Spinning assembly

A technology for spinning components and threads, applied in the field of spinnerets, can solve the problems of reduced component life, deviation of polymer spinning amount, and reduced impurity trapping ability, and achieves the effect of inhibiting deterioration and uniform thermal process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

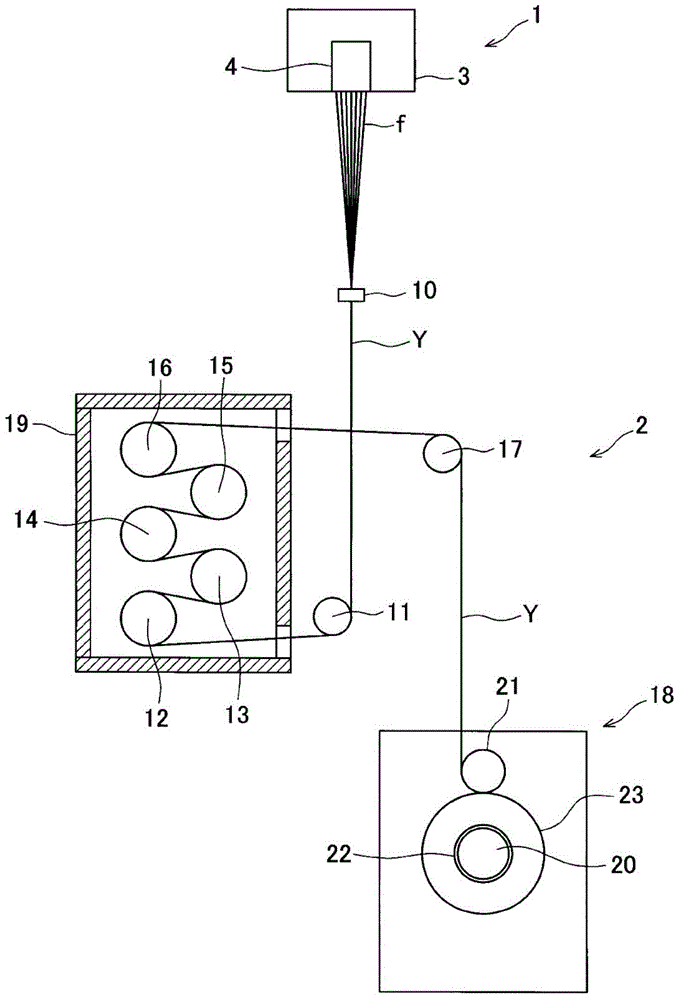

[0057] Next, embodiments of the present invention will be described. figure 1 It is a schematic configuration diagram of the melt spinning device 1 and the spinning take-up machine 2 that winds the yarn Y spun from the melt spinning device 1 according to the present embodiment. Additionally, the figure 1 The up and down direction of is defined as the up and down direction of the melt spinning device 1 and the spinning tractor 2. First, the schematic configuration of the melt spinning device 1 and the spinning drawer 2 will be described.

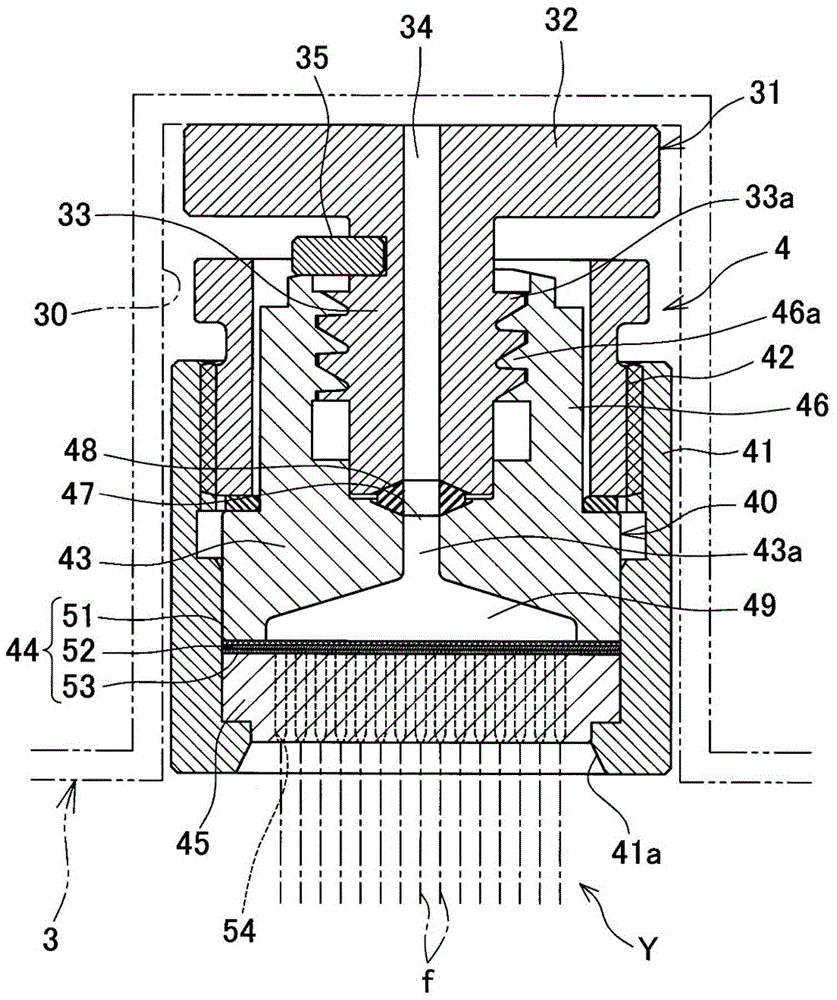

[0058] The melt spinning device 1 includes a heating box 3 and a plurality of spinning packs 4 detachably attached to the heating box 3 . Multiple spin packs 4 along figure 1 Arranged side by side in the vertical direction of the paper. A yarn Y composed of a plurality of single fibers f is spun downward from each spin pack 4 . The structure of the melt spinning device 1 including the spinning pack 4 will be described in detail later.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com