Exhaust purifying apparatus for internal combustion engine and exhaust purifying method for internal combustion engine

一种排气净化装置、内燃机的技术,应用在排气处理装置的电控、排气装置、排气处理装置的诊断装置等方向,能够解决氧浓度低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, embodiments of the present invention will be described in detail based on examples with reference to the drawings. However, unless otherwise specified, dimensions, materials, shapes, and relative arrangements of components described in this embodiment do not limit the scope of the present invention thereto.

[0025]

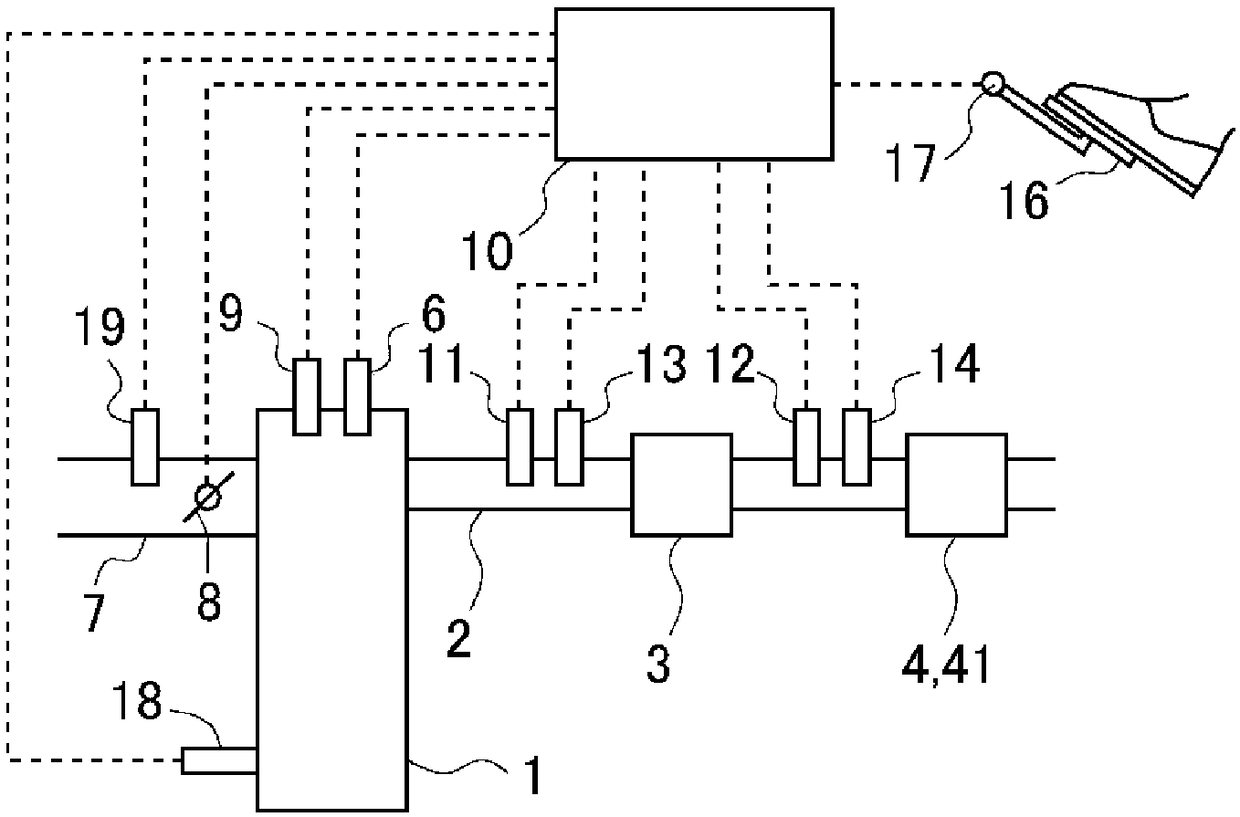

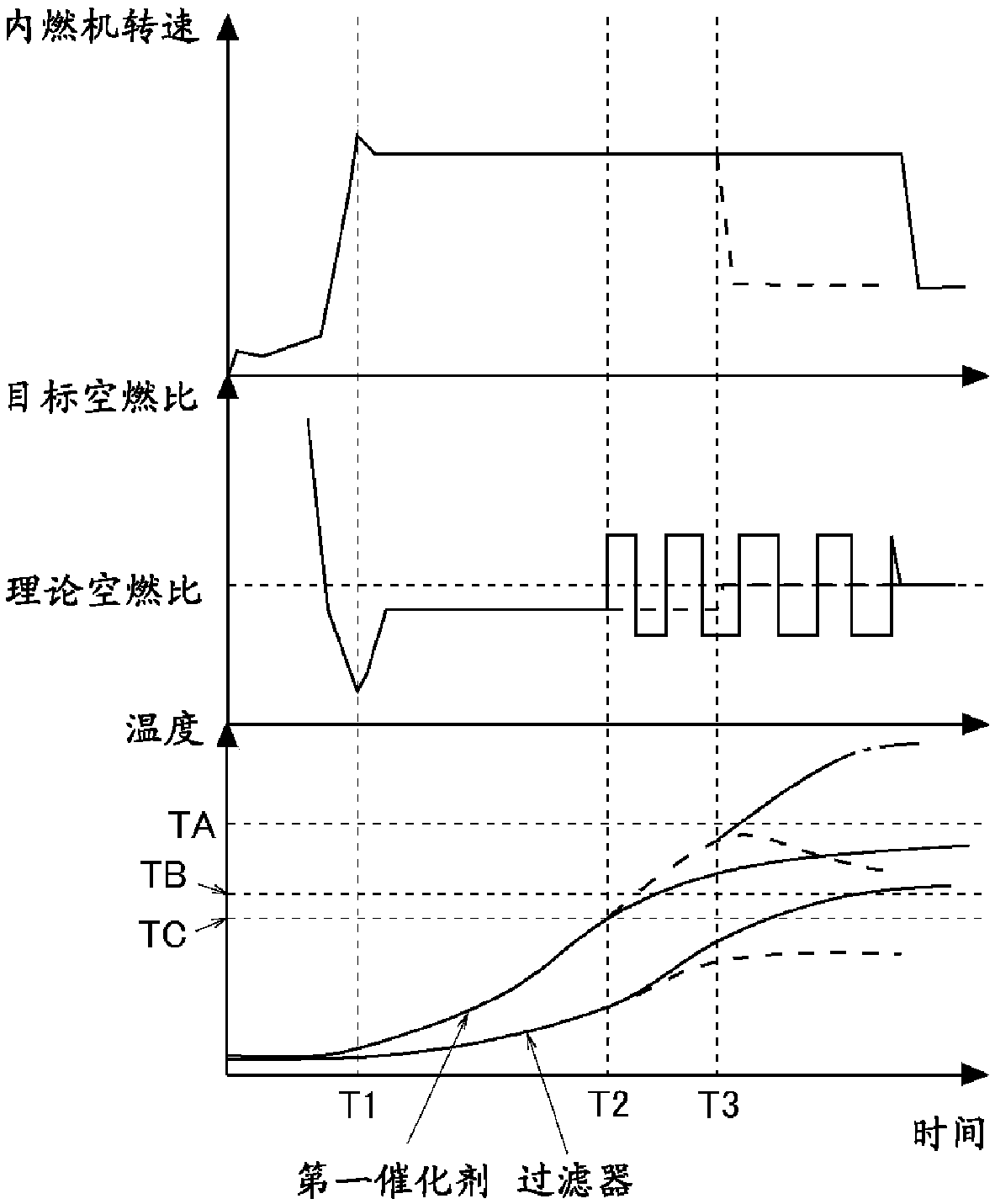

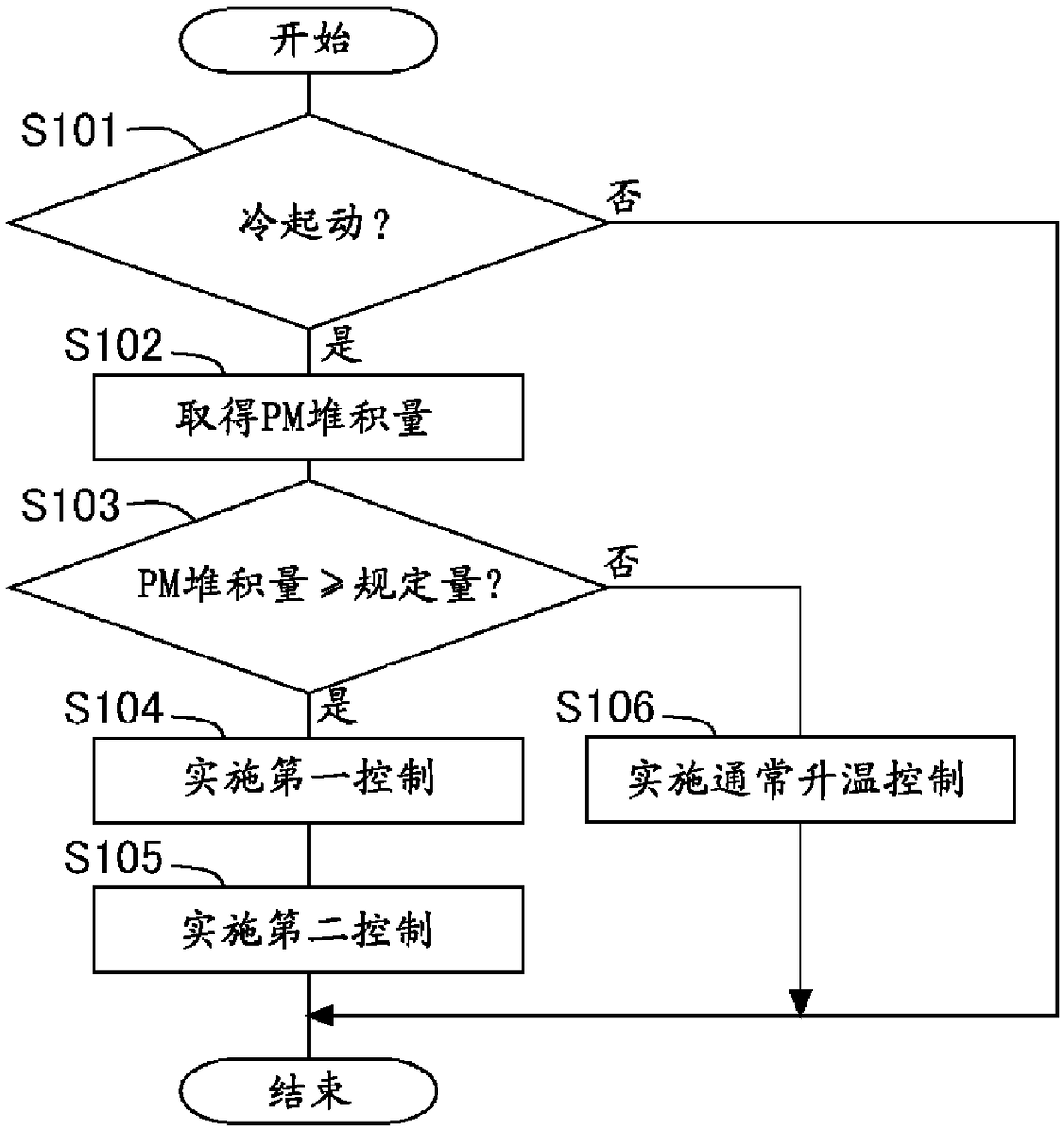

[0026] figure 1 It is a diagram showing the schematic configuration of the internal combustion engine 1 and the intake system and exhaust system of the internal combustion engine according to the present embodiment. figure 1 The internal combustion engine 1 shown is a gasoline engine. The internal combustion engine 1 is mounted on, for example, a vehicle. The exhaust passage 2 is connected to the internal combustion engine 1 . In the middle of the exhaust passage 2, a first catalyst 3 serving as a three-way catalyst and a filter 41 carrying a second catalyst 4 serving as a three-way catalyst are provided in this order from the upstream side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com