Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62results about How to "Inhibition of thermal deterioration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

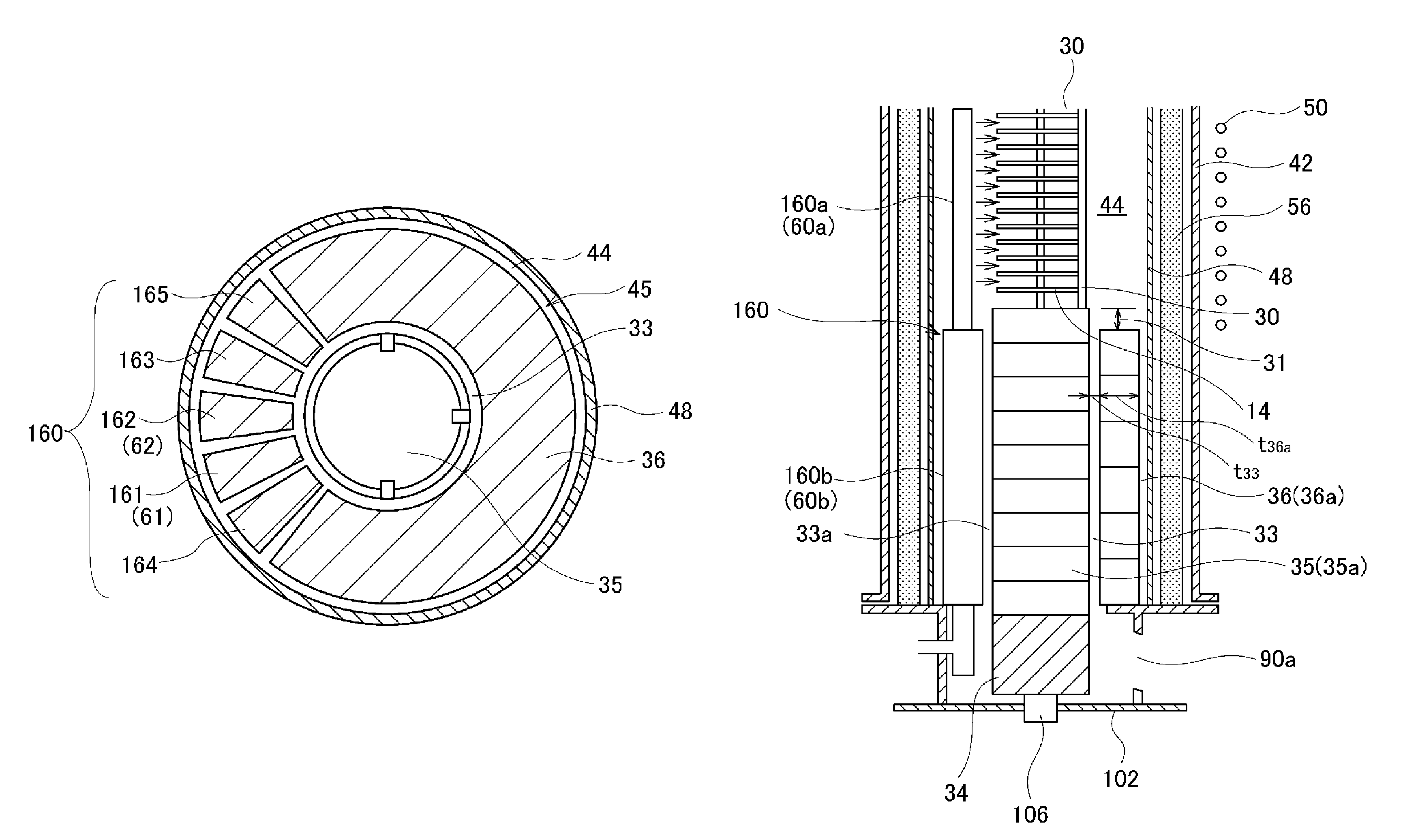

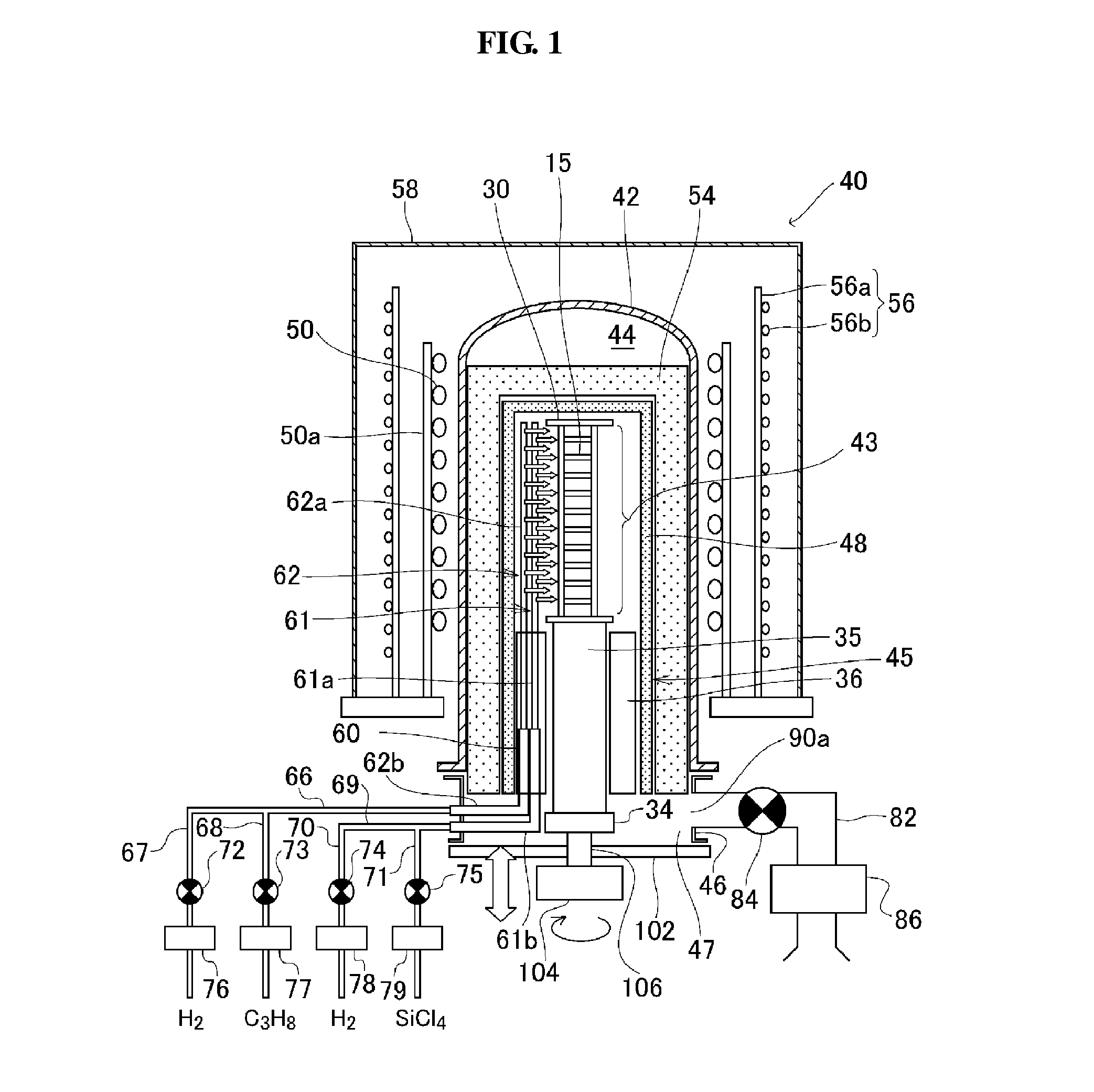

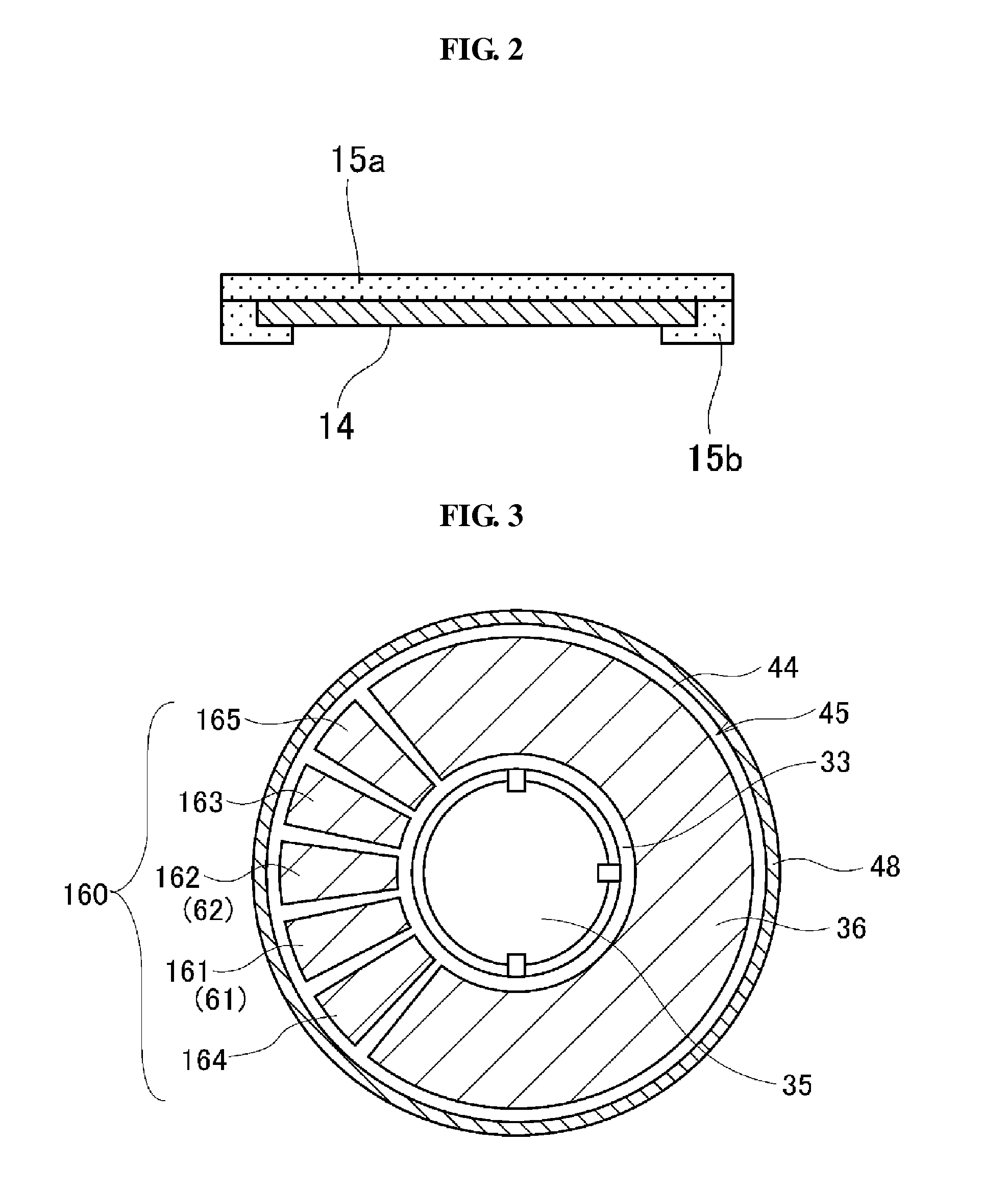

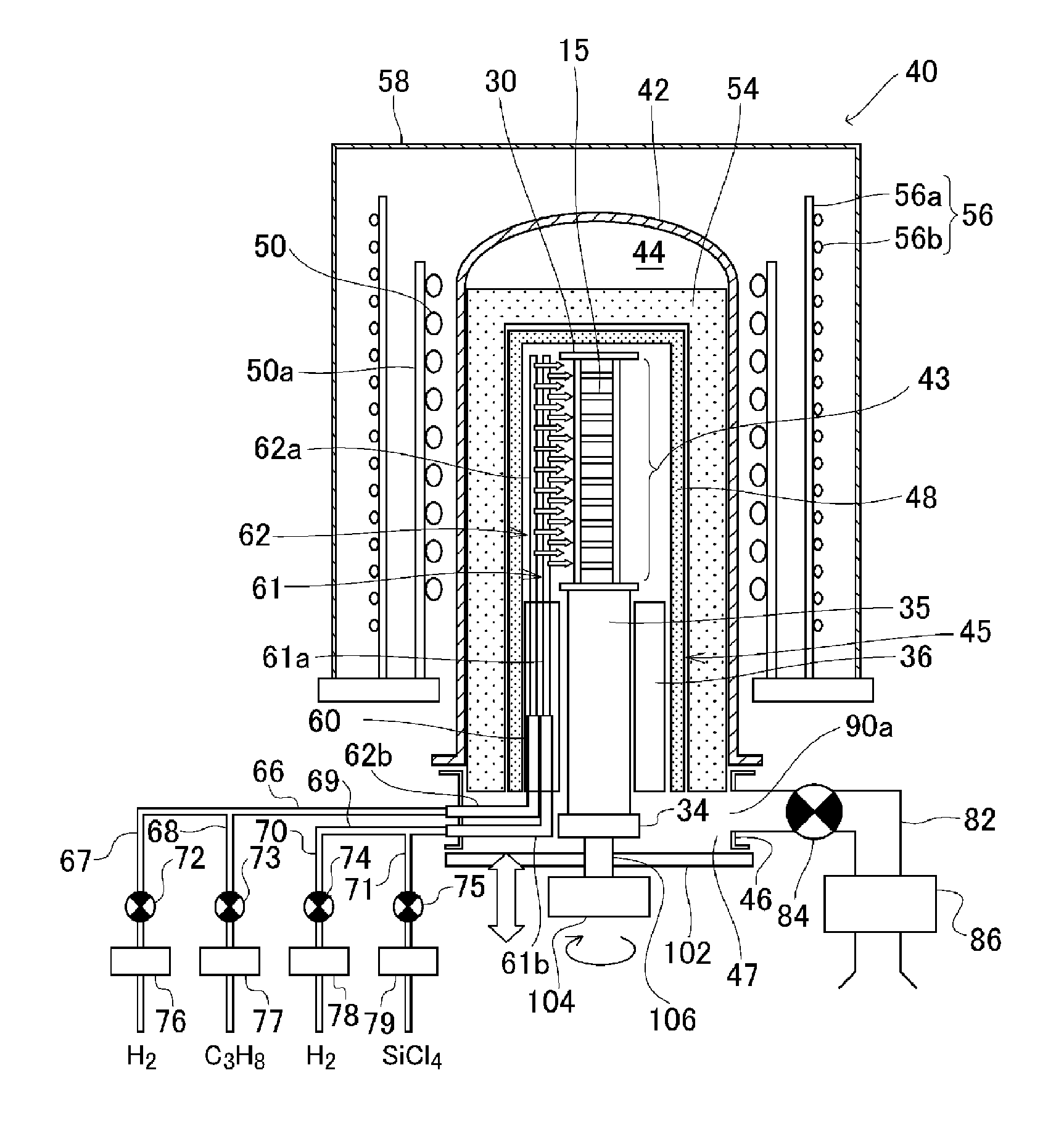

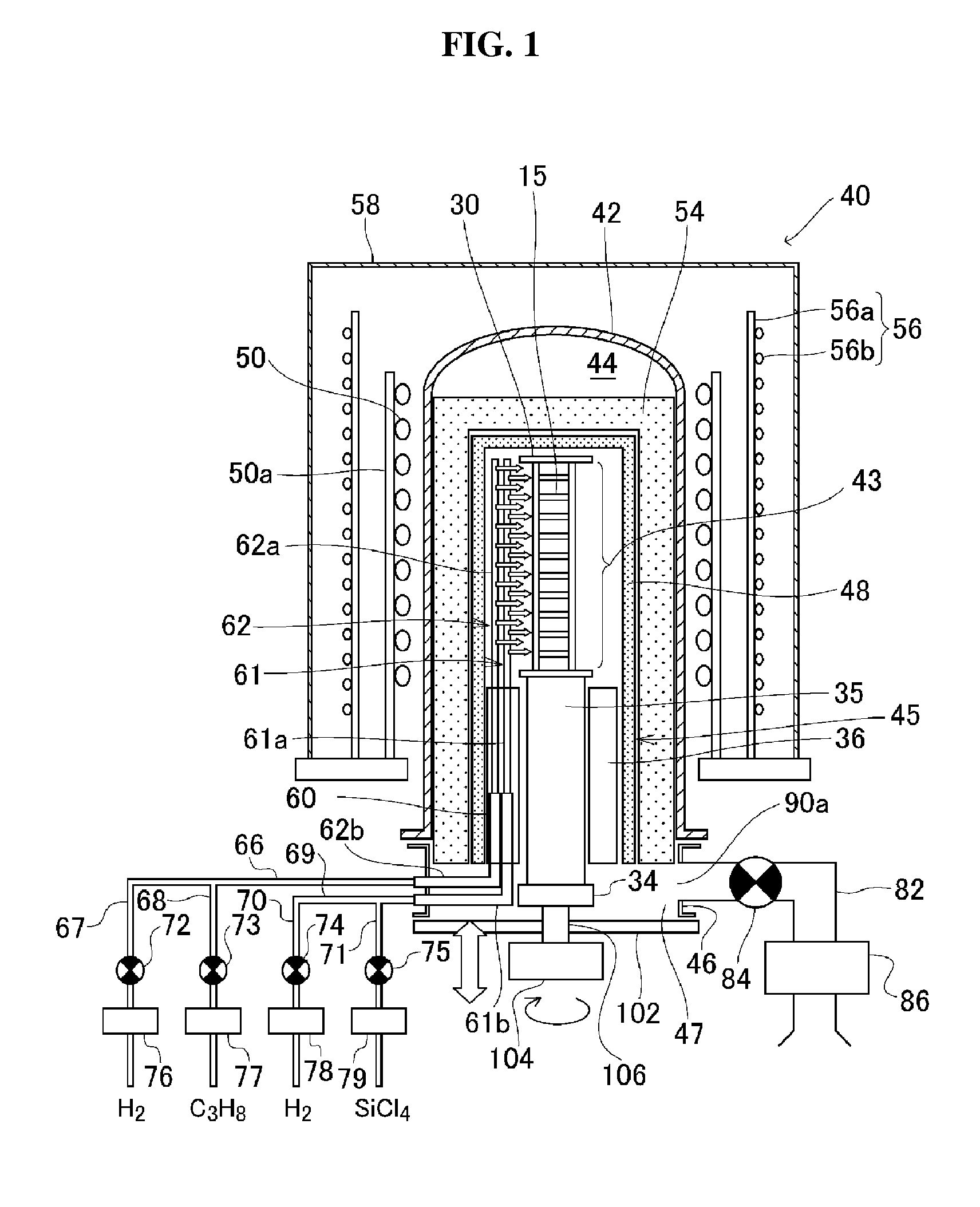

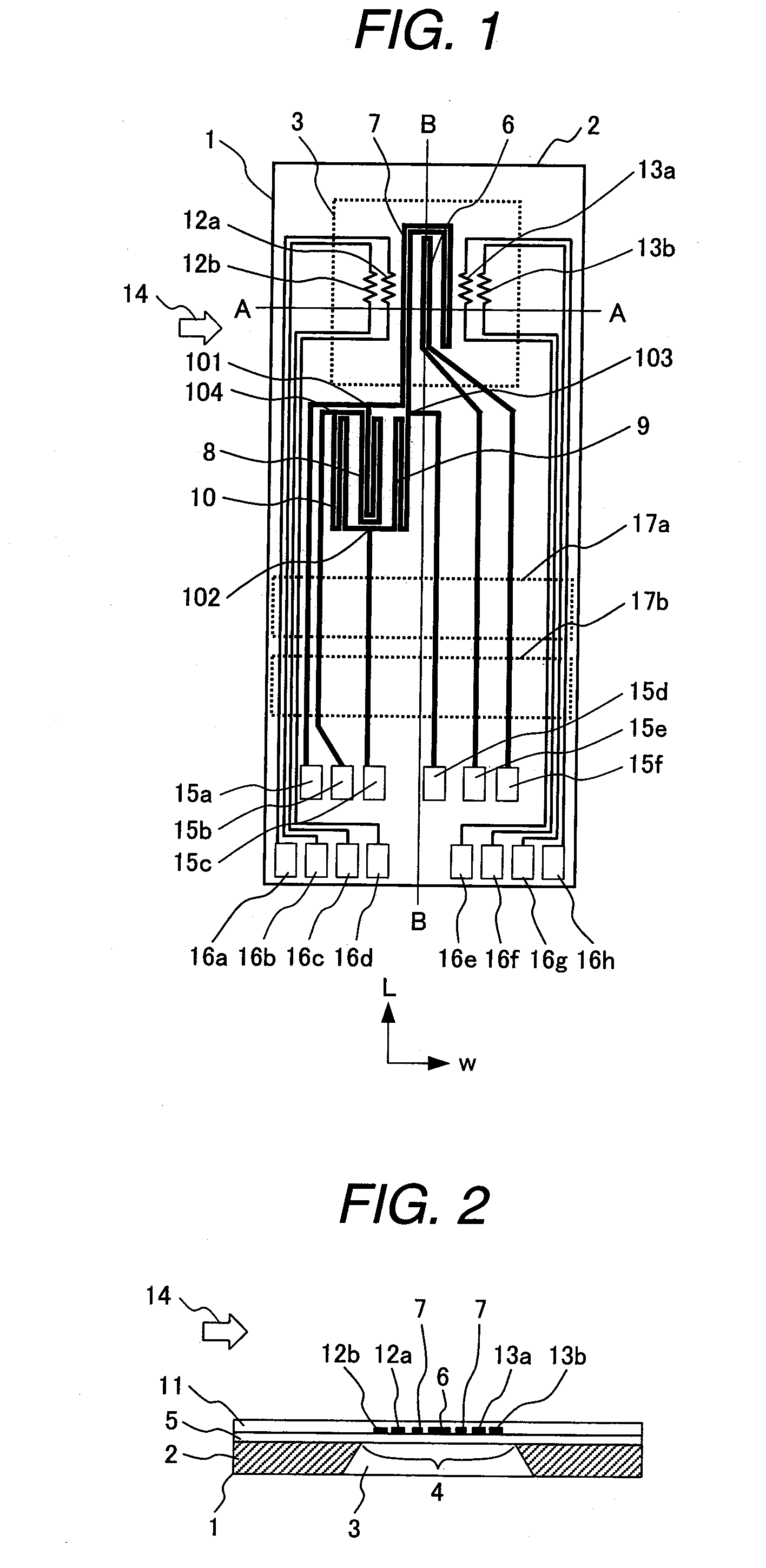

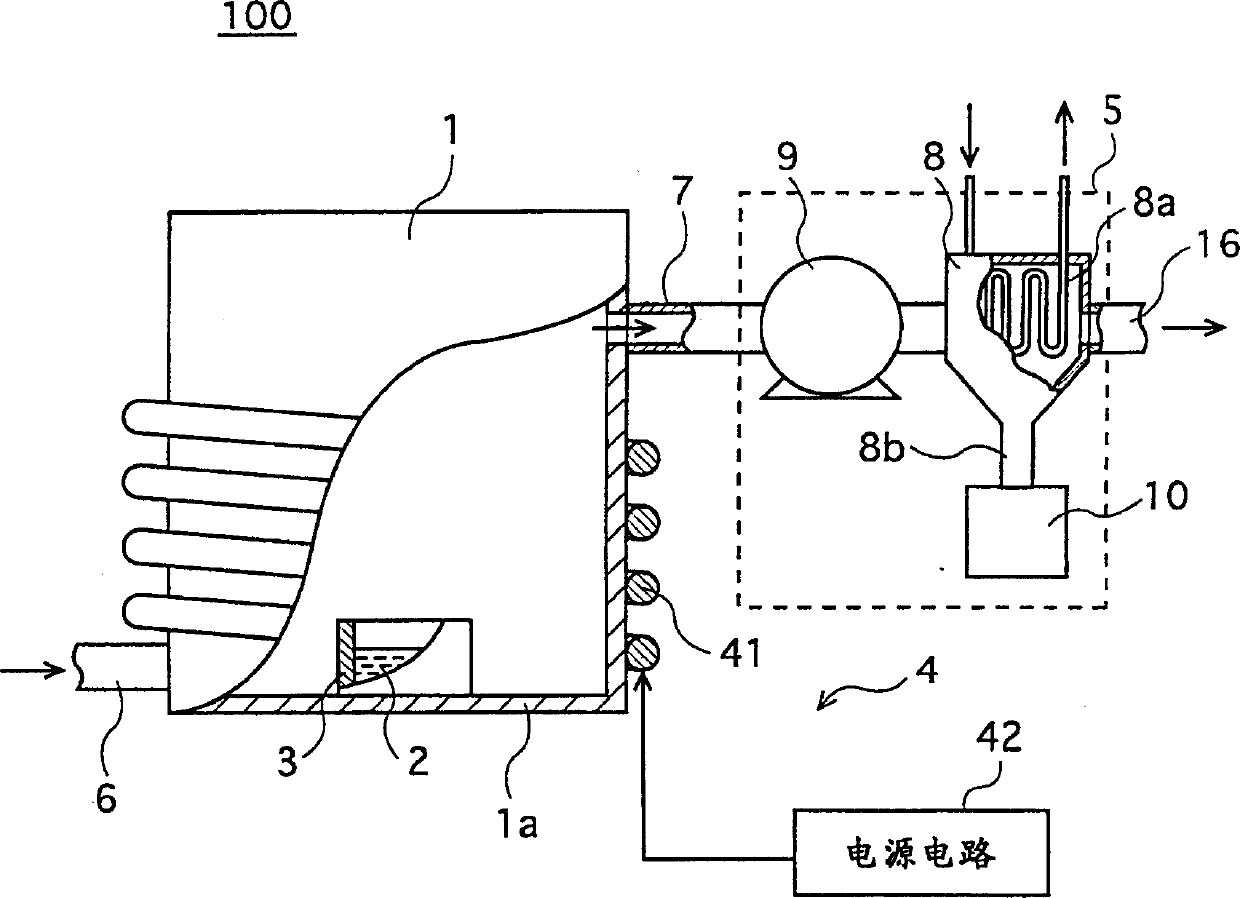

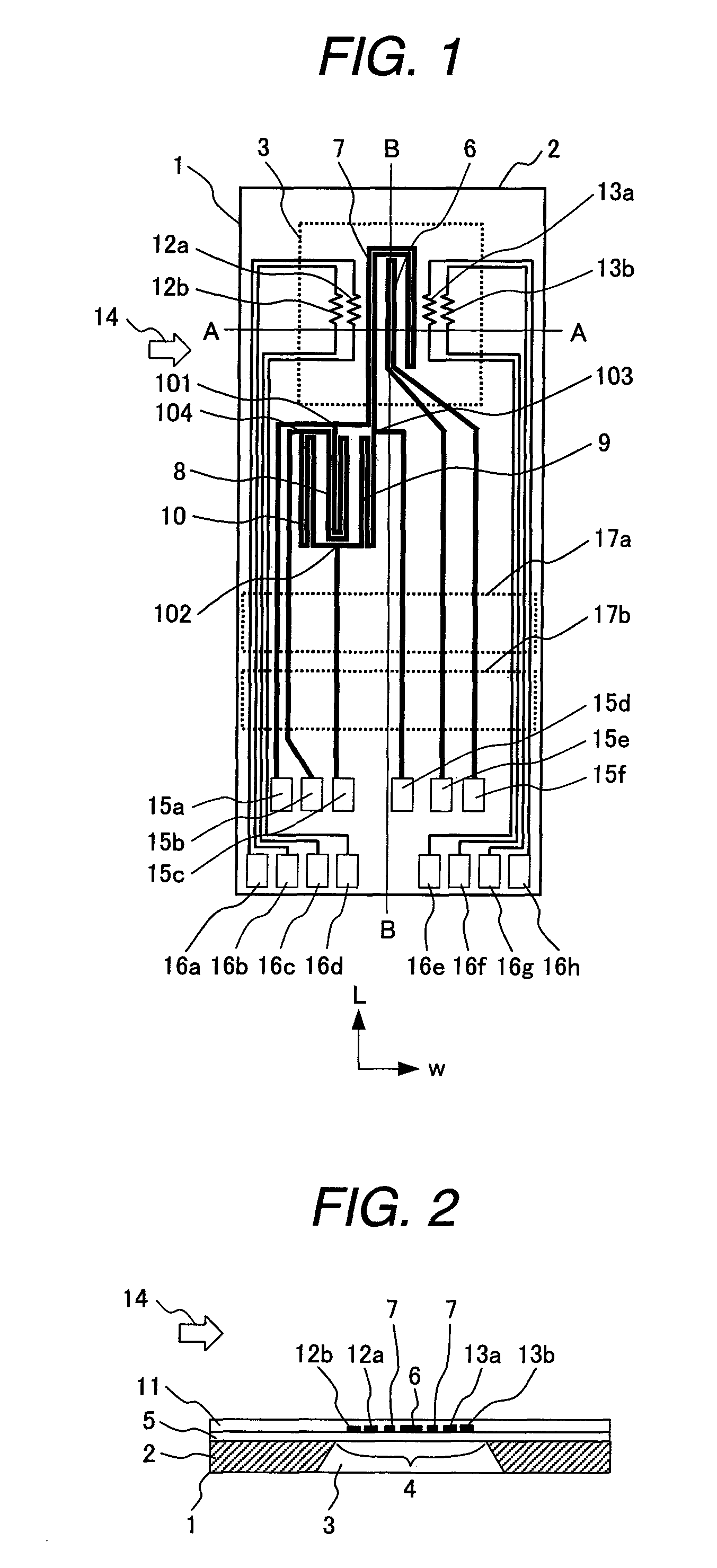

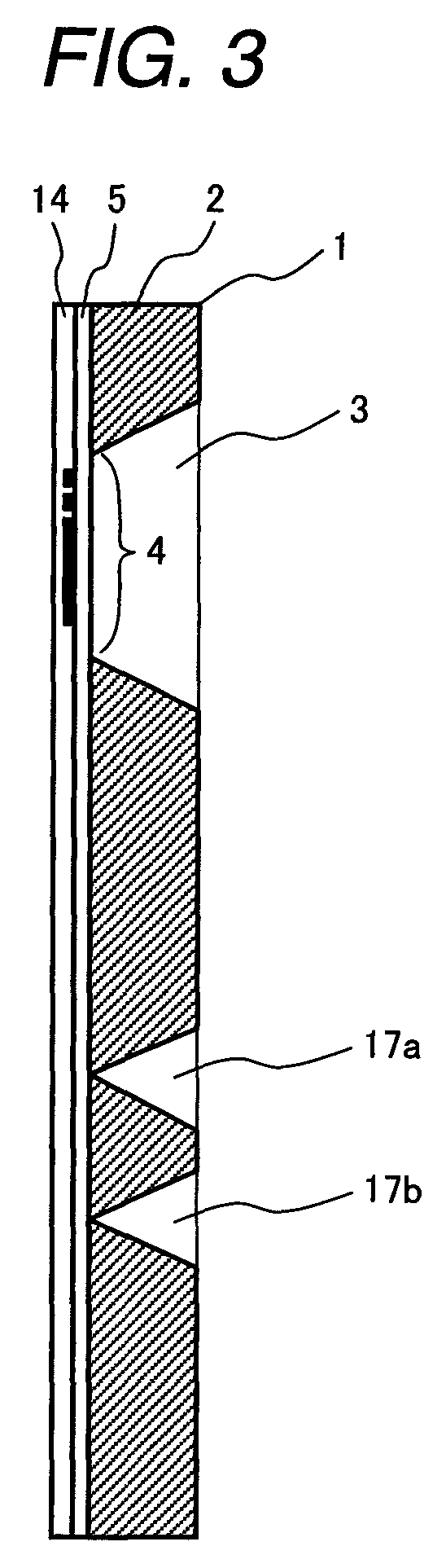

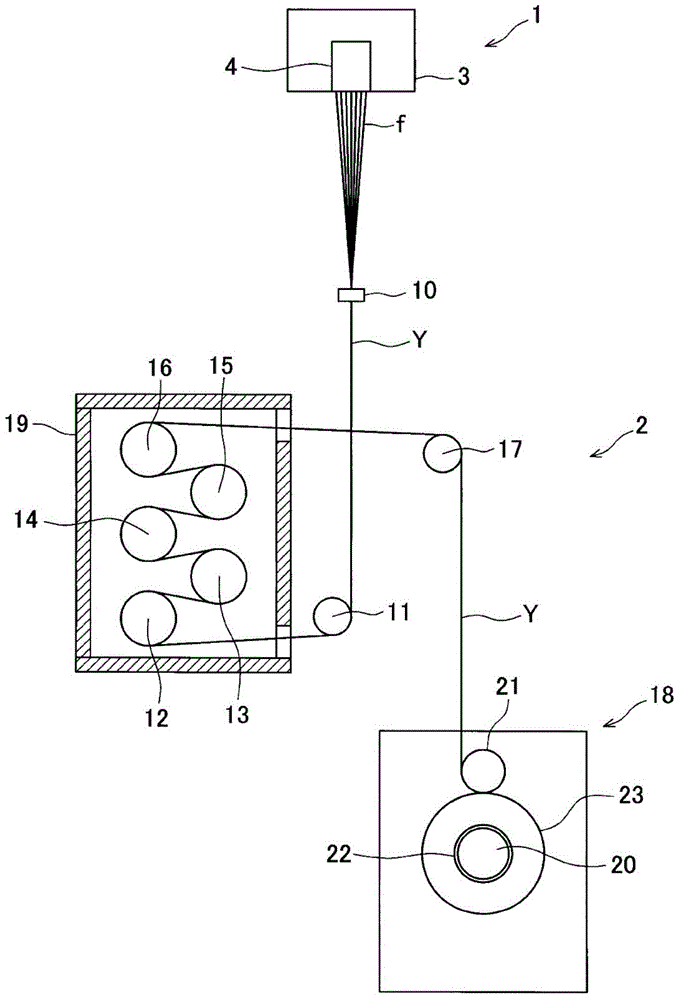

Substrate processing apparatus and method of manufacturing semiconductor device

ActiveUS8882923B2Inhibition of thermal deteriorationHeat deteriorationPolycrystalline material growthSemiconductor/solid-state device manufacturingProcess engineeringSemiconductor

A substrate processing apparatus includes: a process chamber having an object to be heated therein and configured to process a plurality of substrates; a substrate holder configured to hold the substrates with an interval therebetween in a vertical direction in the process chamber; a first heat exchange unit supporting the substrate holder from a lower side thereof in the process chamber and configured to perform a heat exchange with a gas in the process chamber; a second heat exchange unit provided in the process chamber, the second heat exchange unit being horizontally spaced apart from the first heat exchange unit with a gap therebetween and being configured to perform a heat exchange with the gas in the process chamber; and an induction heating unit configured to subject the object to be heated to an induction heating from an outer side of the object to be heated.

Owner:KOKUSA ELECTRIC CO LTD

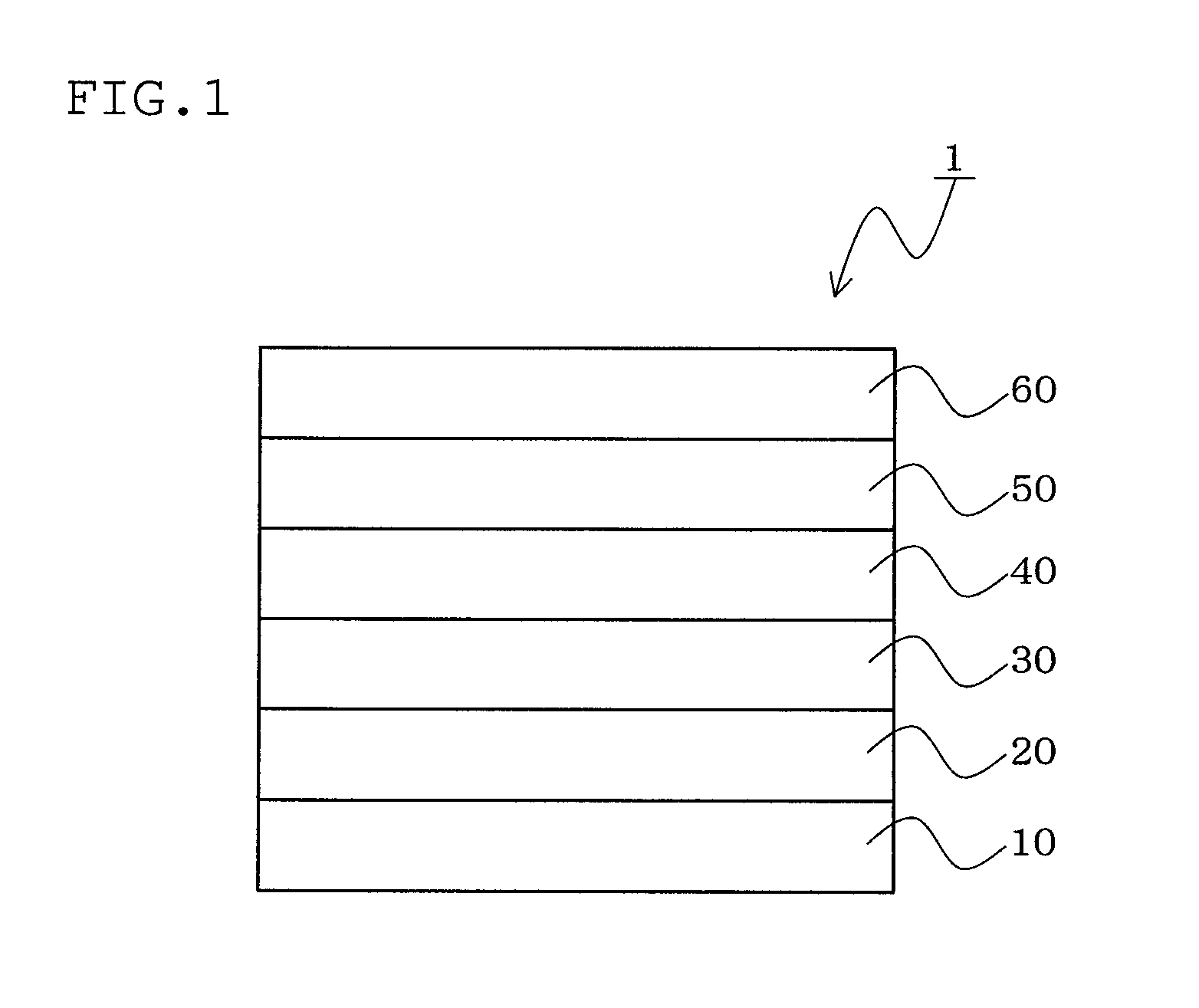

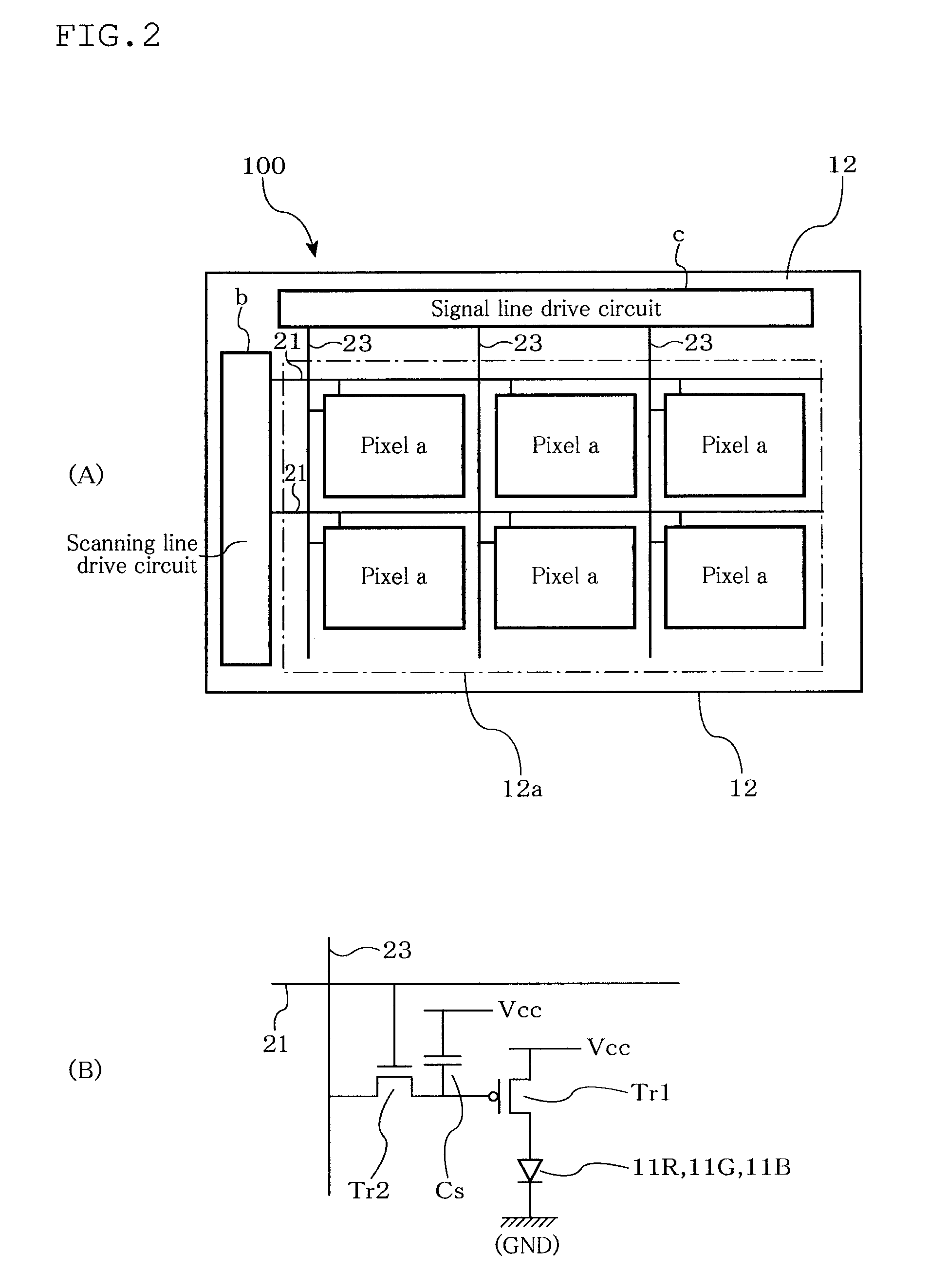

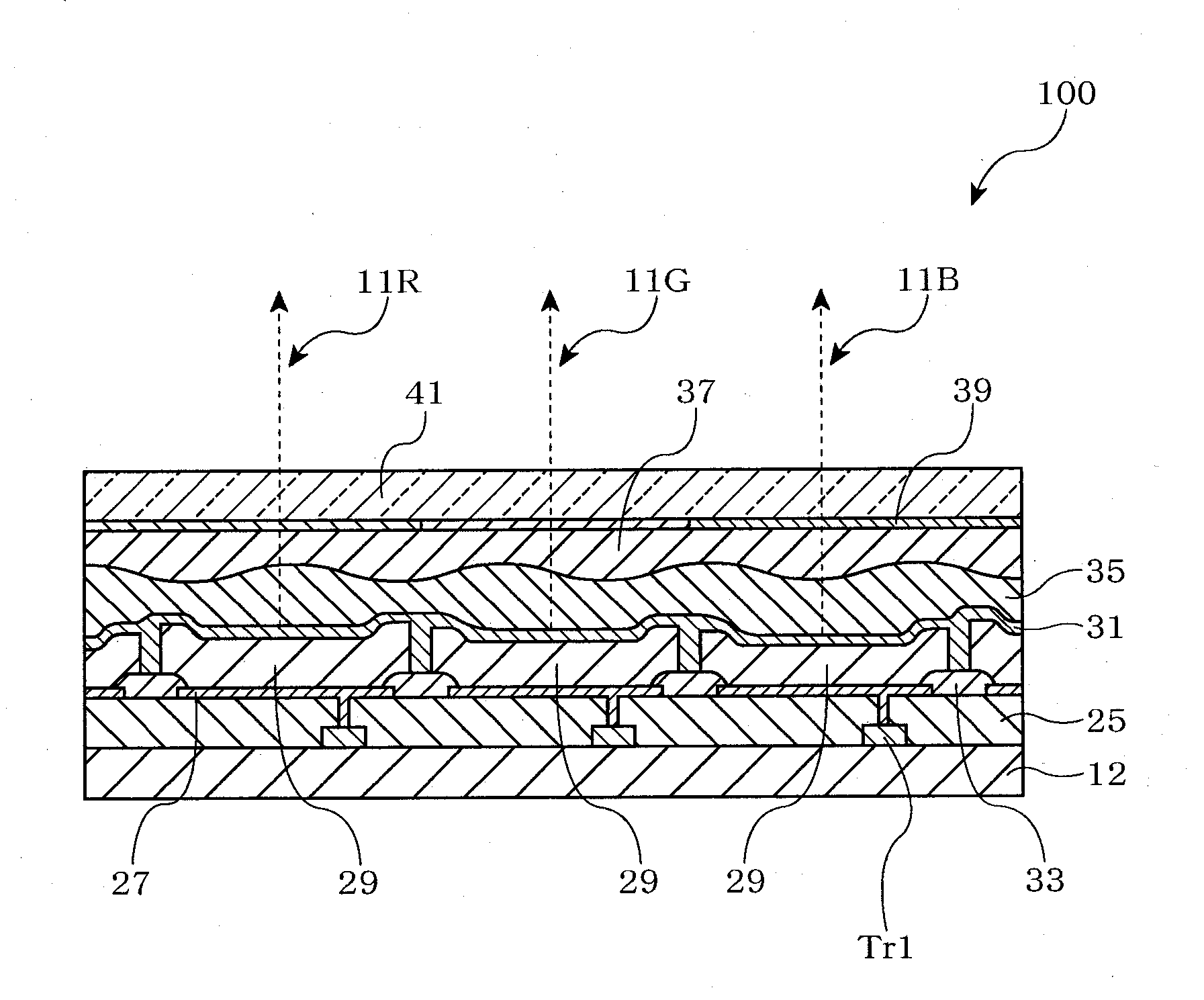

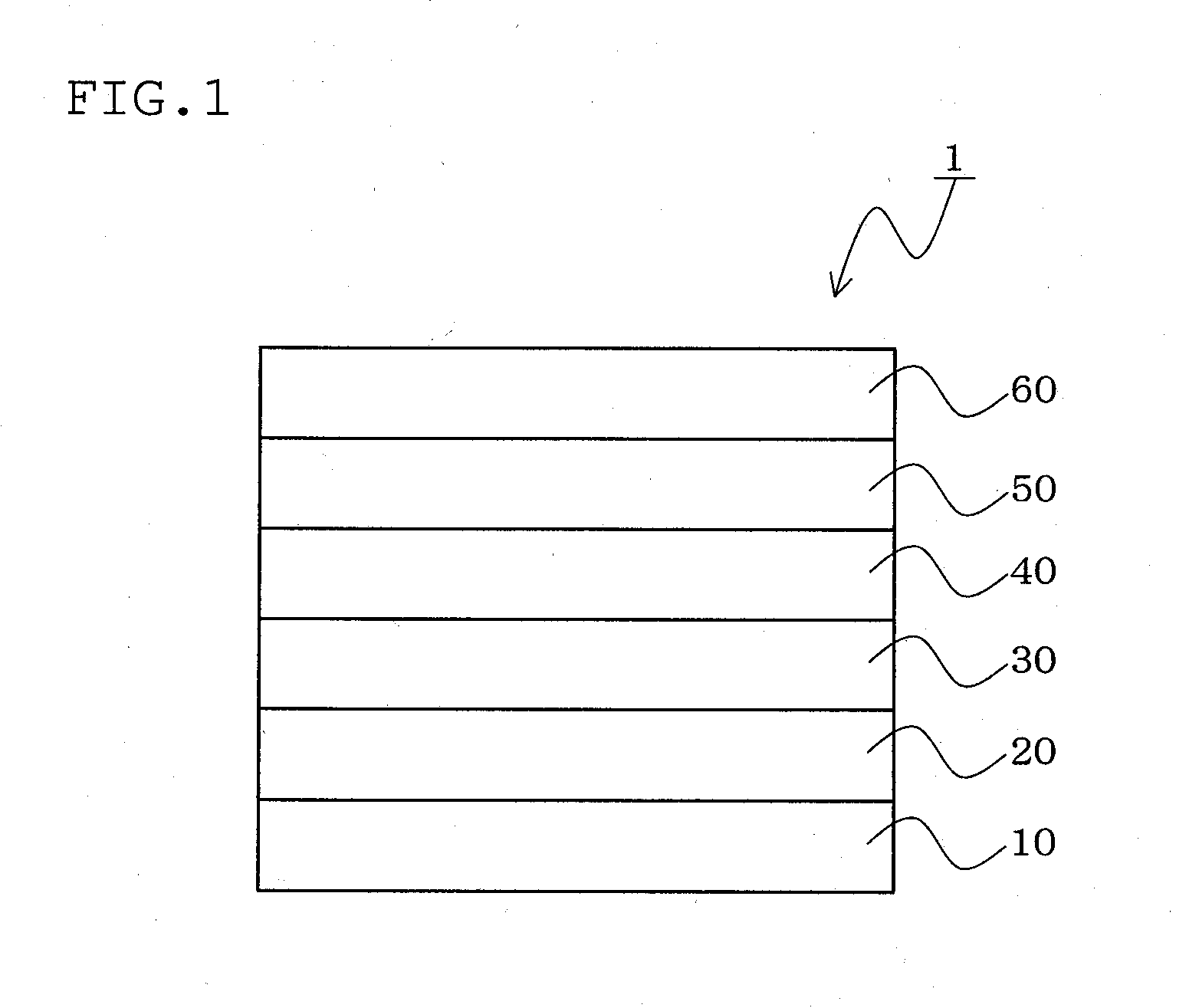

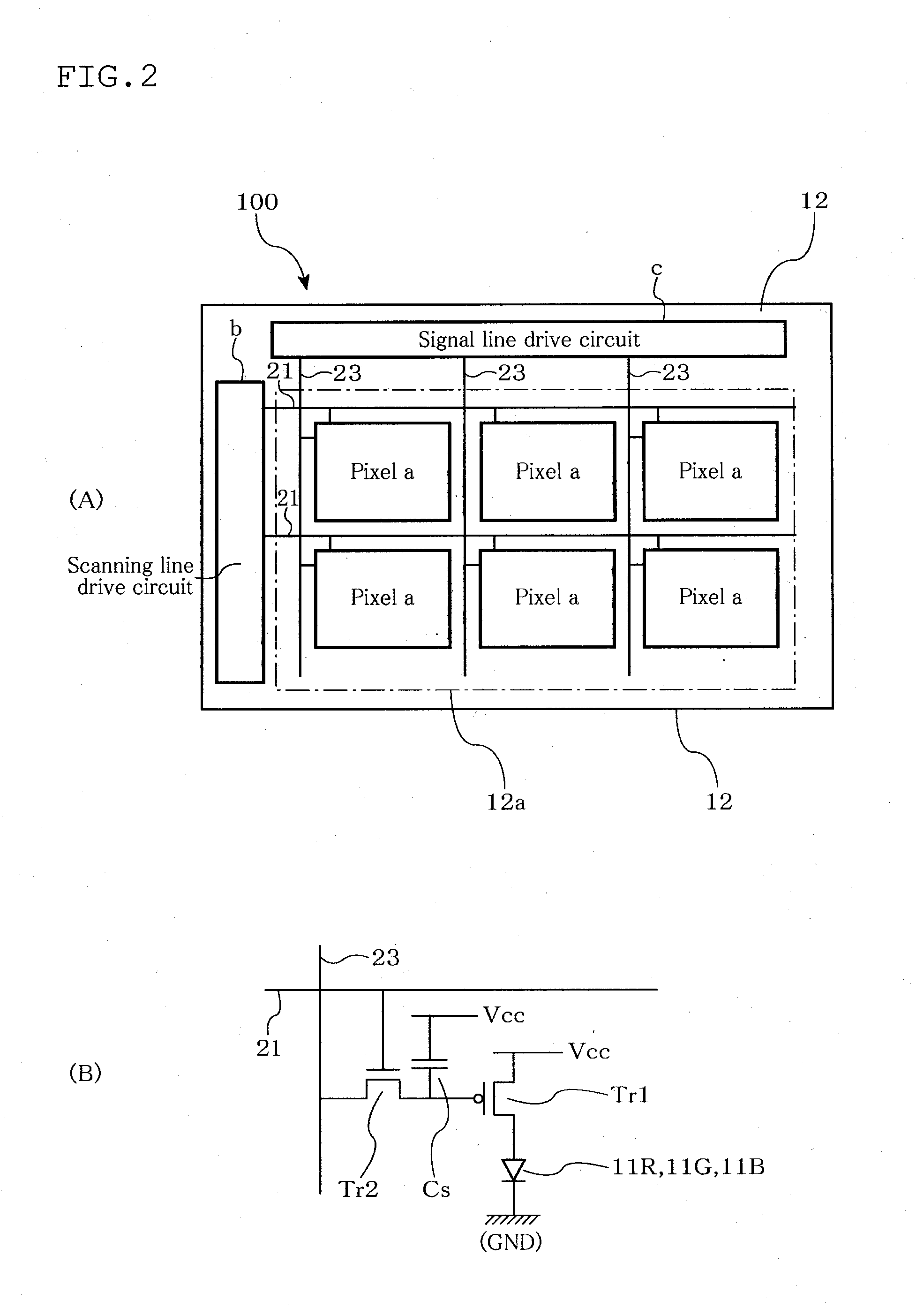

Material for organic electroluminescent device, organic electroluminescent device, and organic electroluminescent display

ActiveUS8044390B2Improve heat resistanceDeposition stabilityOrganic chemistryElectroluminescent light sourcesHalogenHydrogen

A material for an organic electroluminescent device including an imine derivative represented by the following formula (Ia) or (Ib),wherein Y1 to Y4 are independently a carbon atom or a nitrogen atom; R1 to R4 are independently hydrogen, an alkyl group, an aryl group, a heterocycle, a halogen atom, a fluoroalkyl group or a cyano group; and R1 and R2, or R3 and R4 may be bonded together to form a ring.

Owner:IDEMITSU KOSAN CO LTD +1

Substrate Processing Apparatus and Method of Manufacturing Semiconductor Device

ActiveUS20130042803A1Inhibition of thermal deteriorationHeat deteriorationPolycrystalline material growthSemiconductor/solid-state device manufacturingProcess engineeringSemiconductor device

A substrate processing apparatus includes: a process chamber having an object to be heated therein and configured to process a plurality of substrates; a substrate holder configured to hold the substrates with an interval therebetween in a vertical direction in the process chamber; a first heat exchange unit supporting the substrate holder from a lower side thereof in the process chamber and configured to perform a heat exchange with a gas in the process chamber; a second heat exchange unit provided in the process chamber, the second heat exchange unit being horizontally spaced apart from the first heat exchange unit with a gap therebetween and being configured to perform a heat exchange with the gas in the process chamber; and an induction heating unit configured to subject the object to be heated to an induction heating from an outer side of the object to be heated.

Owner:KOKUSA ELECTRIC CO LTD

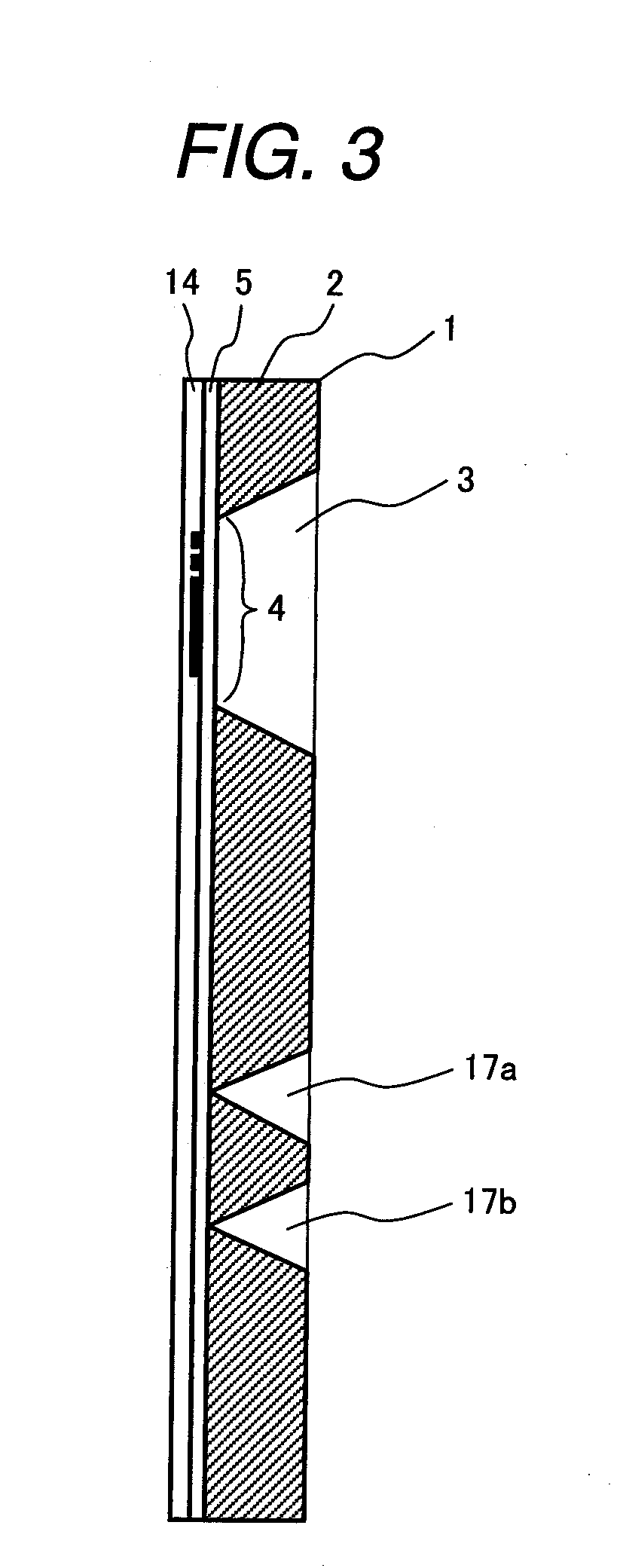

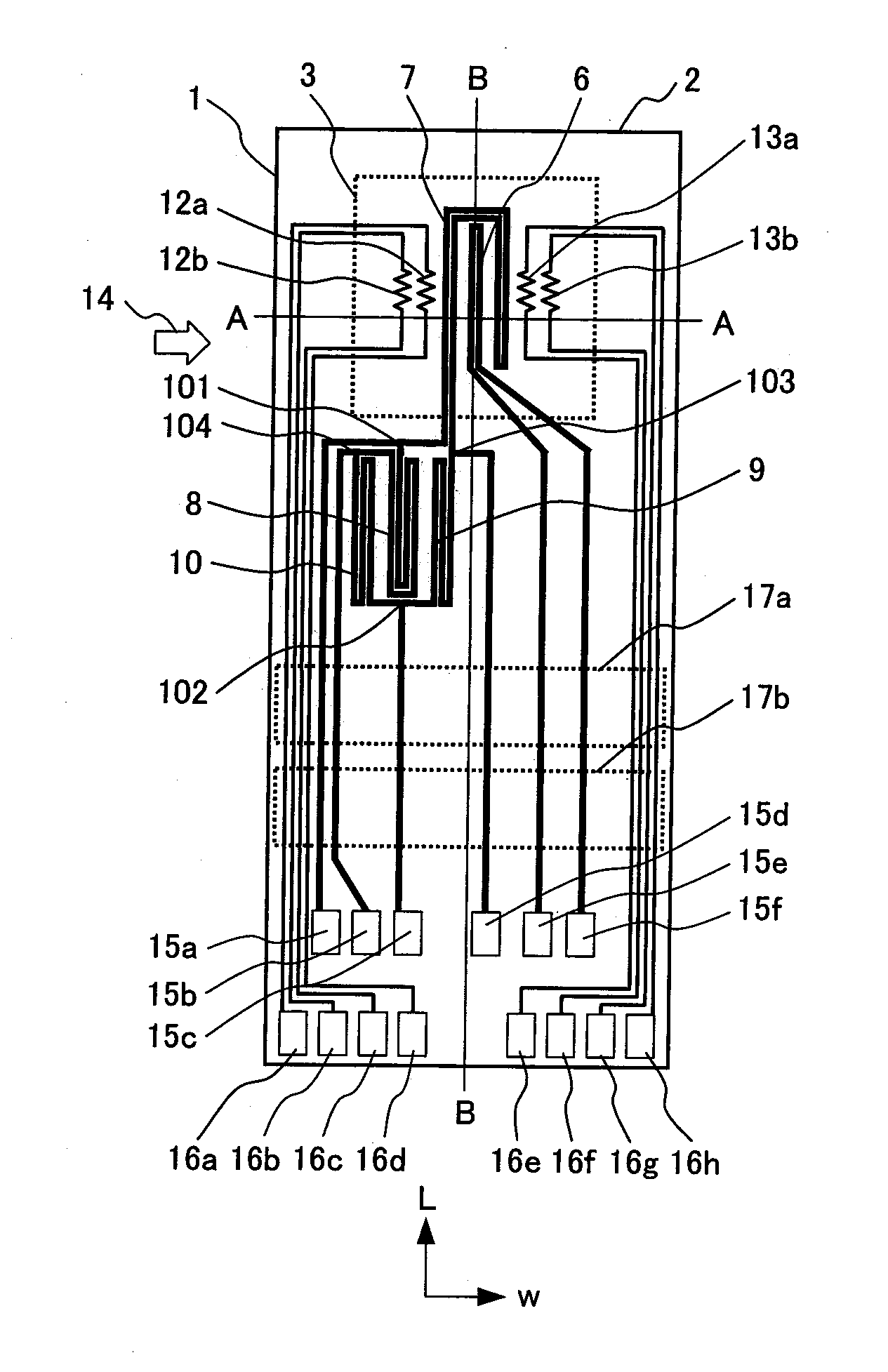

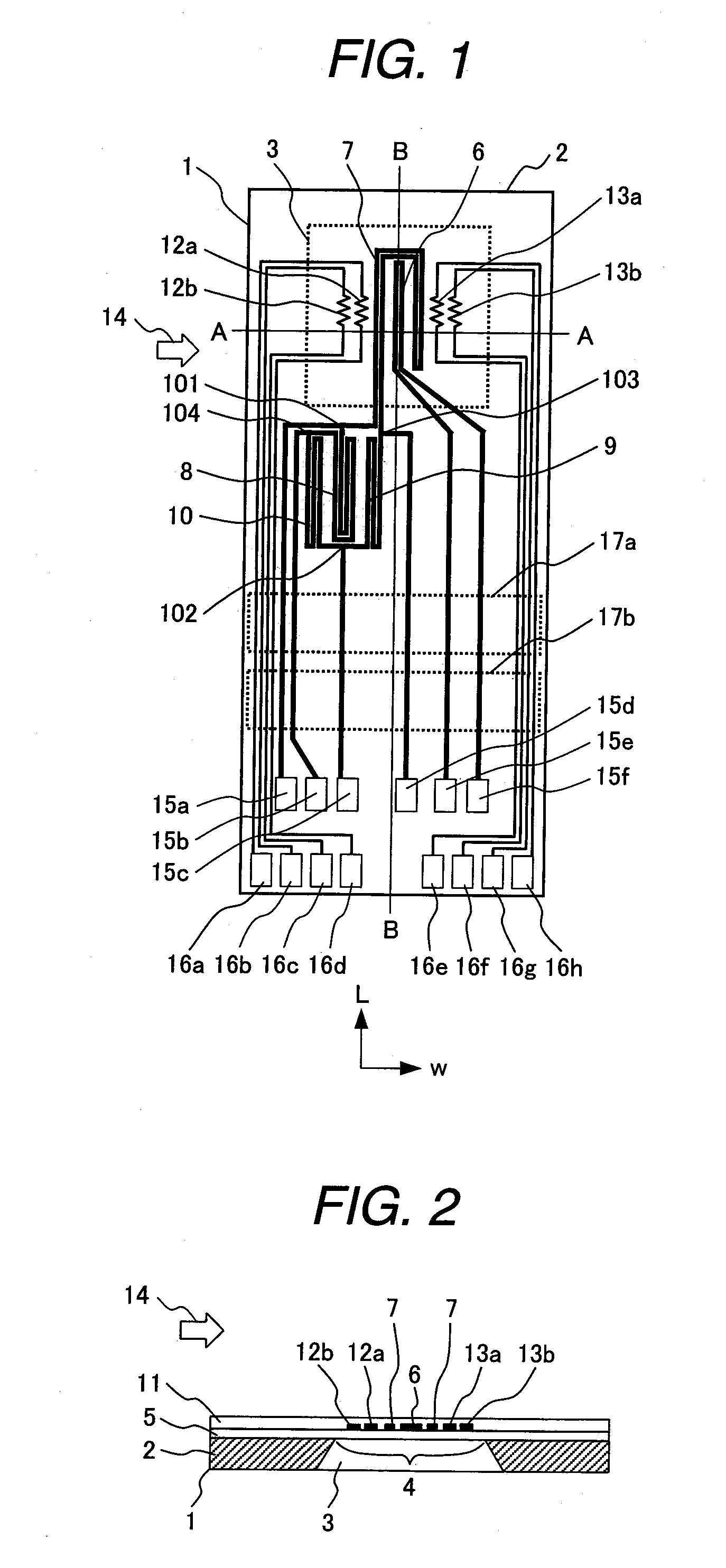

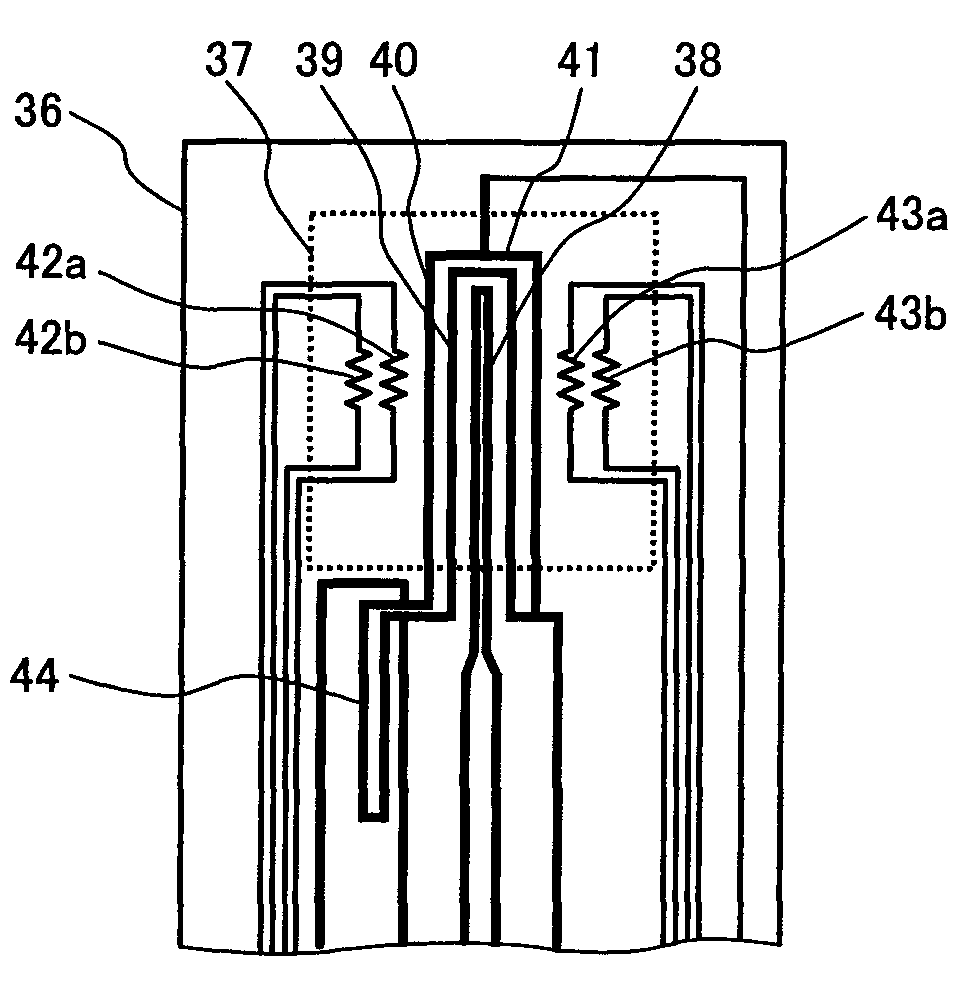

Thermal type flow sensor

ActiveUS20070181554A1Maintain measurement accuracyReduce thermal degradationVolume/mass flow measurementOhmic-resistance heating detailsElectrical resistance and conductanceDriver circuit

A thermal type flow sensor measures a flow rate of a fluid by means of a heat resistive element having a temperature dependency. The sensor is comprised of: plural heat resistive elements used for a flow rate measurement; and a driver circuit for controlling a current applied to these heat resistive elements to cause their heating. The driver circuit is configured to sense a resistance change of a lower-temperature side heat resistive element among the plural heat resistive elements and to control the current to be applied to the plural heat resistive elements in accordance with a sensed value of the lower-resistance's variation.

Owner:HITACHI ASTEMO LTD

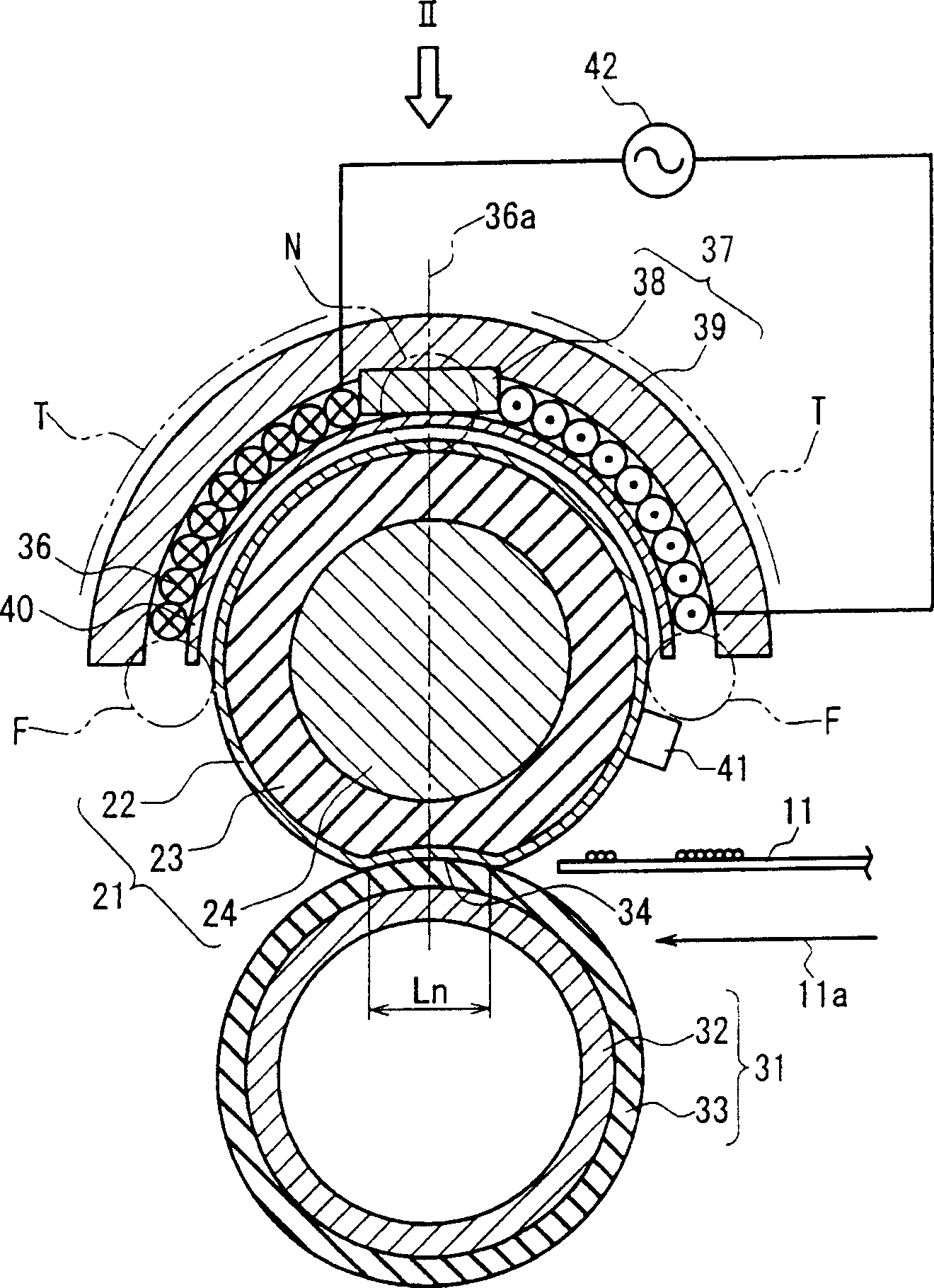

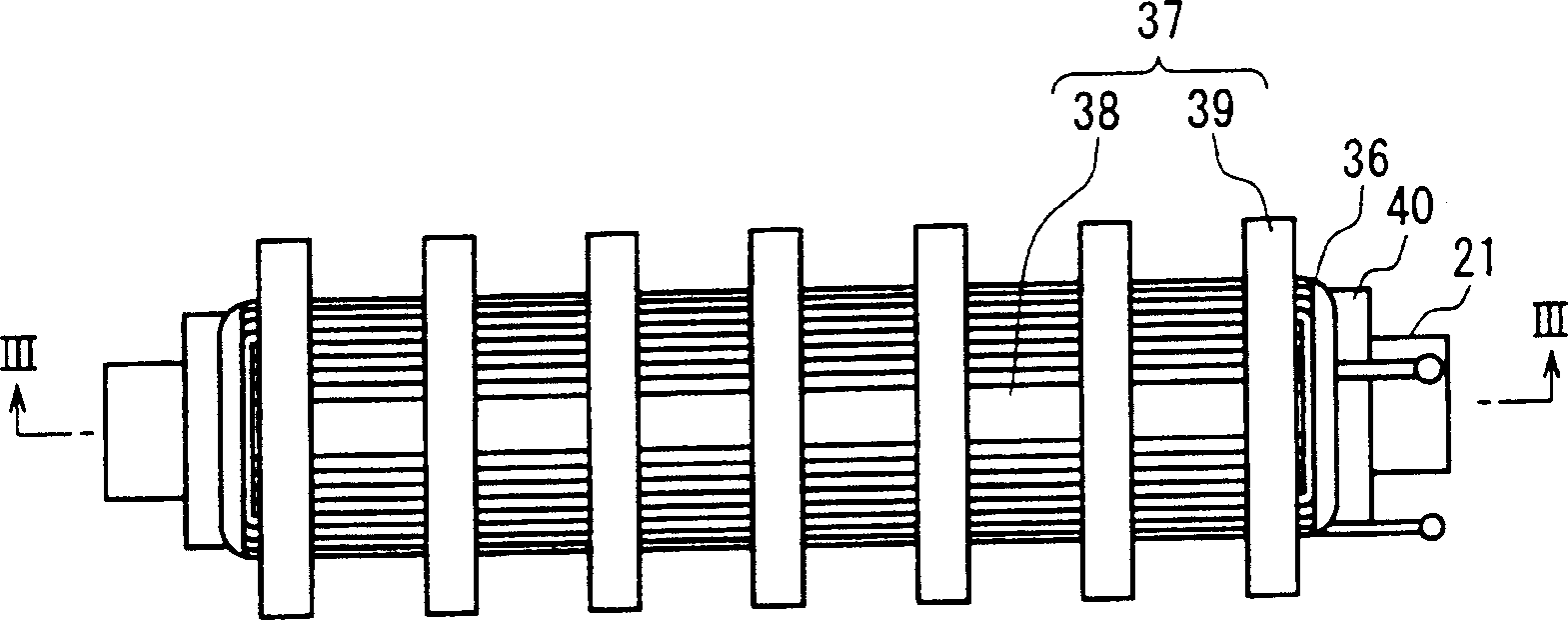

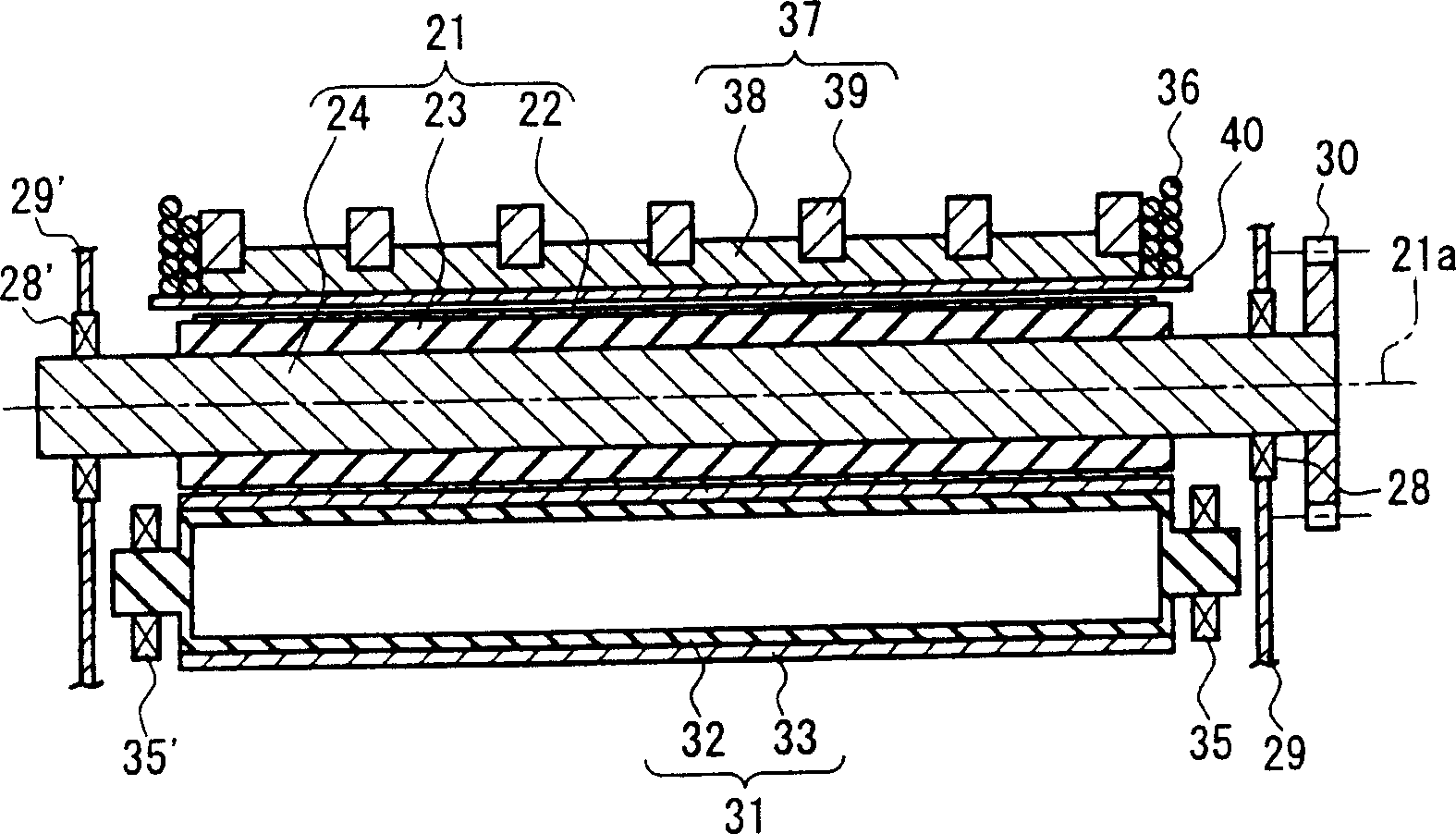

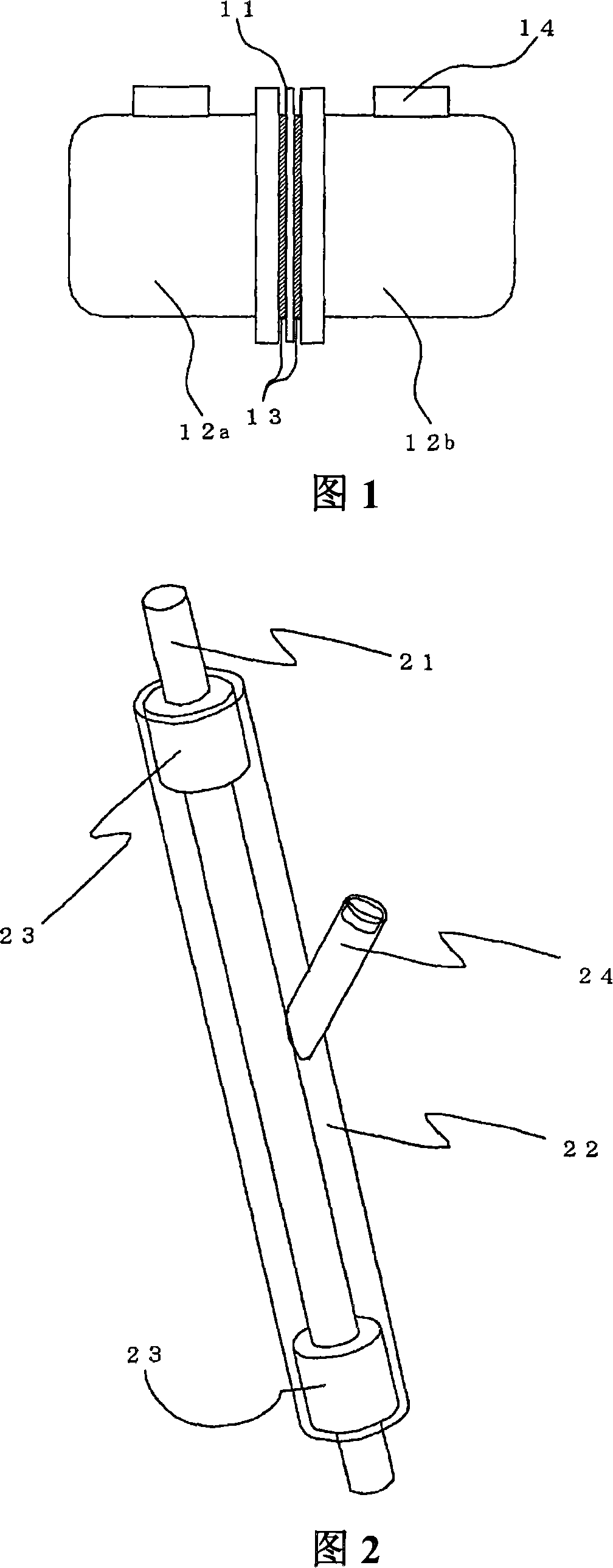

Heating roller, image heating apparatus, and image forming apparatus

InactiveCN1504064AAvoid heatingHeating fastElectrographic process apparatusInduction heating apparatusEddy currentMagnetic flux

A heating roller (21) includes a heat generating layer (22) that generates heat by electromagnetic induction, a heat insulating layer (23), and a supporting layer (24), which are provided inwardly in this order. The supporting layer (24) is formed of a material having a specific resistance of 1 x10<-5 >Omegam or higher. Therefore, even when the heat generating layer (22) has a thickness smaller than a skin depth, i.e. a thickness defined by a flow of an induction current, so that magnetic flux penetrates the heat generating layer (22) and even reaches the supporting layer (24), heat generation of the supporting layer (24) under an eddy current can be suppressed. Thus, the heat generating layer (22) can be decreased in thermal capacity, and heat generation of the supporting layer (24) is suppressed, so that only the heat generating layer (22) can be heated efficiently. As a result, a warm-up time can be reduced. Further, breakage by heat of, for example, bearings supporting the heating roller (21) can be prevented.

Owner:PANASONIC CORP

Thermal type flow sensor

ActiveUS20100170335A1Reduce thermal degradationMaintaining responseVolume/mass flow by thermal effectsElectrical resistance and conductanceDriver circuit

Owner:HITACHI ASTEMO LTD

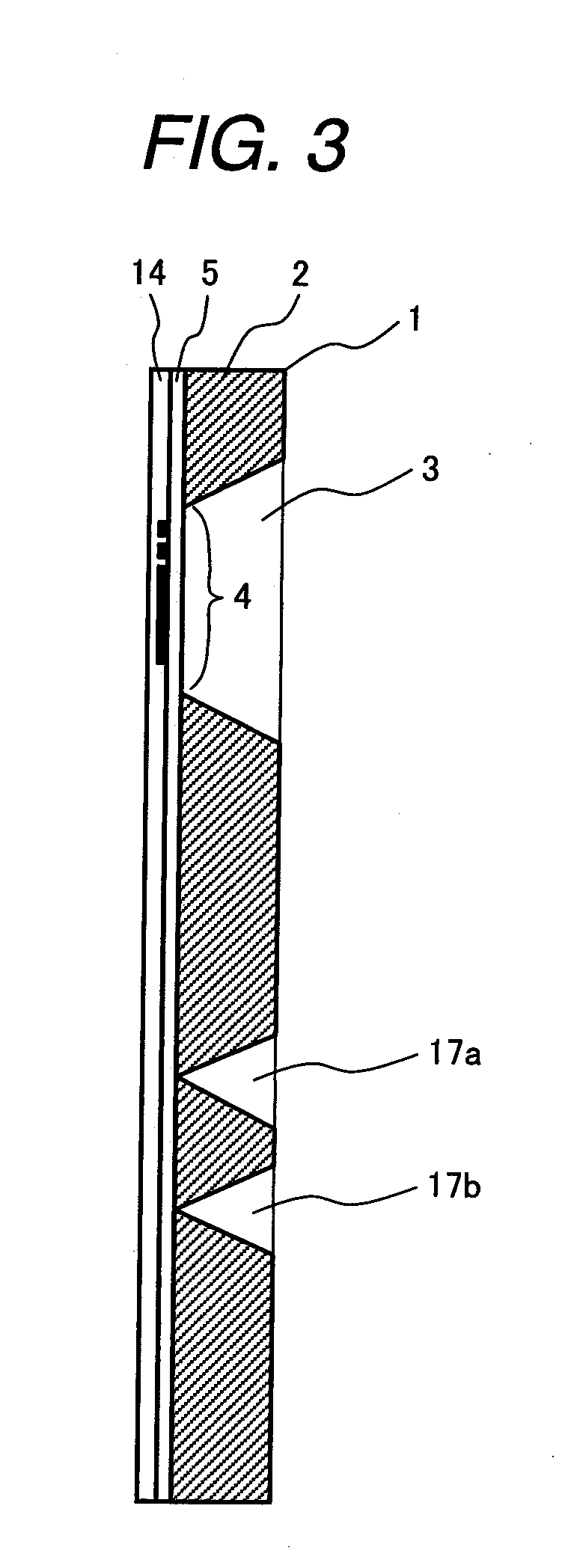

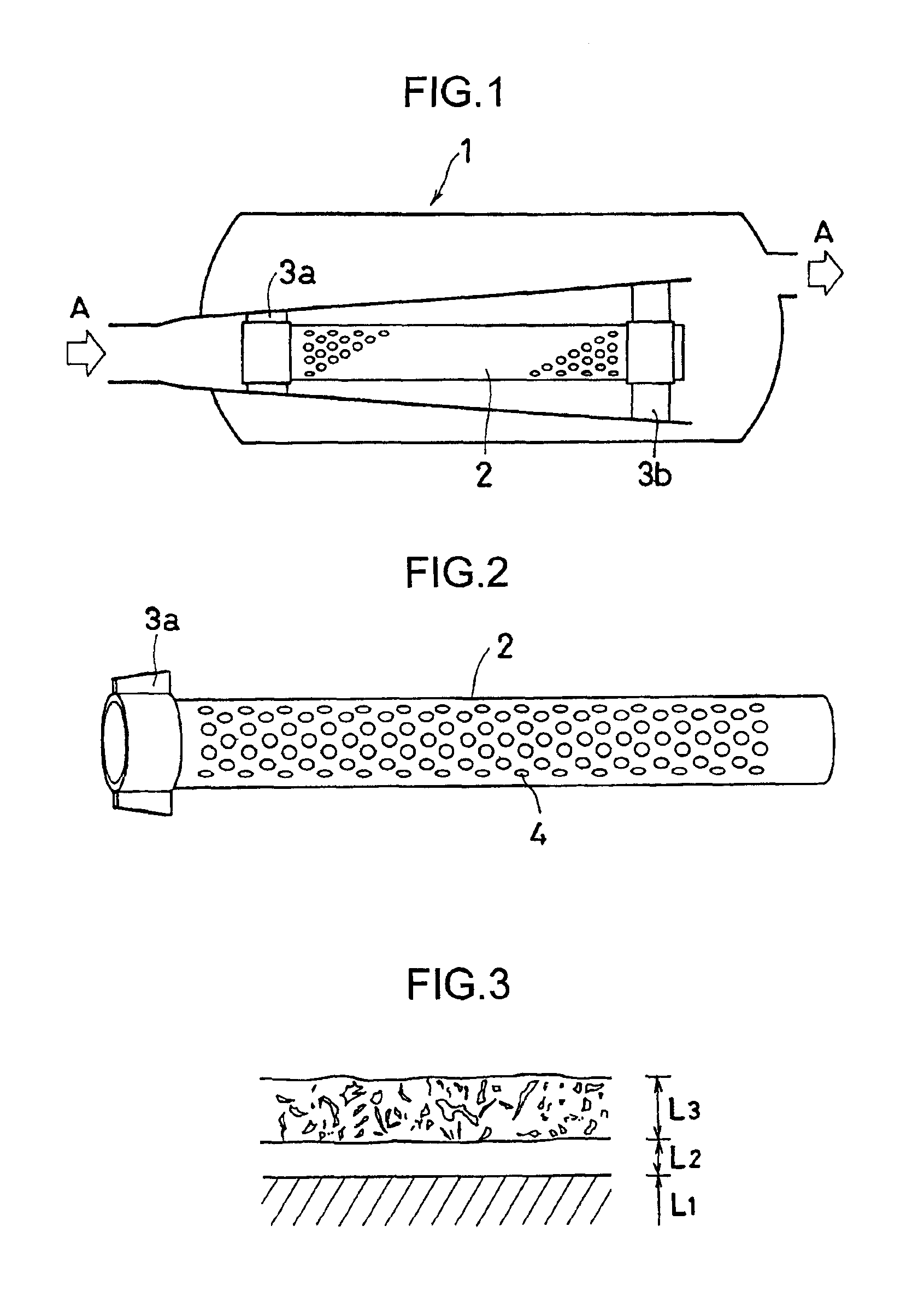

Exhaust gas purification catalyst for internal combustion

InactiveUS6875408B1Improve adhesionAvoid separationCombination devicesInternal combustion piston enginesCombustionOxygen

An object of the present invention is to provide an exhaust gas purification catalyst which can minimize the separation of the catalyst layer due to heat and vibration, can suppress thermal deterioration of the catalytic substance, and can exhibit excellent purification capabilities under severe conditions. Specifically, the present invention relates to an exhaust gas purification catalyst wherein an undercoat layer comprising a heat-resistant inorganic oxide having an oxygen-absorbing substance added thereto is formed on a surface of a metallic carrier, and a catalyst-carrying layer is formed on the undercoat layer.

Owner:SUZUKI MOTOR CORP

Material for organic electroluminescent device, organic electroluminescent device, and organic electroluminescent display

ActiveUS20100181555A1Reduce voltageImprove heat resistanceOrganic chemistryElectroluminescent light sourcesArylHalogen

A material for an organic electroluminescent device including an imine derivative represented by the following formula (Ia) or (Ib),wherein Y1 to Y4 are independently a carbon atom or a nitrogen atom; R1 to R4 are independently hydrogen, an alkyl group, an aryl group, a heterocycle, a halogen atom, a fluoroalkyl group or a cyano group; and R1 and R2, or R3 and R4 may be bonded together to form a ring.

Owner:IDEMITSU KOSAN CO LTD +1

Method and device for separating and recovering mercury

InactiveCN1379430APrevents deterioration of characteristics such as brightnessFacilitate vaporization separationSolid waste disposalDistillation separationRecovery methodPhosphor

The invention relates to a method and device for separating and recovering mercury. By cutting off both ends of a lamp tube of a waste fluorescent lamp and peeling off a phosphor film formed on the inner surface of the lamp tube, phosphor powder containing mercury is recovered. Adding an organic reducing agent to the recovered phosphor powder and heating it to perform dry heating reduction treatment to vaporize and separate mercury from the phosphor powder. This vaporized mercury is condensed and recovered.

Owner:PANASONIC CORP

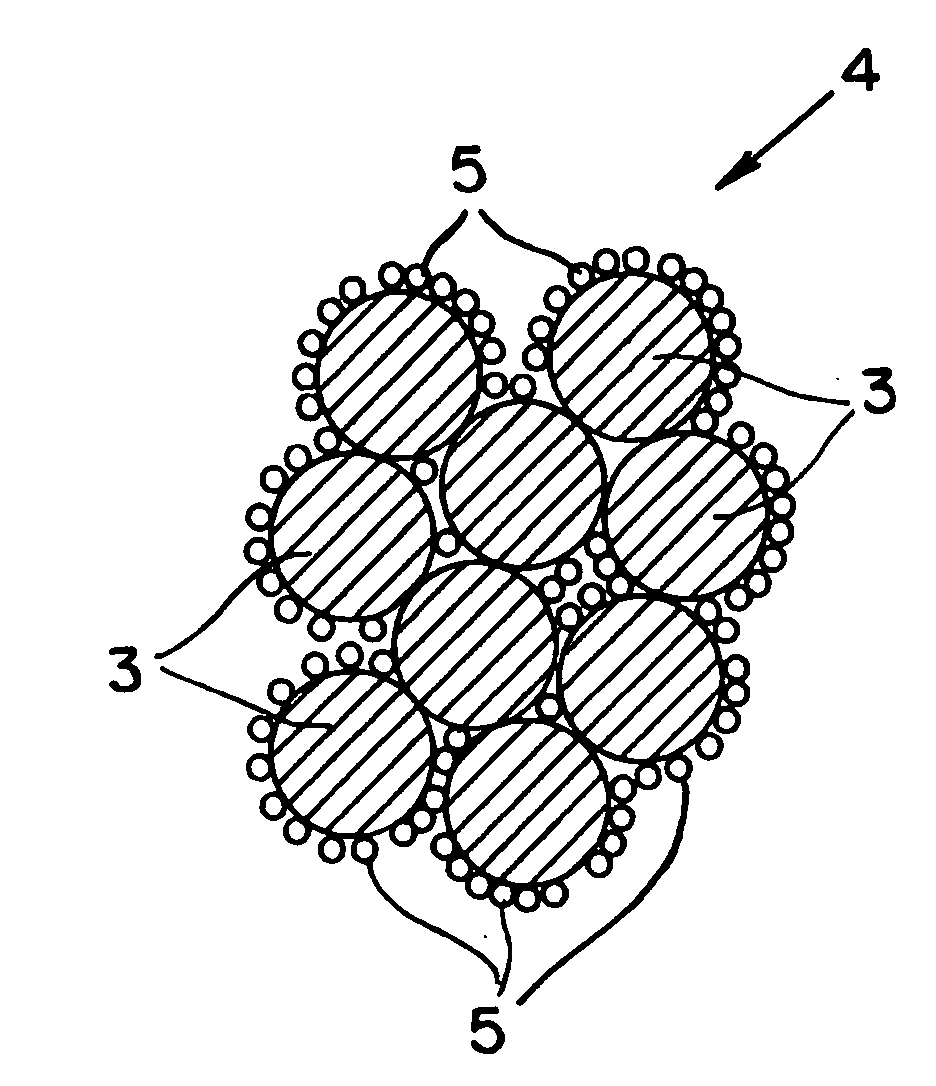

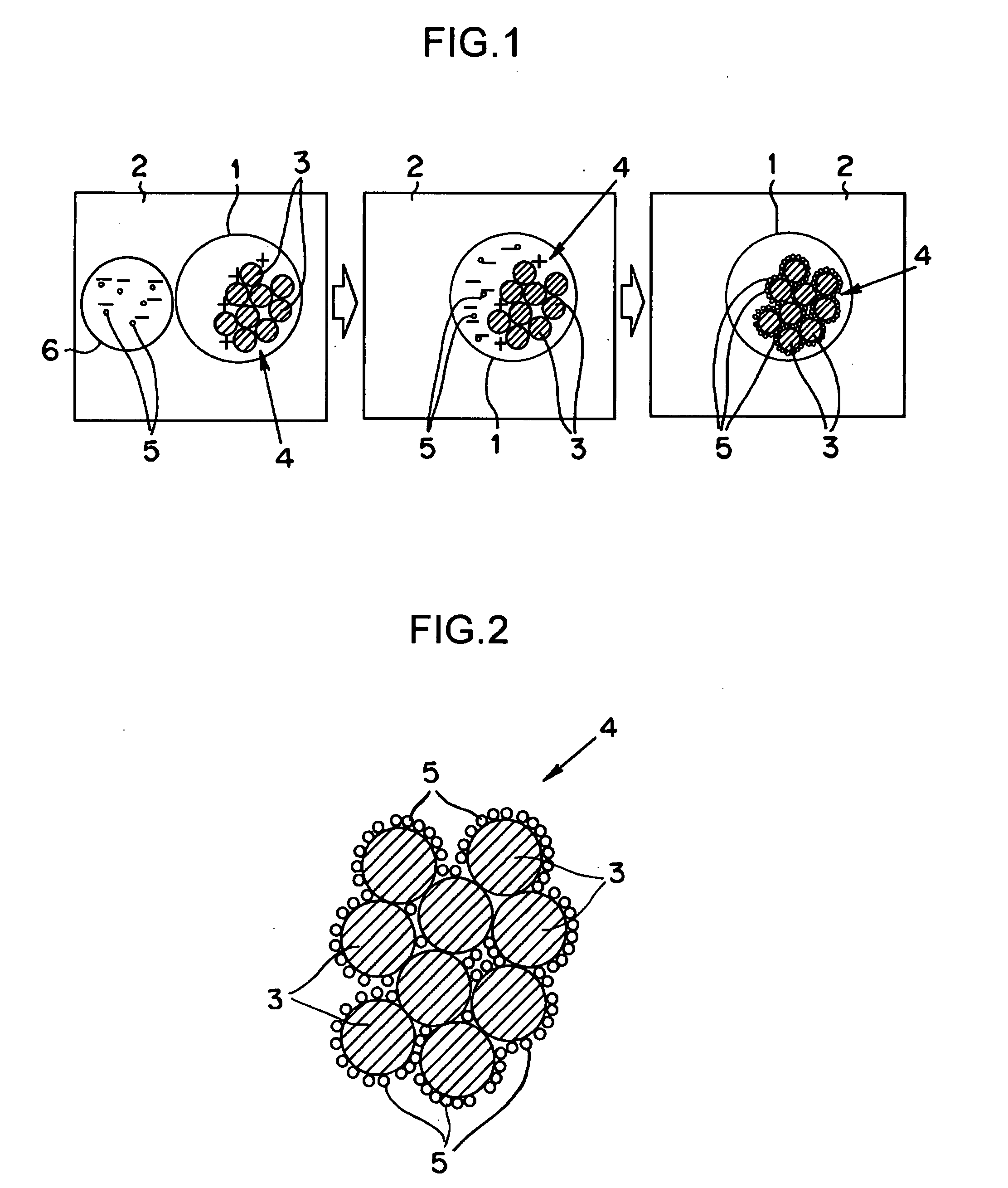

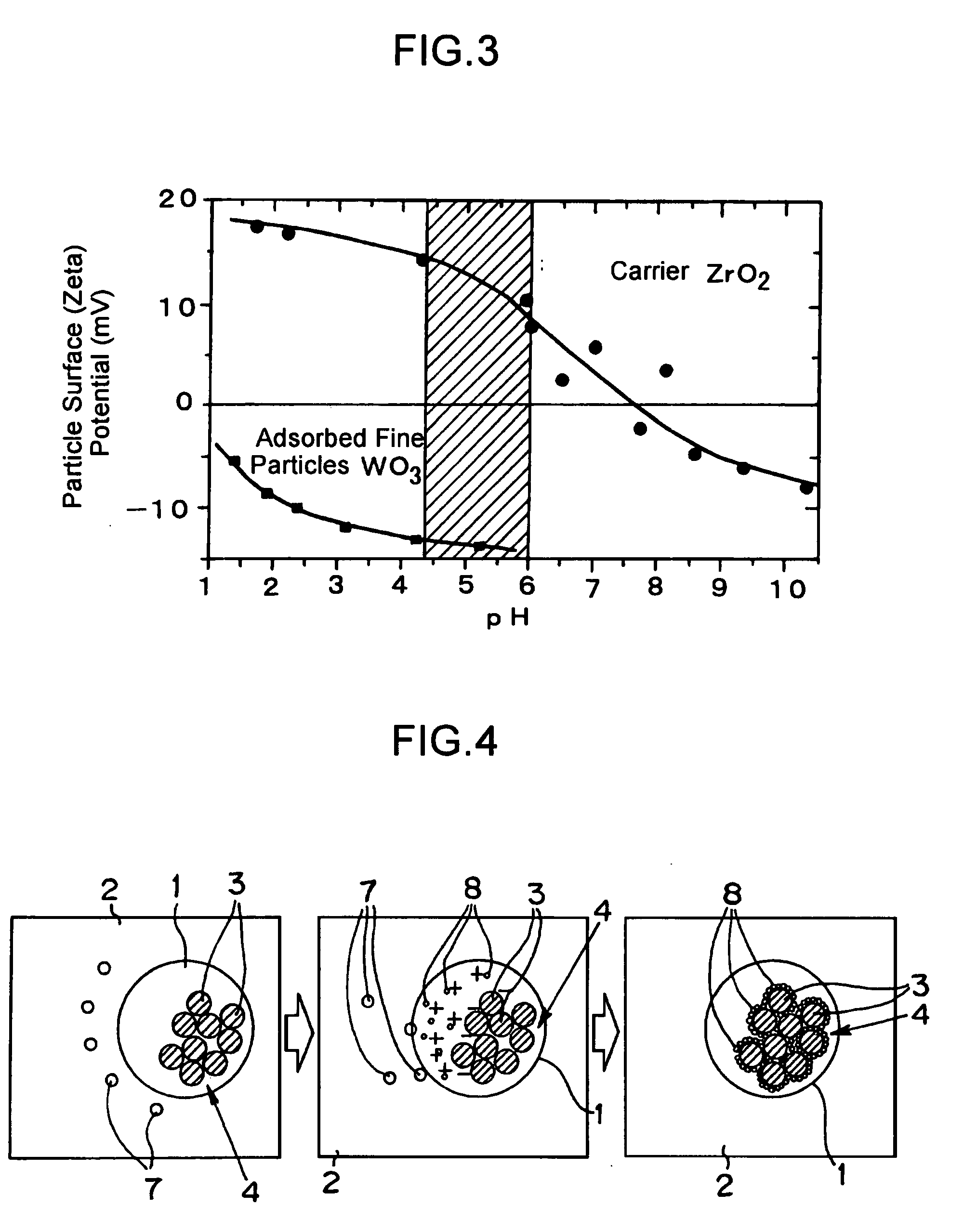

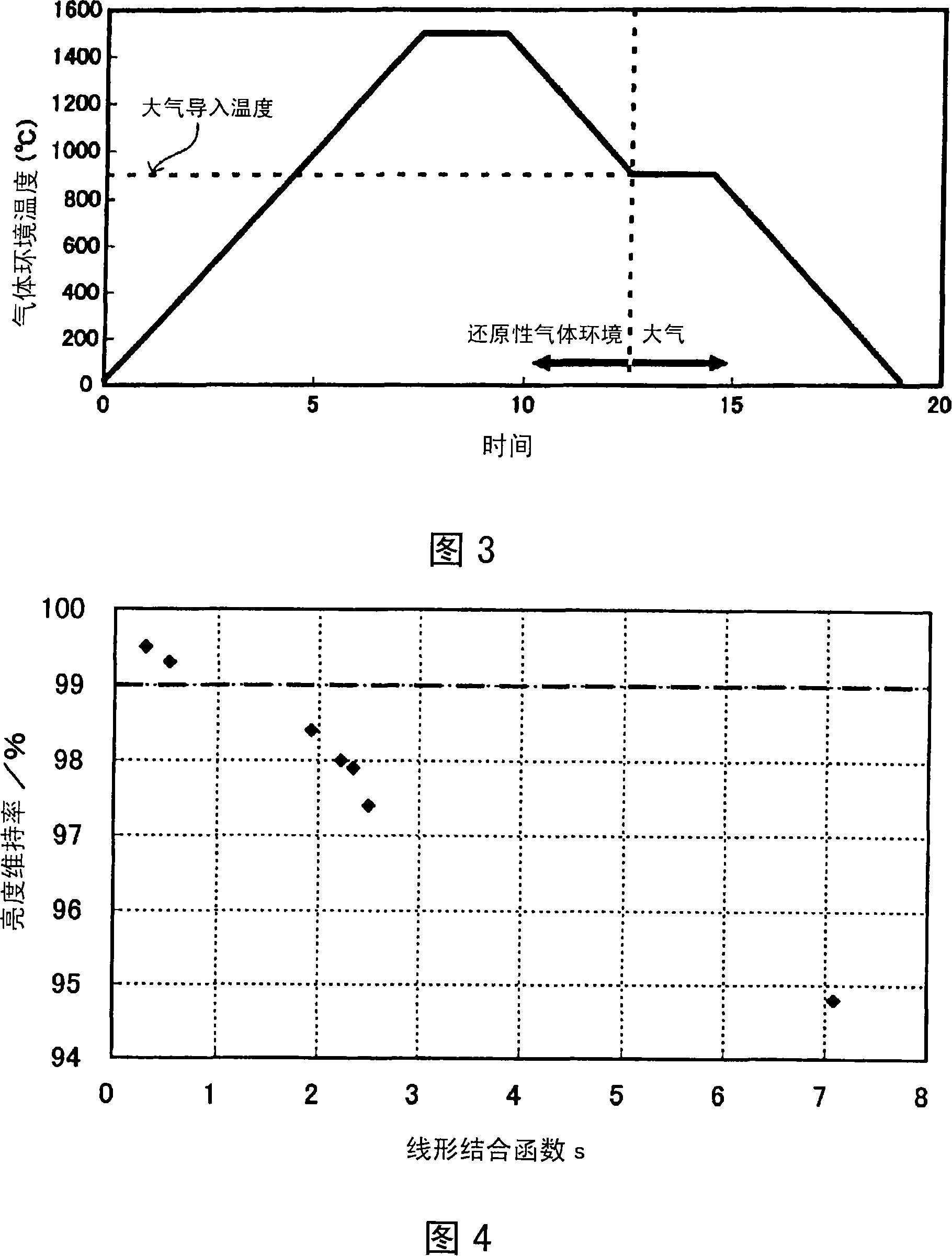

Method For Producing Heat-Resisting Compound Oxides

InactiveUS20090029851A1Easily adjustInhibition of thermal deteriorationInternal combustion piston enginesZirconium compoundsComposite oxideOxide

A method for producing a heat-resisting compound oxide in which oxide particles are made to carry fine particles having a smaller particle diameter than that of said oxide particles. Said oxide particles or their precursor particles are charged to a potential inverse to that of said fine particles or their precursor particles so that said oxide particles adsorb said fine particles, and are then sintered to carry said fine particles. Thus, the fine particles can be homogeneously dispersed and firmly adhered to the surfaces of the oxide particles. As a result, the compound oxide is so excellent in heat resistance that it has little change, even subjected to a treatment such as a sintering, in the structure of the oxide particles for a carrier or in the adsorption state of the ultrafine particles, and has little thermal deterioration.

Owner:TOYOTA JIDOSHA KK

Thermal type flow sensor

ActiveUS8203102B2Reduce thermal degradationMaintaining responseVolume/mass flow measurementOhmic-resistance heating detailsDriver circuitFlow transducer

A thermal type flow sensor measures a flow rate of a fluid by means of a heat resistive element having a temperature dependency. The sensor is comprised of: plural heat resistive elements used for a flow rate measurement; and a driver circuit for controlling a current applied to these heat resistive elements to cause their heating. The driver circuit is configured to sense a resistance change of a lower-temperature side heat resistive element among the plural heat resistive elements and to control the current to be applied to the plural heat resistive elements in accordance with a sensed value of the lower-resistance's variation.

Owner:HITACHI ASTEMO LTD

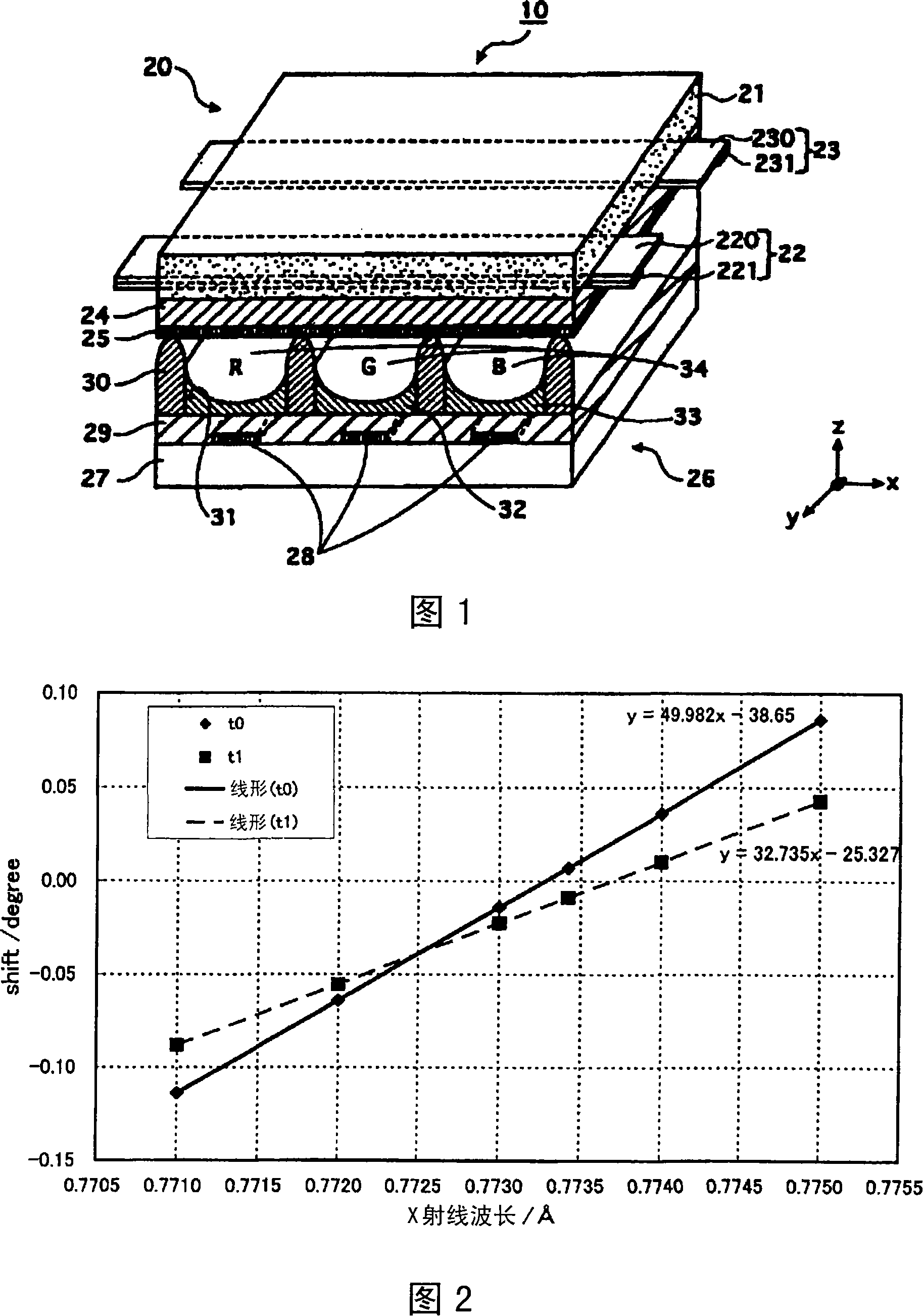

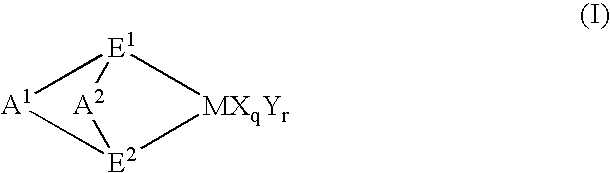

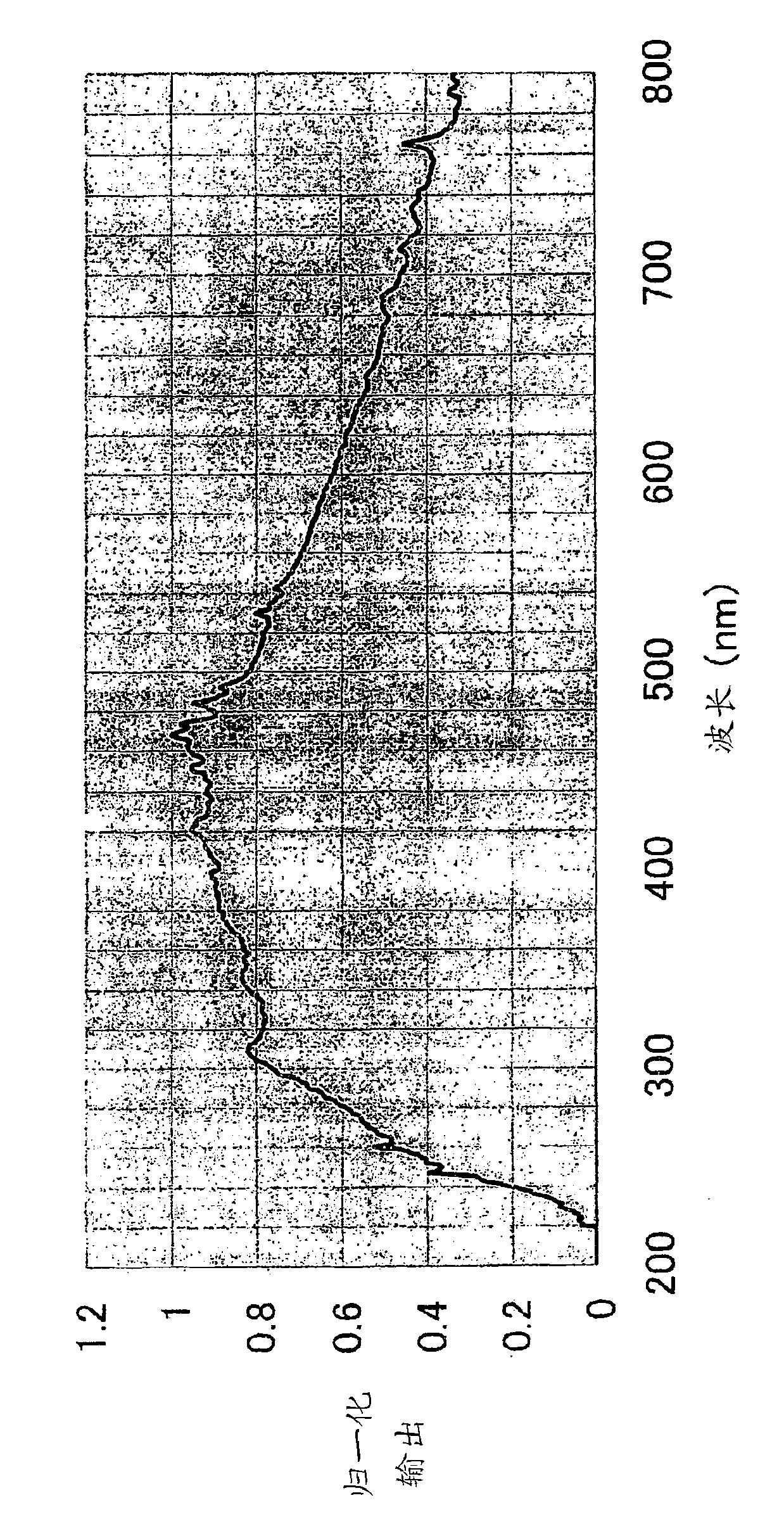

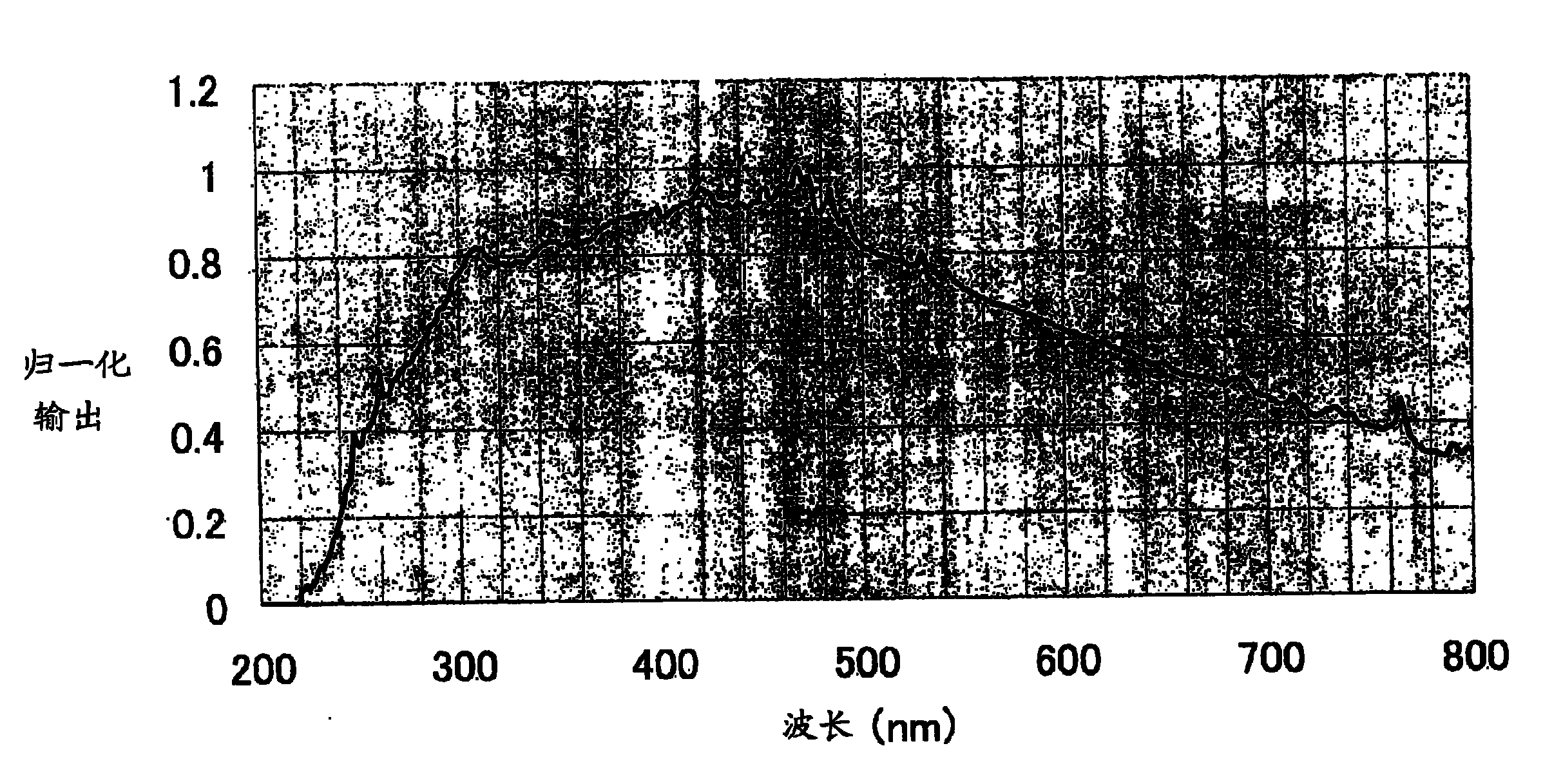

Luminescent device

InactiveCN101151347AInhibition of thermal deteriorationPrevent thermal deteriorationGas-filled discharge tubesLuminescent compositionsSpace groupFluorescence

This invention provides a luminescent device comprising a blue fluorescent substance-containing fluorescent substance layer. The fluorescent substance layer comprises, as a blue fluorescent substance, an aluminate fluorescent substance comprising Ba, Sr, Eu, Mg, Al and O as constituent elements at an atomic ratio of Ba : Sr : Eu : Mg : Al : O = p : q : r : 1 : w : 17, wherein 0.70 = p = 0.95, 0 = q = 0.15, 0.05 = r = 0.20, p + q + r = 1, and 9.8 = w = 10.5. When the aluminate fluorescent substance is subjected to X-ray crystal structure analysis on the assumption that the aluminate fluorescent substance belongs to a space group P63 / mmc, the aluminate fluorescent substance has a linear bond function s of not more than 1 as calculated by s = -11622 + 2043.07La + 199.24L1 - 116.91L2 wherein La represents a lattice constant, AA; L1 represents atomic distance between Al(2) and O(5), AA; and L2 represents atomic distance between Al(1) and O(4), AA.

Owner:PANASONIC CORP

Master Batch Composition, Polyolefin Resin Composition Comprising The Same, And Molded Product Thereof

The present invention pertains to a master batch composition which contains 10 to 95% by mass of an additive for plastics, 1 to 50% by mass of an olefin polymer having specific physical properties, and 1 to 89% by mass of a polyolefin resin as a carrier, which is useful for producing a polyolefin resin, particularly an injection molded product of a polypropylene resin, which can improve dispersibility of additives in the polyolefin molded product, which permits high density filling of various additives in the master batch composition, and which is free of blocking. The present invention is also directed to a polyolefin resin composition in which the master batch composition is compounded in a polyolefin resin, and to a polyolefin molded product using the resin composition.

Owner:IDEMITSU KOSAN CO LTD

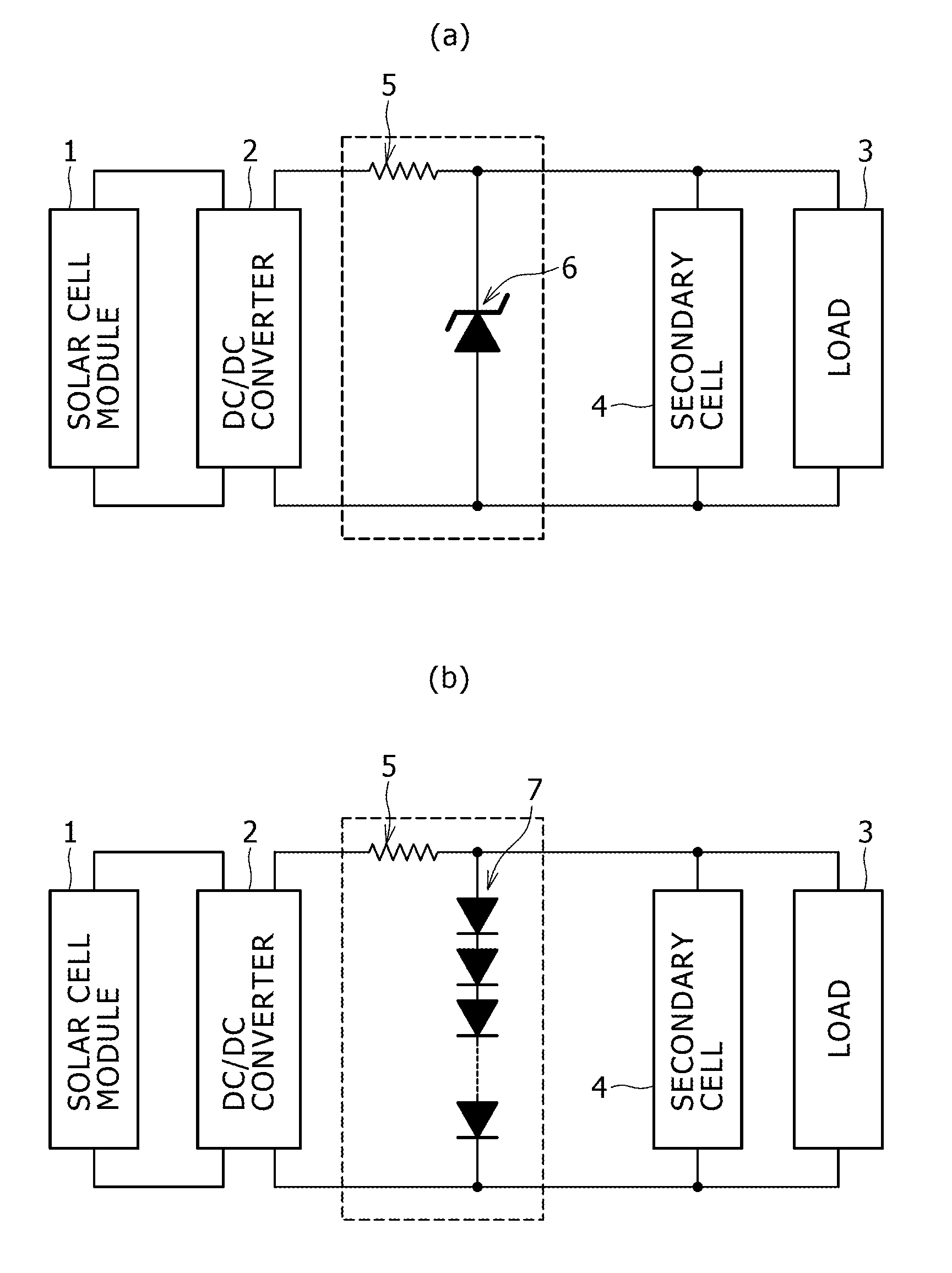

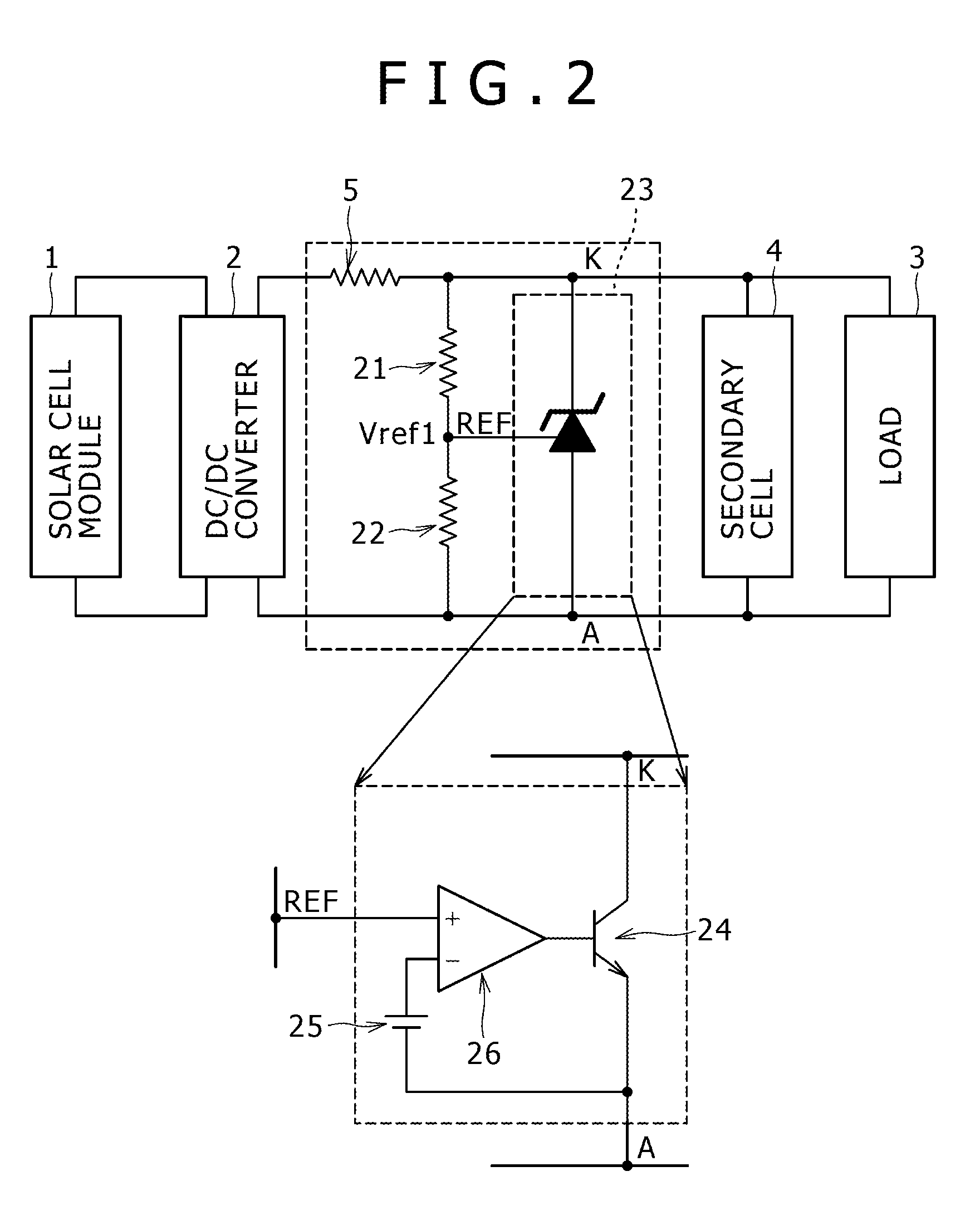

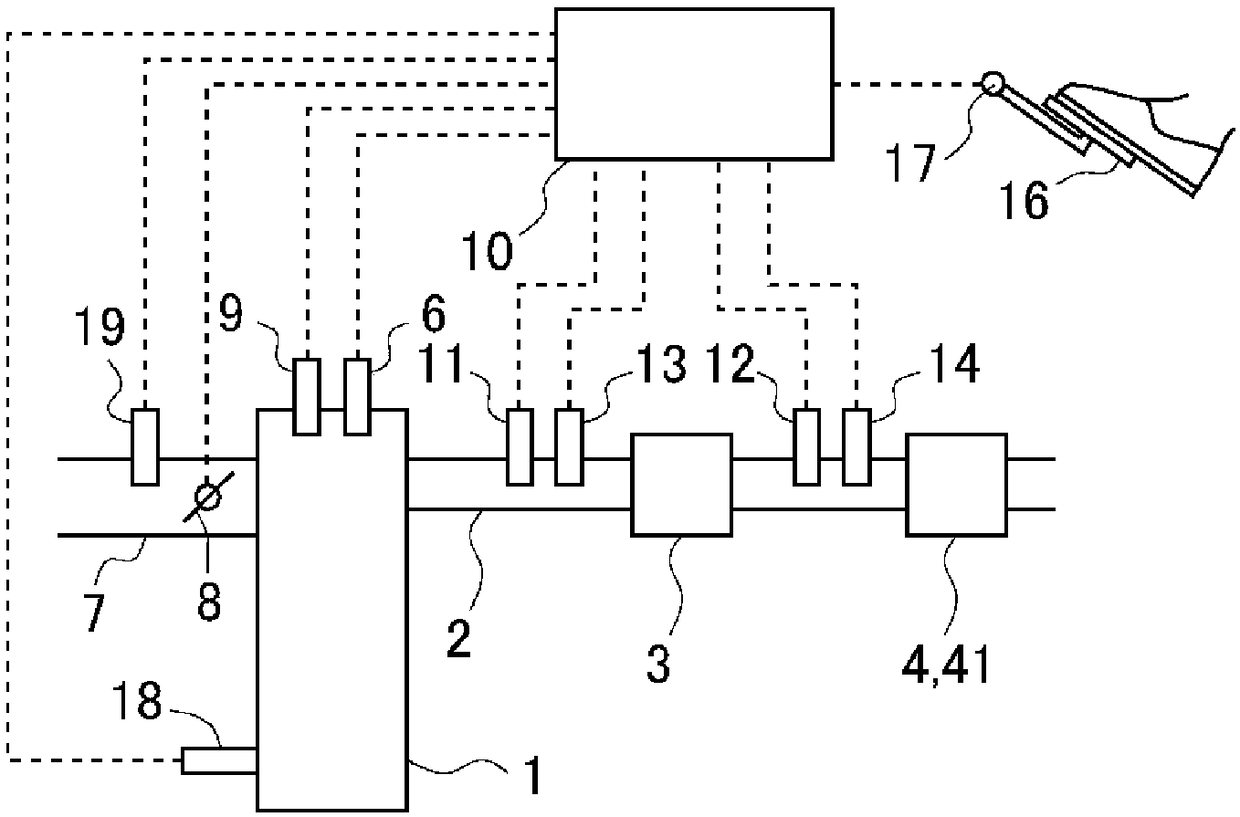

Hybrid power source system

ActiveUS20120219829A1Overall size miniaturizationEfficient use ofBatteries circuit arrangementsFuel and secondary cellsFuel cellsElectric power system

To provide a hybrid power source system in which either a solar cell or a fuel cell and a secondary cell are combined with each other, and the secondary cell is used as an electric power buffer and which can maintain a high energy efficiency even when there is a change in a charging state of the secondary cell, a change in an operating condition, or a secular change in a member, prevent overcharging of the secondary cell, and suppress thermal deterioration of the solar cell or the fuel cell due to generation of a surplus electric power unable to be taken out. A hybrid power source system is composed of a solar cell module 1 or a fuel cell module, a DC / DC converter (2) which supplies a suitable voltage to a load (3) and a secondary cell (4) after converting an electric power generated by the module into the suitable voltage, the secondary cell (4), and a shunt circuit (a constant voltage diode (6) or a shunt regulator IC) which is connected in parallel with the secondary cell (4), and which, when the secondary cell (4) is substantially in a full charging state, transforms substantially all of a surplus electric power which is not consumed in the load (3), of the generated electric power, into heat to abandon the resulting heat.

Owner:MURATA MFG CO LTD

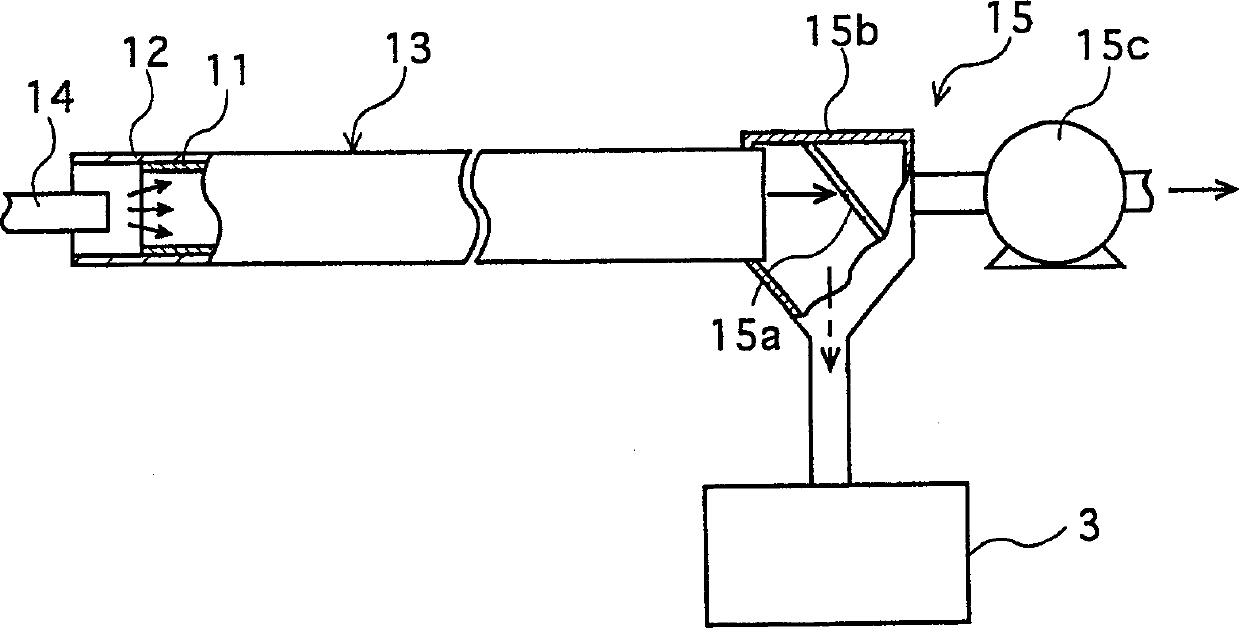

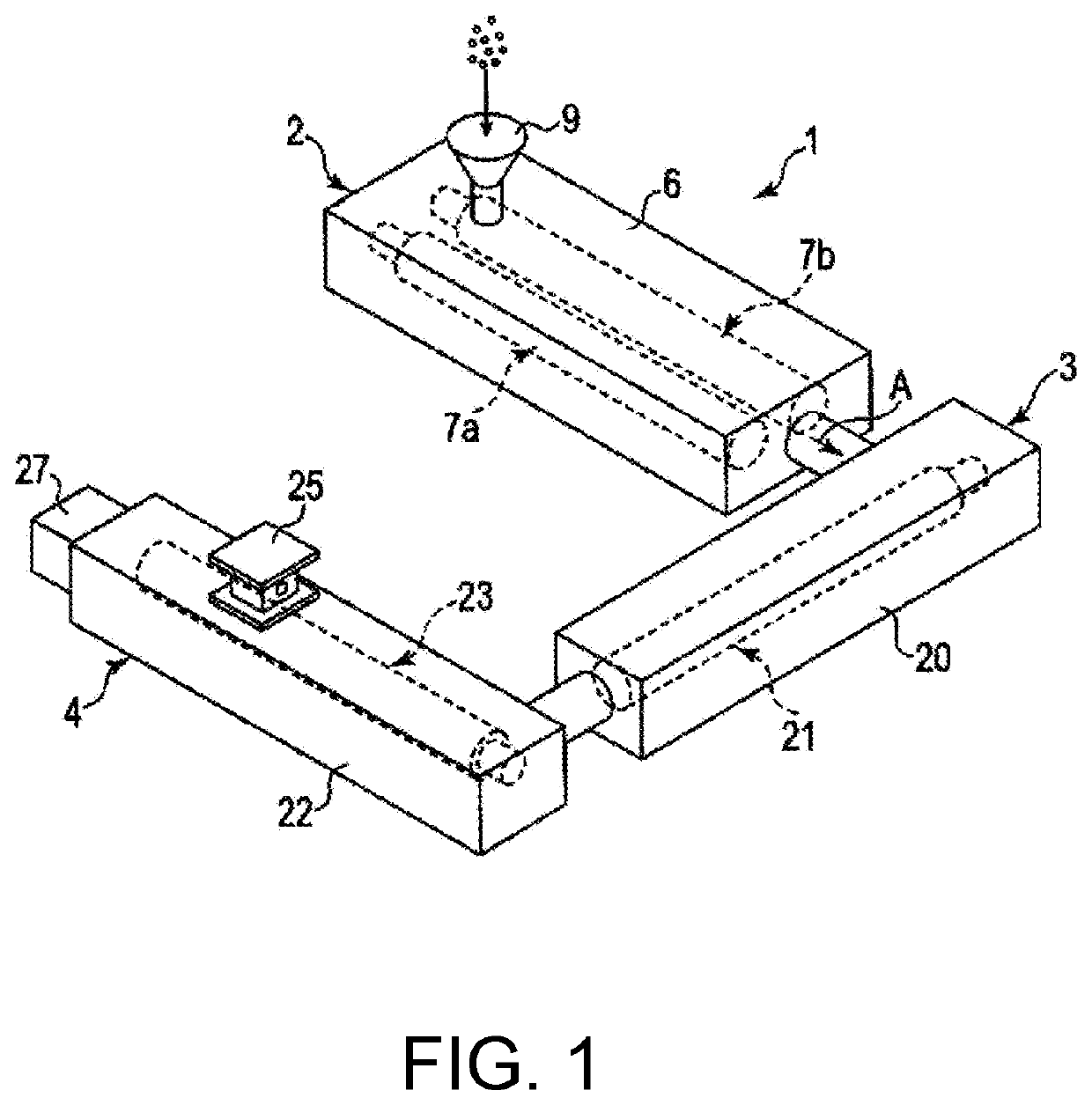

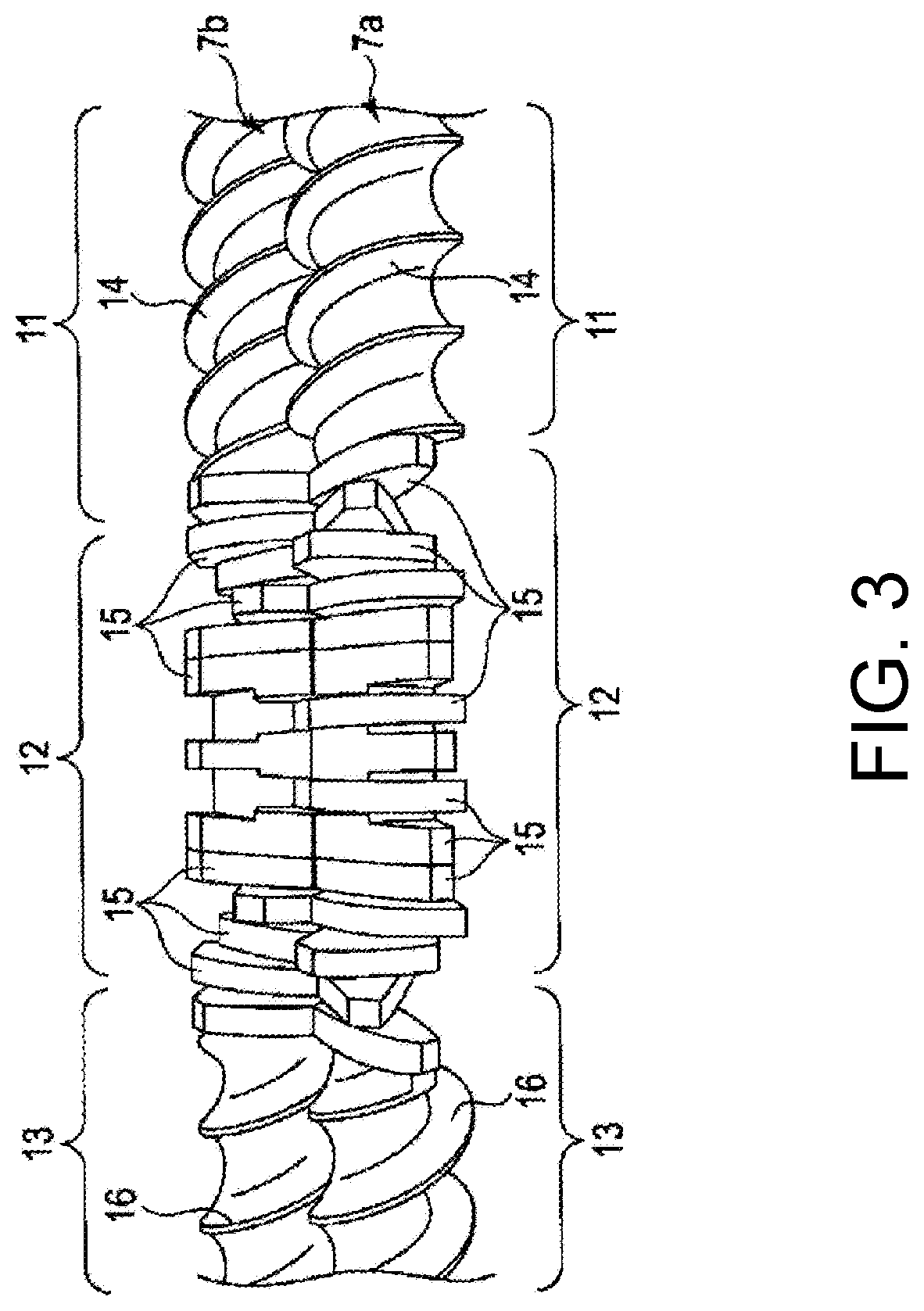

Production method for low molecular weight polymer, and production device and production method for melt-blown non-woven fabric

A production method for a low molecular weight polymer suitable for a melt-blown non-woven fabric and a production device for melt-blown non-woven fabric, with which a high molecular weight polymer can be reduced in molecular weight by applying a shear force to the high molecular weight polymer without adding an additive. The low molecular weight polymer and the melt-blown non-woven fabric are produced using a continuous high shearing device that applies a shear force to the high molecular weight polymer serving as a raw material by rotation of a screw body to reduce the molecular weight of the high molecular weight polymer so as to obtain a low molecular weight polymer, and cools the low molecular weight polymer by passing the low molecular weight polymer through a passage arranged in the axial direction inside the screw body.

Owner:SHIBAURA MASCH CO LTD +1

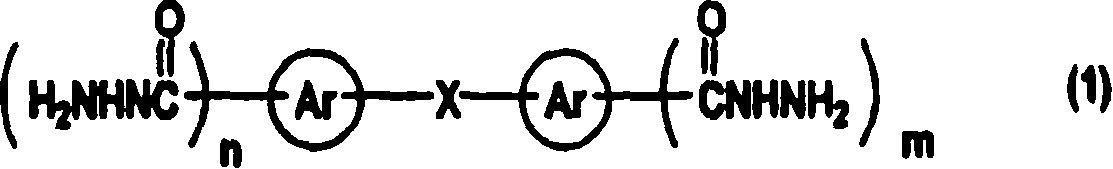

Polyacetal resin composition

A polyacetal resin composition is composed of a polyacetal resin and a polycyclic aromatic carboxylic acid hydrazide which may have a substituent. With respect to 100 parts by weight of the polyacetal resin, the ratio of the polycyclic aromatic carboxylic acid hydrazide may be about 0.001-20 parts by weight. The above-mentioned polyacetal resin composition can also contain at least one selected from the group consisting of antioxidants, heat-resistant stabilizers, processing stabilizers, weather-resistant (light) stabilizers, impact resistance modifiers, slipperiness modifiers, colorants and fillers. kind. The resin composition improves the stability of the polyacetal resin and suppresses the occurrence of formaldehyde.

Owner:POLYPLASTICS CO LTD

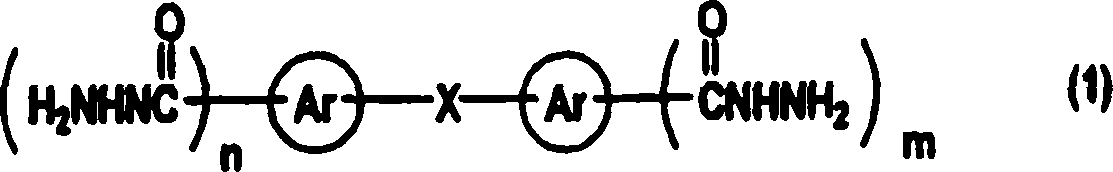

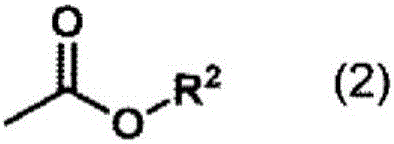

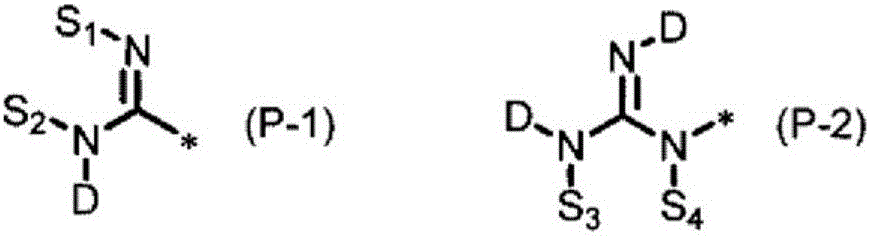

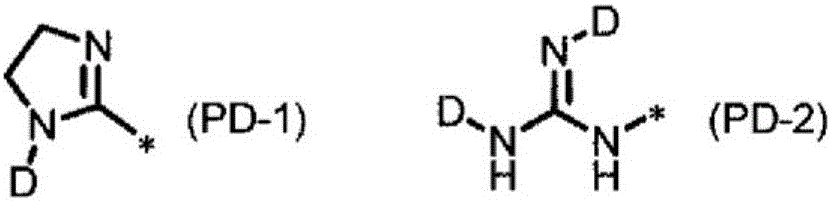

Liquid crystal aligning agent, liquid crystal alignment film and liquid crystal display element

ActiveCN106716237ALess coloringExcellent afterimage characteristicsNon-linear opticsAfterimageSolvent

Provided are: a liquid crystal alignment film which is able to be suppressed in separation of the film or occurrence of foreign substances caused by a physical impact, while enhancing transmittance characteristics of an element and having excellent afterimage characteristics by alternating-current driving; and a liquid crystal aligning agent. A liquid crystal aligning agent which contains a component (A) and a component (B) described below as well as a solvent that dissolves these components. Component (A): a compound represented by formula (1) (In the formula, P has at least one group wherein a carbon atom is substituted by at least two nitrogen atoms, and at least one of the nitrogen atoms is substituted by a monovalent thermally cleavable group having 1-24 carbon atoms, said monovalent thermally cleavable group being substituted by a hydrogen atom by means of heat; X represents a single bond or the like; and Q represents a benzene ring or the like.) Component (B): at least one polymer that is selected from the group consisting of polyimide precursors and polyimides

Owner:NISSAN CHEM IND LTD

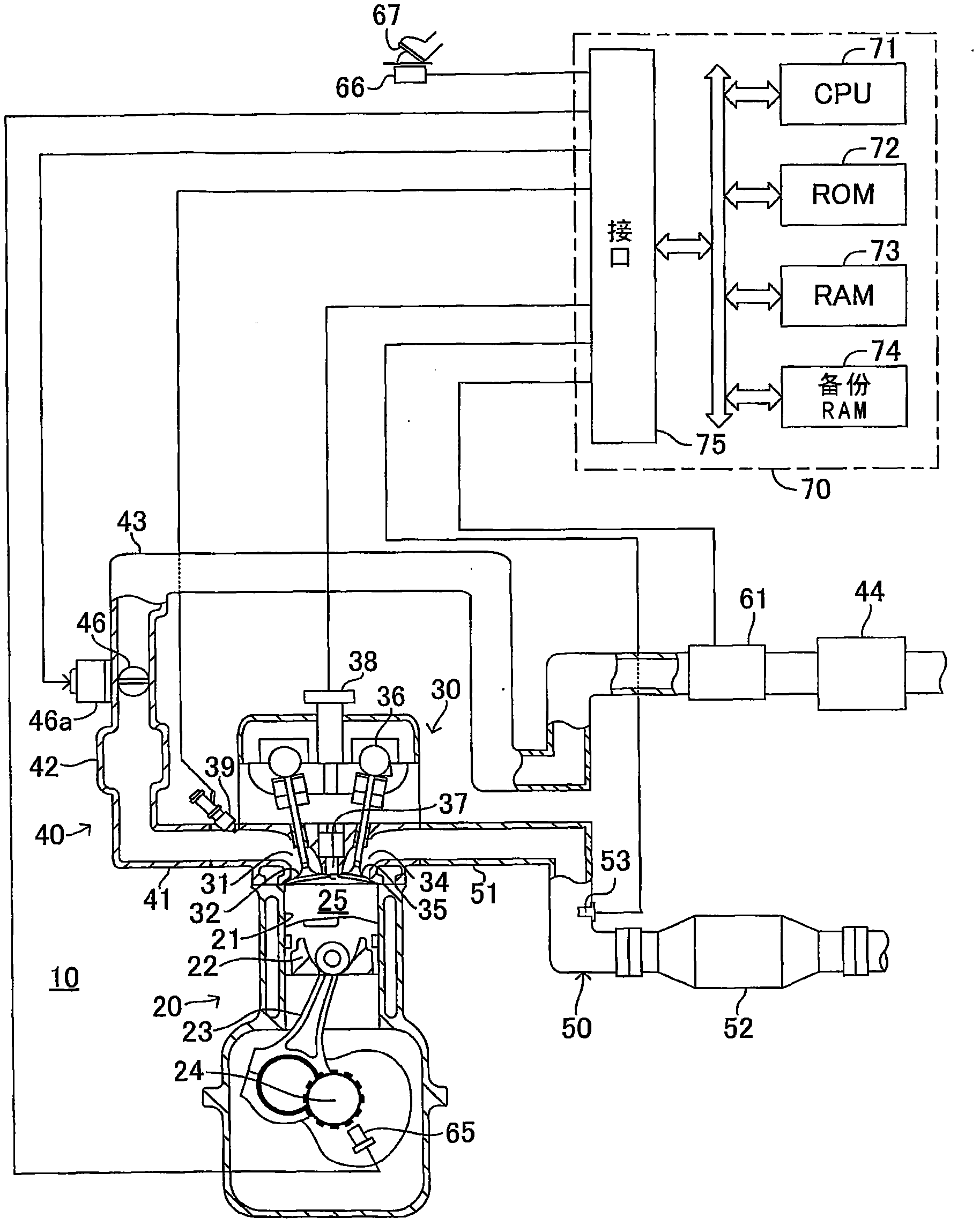

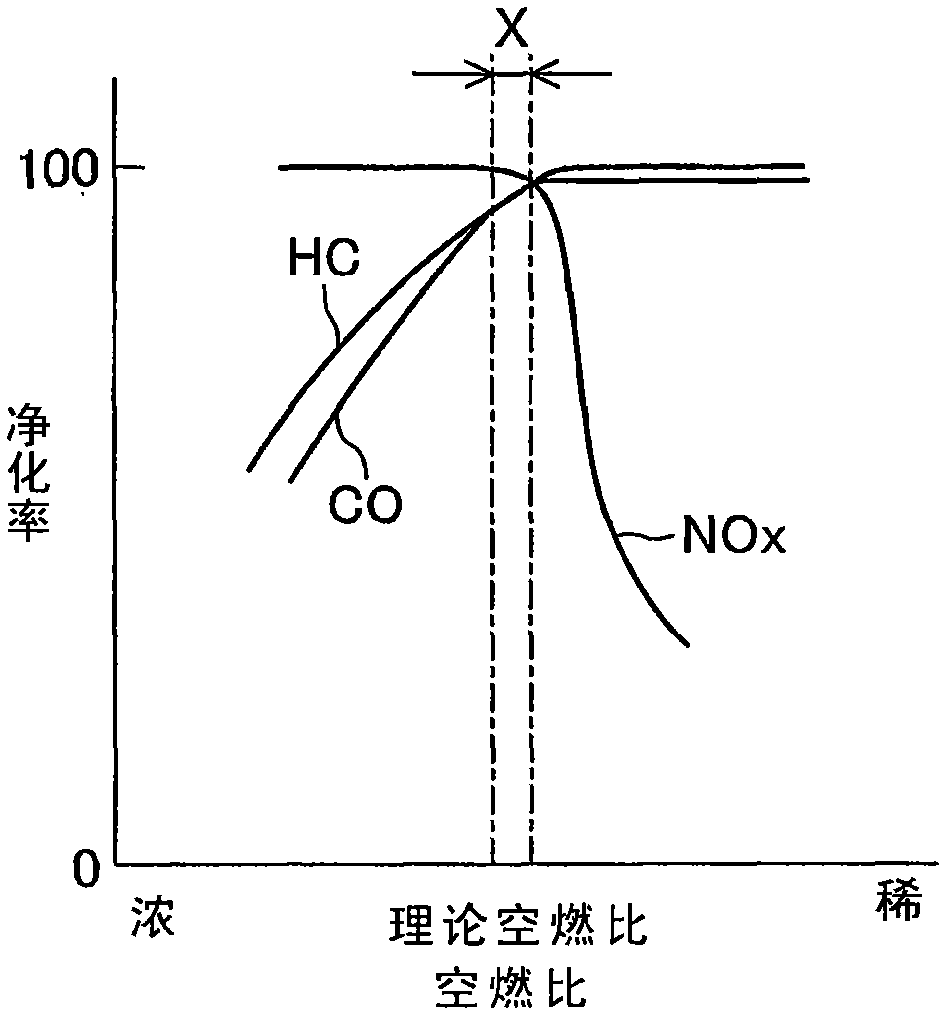

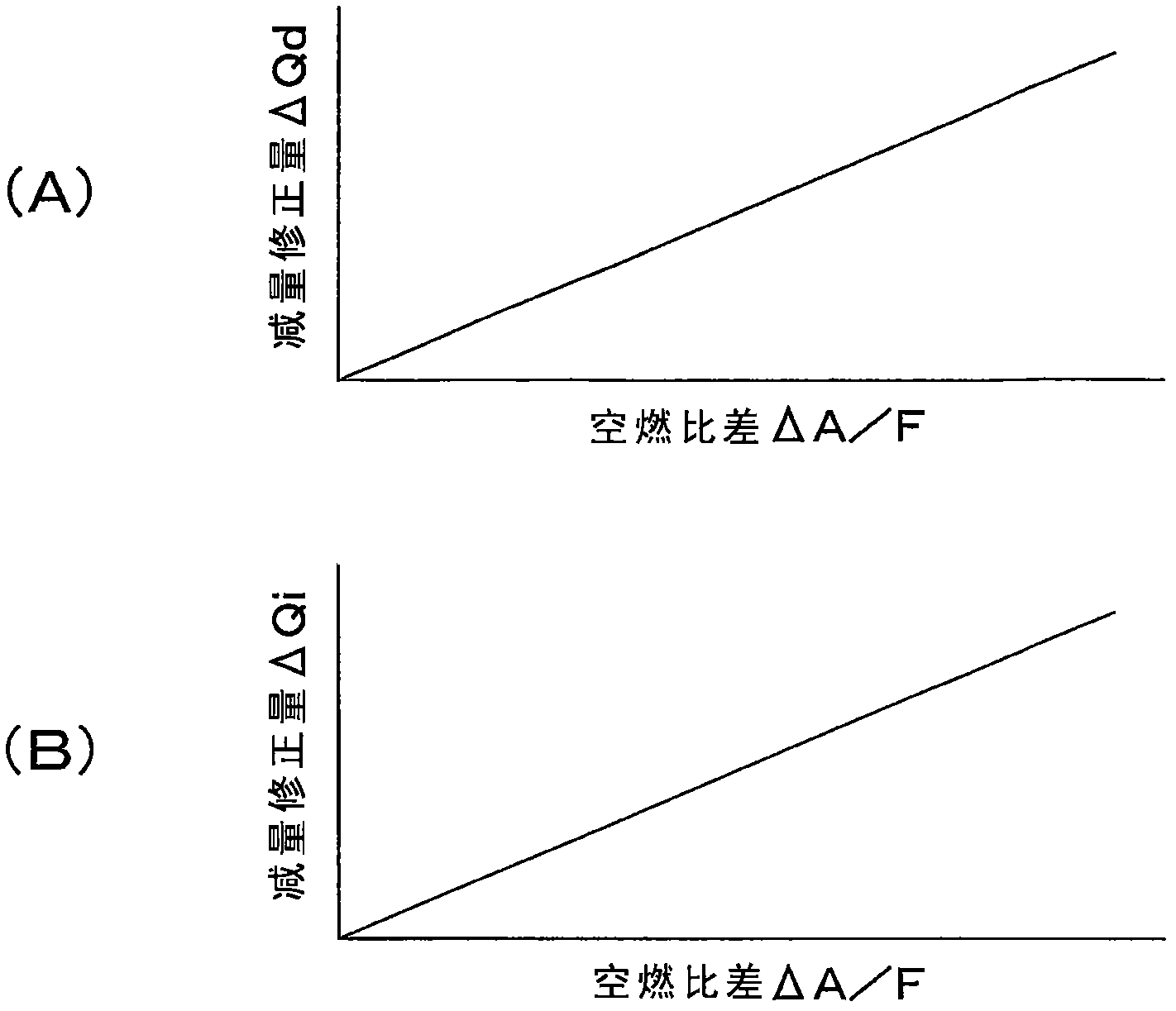

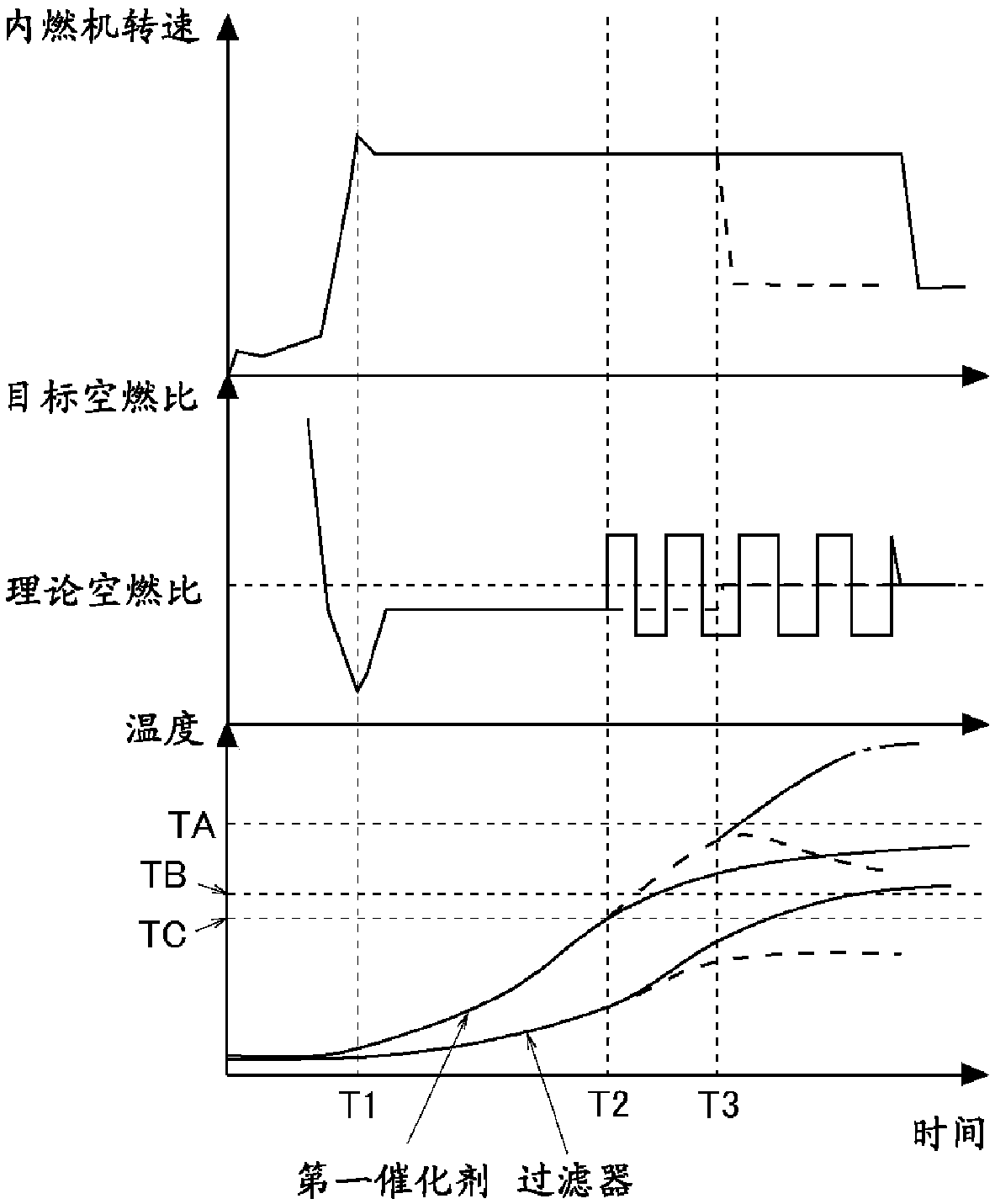

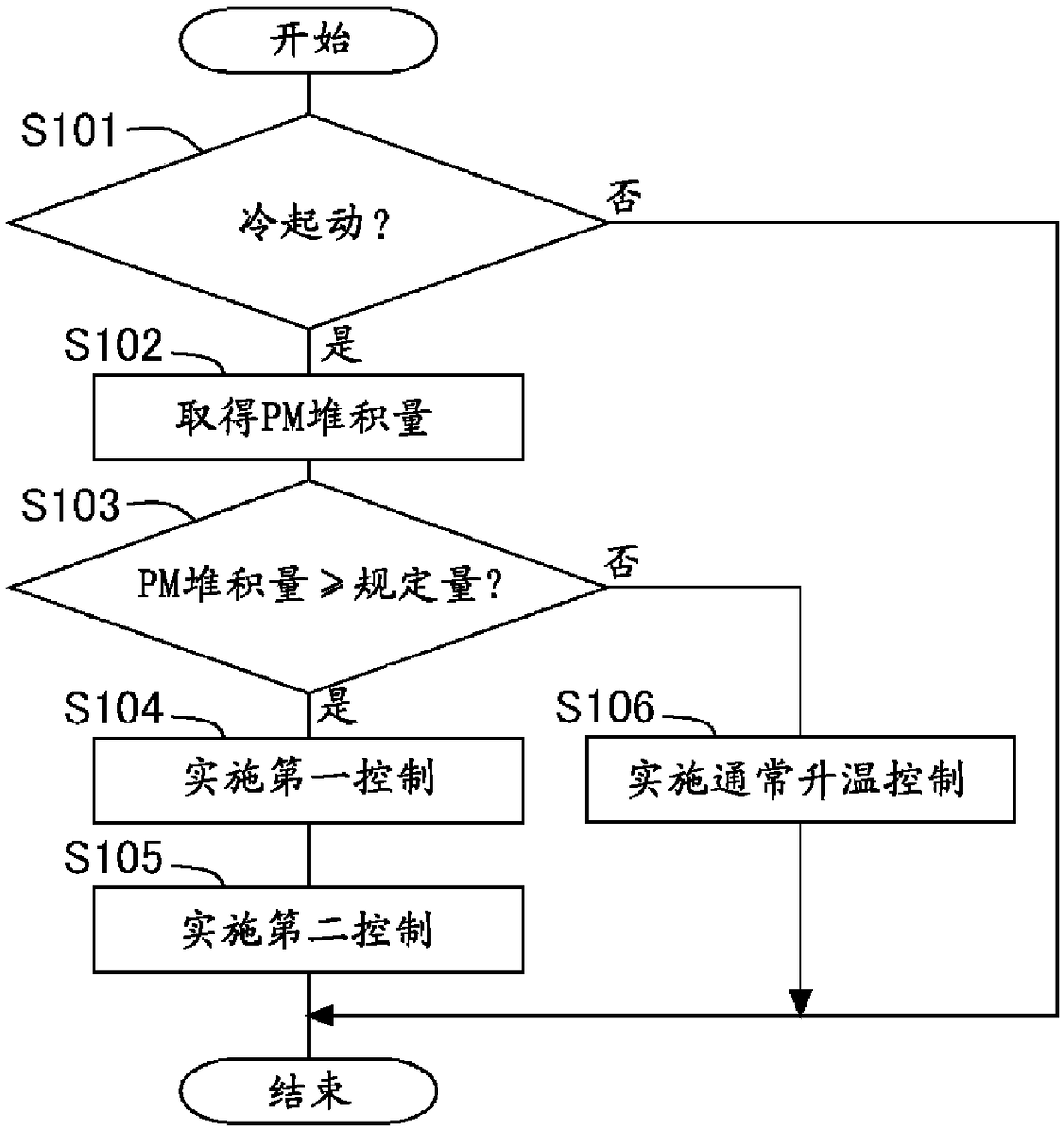

Air/fuel ratio control device for internal combustion engine

InactiveCN102667116AInhibition of thermal deteriorationElectrical controlExhaust apparatusExternal combustion engineEngineering

Owner:TOYOTA JIDOSHA KK

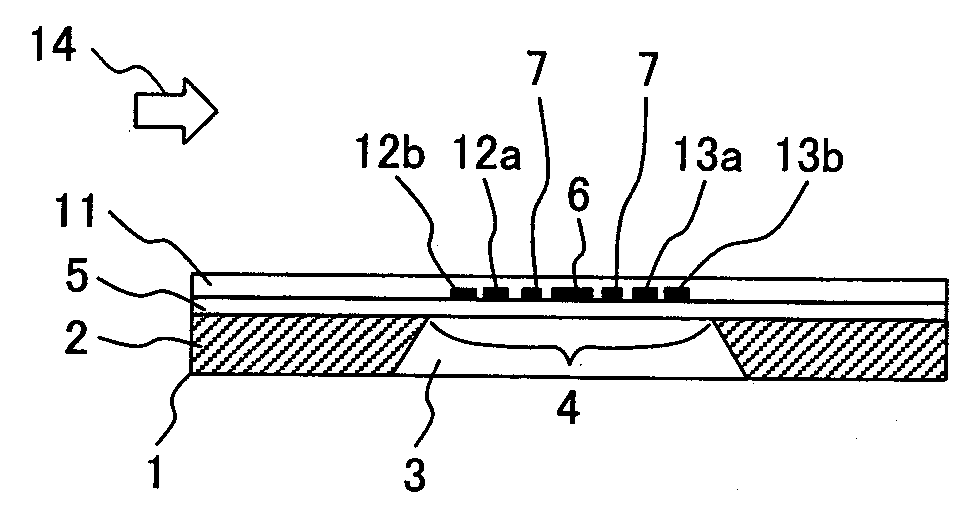

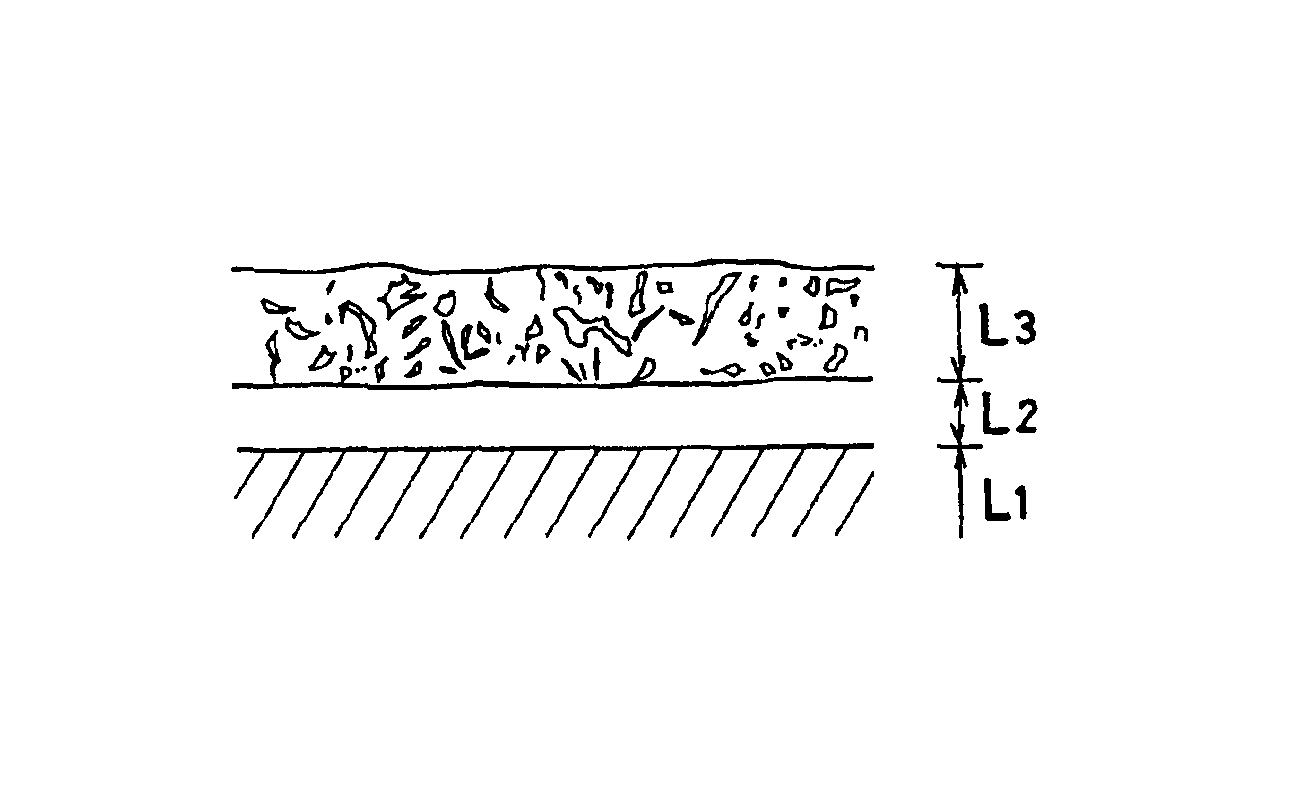

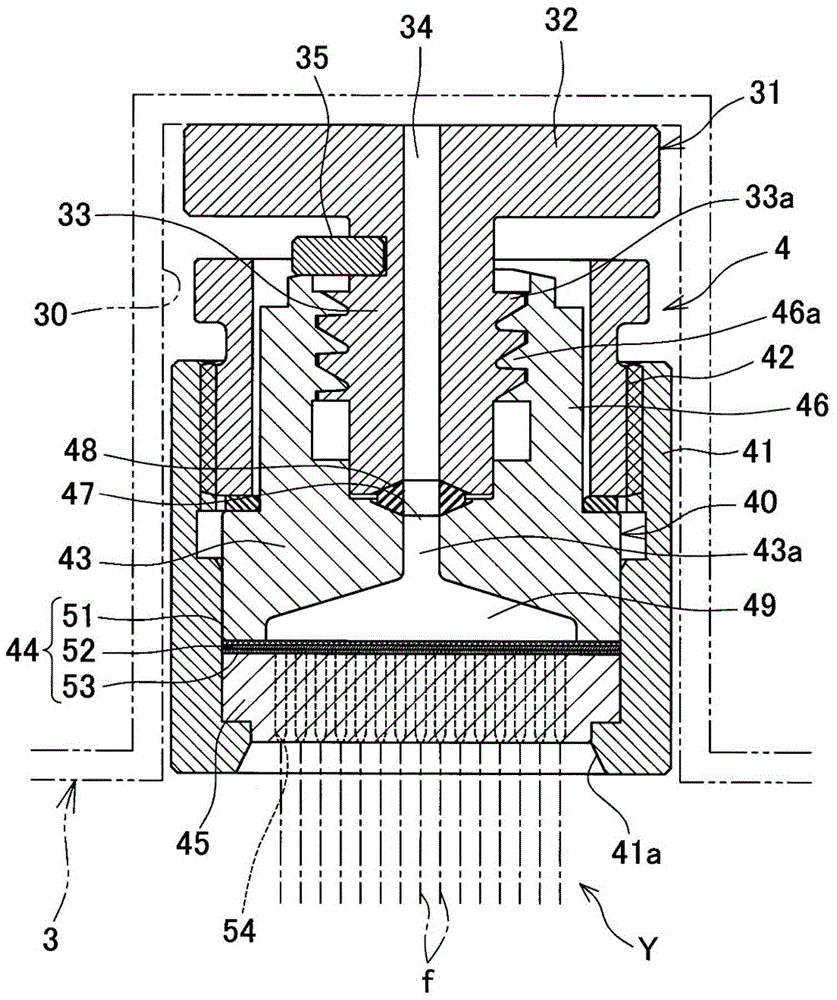

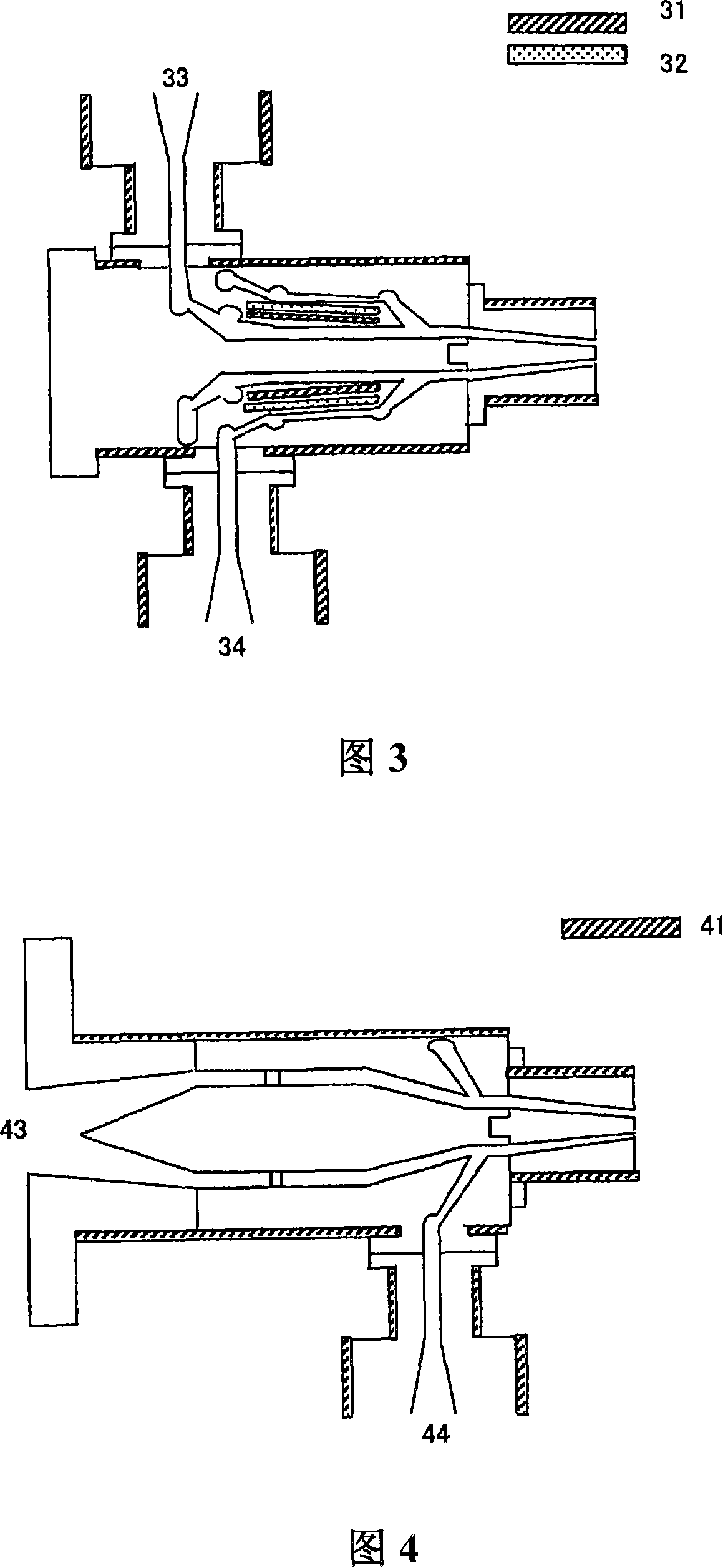

Spinning assembly

InactiveCN104562225APrevent spoilageShorten the timeSpinning solution de-aeratingSpinnerette packsFiberSpin out

The invention provides a spinning assembly. In a spinning assembly without using granulous filtering materials, sufficient refining of gel-shaped parts of polymer, reduction of residence time of the polymer in the assembly and uniformization of spun-out volume of the polymer among multiple nozzles are achieved. The spinning assembly (4) is provided with a polymer flowing-in part (43), a filter (44) and a spinning nozzle (45). The polymer flowing-in part is provided with a guiding-in part (47) with to-be-guided-in fused polymer and a buffering space (49) directly connected to the guiding-in part (47) via a polymer supplying hole (43a). The filter is disposed to the lower part of the buffering space (49). The spinning nozzle is connected with the filter (44) and multiple nozzles (54) for separately spinning out fused polymers passing through the filter (44) are formed on the spinning nozzle (45). The filter (44) also comprises a first filtering layer (51) which is formed via sintering of metal short fibers with polygonal cross sections.

Owner:TMT MACHINERY INC

Laminated glass, head up display system, and method for manufacturing head up display system

PendingCN111918852AInhibition of thermal deteriorationWindowsStatic indicating devicesHead-up displayDisplay device

Provided is a laminated glass that is served as a head up display, whereby it becomes possible to prevent the thermal deterioration of a light source device for irradiating the laminated glass with light for image display use. The laminated glass according to the present invention is a head up display, has a wedge angle of 0.1 mrad or more or contains a light-emitting material, and is provided with a first laminated glass member, a second laminated glass member and an intermediate film, wherein the first laminated glass member is arranged on a first surface side of the intermediate film, the second laminated glass member is arranged on a second surface side, which is opposed to the first surface, of the intermediate film, the solar transmittance of the laminated glass is 50% or less, and the solar reflectance of the laminated glass is 15% or more.

Owner:SEKISUI CHEM CO LTD

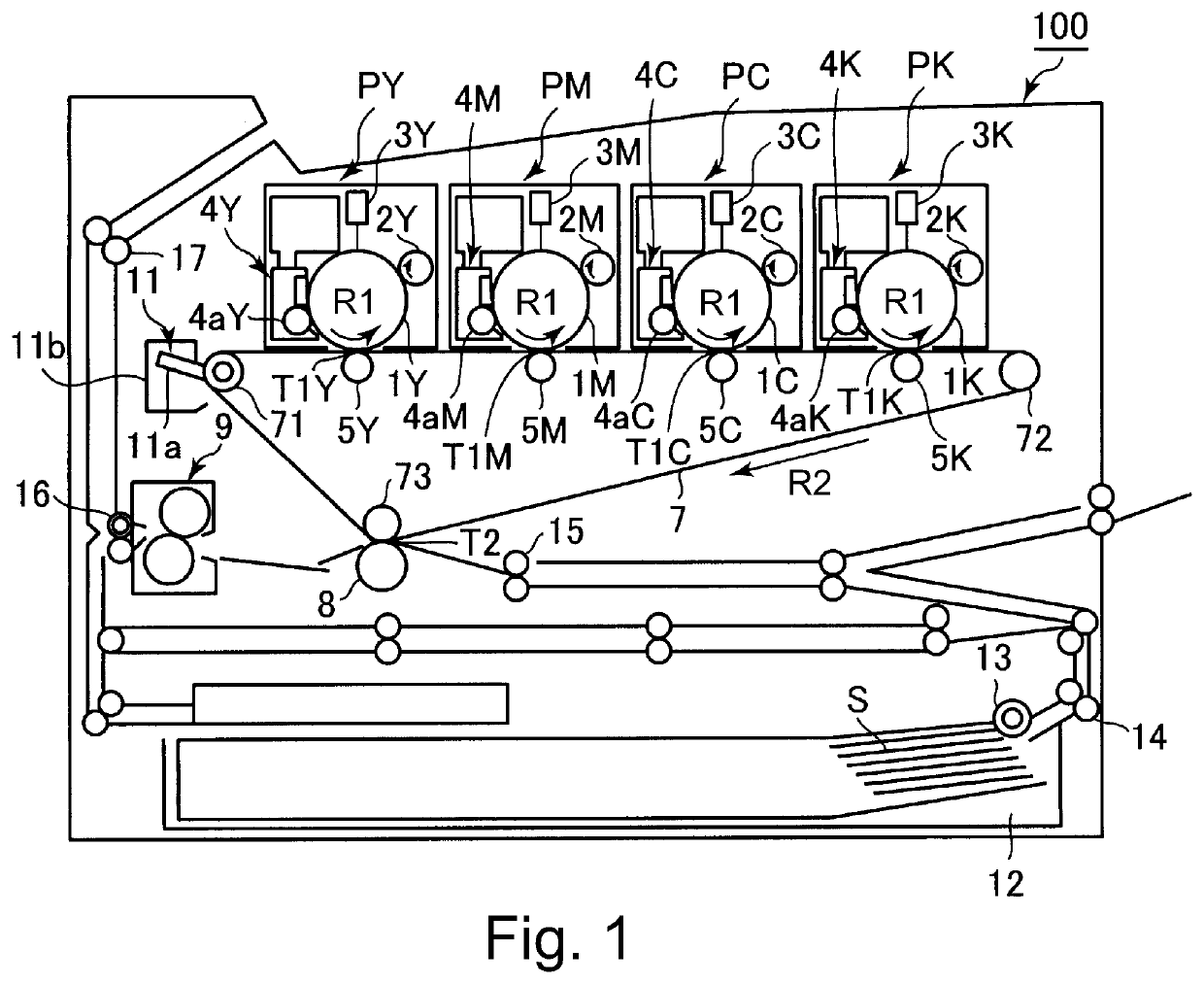

Intermediary transfer belt, manufacturing method of the intermediary transfer belt, and image forming apparatus

ActiveUS20200019093A1Suppressing scattering and a ghostInhibition of thermal deteriorationElectrographic process apparatusTubular articlesPolymer scienceDi n butyl phthalate

An intermediary transfer belt having surface resistivity ρs of 1×109 Ω / square or more and volume resistivity ρv of 1×1012 Ω·cm or less includes a thermoplastic resin material containing carbon black. The carbon black contained in the thermoplastic resin material has a weight ratio of 22.5-28.5 weight % and include first carbon black and second carbon black. The first carbon black of the carbon black contained in the thermoplastic resin material has a weight ratio of 50-90 weight % and dibutyl phthalate absorption of 93-127 ml / 100 g, and the second carbon black of the carbon black contained in the thermoplastic resin material has a weight ratio of 10-50 weight % and dibutyl phthalate absorption of 36-79 ml / 100 g.

Owner:CANON KK

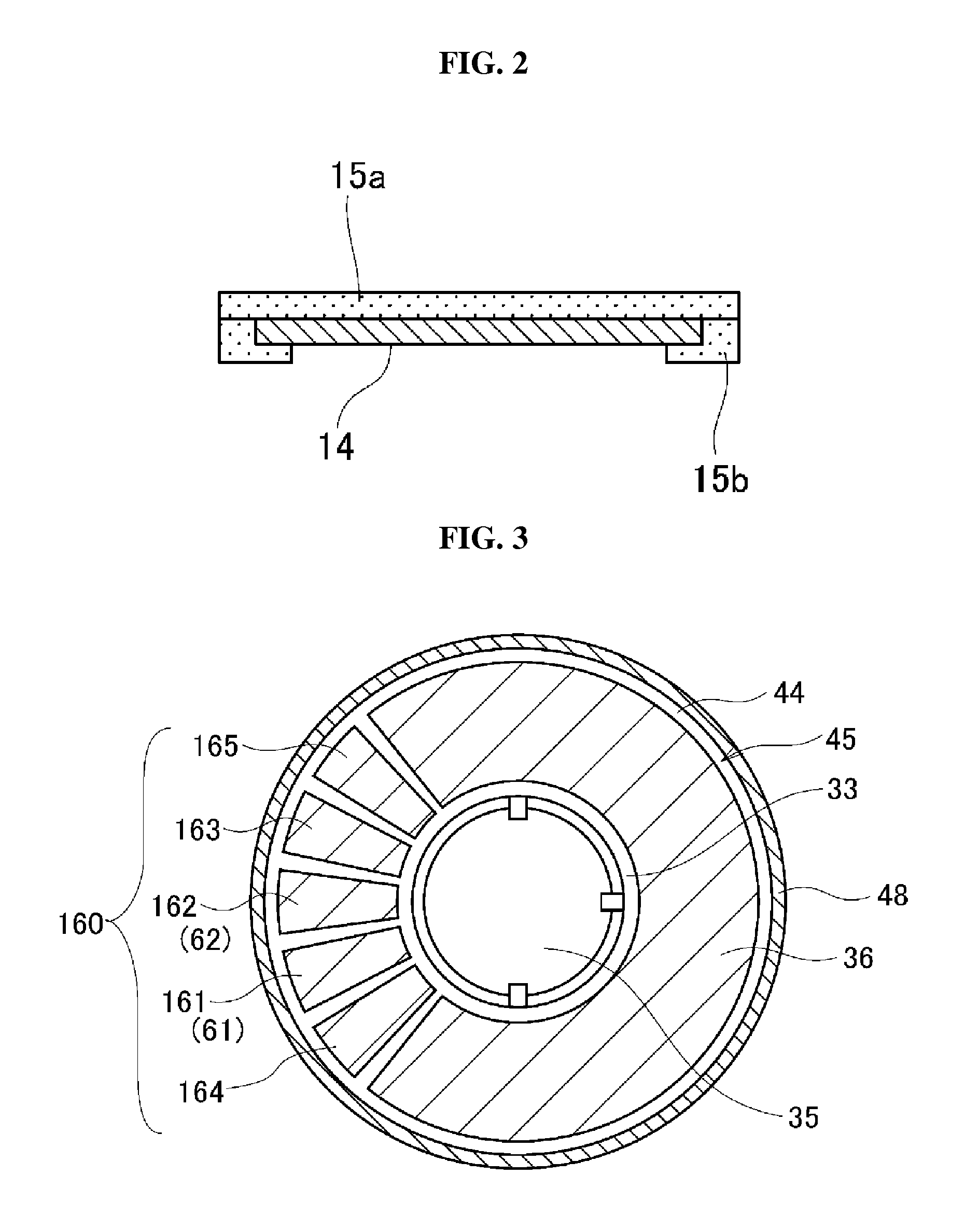

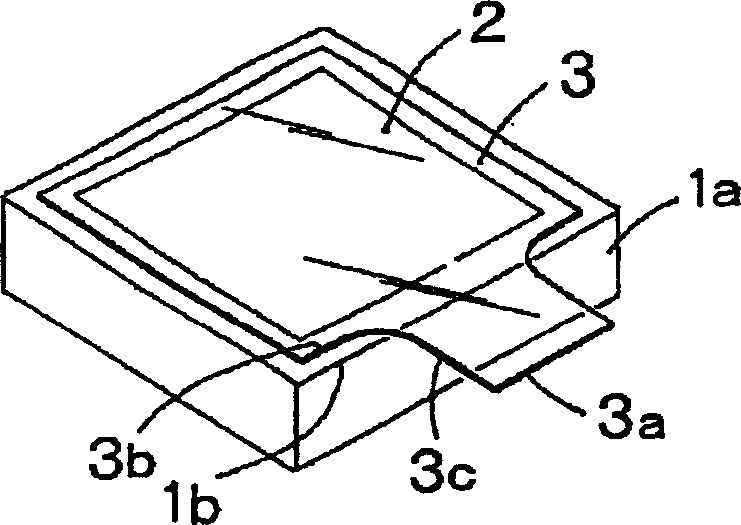

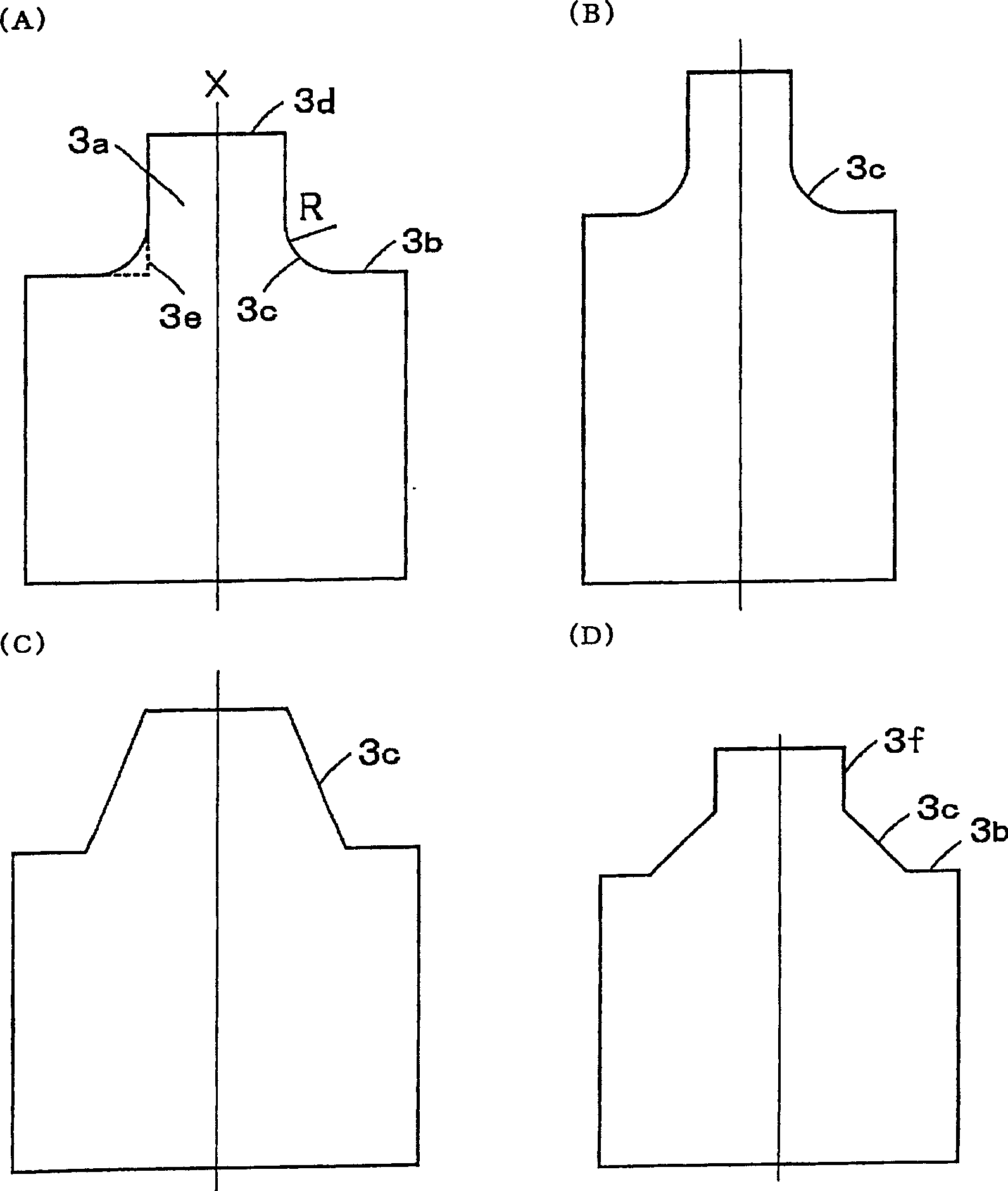

Imaging sensor mounting method and adhesive tape used thereby

InactiveCN1691299APrevent thermal deformationInhibition of contractionFilm/foil adhesivesSemiconductor/solid-state device manufacturingVideo sensorsAdhesive

The objective is to provide a mounting method of a video sensor capable of attaining solder reflow in a state that an adhesive tape is adhered to a light receiving side of the video sensor and protecting the light receiving side of the video sensor even during the solder reflow in a mounting step of the video sensor employing a solid-state imaging device and to provide the protective adhesive tape used for the method. The mounting method is characterized in that solder connection reflow is applied to terminals of the video sensor with a board side by heating the terminals at a temperature of 170 [deg.]C or over while the adhesive tape employing a polyimide film for a configuration material of the its material is adhered to the light receiving side of the video sensor, the adhesive tape having an adhesive coated on one side and an anti-static agent coated on the other side. Further, at least a silicone group material is characterized in to be used for the adhesive configuration material of the adhesive tape.

Owner:NITTO DENKO CORP

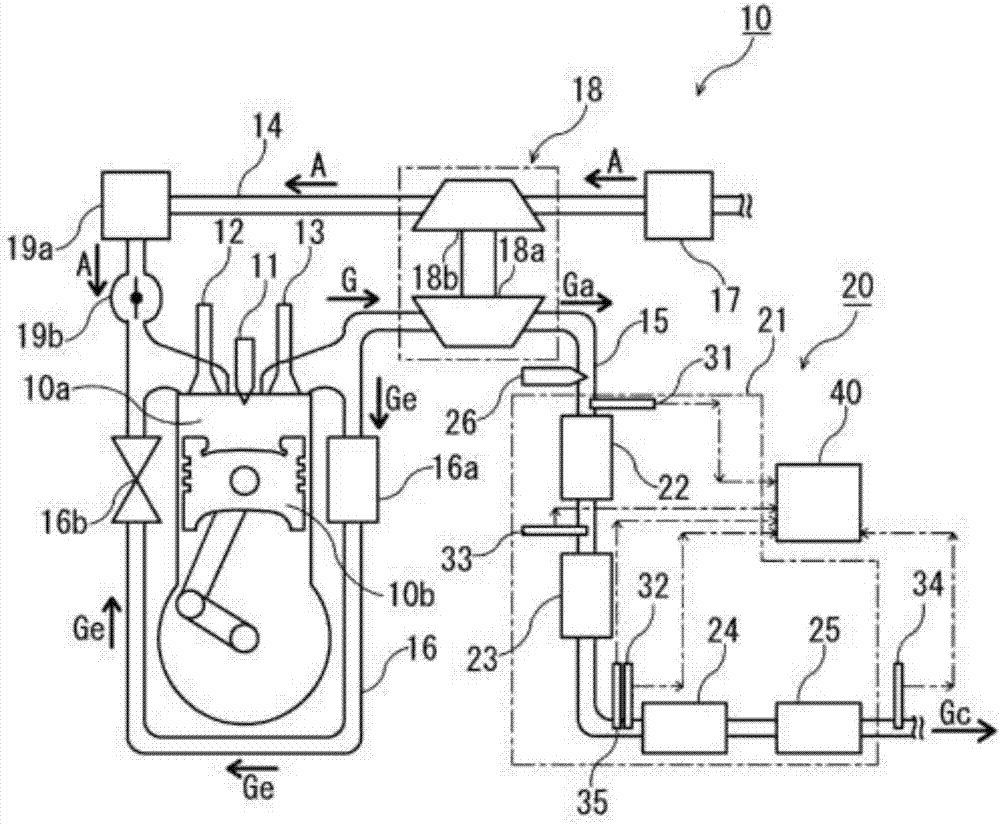

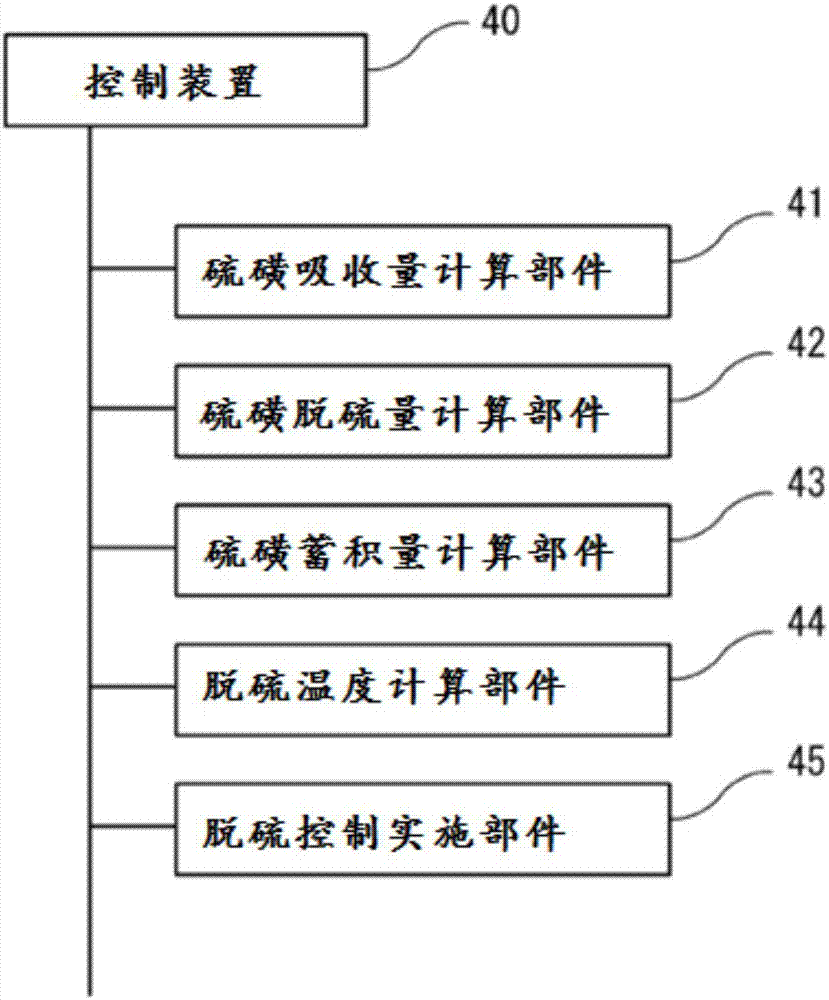

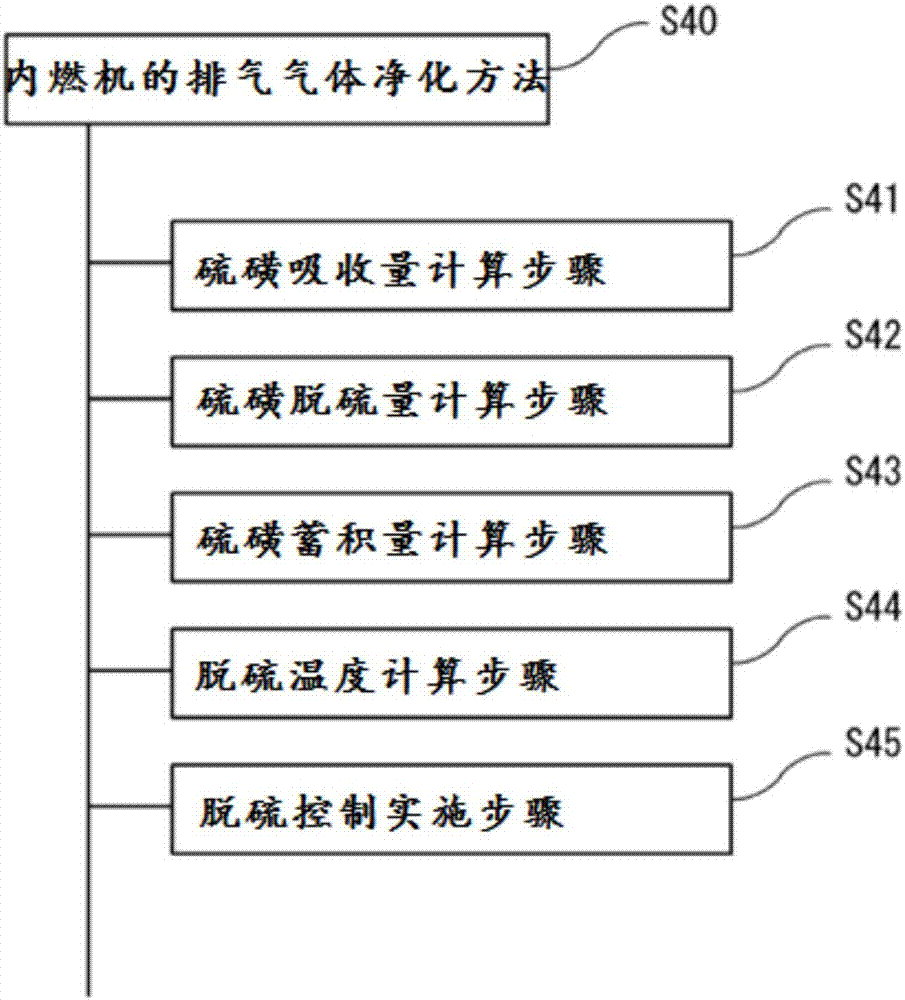

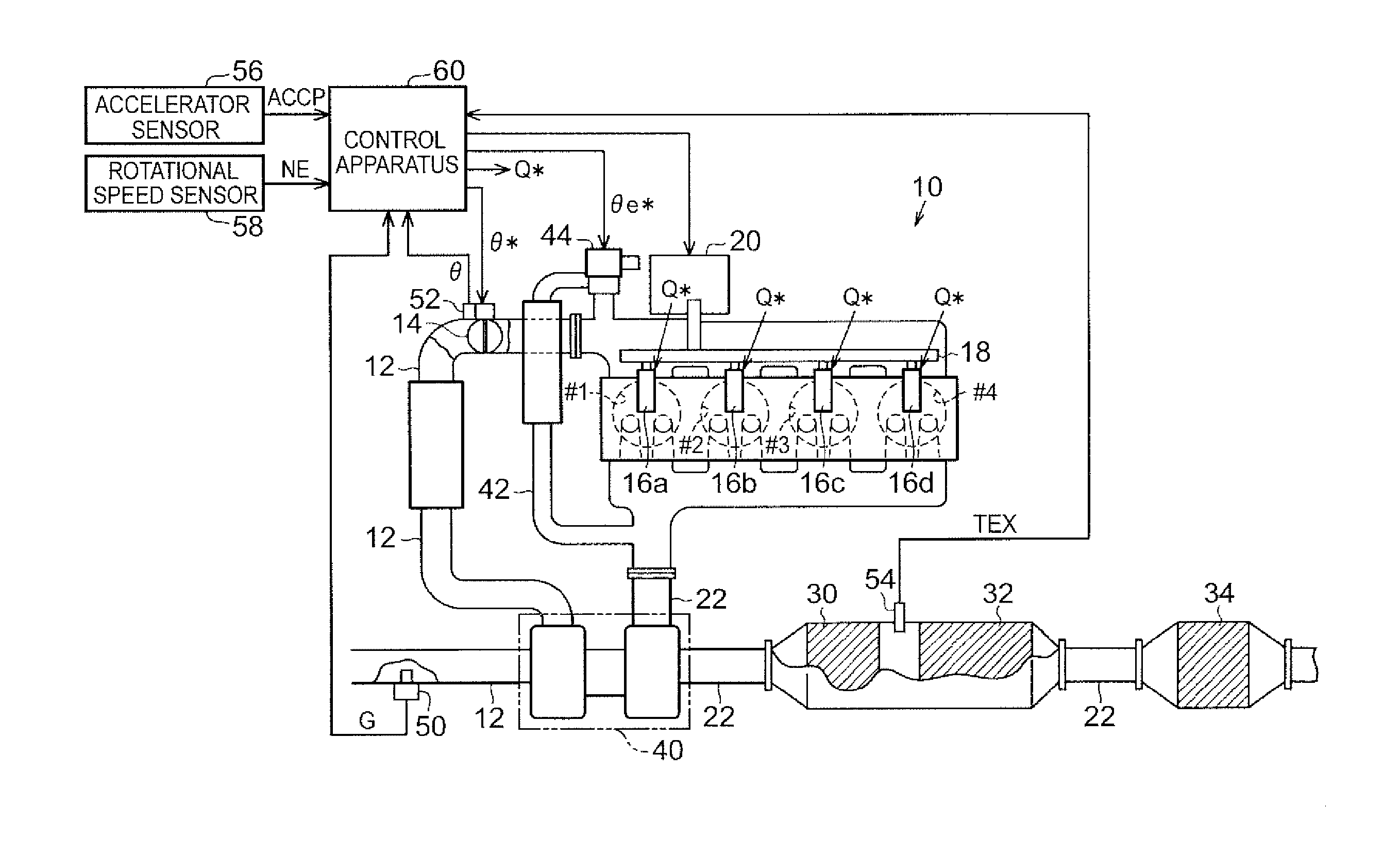

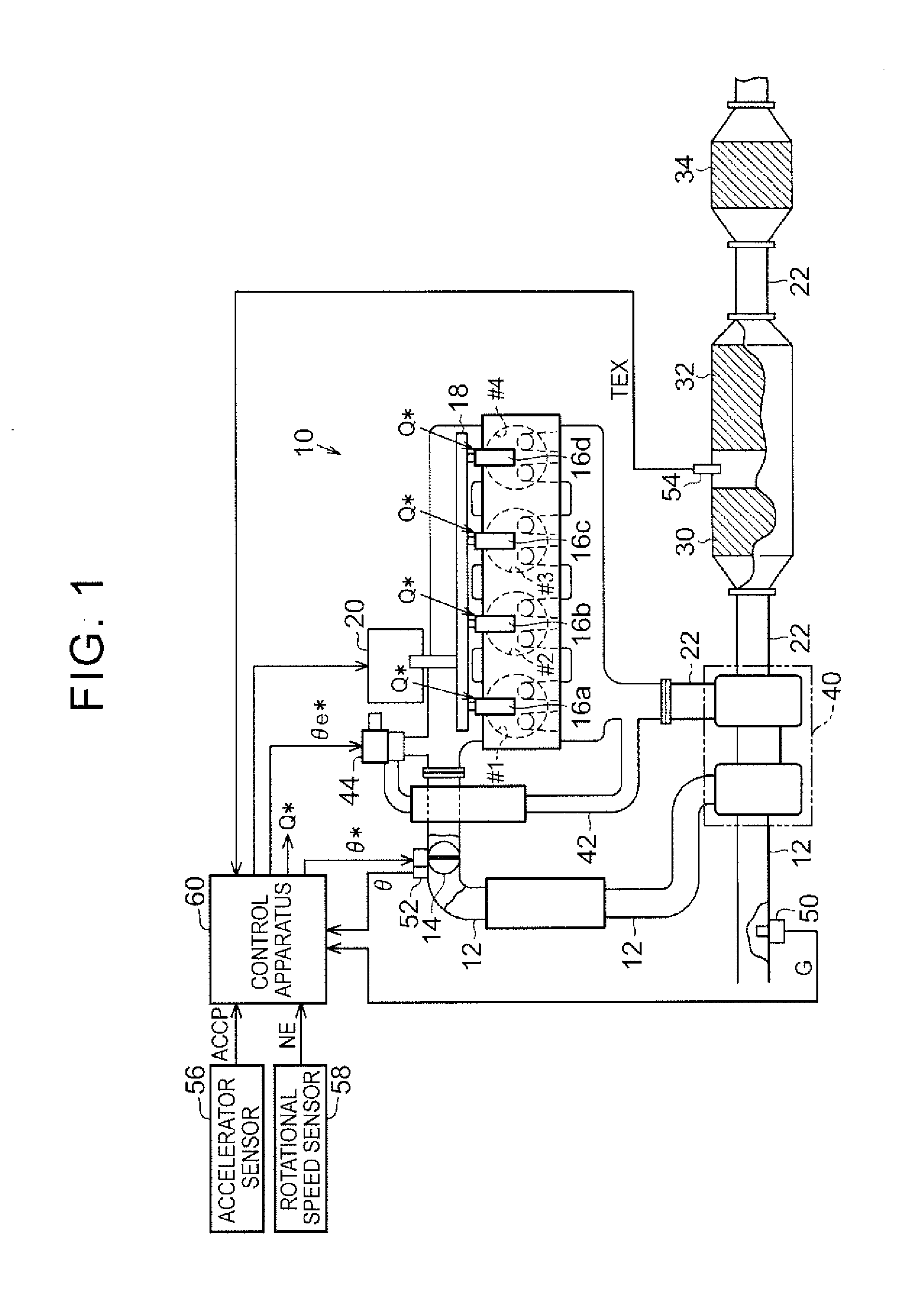

Exhaust gas purification system for internal combustion engine, internal combustion engine, and exhaust gas purification method for internal combustion engine

InactiveCN107208522AInhibition of thermal deteriorationReliable desulfurization treatmentInternal combustion piston enginesExhaust apparatusExternal combustion engineInternal combustion engine cooling

In this exhaust gas purification system 20 for an internal combustion engine, a lean NOx trap catalyst device 24 is provided to an exhaust passage 15 of an engine 10. A control device 40 for controlling the exhaust gas purification system 20 is configured such that a desulfurization temperature Tt, which serves as a target temperature for when performing desulfurization control on the lean NOx trap catalyst device 24, is set so as to correspond to the sulfur storage amount Sa stored in the lean NOx trap catalyst device 24. As a result, an exhaust gas purification system for an internal combustion engine, an internal combustion engine, and an exhaust gas purification method for an internal combustion engine are provided, with which, when desulfurization control is performed on the lean NOx trap catalyst device provided to the exhaust gas purification system for an internal combustion engine, desulfurization treatment is reliably performed while heat deterioration and erosion of the lean NOx trap catalyst device are inhibited, and desulfurization control exhibiting excellent robustness is performed, and thus a high NOx purification rate is maintained.

Owner:ISUZU MOTORS LTD

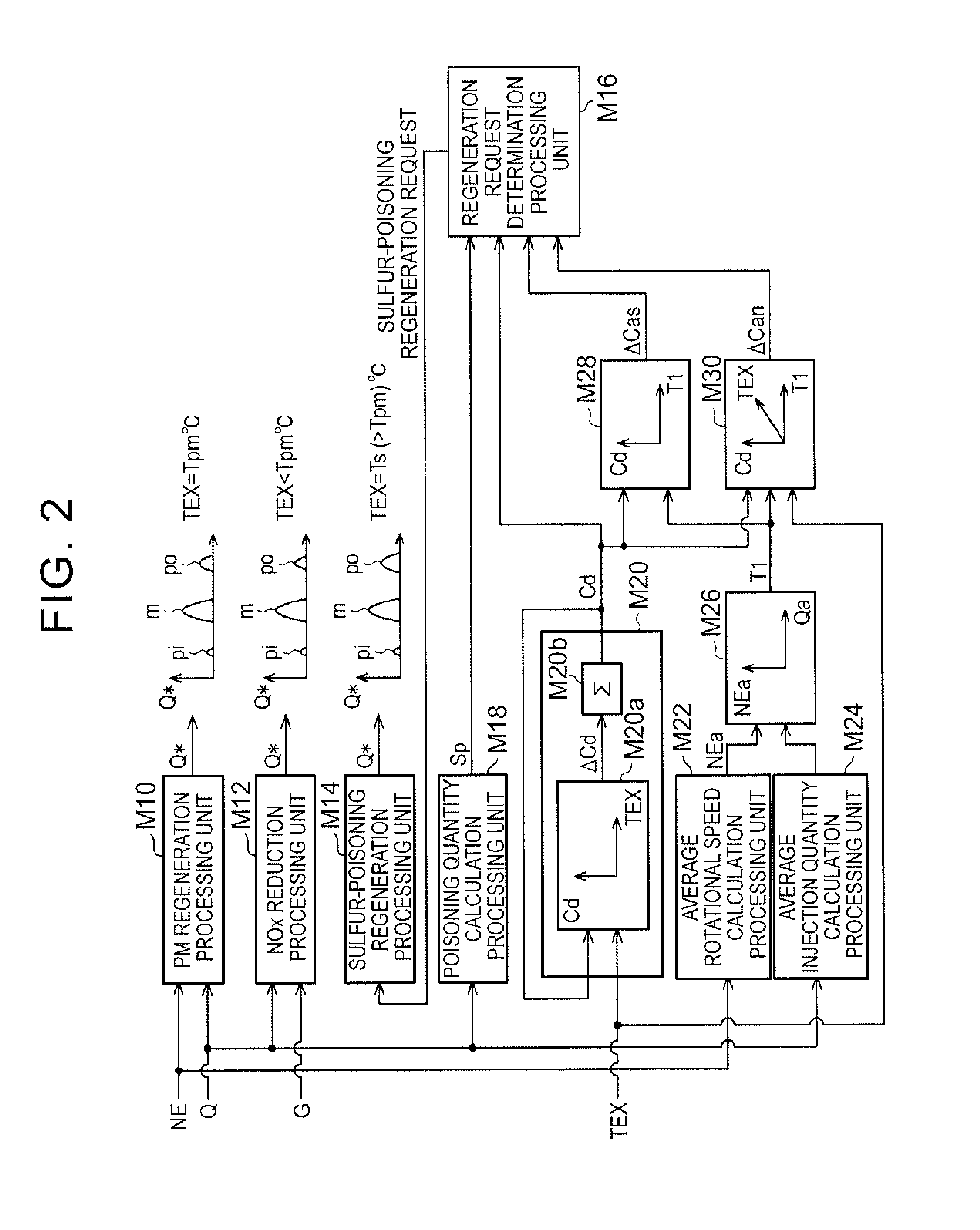

Catalyst regeneration processing apparatus

InactiveUS20160290207A1Suppress executionInhibition of thermal deteriorationElectrical controlExhaust apparatusSulfurProcess engineering

A catalyst regeneration processing apparatus for an internal-combustion engine includes an electronic control unit. The electronic control unit is configured to determine whether a gap is equal to a predetermined degree or less, the gap being a difference between (a) a progress degree of heat deterioration of a NOx catalyst in a predetermined time in a case of assuming that a regeneration process is executed for the predetermined time and (b) a progress degree of heat deterioration of the NOx catalyst in the predetermined time in a case of assuming that the regeneration process is not executed. The electronic control unit is configured to execute the regeneration process in a case of determining that the gap is equal to the predetermined degree or less, even when a sulfur poisoning quantity does not exceed a permissible upper limit quantity.

Owner:TOYOTA JIDOSHA KK

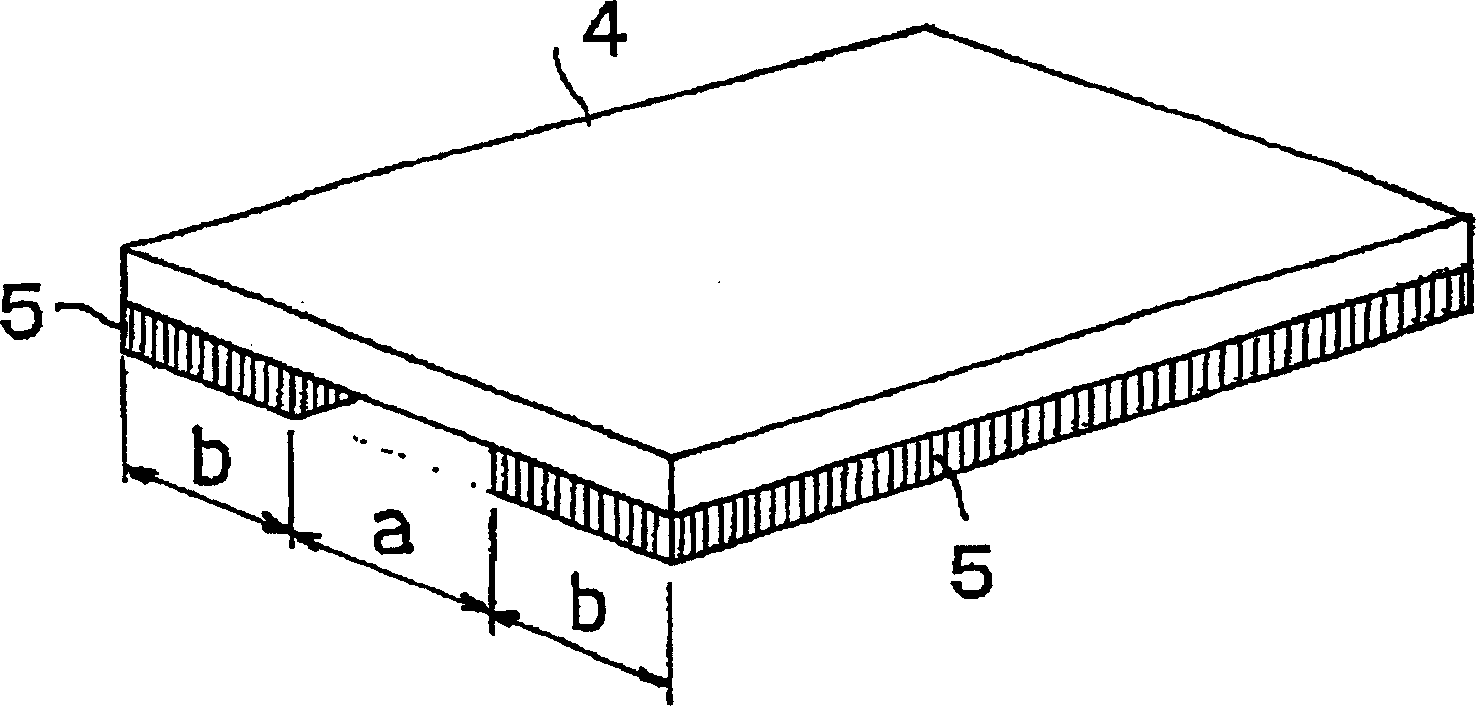

Chlorotrifluoroethylene copolymer containing laminate and process for production thereof

InactiveCN101137504AReduce permeabilityGood lookingSynthetic resin layered productsVinyl etherHexafluoropropylene

A chlorotrifluoroethylene (CTFE) copolymer containing laminate which is produced by coextruding a layer of tetrafluoro- ethylene / perfluoro vinyl ether copolymer (PFA) and / or a tetra- fluoroethylene / hexafluoropropylene copolymer (FEP) and a CTFE copolymer layer with the latter being inhibited from thermal deterioration and which is improved in the resistance to permeation of chemical fluids and so on; and a process for the production of the laminate. The invention relates to a CTFE copolymer containing laminate comprising a layer (A) of PFA and / or FEP and a layer (B) of a CTFE copolymer, characterized by being produced by coextruding the layers (A) and (B) under such conditions that in the stage before the contact of material (a) for the layer (A) with material (b) for the layer (B) in a multilayer die, the temperature of a passageway (pa) through which the material (a) flows lies within the range of 300 to 400 DEG C and the temperature of a passageway (pb) through which the material (b) flows lies within the range of 250 to 350 DEG C.

Owner:DAIKIN IND LTD

Method for modifying a transparent electrode film

ActiveCN102150221ALow resistivityInhibition of thermal deteriorationVacuum evaporation coatingSolid-state devicesOptoelectronicsFlash light

A method for modifying a transparent electrode film contained in a transparent electrode film-attached substrate having a substrate and the transparent electrode film formed on the substrate includes annealing the transparent electrode film by applying flash light having an optical pulse duration time of 0.1 msec to 10 msec to the transparent electrode film using a flash lamp, thereby heating thetransparent electrode film.

Owner:SUMITOMO CHEM CO LTD

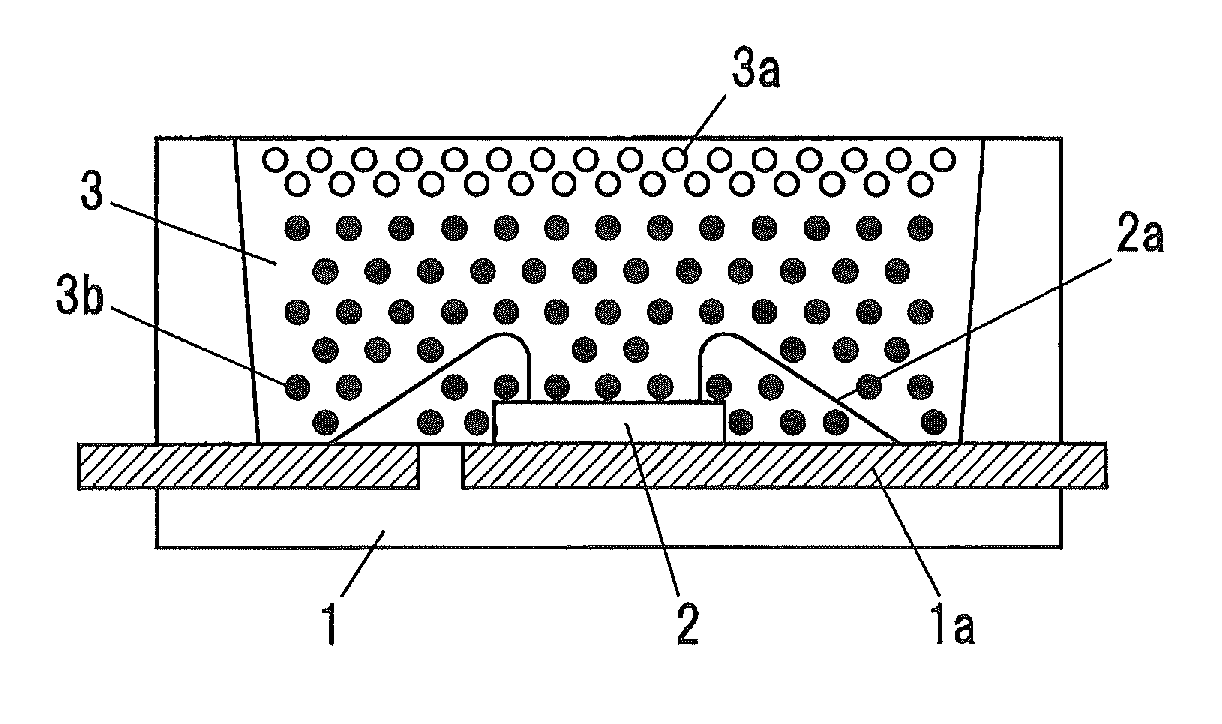

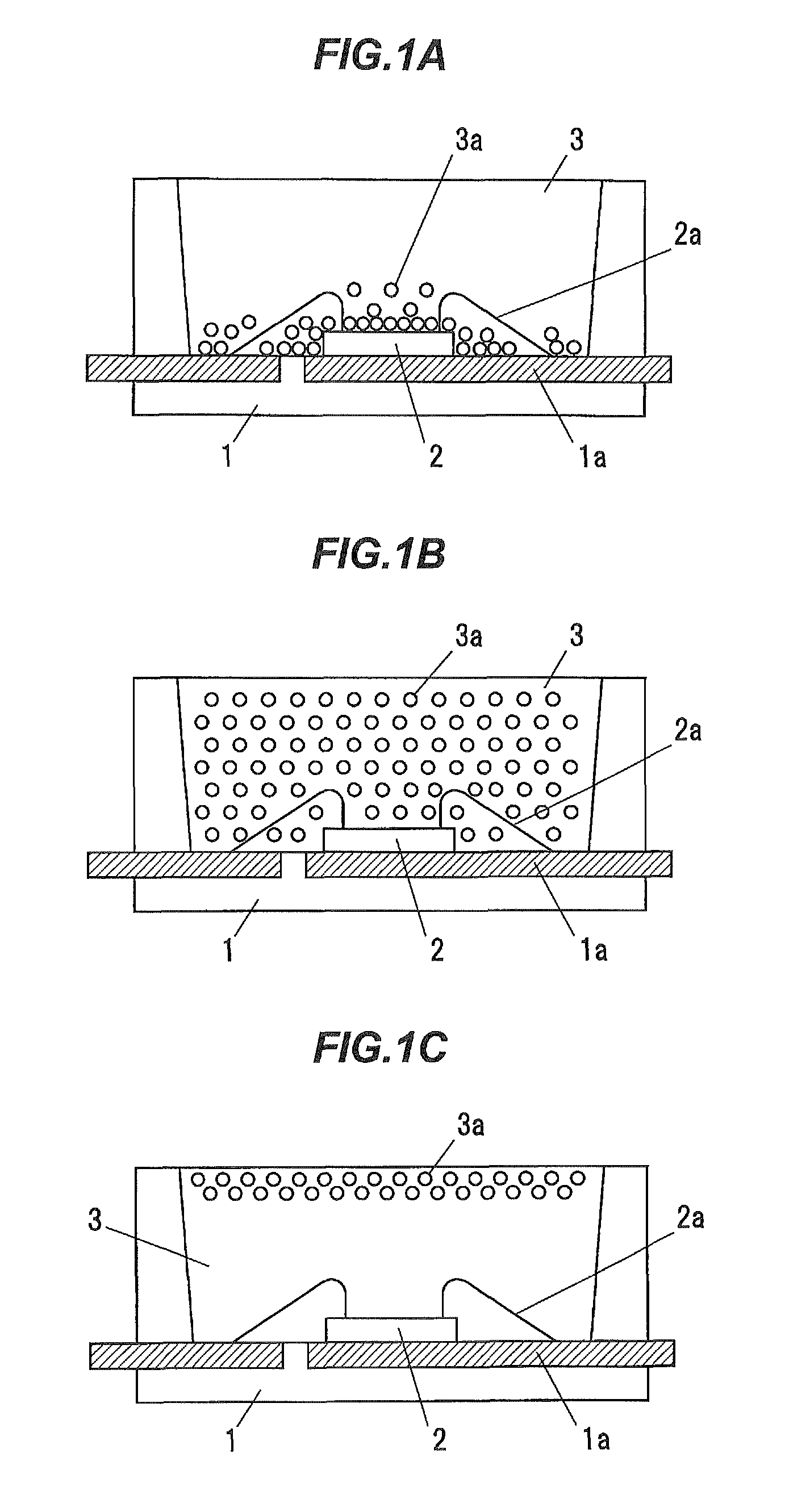

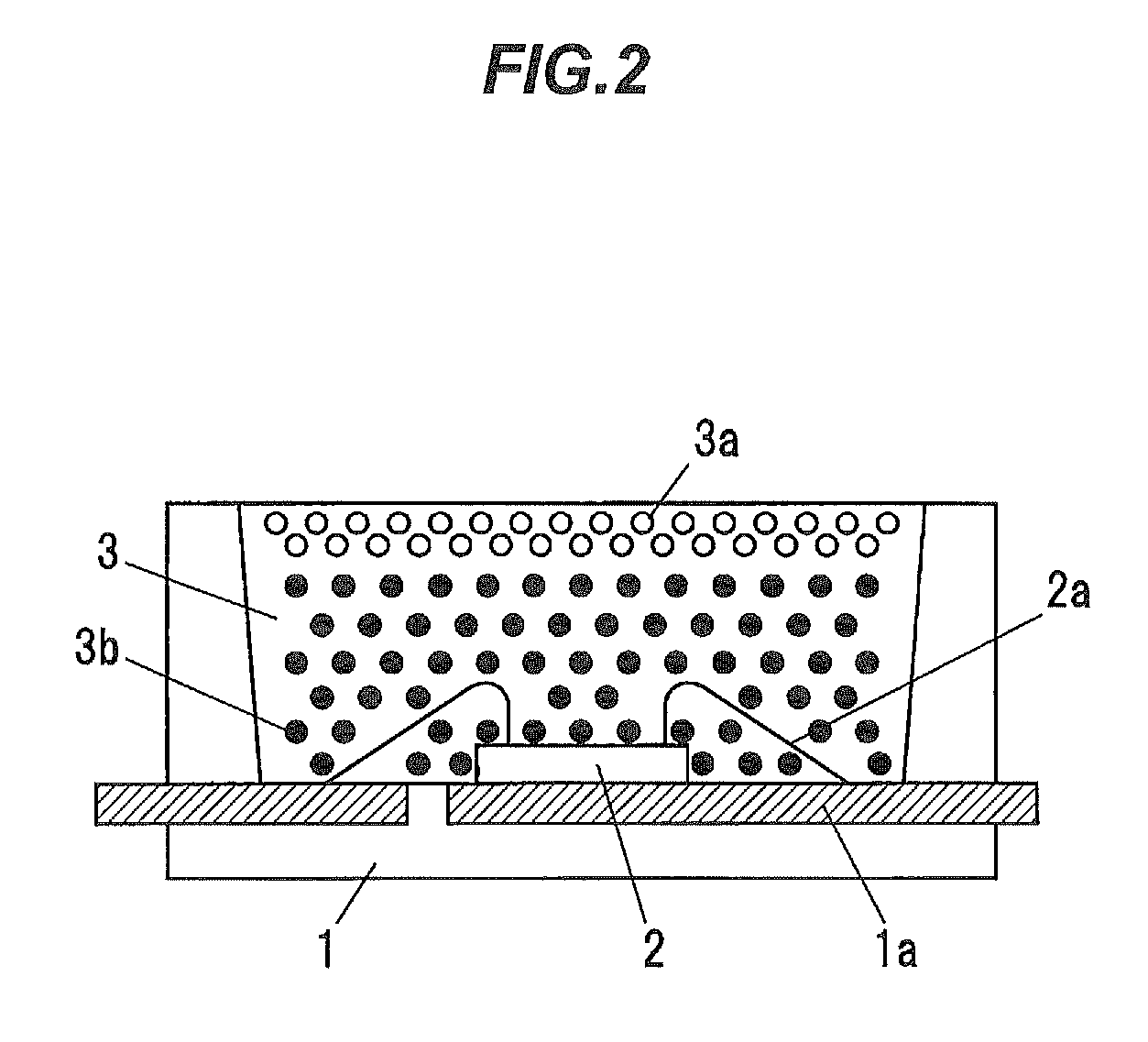

Light-emitting device and method of manufacturing the same

ActiveUS9310062B2Improve cooling effectInhibition of thermal deteriorationLighting heating/cooling arrangementsElectroluminescent light sourcesElectrical conductorPhosphor

A light-emitting device includes a base material having a conductor layer on a surface thereof, the conductor layer being configured to be connected to an external power source, a light-emitting element mounted on the base, a phosphor layer arranged above the light-emitting element, and a resin layer contacting both of the phosphor layer and the conductor layer and containing heat-conductive particles dispersed therein. The heat-conductive particles have a thermal conductivity of not less than 100 W / m·K and an insulator property or a semiconductor property.

Owner:TOYODA GOSEI CO LTD

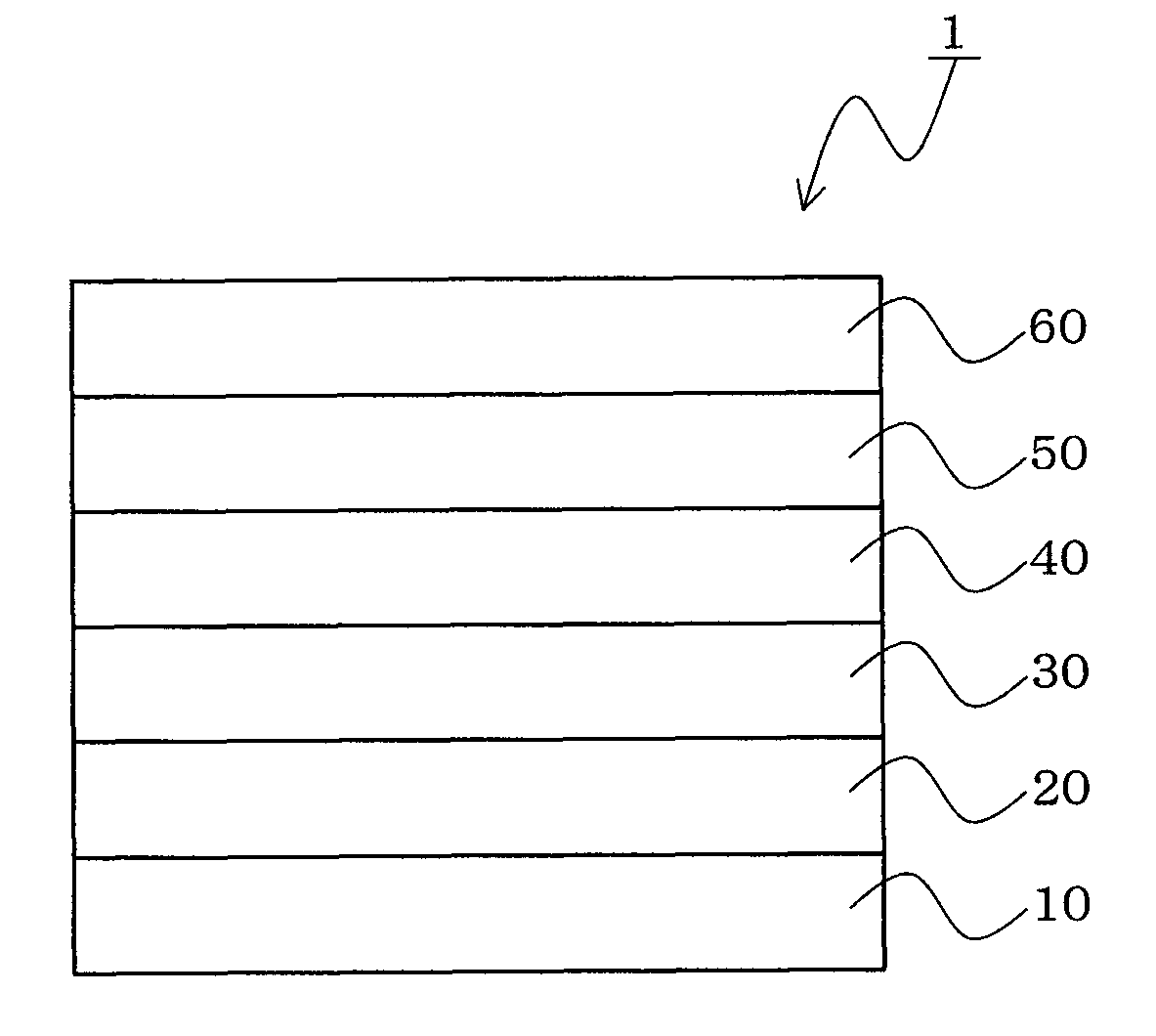

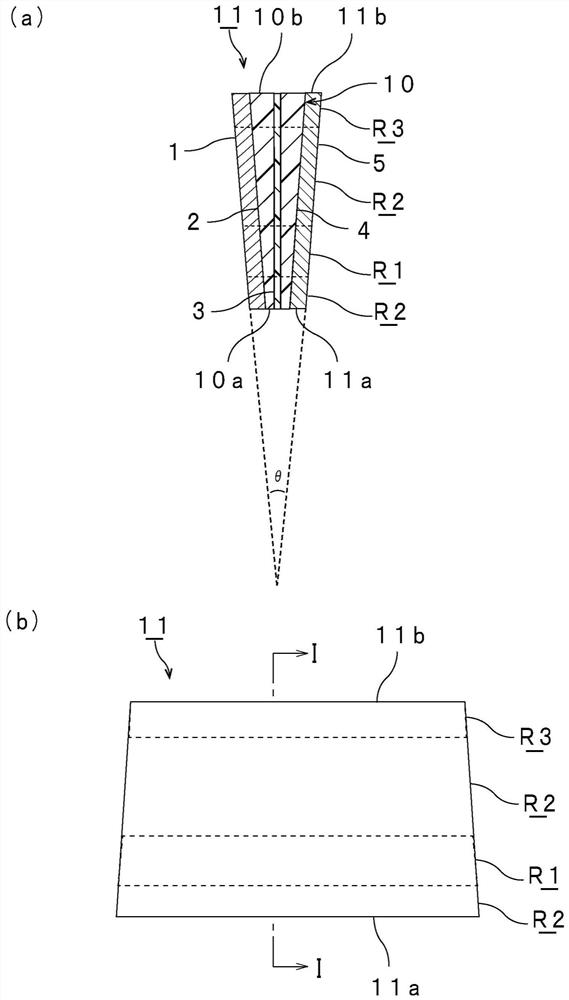

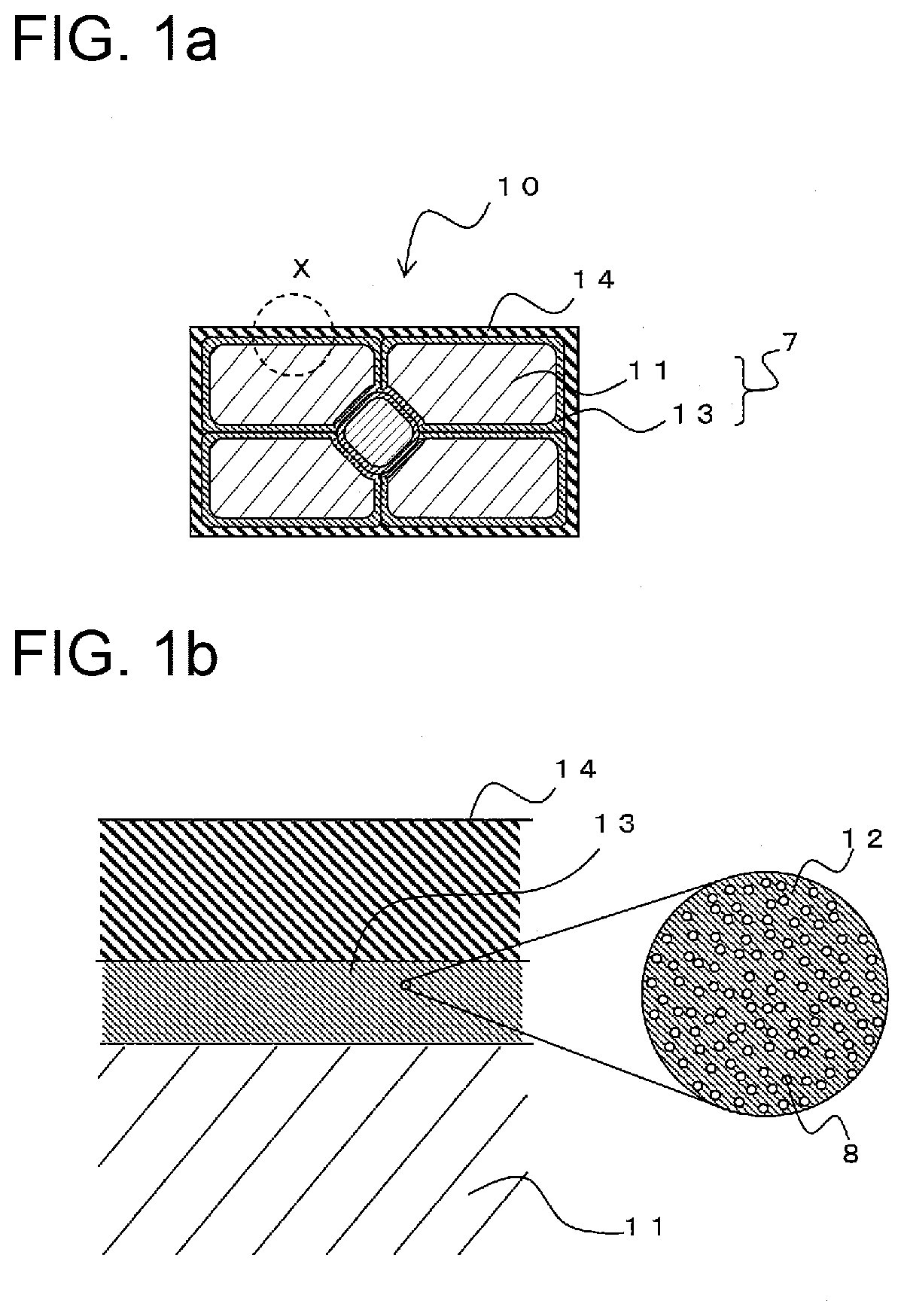

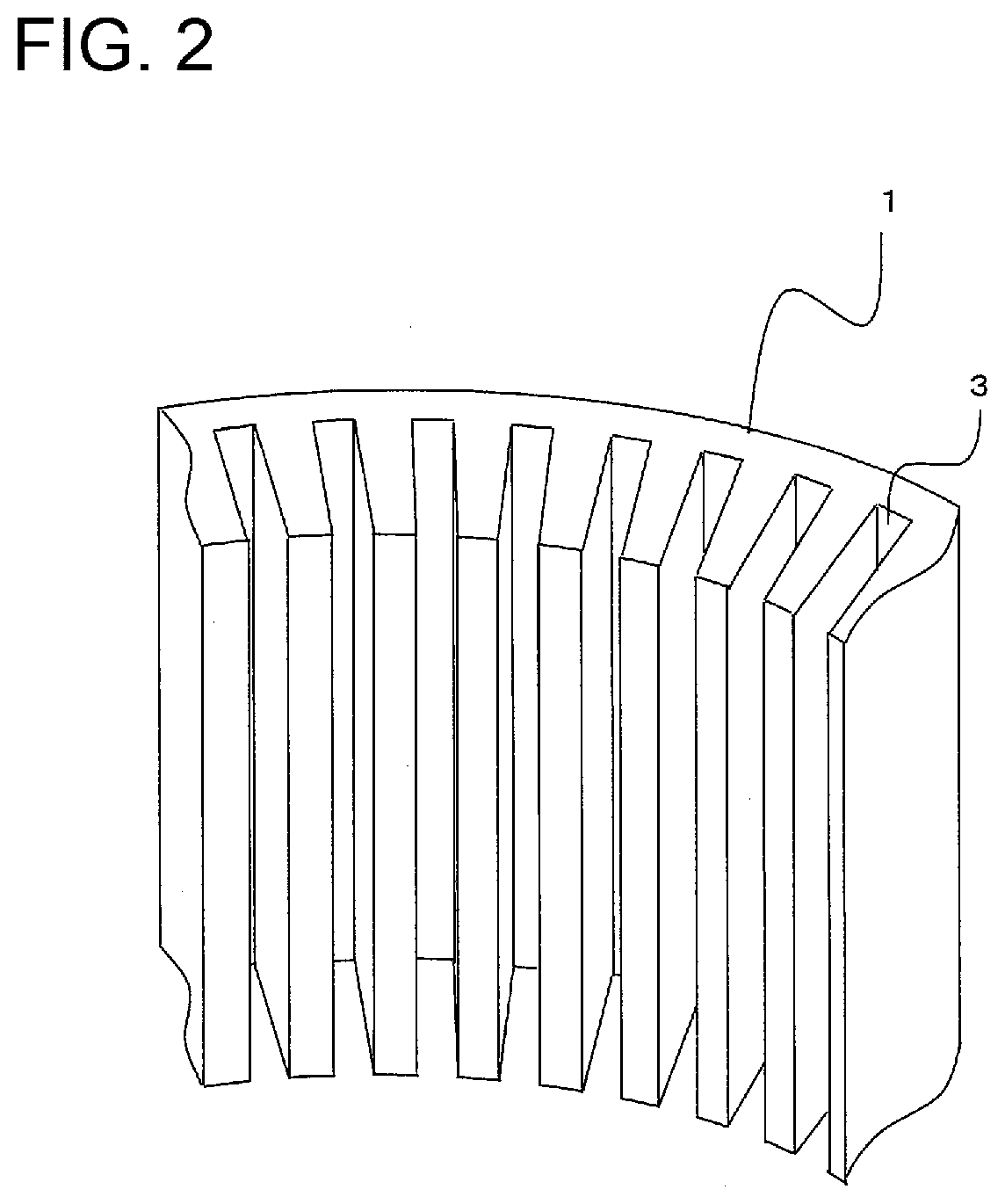

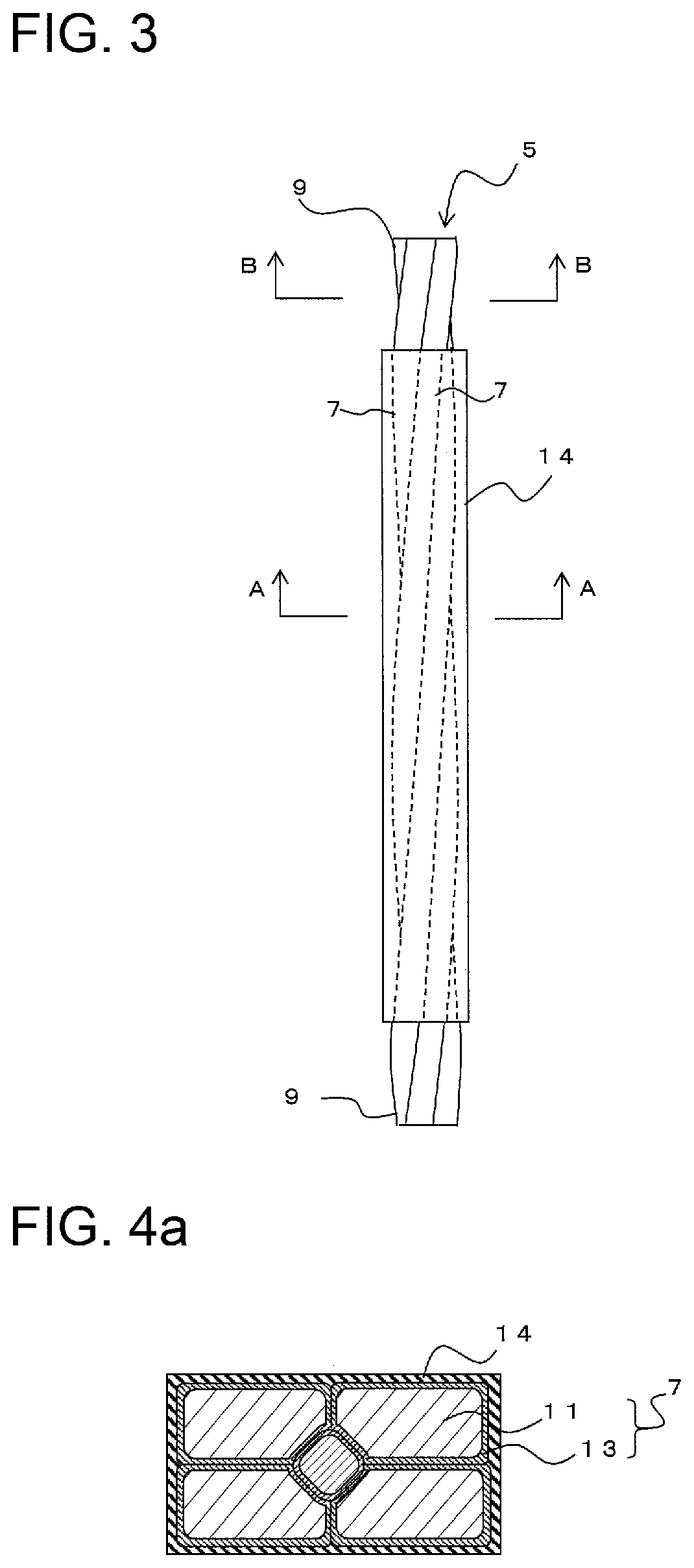

Assembled wire, segmented conductor, and segment coil and motor using the same

ActiveUS20200365294A1Improve heat resistanceInhibition of thermal deteriorationWindings insulation materialWindings insulation shape/form/constructionCarbide siliconWire rod

Provided is an assembled wire 10 having a substantially rectangular cross section, and is formed by assembling a plurality of strands 7. Each strand 7 has a conductor portion 11 and a strand insulating layer 13 covering the conductor portion 11. The strand insulating layer 13 preferably contains at least one kind of resin in which 50% weight loss in Tg-DTA occurs at from 300° C. to 500° C. The strand insulating layer 13 contains particles. The particles are particles having volume resistivity of 1×106 Ω·cm or more, and, for example, inorganic substances such as silica, titania, alumina, aluminum nitride, magnesium oxide, silicon nitride, and silicon carbide; and resins such as silicone are applicable.

Owner:ESSEX FURUKAWA MAGNET WIRE JAPAN CO LTD

Exhaust purifying apparatus for internal combustion engine and exhaust purifying method for internal combustion engine

InactiveCN108301900AInhibition of thermal deteriorationEarly regenerationElectrical controlInternal combustion piston enginesLean controlExternal combustion engine

Owner:TOYOTA JIDOSHA KK

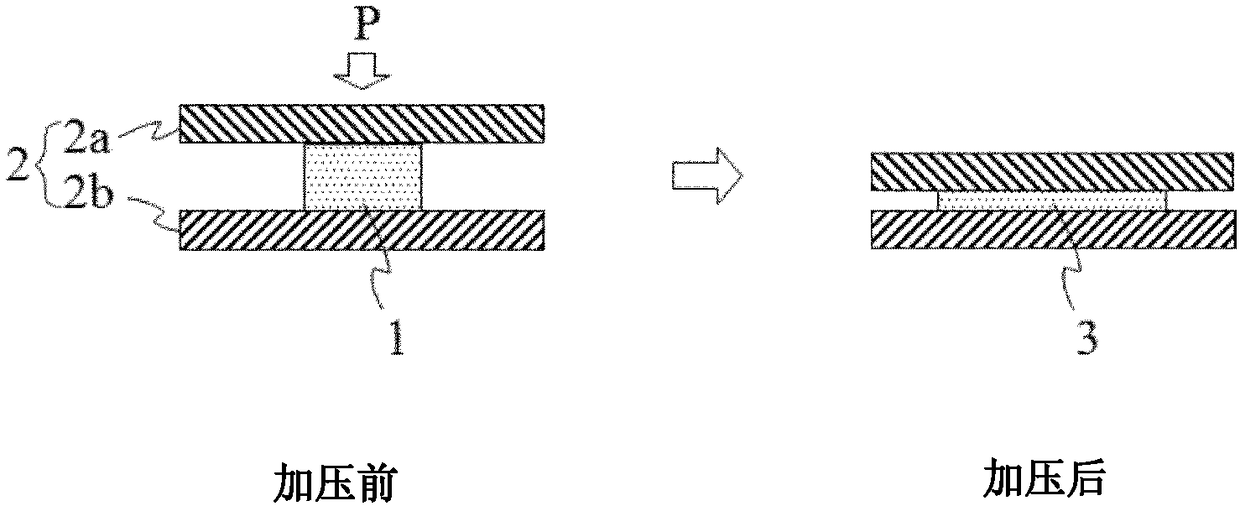

Production method for wavelength conversion members

InactiveCN108140702AInhibition of thermal deteriorationLuminescent compositionsSemiconductor devicesWavelength conversionMaterials science

Provided is a production method for wavelength conversion members that can limit the thermal degradation of inorganic fluorescent nanoparticles. The production method for wavelength conversion membersis characterized in that a mixture 1 comprising a glass powder and inorganic fluorescent nanoparticles is sintered by means of hot-pressing using a mold 2.

Owner:NIPPON ELECTRIC GLASS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com