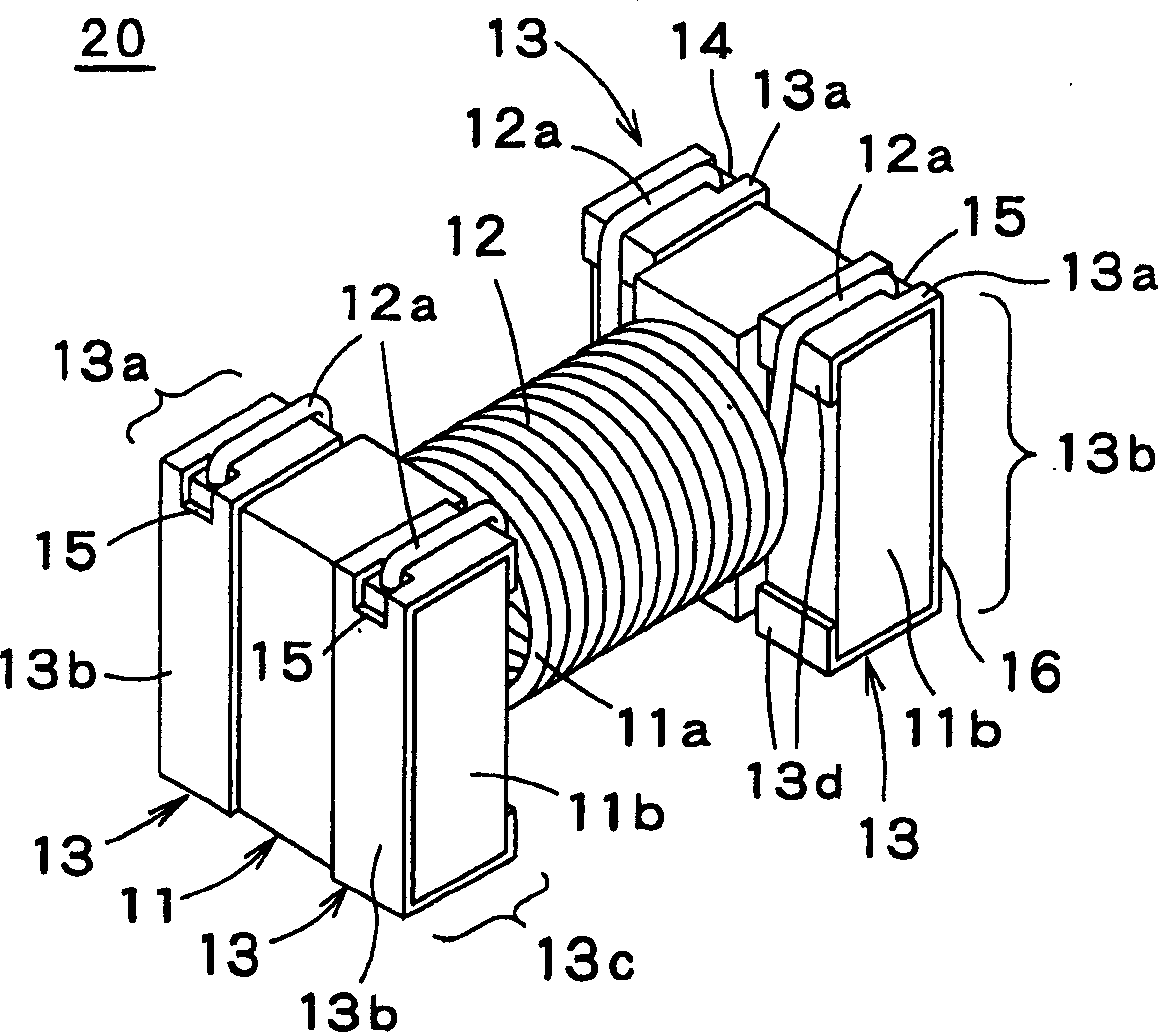

[0032] figure 1 It is a perspective view of the surface mount coil component 10 of the first embodiment of the present invention, figure 2 It is an exploded perspective view of the surface mount coil component 10 of the first embodiment. exist figure 1 and figure 2 Among them, 1 is the magnetic core, 2 is the winding, 2a is the end of the winding, and 3 is the metal plate terminal.

[0033] The winding 2 is an air-core coil formed as a so-called outer-outer winding in which the ends 2a, 2a are drawn out to the outside using a so-called rectangular wire with a square cross-section and an insulating coating on the surface.

[0034] The magnetic core 1 is made of a magnetic body, has a reel 1a in the center, and has a concave portion 1b for accommodating the winding 2, and is formed into an E-shaped substantially quadrangular cross section. A taper is provided on a pair of opposite corners, and notches a and b are provided on the opening of the taper, and holes for allowi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com