Polyacetal resin composition

A polyacetal resin and resin composition technology, applied in the field of molded products, can solve the problems of insufficient suppression of mold deposition and exudation, improvement of thermal stability of resin composition, and exudation of carboxylic acid hydrazide, etc., to achieve improved peripheral Environment, improvement of thermal stability, effect of physical property improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0141] (Manufacturing method of polyacetal resin composition)

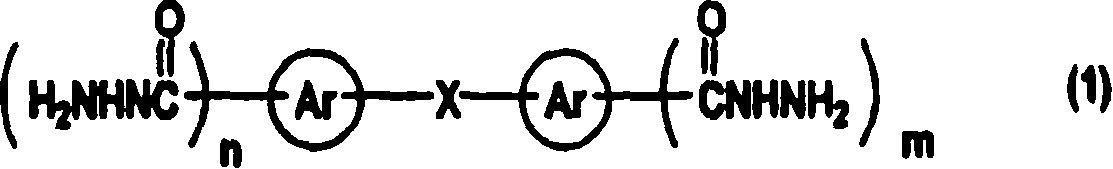

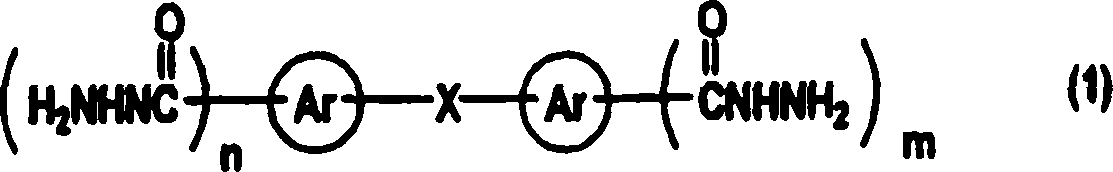

[0142]The polyacetal resin composition of the present invention can be powder granular mixture or melting mixture, can mix polyacetal resin and polycyclic aromatic carboxylic acid hydrazide, and other additives [stabilizer (antioxidant, processing stabilizing agent] as required agent, heat-resistant stabilizer and weather-resistant (light) stabilizer), impact modifier, sliding property modifier, coloring agent and / or filler] are prepared by mixing by a usual method. For example, the following methods can be used: (1) Feed all the ingredients from the main feeding port, knead and extrude through an extruder (single-screw or twin-screw extruder, etc.) to make pellets, and then carry out molding Method; (2) will not contain above-mentioned polycyclic aromatic carboxylic acid hydrazide composition (polyacetal resin, above-mentioned other additives etc.) by main feeding port feeding, will at least contain above-mention...

Embodiment 1-13 and 18-20

[0175] According to the ratio shown in Table 1 and Table 2, premix polycyclic aromatic carboxylic acid hydrazide, antioxidant, processing stabilizer, heat-resistant stabilizer, coloring agent, weather resistance in 100 parts by weight of polyacetal resin copolymer The (light) stabilizer was then added to the main feed port of a 30 mm diameter twin-screw extruder with a vent port, melt mixed, and made into a pellet-like composition. The obtained pellets were molded into predetermined test pieces by an injection molding machine, and the formaldehyde generation amount of the test pieces was evaluated. The results are shown in Table 1 and Table 2.

Embodiment 14-16

[0177] According to the ratio shown in Table 2, in 95 parts by weight of polyacetal resin copolymer (a-1), premix polycyclic aromatic carboxylic acid hydrazide (b-1), antioxidant (c-1), process Stabilizer (d-1), heat-resistant stabilizer (e-1), then from the main feed inlet of a 30mm diameter twin-screw extruder with an exhaust port, simultaneously from the rear of the exhaust port The side feeding port adds the granule of 5 weight parts polyacetal resin copolymer (a-1) and 0.05 weight part heat-resistant stabilizer [is (e-5) in the embodiment 14, is (e in the embodiment 15) -6), the mixture that is (e-7) heat-resistant stabilizer] in embodiment 16, melt mix, make the composition of pellet shape. The obtained pellets were molded into predetermined test pieces by an injection molding machine, and the formaldehyde generation amount of the test pieces was evaluated. The results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com