Gas discharge lamp

A technology for gas discharge lamps and discharge tubes, which is applied to gas discharge lamps, discharge lamps, and parts of gas discharge lamps, etc., can solve the problems of complicated auxiliary electrode structures and too expensive mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

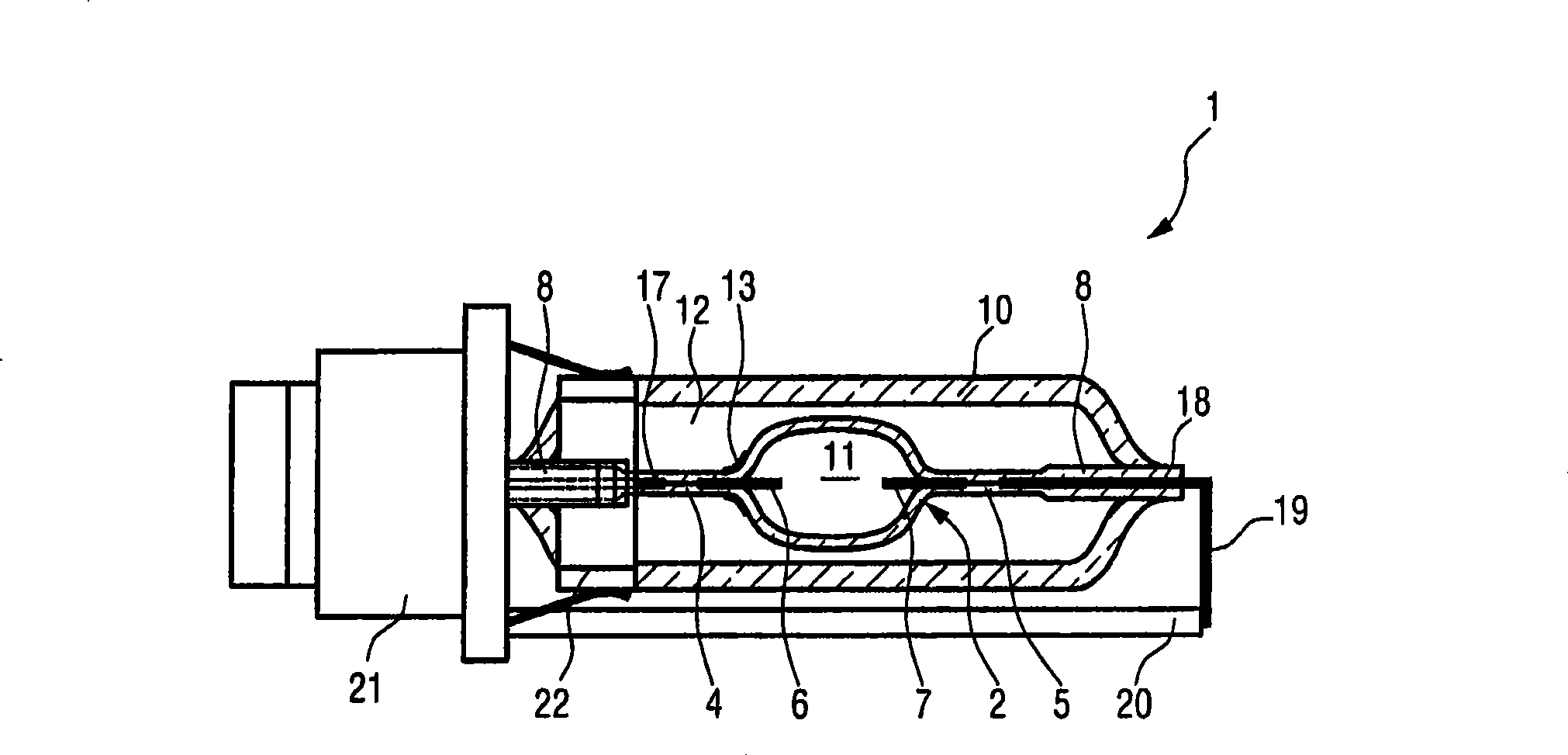

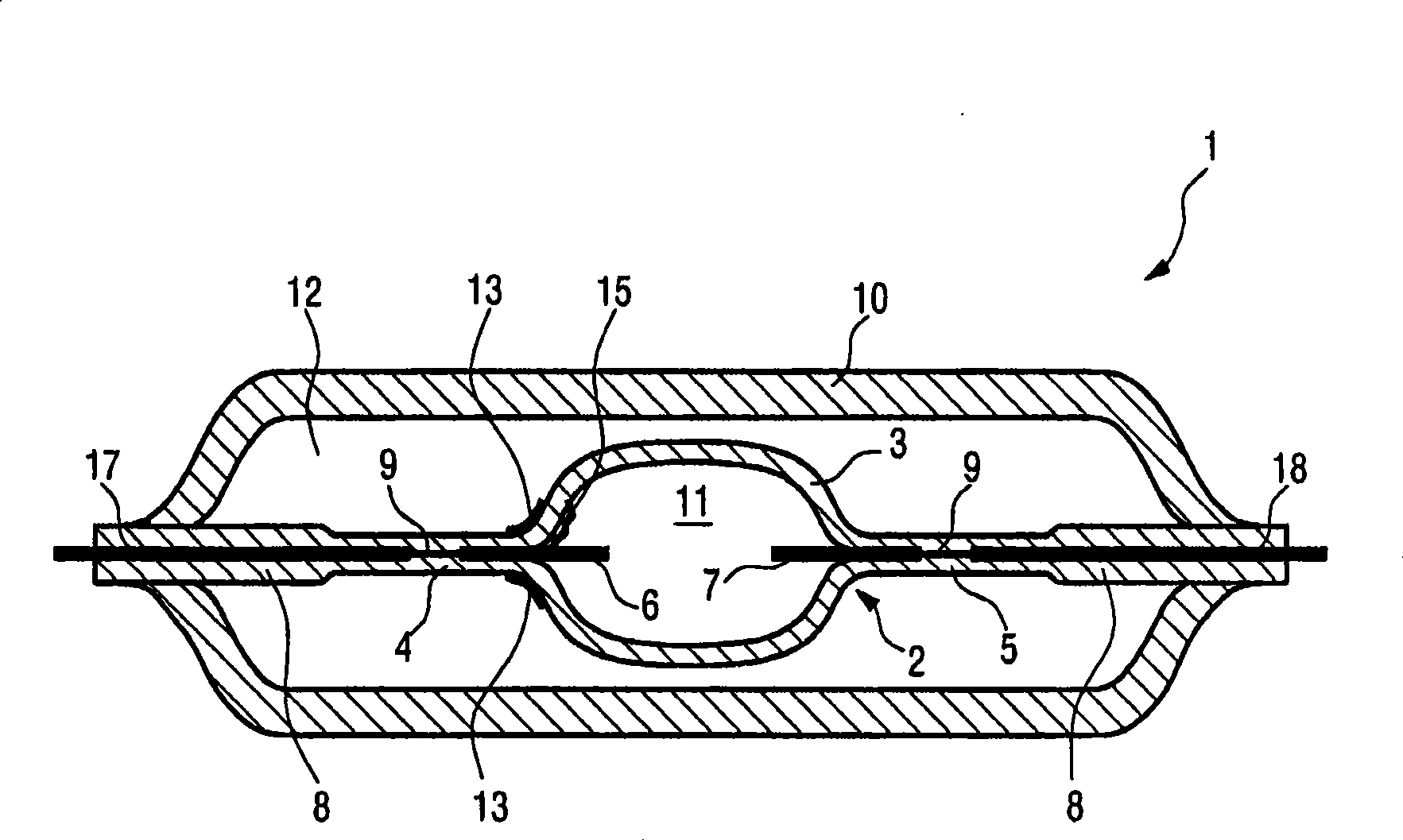

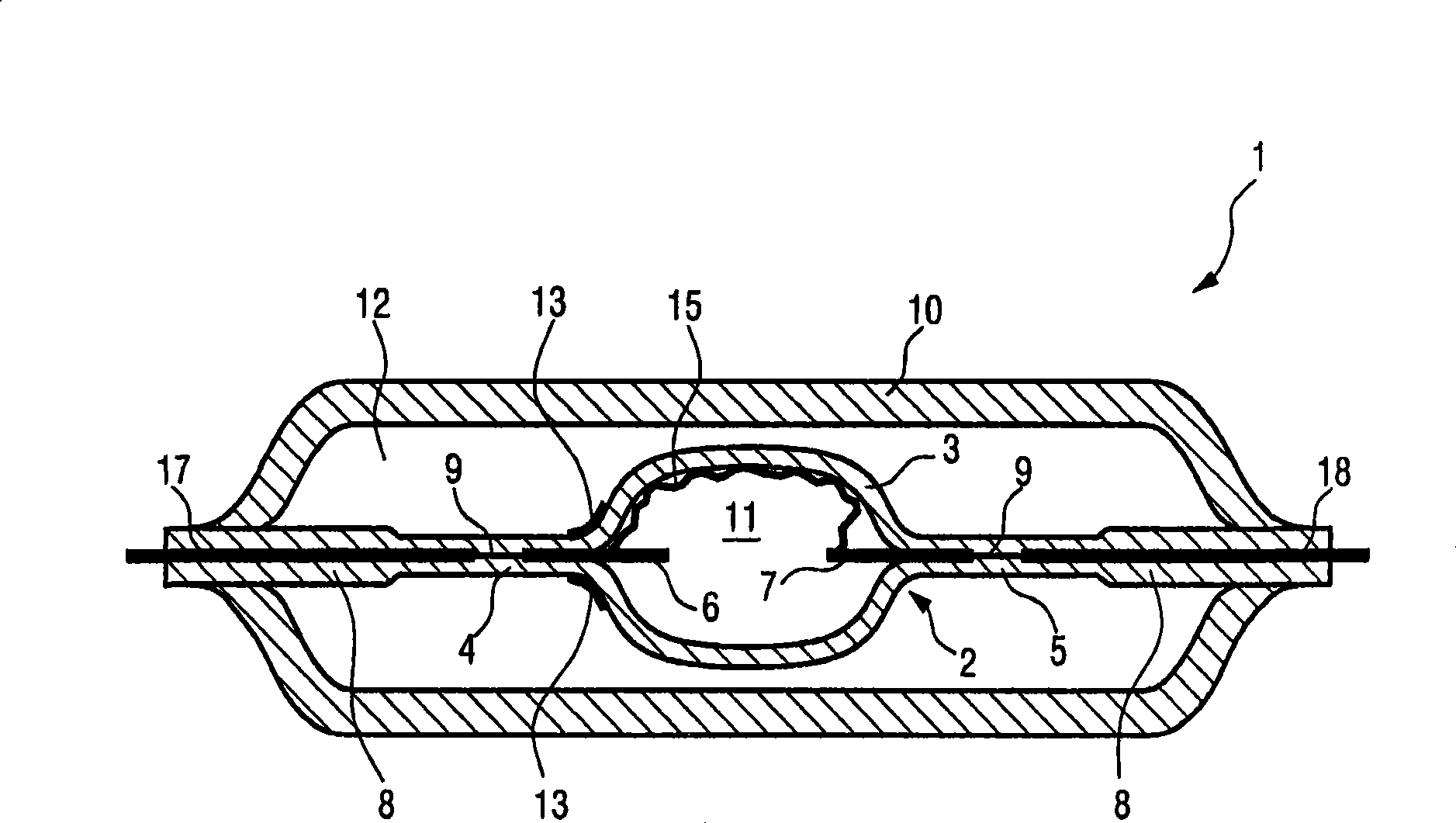

[0032] The embodiment shown in the drawings (not intended to limit the invention) is a preferred MPXL lamp constructed in a conventional manner with an inner bulb 2 and an outer bulb 10 surrounding the inner bulb 2 . The inner bulb 2 here comprises the actual discharge vessel (burner) 3 made of quartz glass with quartz glass end pieces 8 molded onto the discharge vessel 3 on two opposite sides. Immediately adjacent to the discharge vessel 3 , a quartz glass terminal piece 8 is formed as the sealing portion 4 , 5 . Electrodes 6 , 7 protrude from these seals 4 , 5 into discharge vessel 3 . In the sealing part, the electrodes 6, 7 are respectively connected to the thinner and shorter conductive film part 9, wherein the other end of the conductive film part is connected to the power lines 17, 18 respectively. In the region of the sealing parts 4 , 5 , the quartz glass termination pieces 8 are rolled together so that the conductive film part 9 is tightly sealed in the sealing part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com