Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2282 results about "Flash-lamp" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The electric flash-lamp uses electric current to start flash powder burning, to provide a brief sudden burst of bright light. It was principally used for flash photography in the early 20th century but had other uses as well. Previously, photographers' flash powder, introduced in 1887 by Adolf Miethe and Johannes Gaedicke, had to be ignited manually, exposing the user to greater risk.

Semiconductor thin film forming method, production methods for semiconductor device and electrooptical device, devices used for these methods, and semiconductor device and electrooptical device

InactiveUS7183229B2Promote crystallizationTransistorDrying solid materials with heatSingle crystalCrystallinity

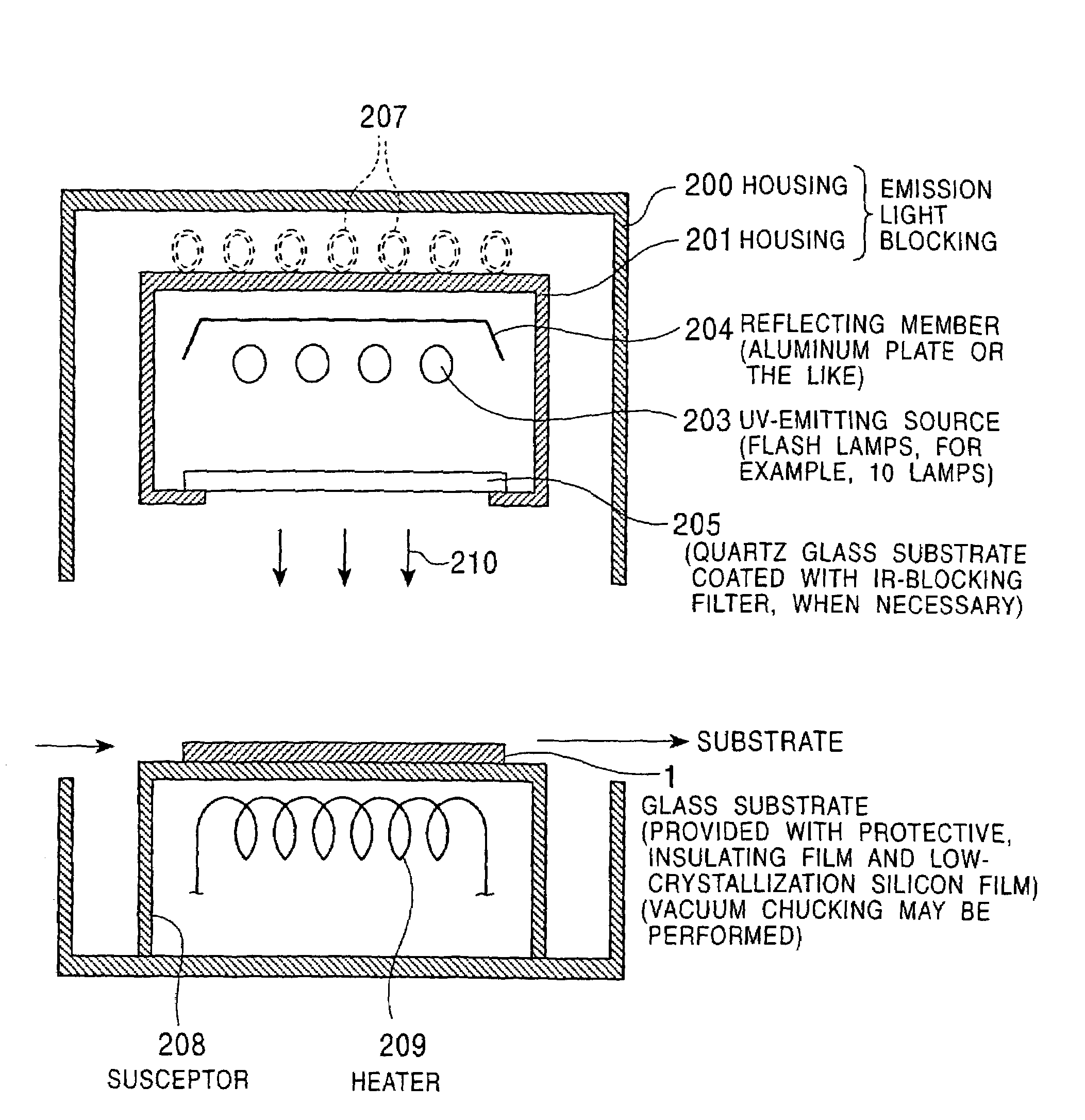

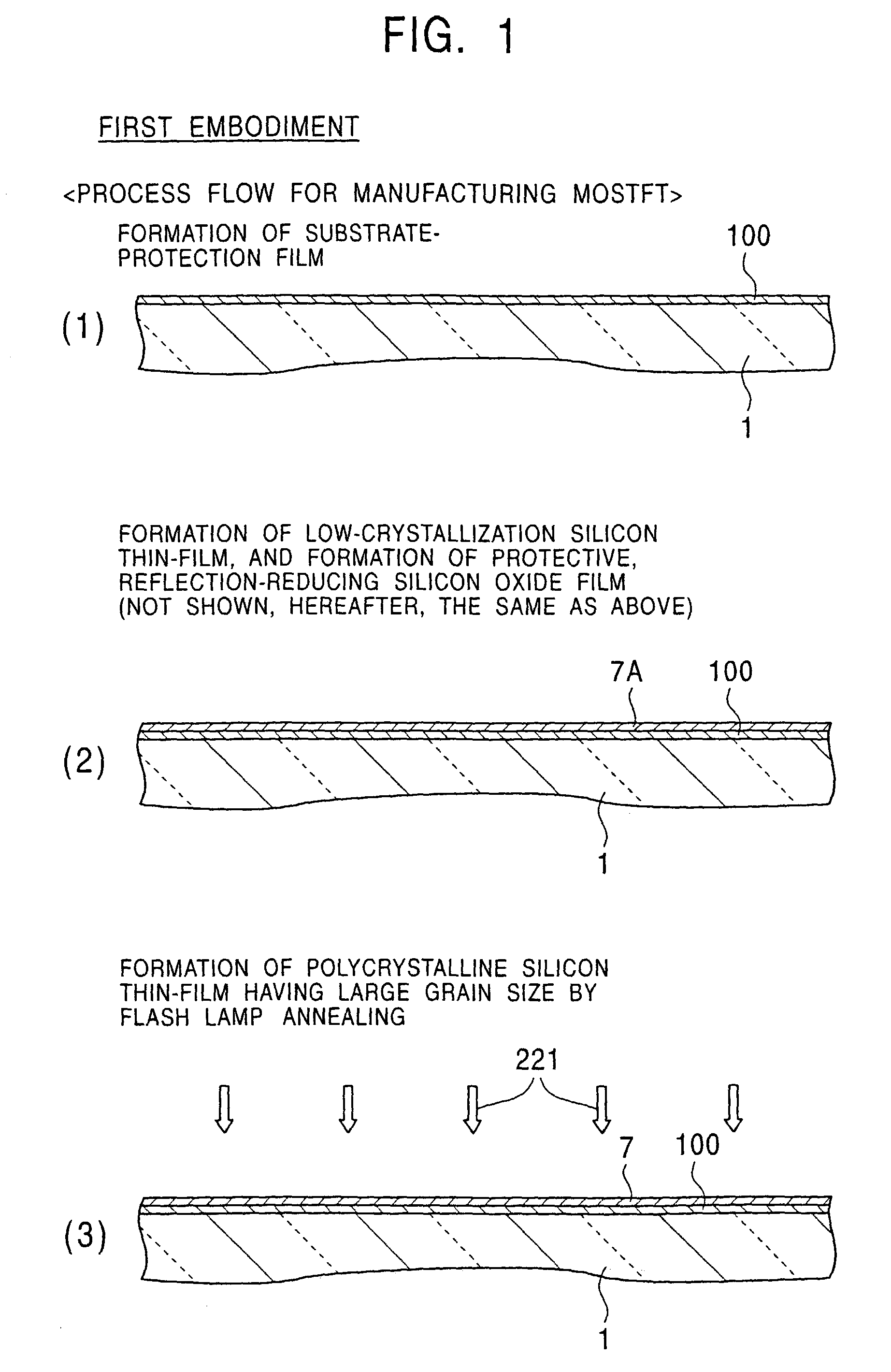

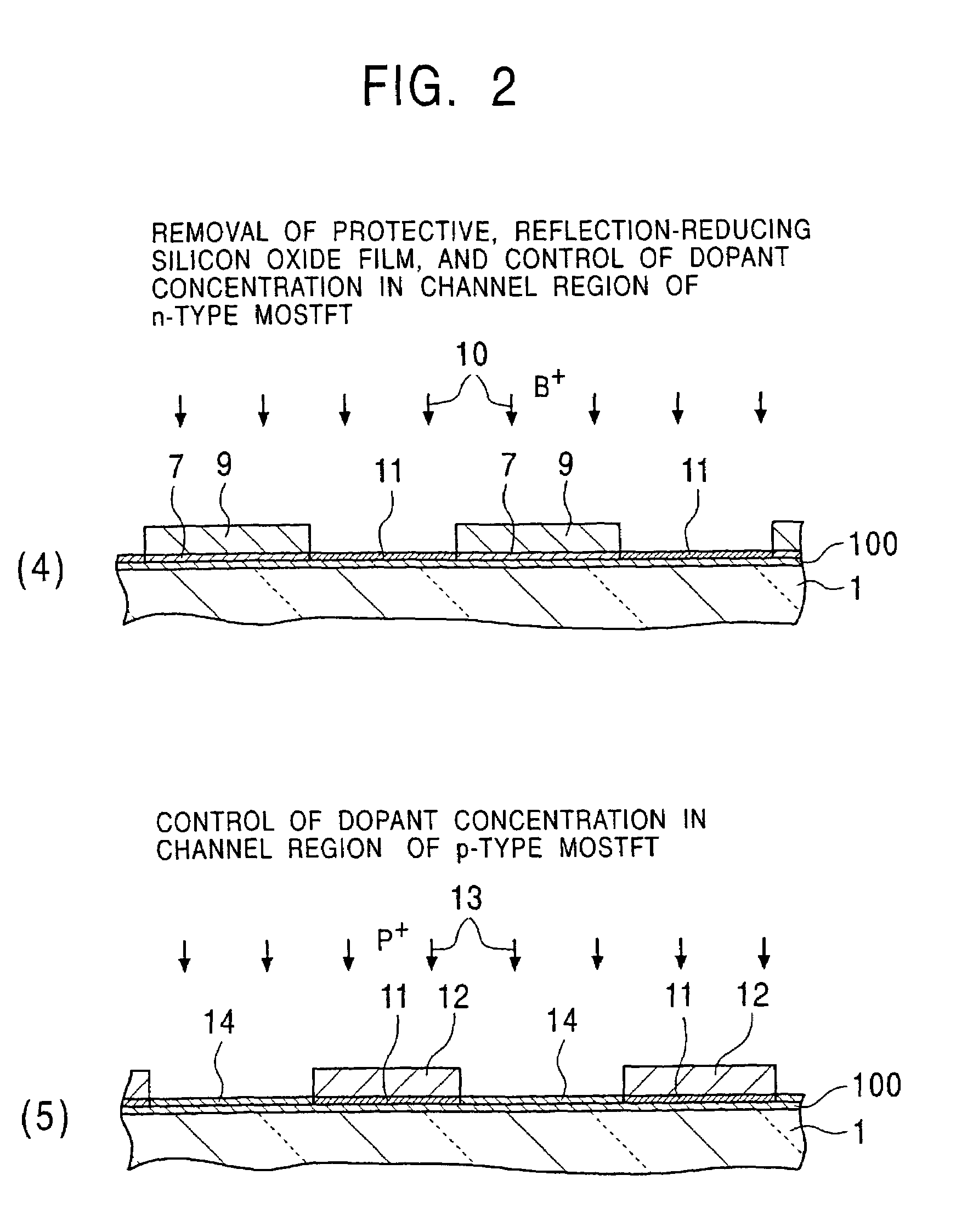

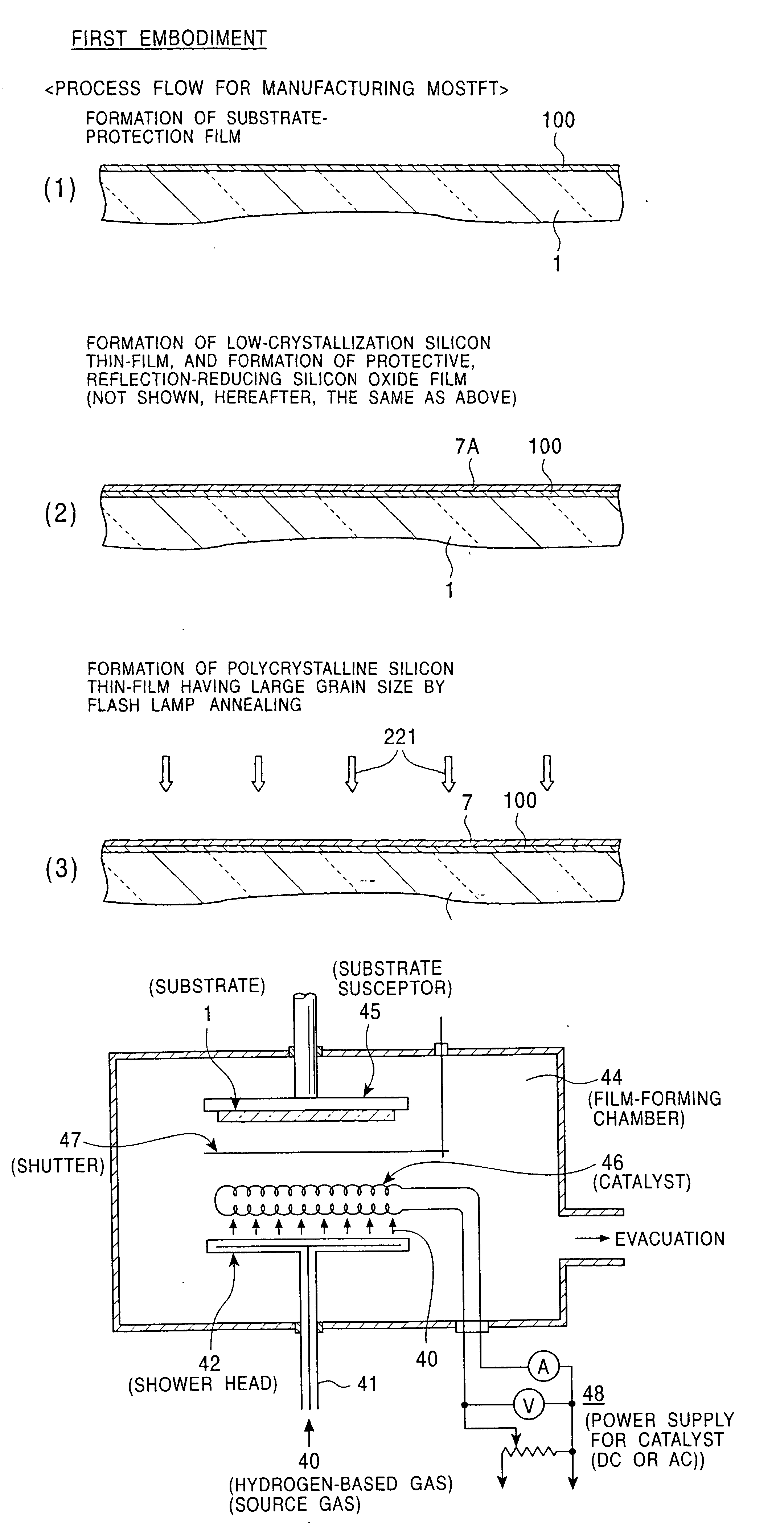

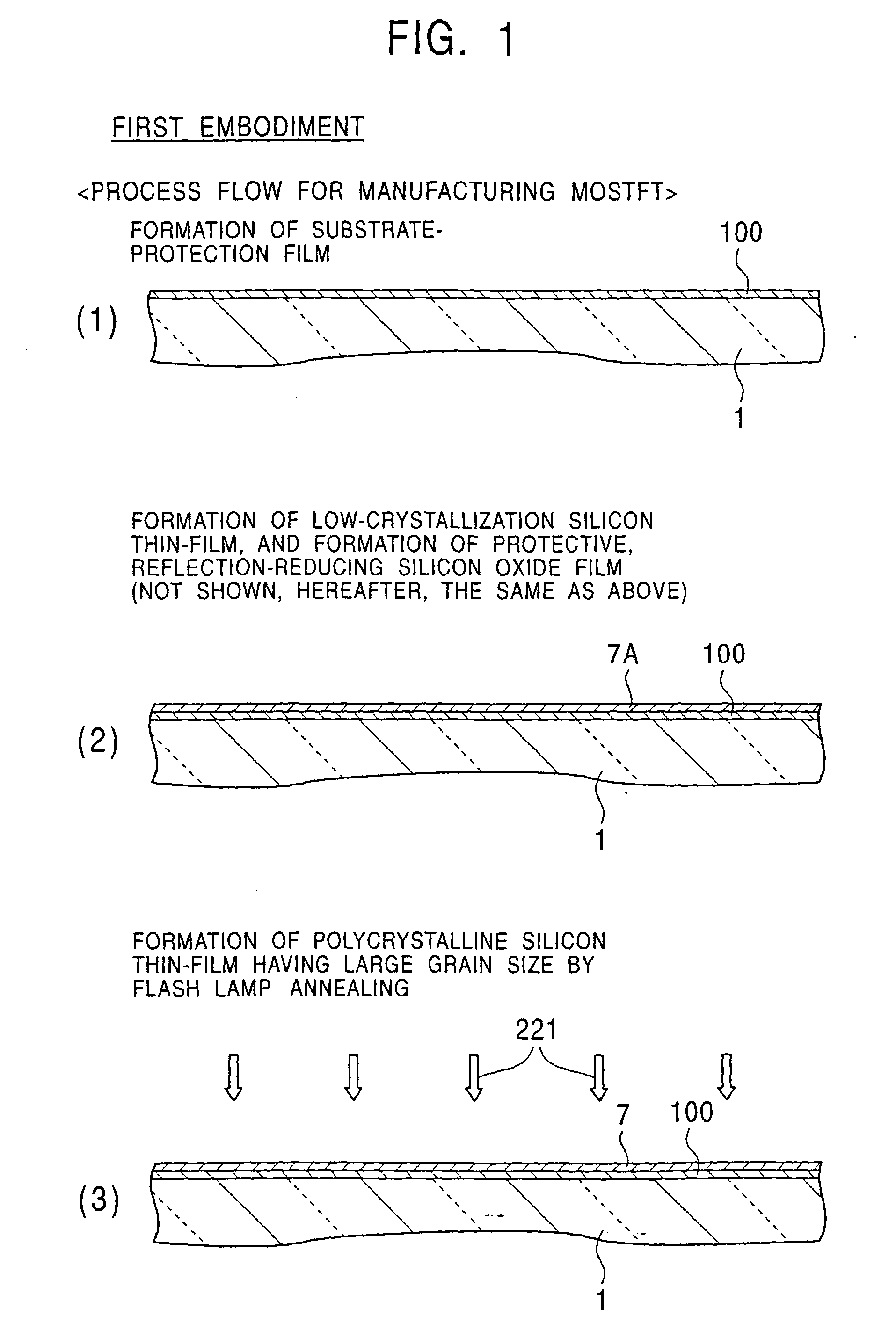

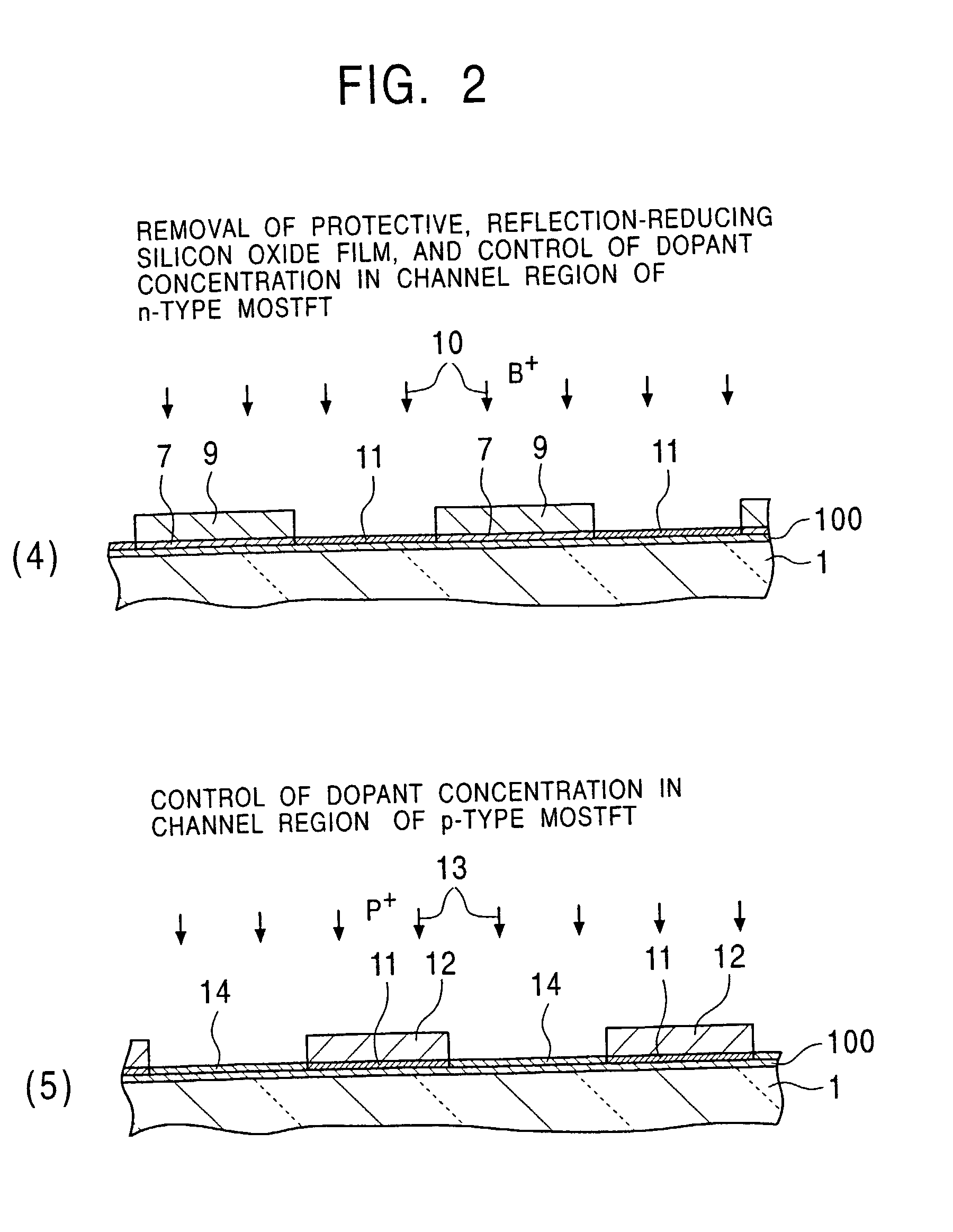

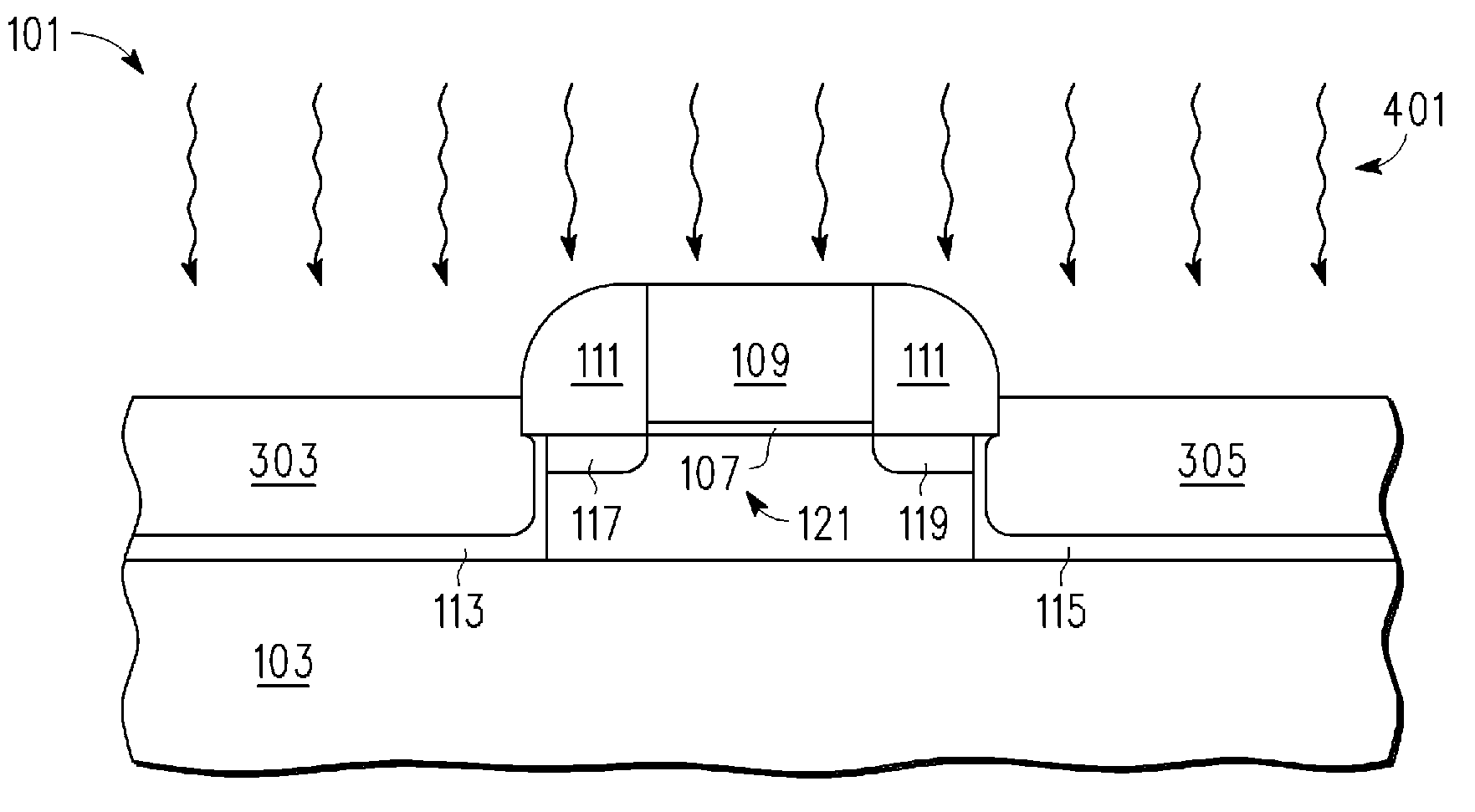

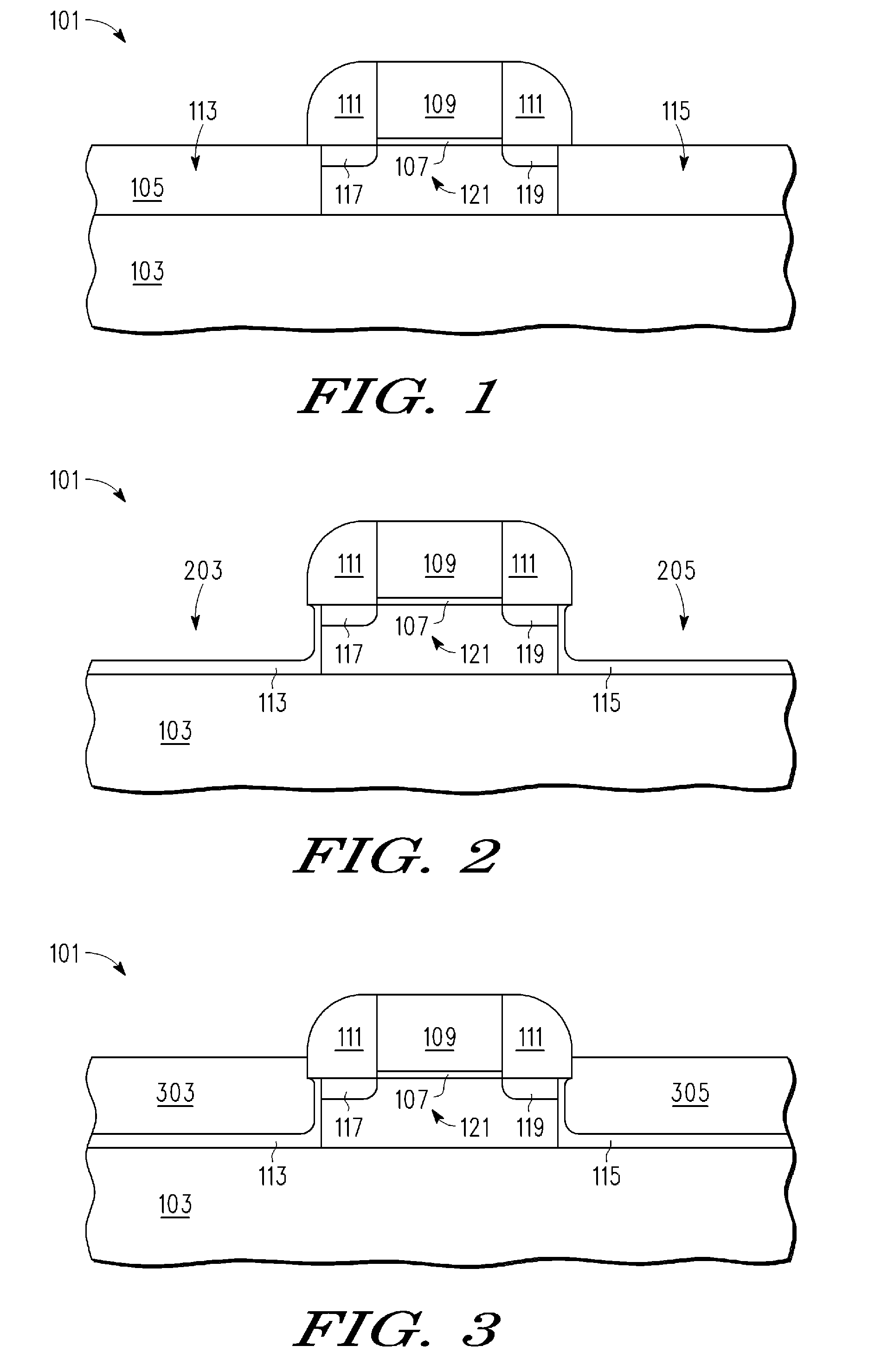

An object of the present invention is to provide a method for easily forming a polycrystalline semiconductor thin-film, such as polycrystalline silicon having high crystallinity and high quality, or a single crystalline semiconductor thin-film at inexpensive cost, the crystalline semiconductor thin-film having a large area, and to provide an apparatus for processing the method described above. In forming a polycrystalline (or single crystalline) semiconductor thin-film (7), such as a polycrystalline silicon thin-film, having high crystallinity and a large grain size on a substrate (1), or in forming a semiconductor device having the polycrystalline (or single crystalline) semiconductor thin-film (7) on the substrate (1), a method comprises forming a low-crystallization semiconductor thin-film (7A) on the substrate (1), and subsequently heating and cooling this low-crystallization semiconductor thin-film (7A) to a fusion, a semi-fusion, or a non-fusion state by flash lamp annealing to facilitate the crystallization of the low-crystallization semiconductor thin-film, whereby a polycrystalline (single crystalline) semiconductor thin-film (7) is obtained. A method for forming the semiconductor device and an apparatus for processing the methods are also disclosed.

Owner:SONY CORP

Semiconductor thin film forming method, production methods for semiconductor device and electrooptical device, devices used for these methods, and semiconductor device and electrooptical device

InactiveUS20030013280A1Promote crystallizationTransistorPolycrystalline material growthSingle crystalCrystallinity

An object of the present invention is to provide a method for easily forming a polycrystalline semiconductor thin-film, such as polycrystalline silicon having high crystallinity and high quality, or a single crystalline semiconductor thin-film at inexpensive cost, the crystalline semiconductor thin-film having a large area, and to provide an apparatus for processing the method described above. In forming a polycrystalline (or single crystalline) semiconductor thin-film (7), such as a polycrystalline silicon thin-film, having high crystallinity and a large grain size on a substrate (1), or in forming a semiconductor device having the polycrystalline (or single crystalline) semiconductor thin-film (7) on the substrate (1), a method comprises forming a low-crystallization semiconductor thin-film (7A) on the substrate (1), and subsequently heating and cooling this low-crystallization semiconductor thin-film (7A) to a fusion, a semi-fusion, or a non-fusion state by flash lamp annealing to facilitate the crystallization of the low-crystallization semiconductor thin-film, whereby a polycrystalline (single crystalline) semiconductor thin-film (7) is obtained. A method for forming the semiconductor device and an apparatus for processing the methods are also disclosed.

Owner:SONY CORP

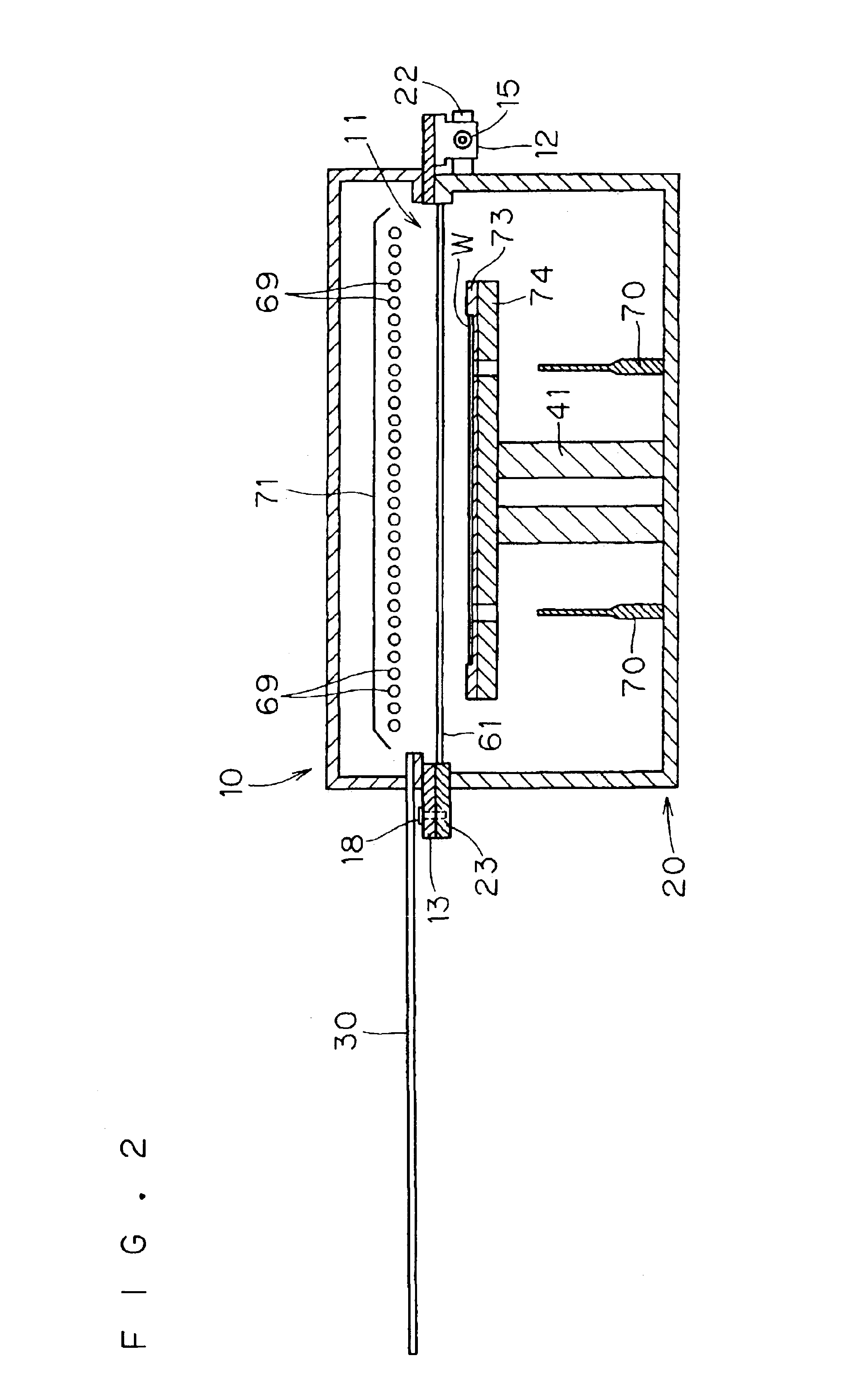

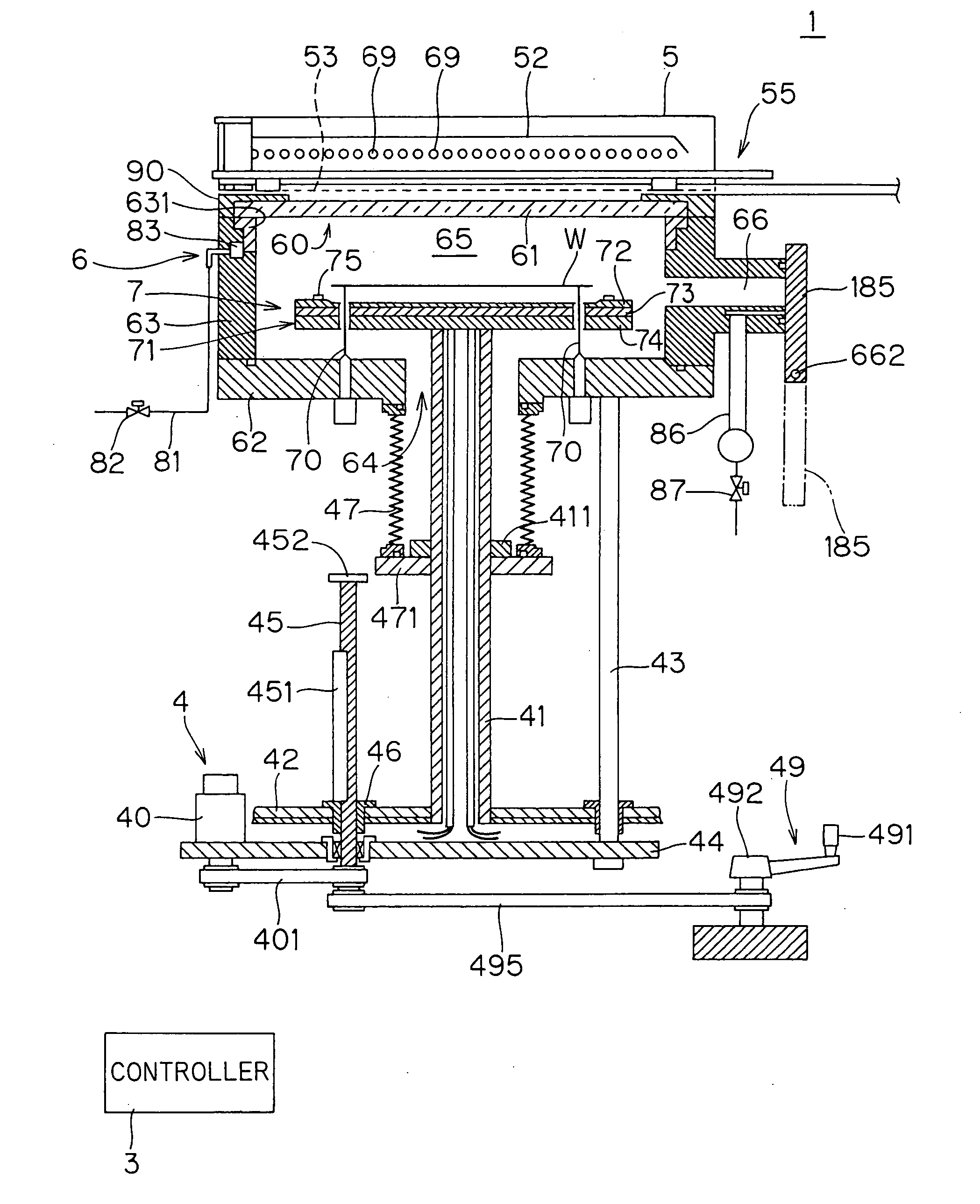

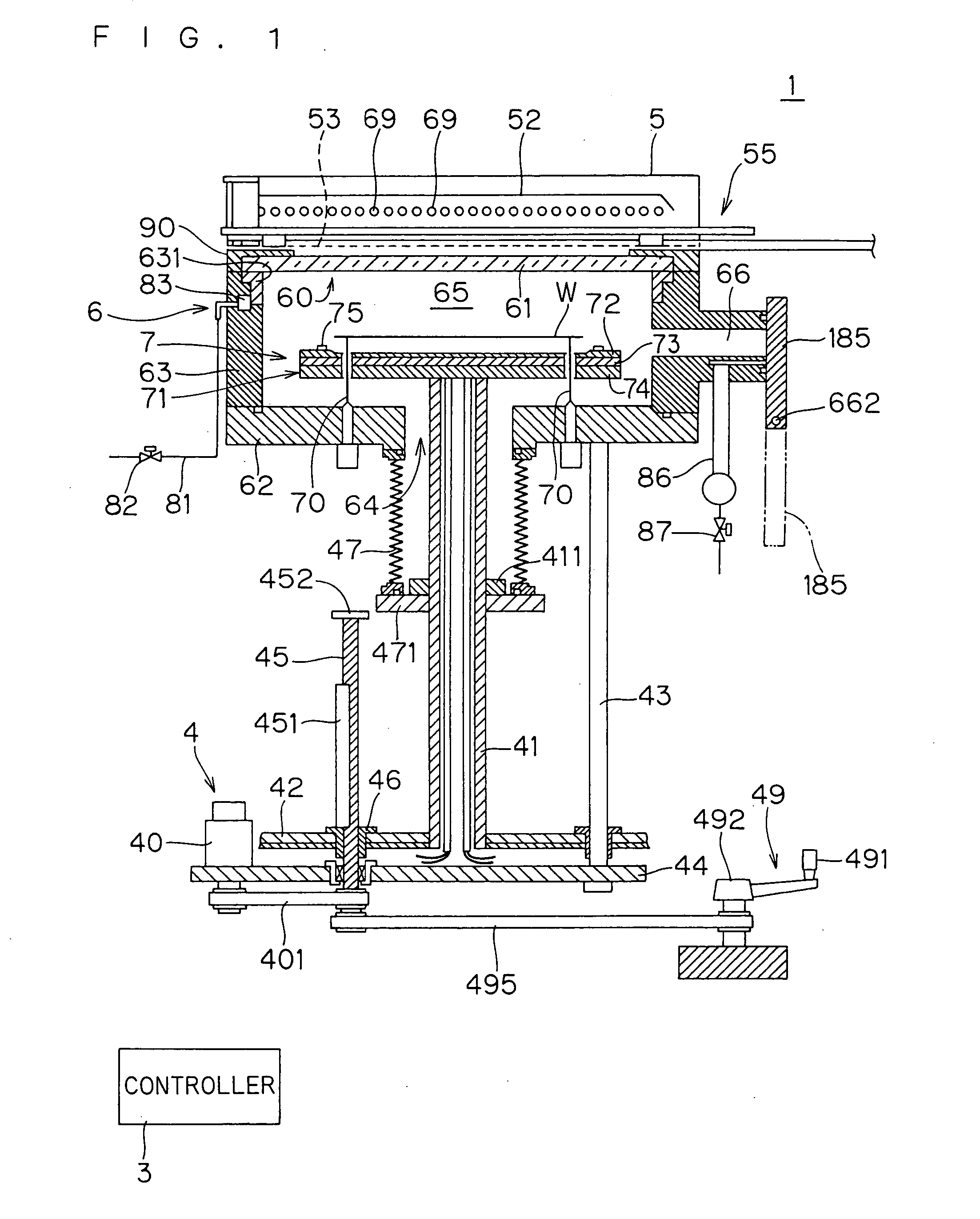

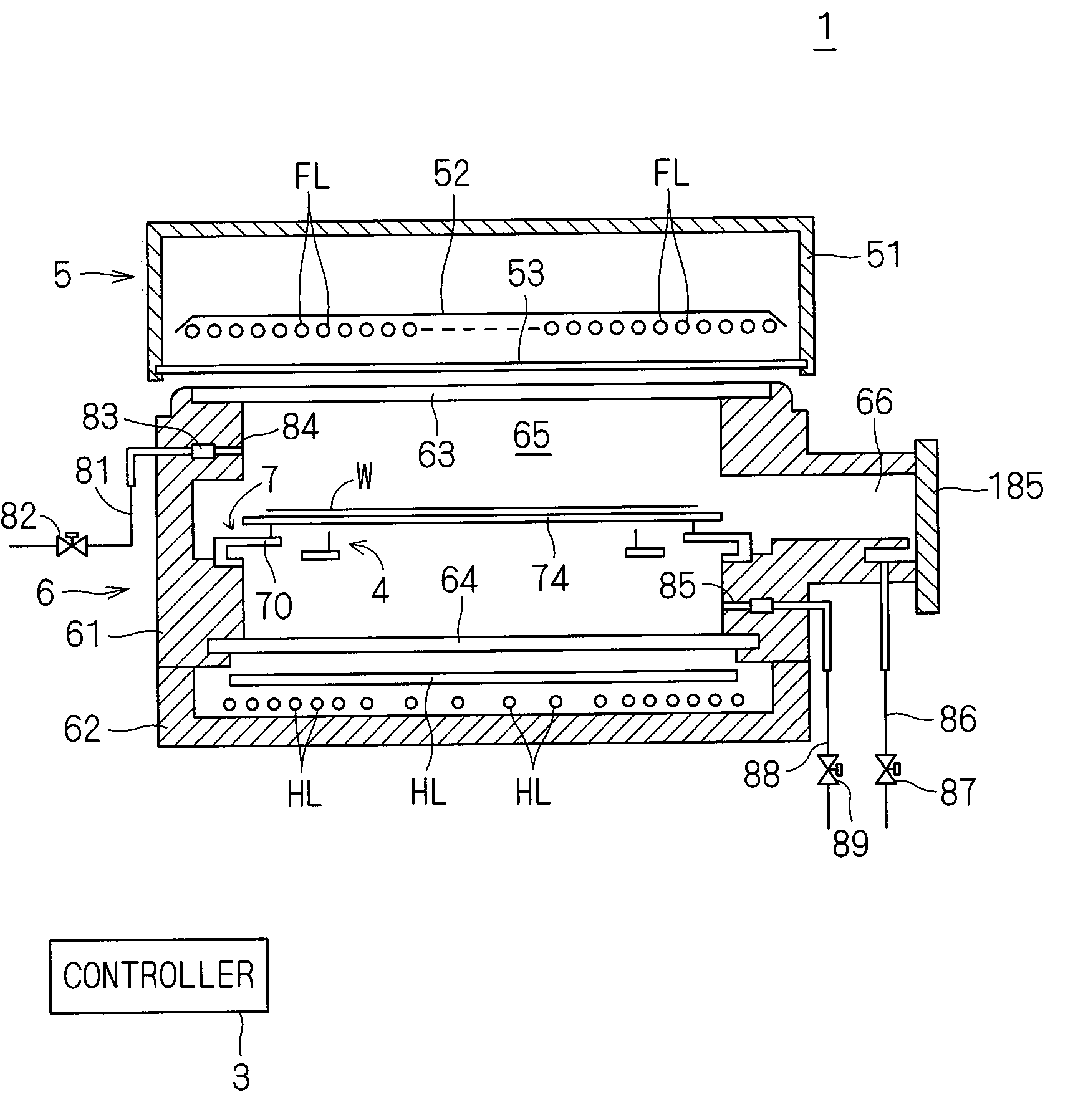

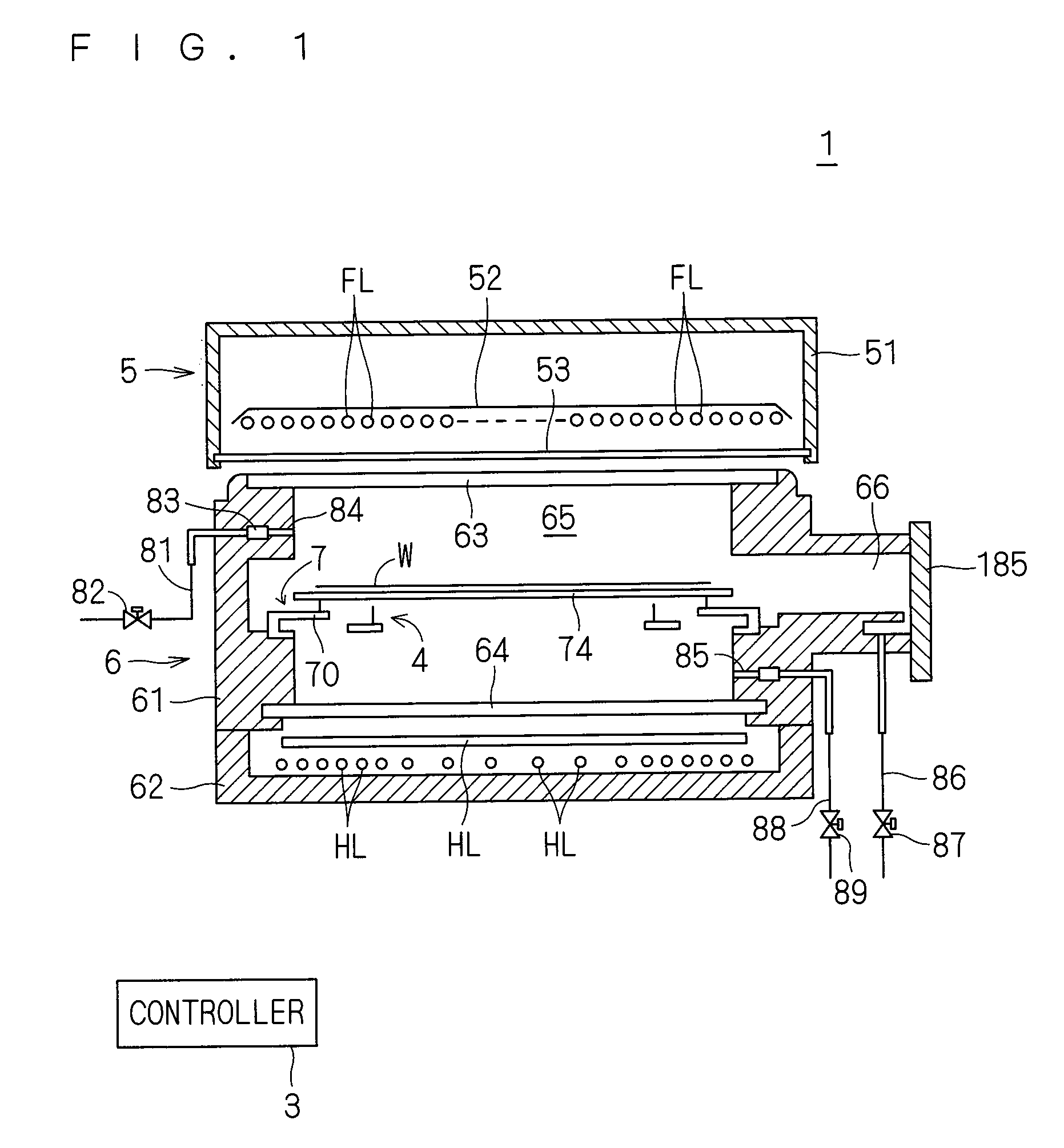

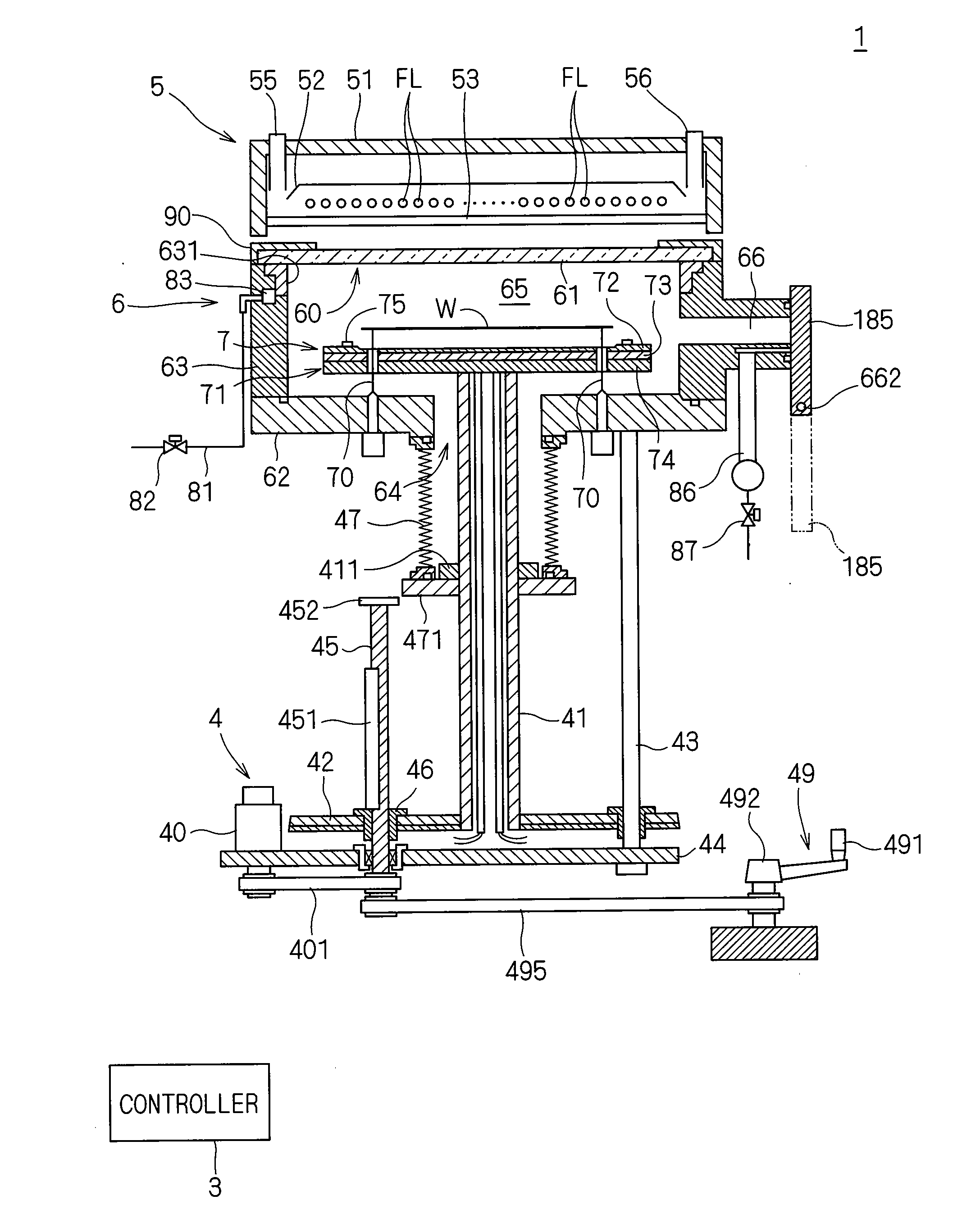

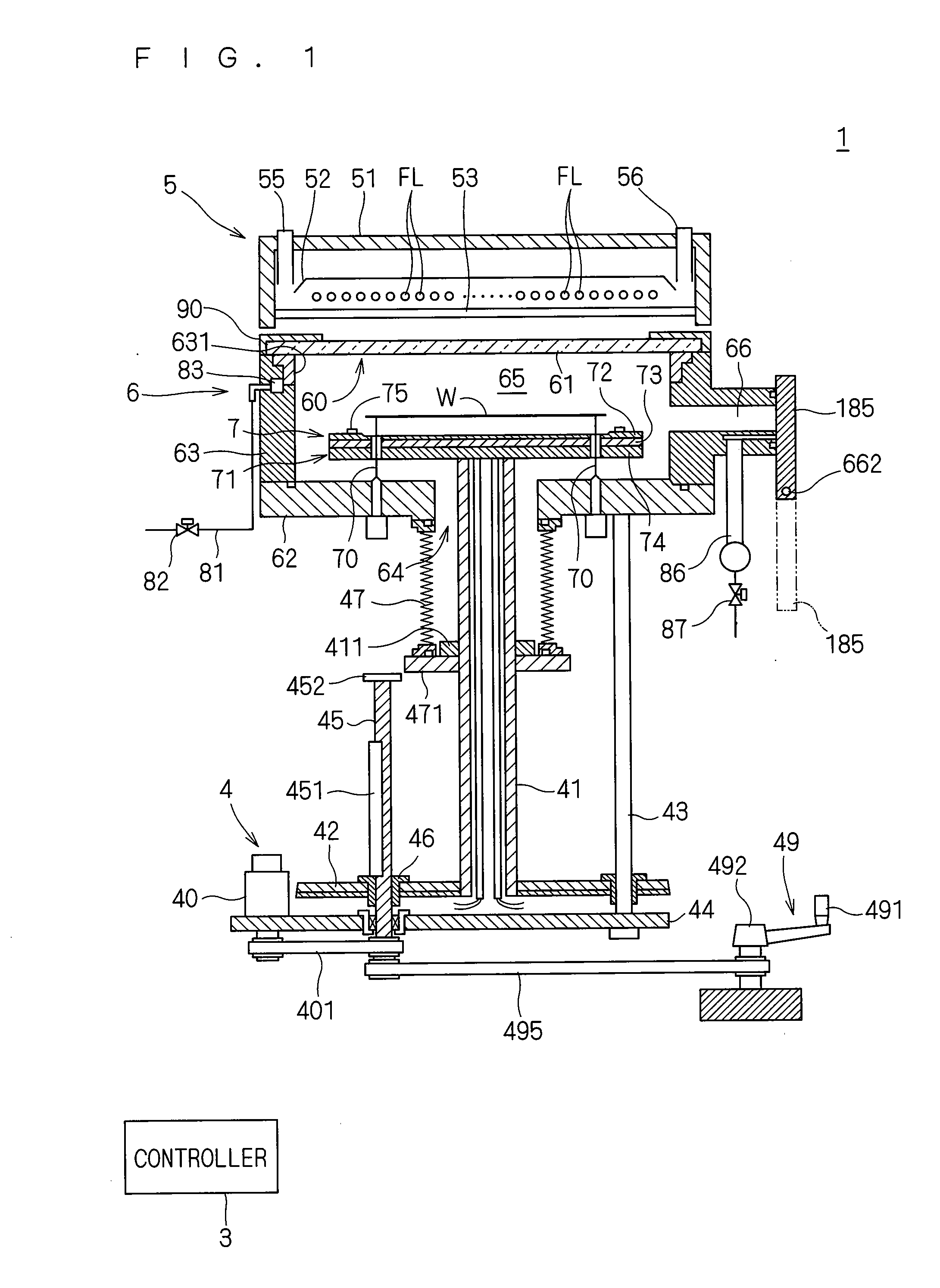

Thermal processing apparatus for substrate employing photoirradiation

ActiveUS6843202B2Avoid breakingSemiconductor/solid-state device manufacturingRadiation thermographyIrradiationSemiconductor

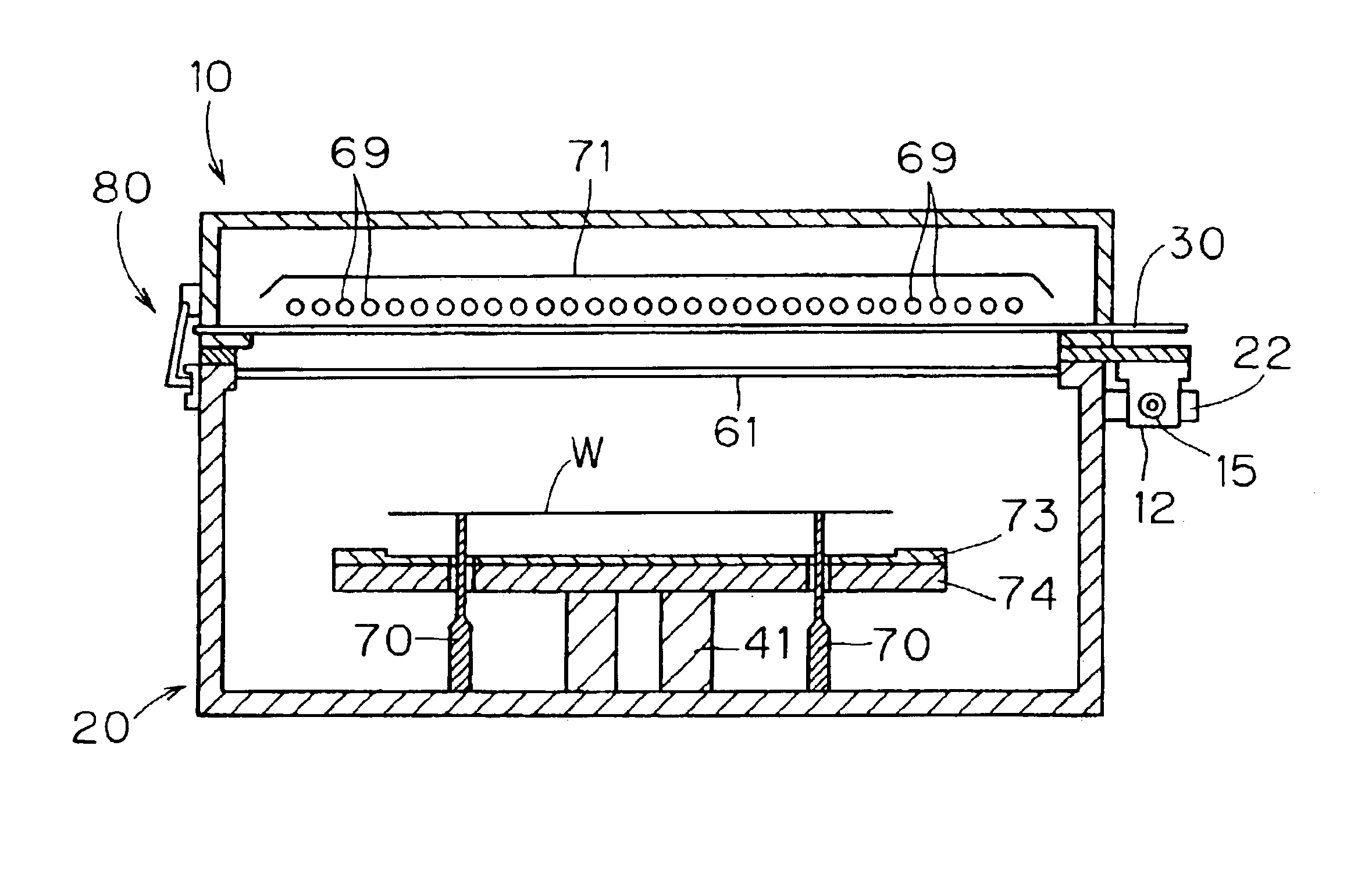

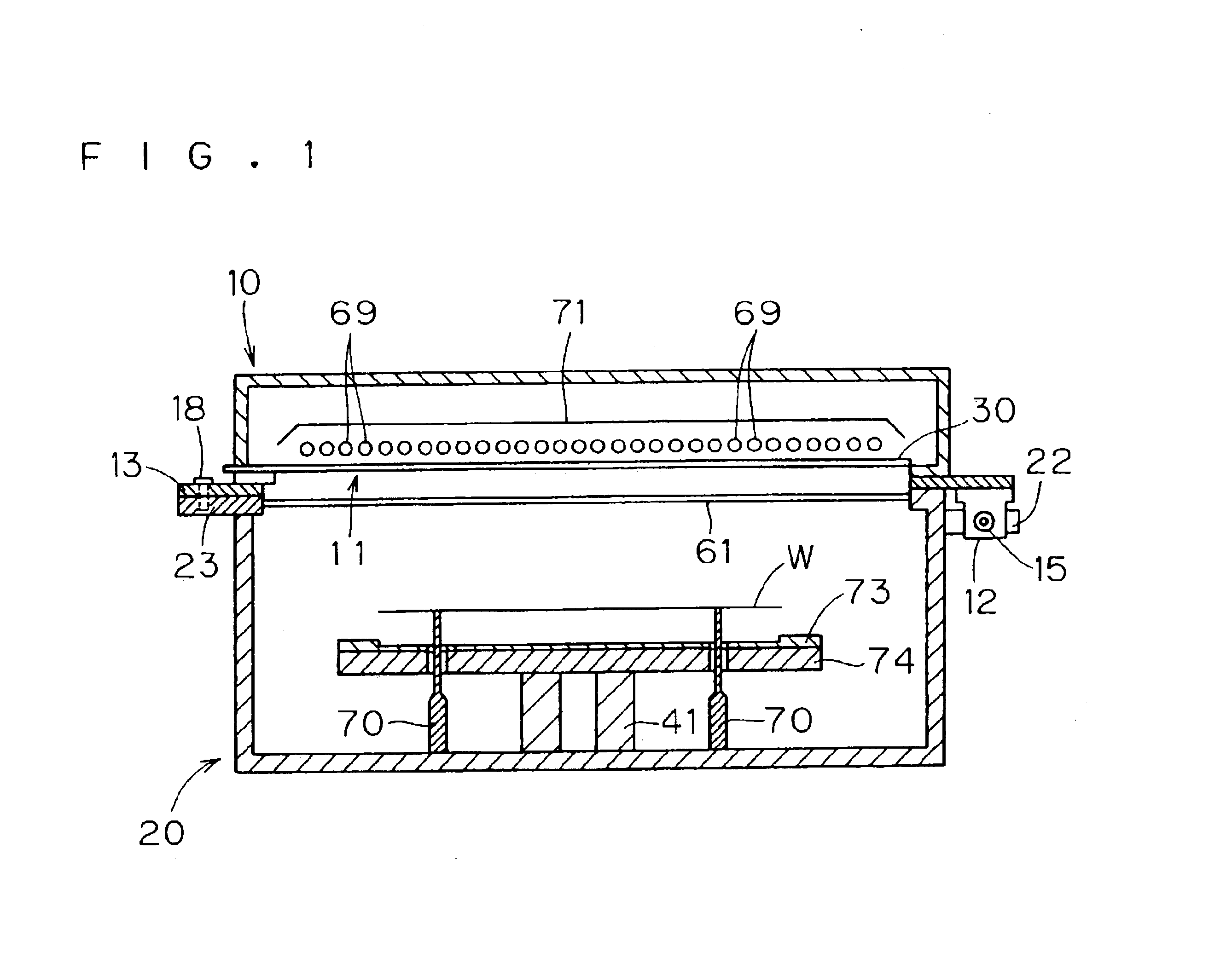

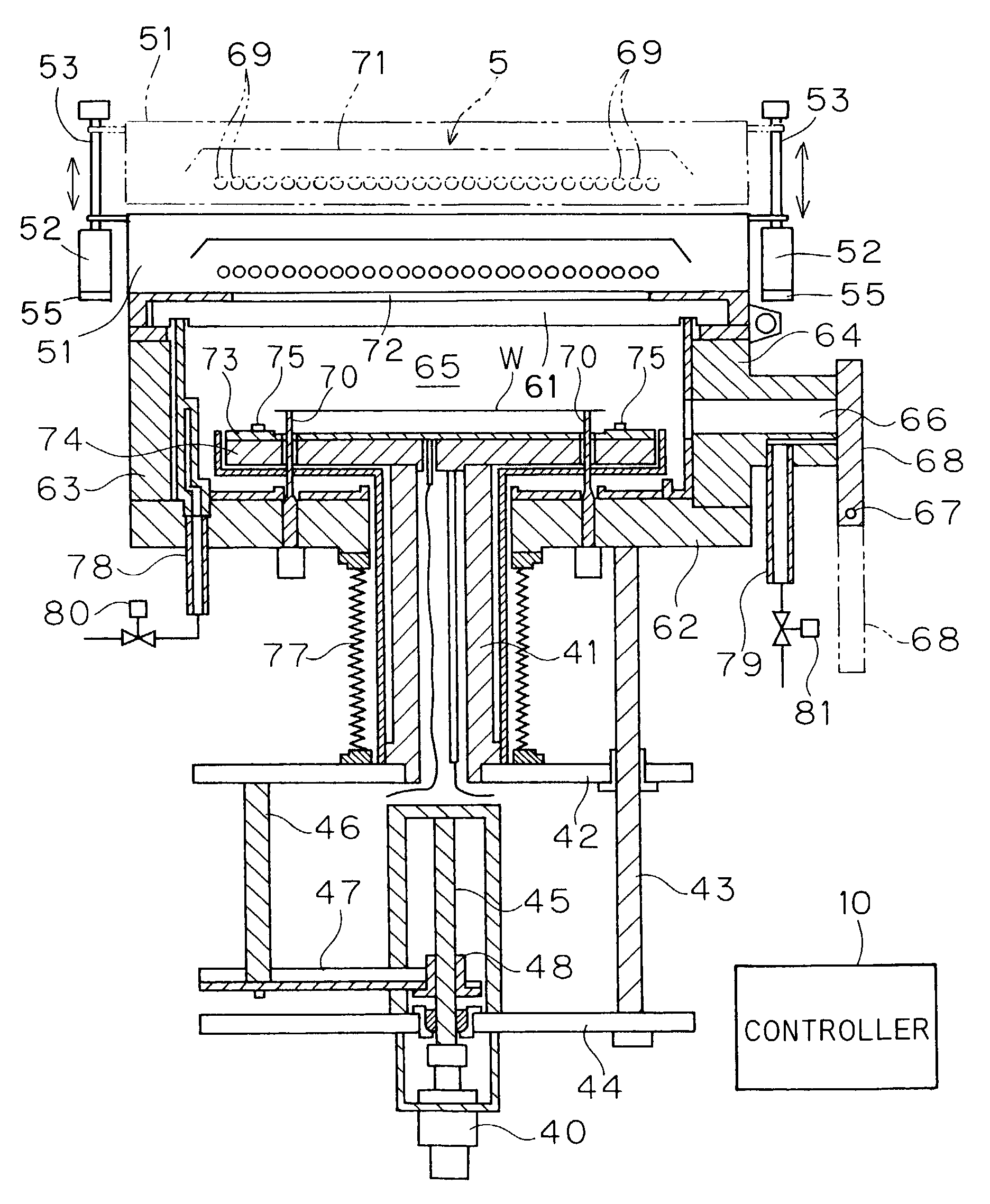

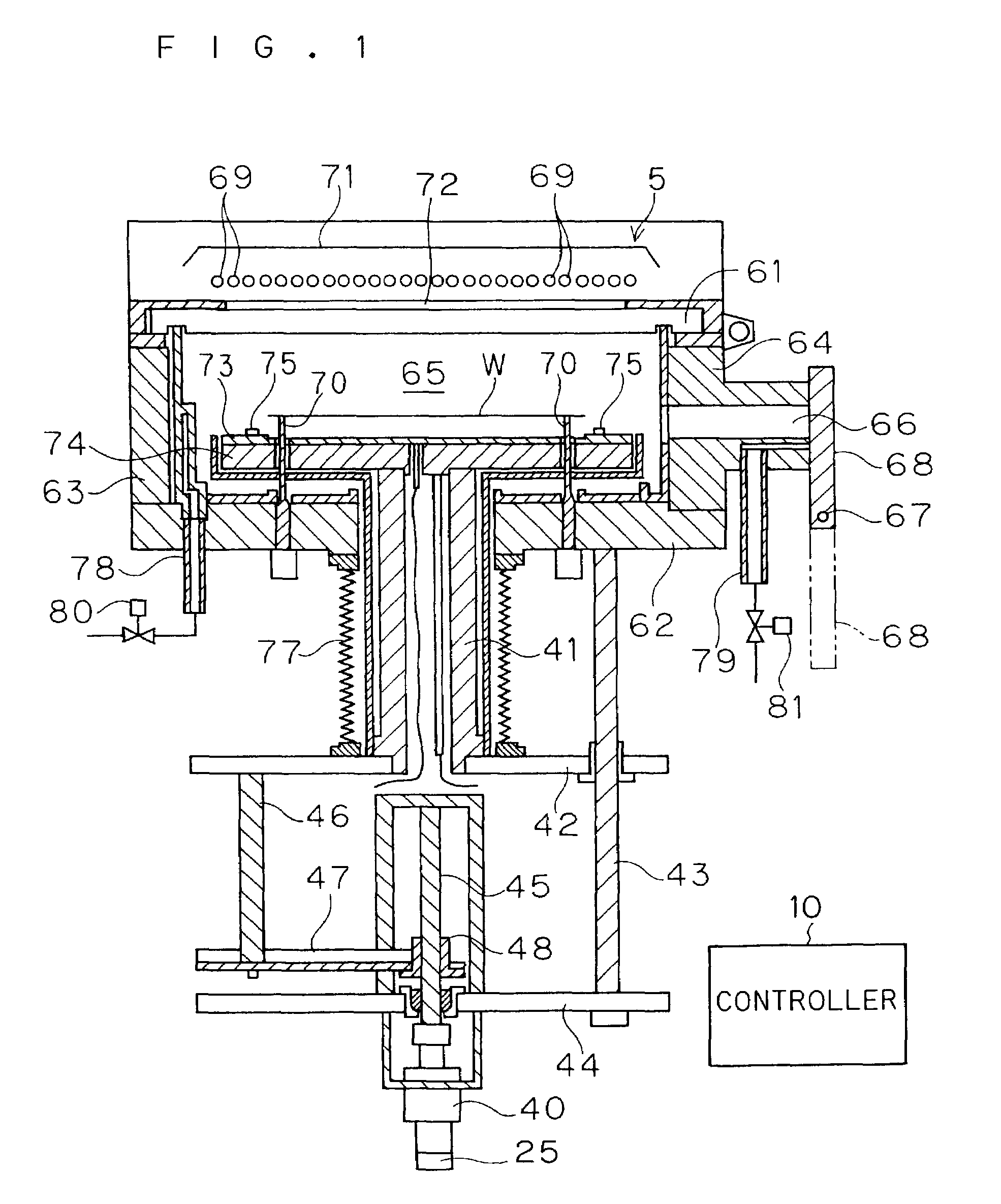

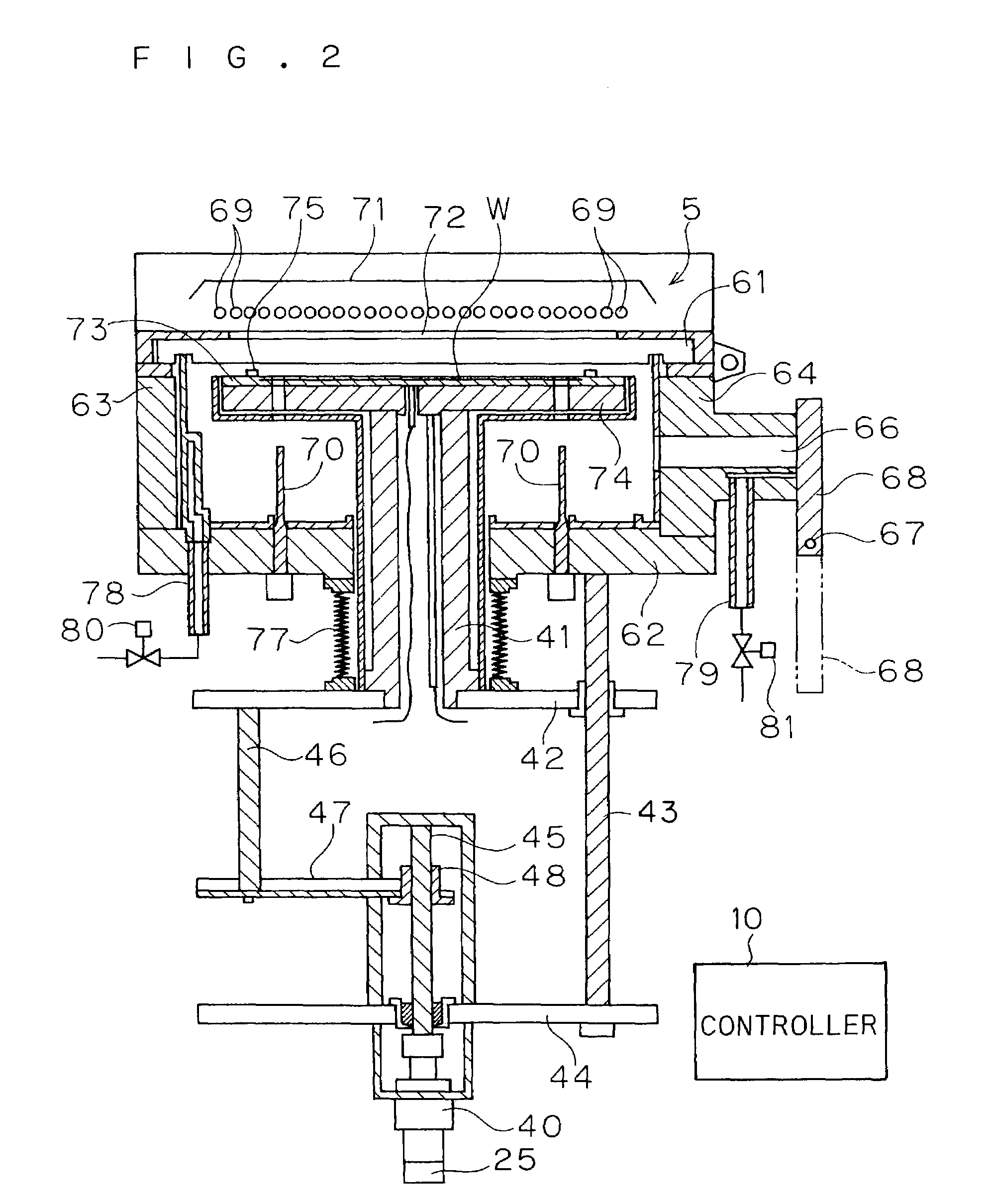

A lamp house storing a plurality of flash lamps and a chamber storing and holding a semiconductor wafer are fitted to each other in an openable / closable manner. The lamp house and the chamber are fixed to a closed state with male screws. In order to process a semiconductor wafer, a shutter plate is drawn out to open an irradiation window. In this state, the shutter plate shields a space located above the male screws so that the male screws cannot be detached for opening the lamp house and the chamber. In order to open the lamp house and the chamber, the shutter plate must be inserted for shielding the irradiation window while opening the space located above the male screws. Thus, a thermal processing apparatus capable of preventing the lamps from breaking during maintenance thereof is provided.

Owner:DAINIPPON SCREEN MTG CO LTD

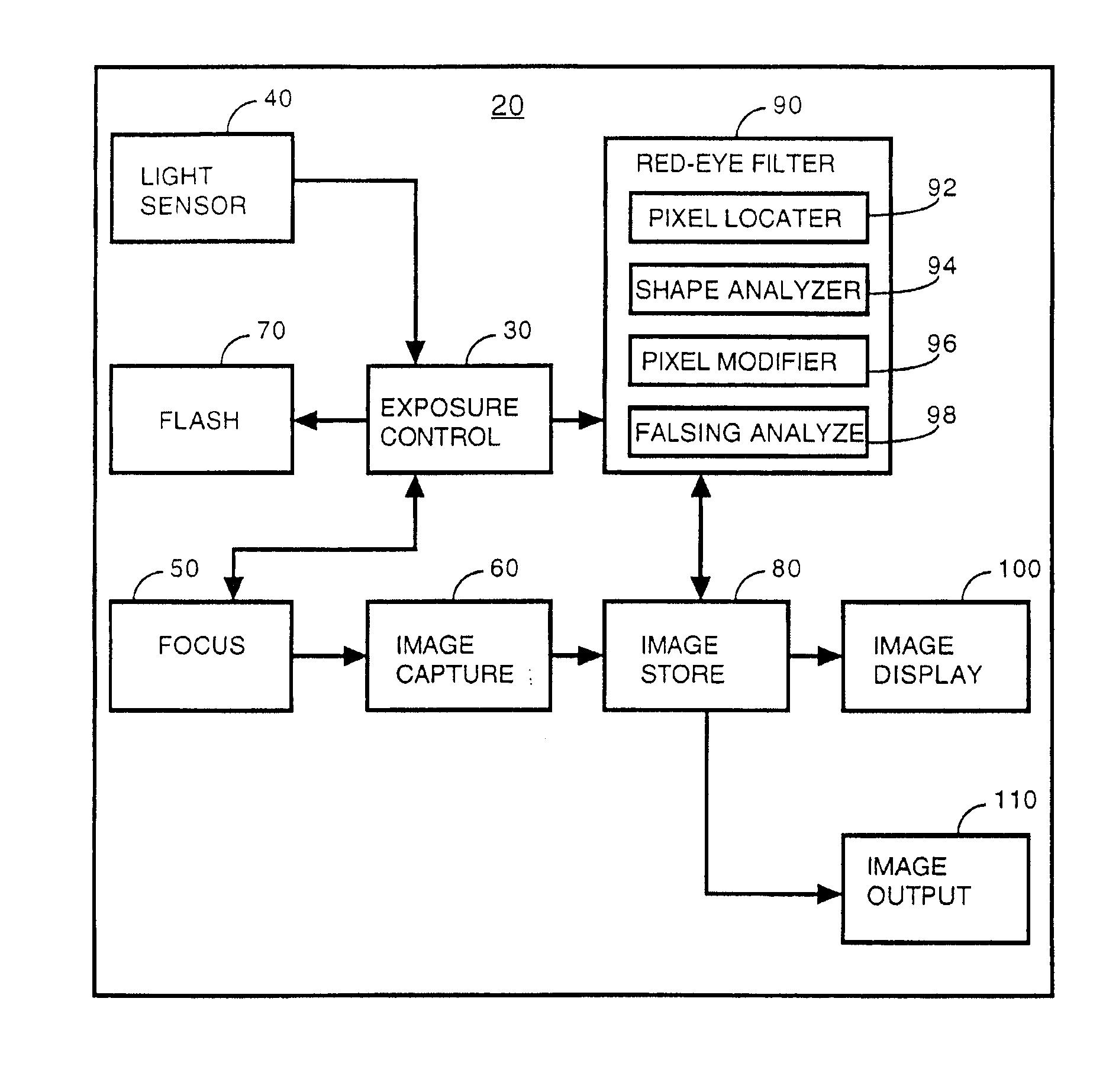

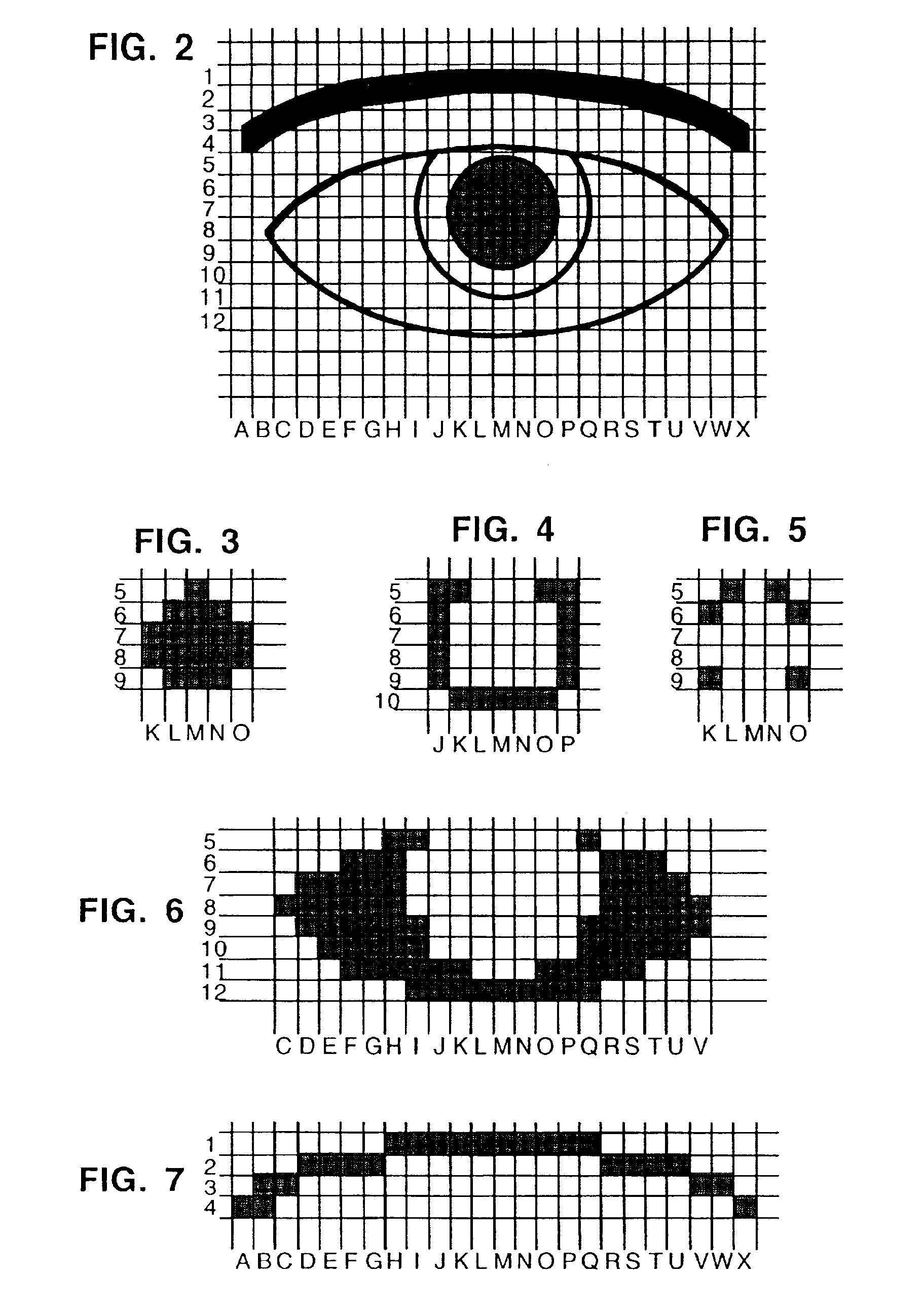

Optimized Performance and Performance for Red-Eye Filter Method and Apparatus

A digital camera has an integral flash and stores and displays a digital image. Under certain conditions, a flash photograph taken with the camera may result in a red-eye phenomenon due to a reflection within an eye of a subject of the photograph. A digital apparatus has a red-eye filter which analyzes the stored image for the red-eye phenomenon and modifies the stored image to eliminate the red-eye phenomenon by changing the red area to black. The modification of the image is enabled when a photograph is taken under conditions indicative of the red-eye phenomenon. The modification is subject to anti-falsing analysis which further examines the area around the red-eye area for indicia of the eye of the subject. The detection and correction can be optimized for performance and quality by operating on subsample versions of the image when appropriate.

Owner:FOTONATION LTD

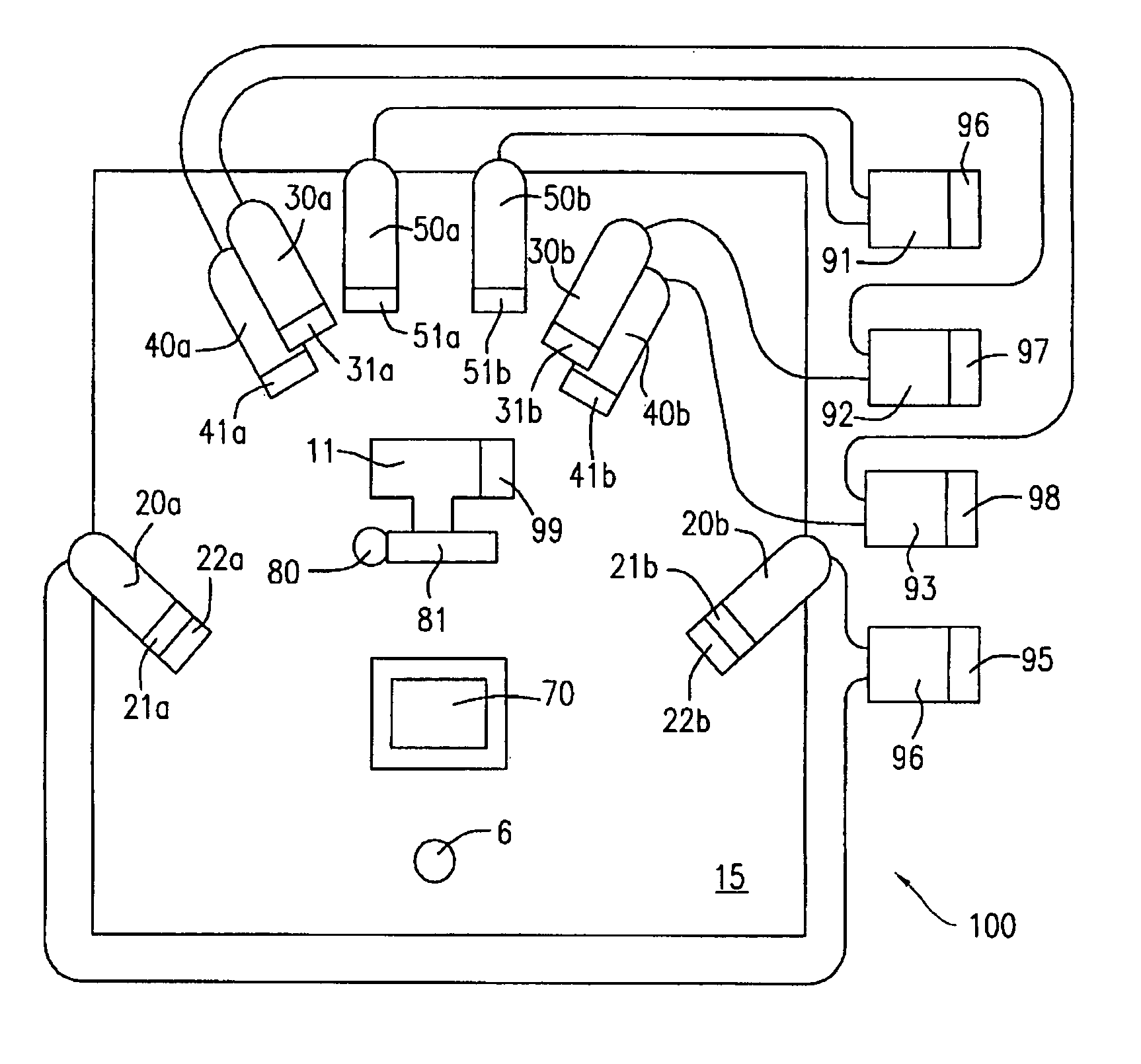

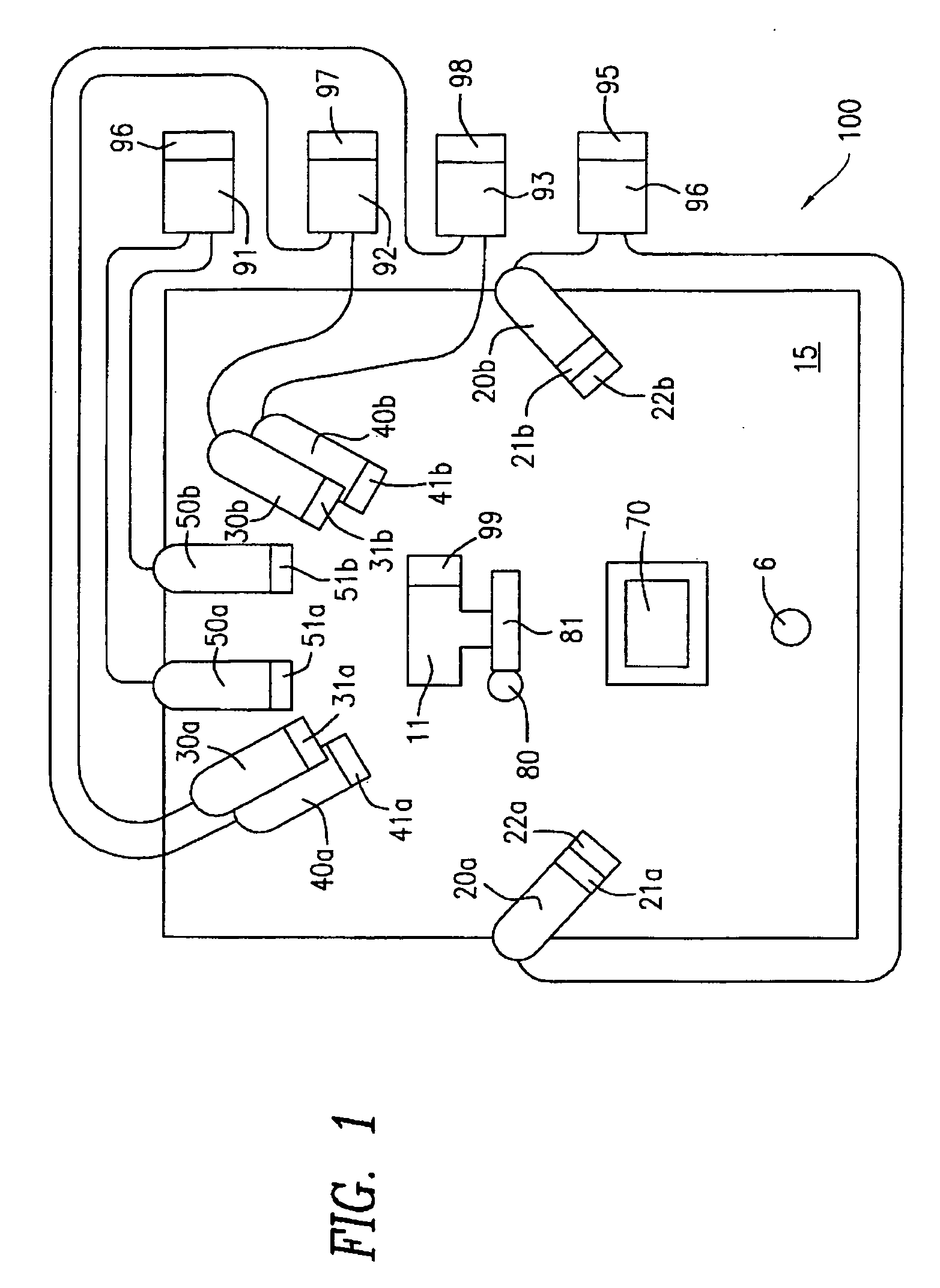

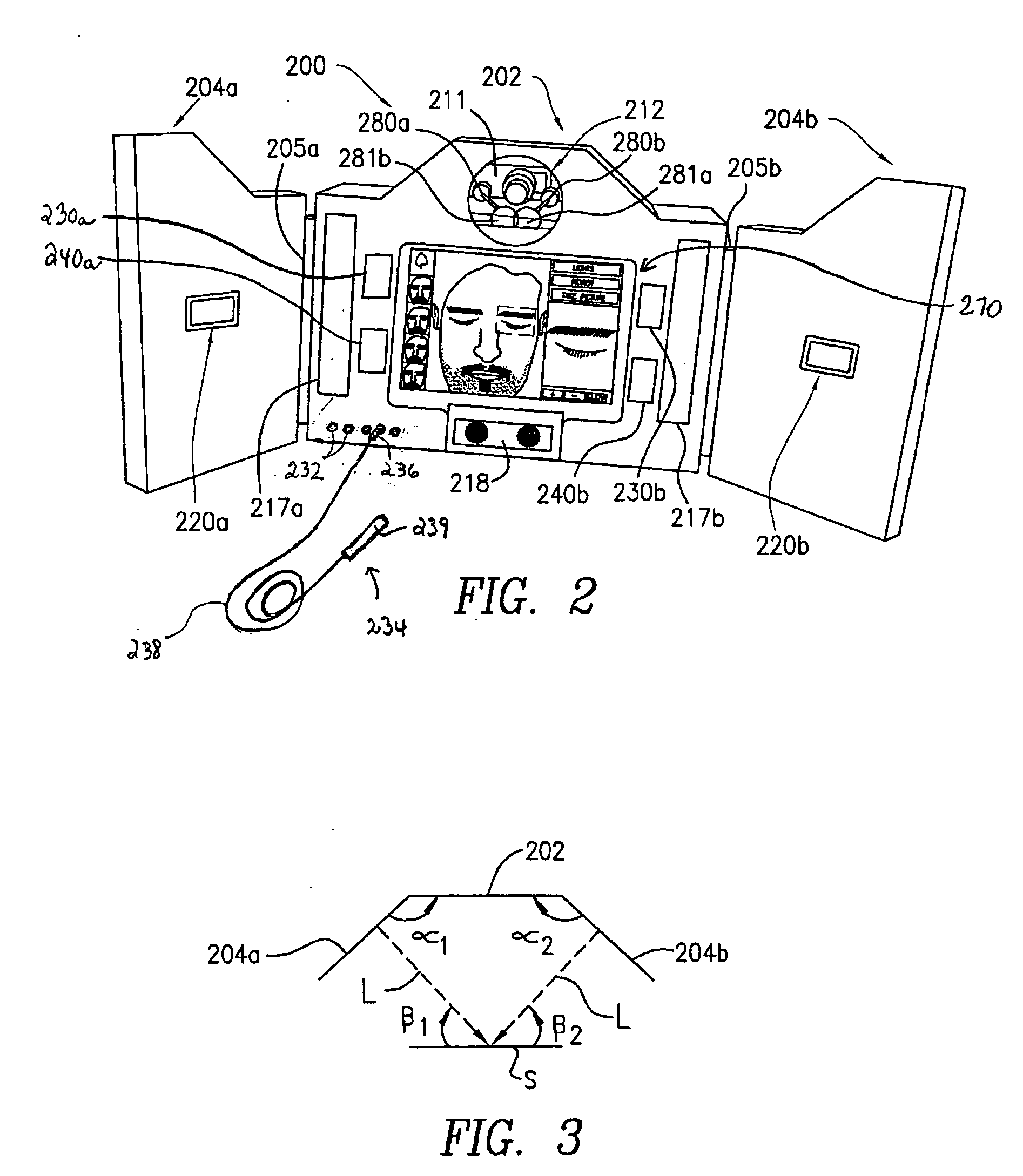

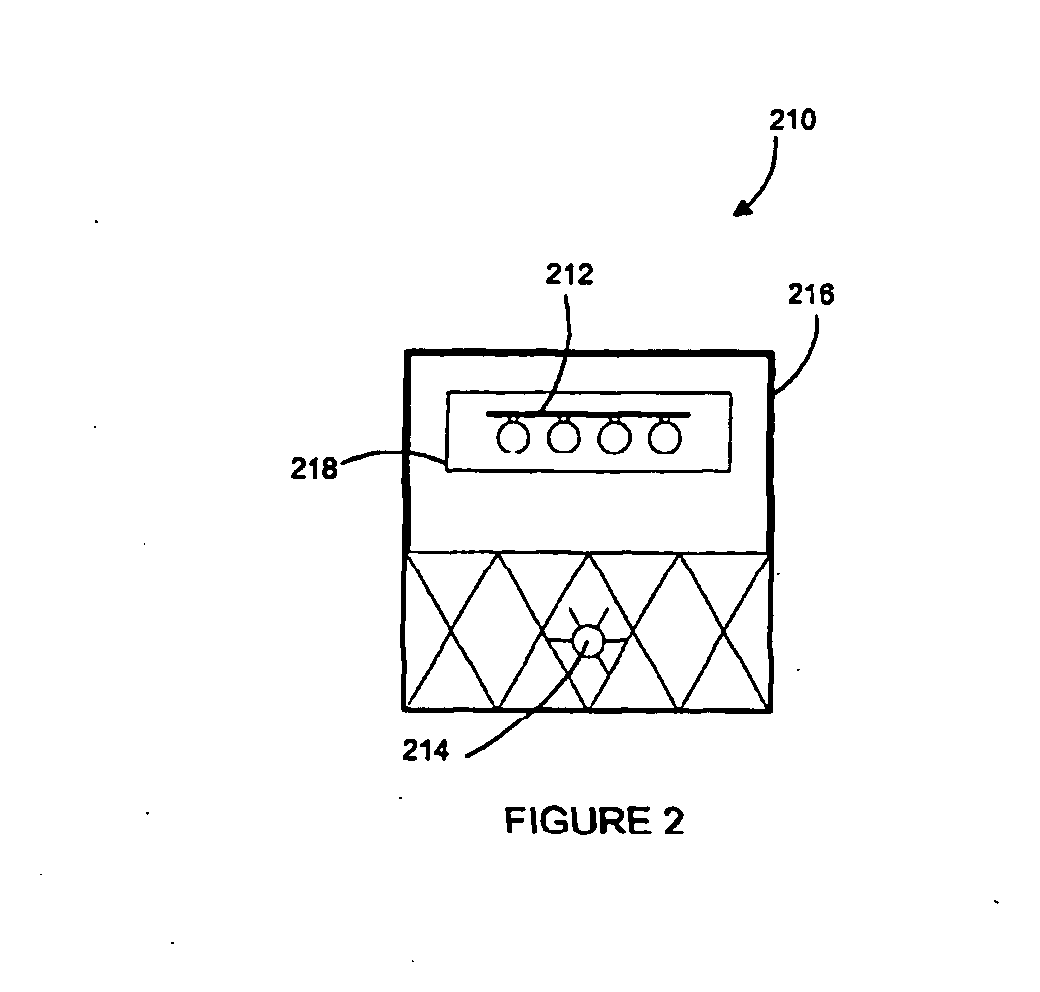

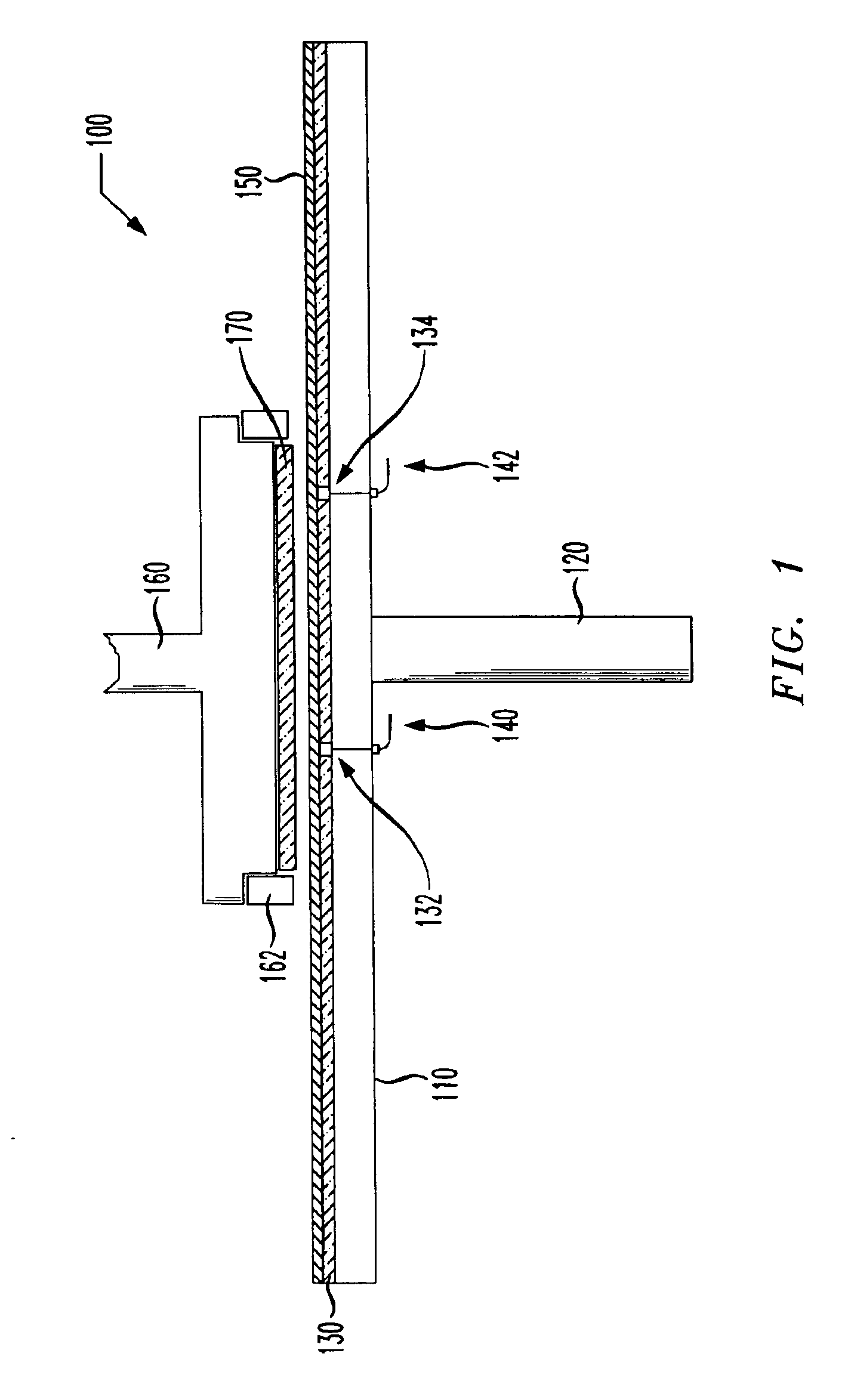

Skin Imaging system with probe

ActiveUS20060092315A1Television system detailsDiagnostics using spectroscopyAngle of incidenceSkin test

A skin testing and imaging station and corresponding method for capturing, displaying and analyzing images of a person and for testing the skin using a variety of probes includes a digital camera, a light source capable of providing at least two different wavelengths of light, a plurality of probes for conducting skin tests, a touch-screen display and a computer for controlling the components of the station. The apparatus selectively captures and displays a plurality of digital images using different wavelengths of illuminating light, e.g., using a plurality of flashes and filters, some of which may be adjustable to adjust the angle of incidence of the illuminating light on the subject. In video mode, the camera displays a real time image on the display facilitating a user to position a probe for testing any specific area of the skin. Preferably, the apparatus is self-serve, allowing any person to capture, review and analyze the images and skin data. Verbal and / or graphic instructions to a user aid in use of the station. An intuitive graphic user interface with thumbnail images is employed. Focus control, zoom and synchronized side-by side comparison of images are available.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

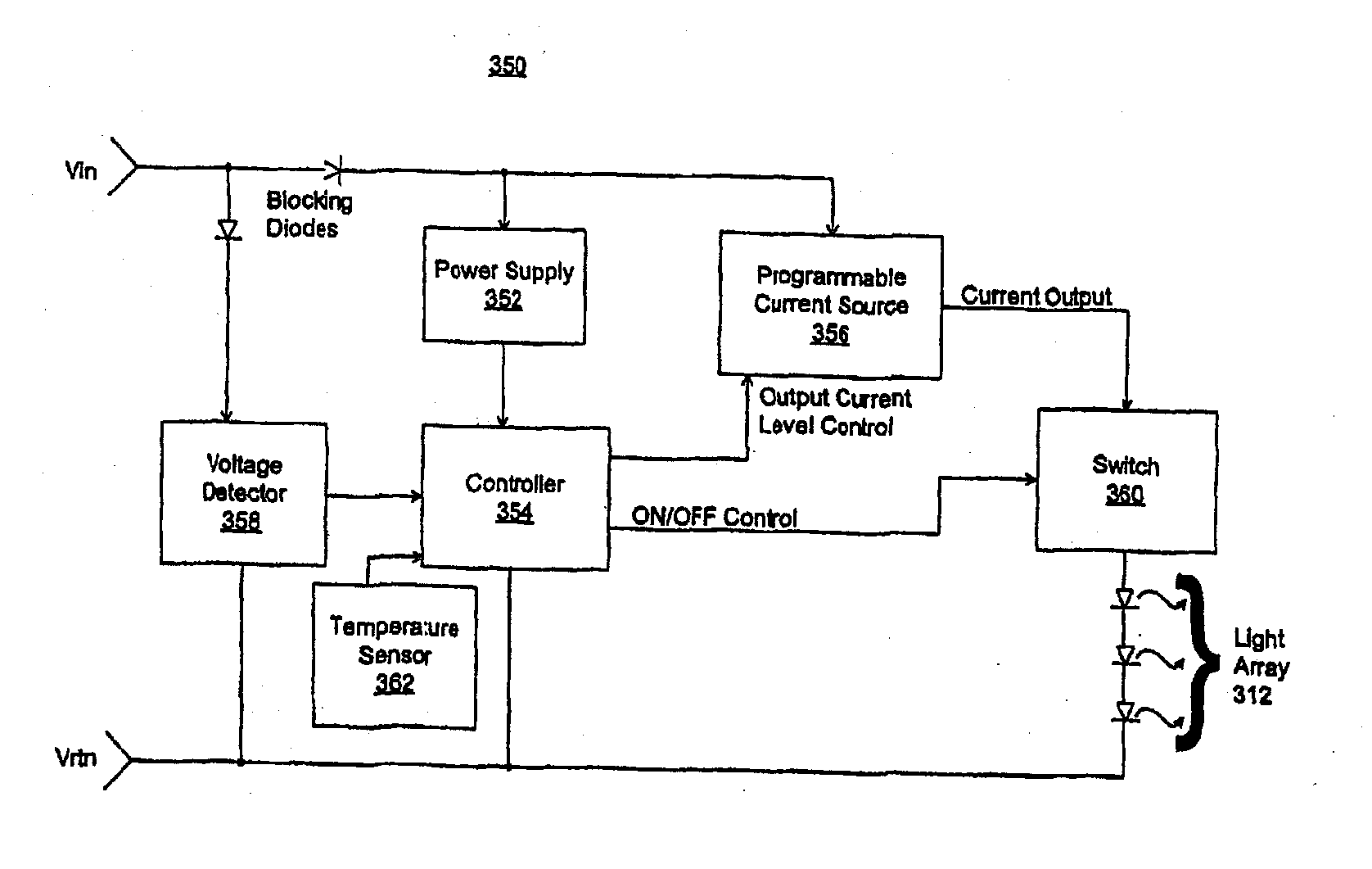

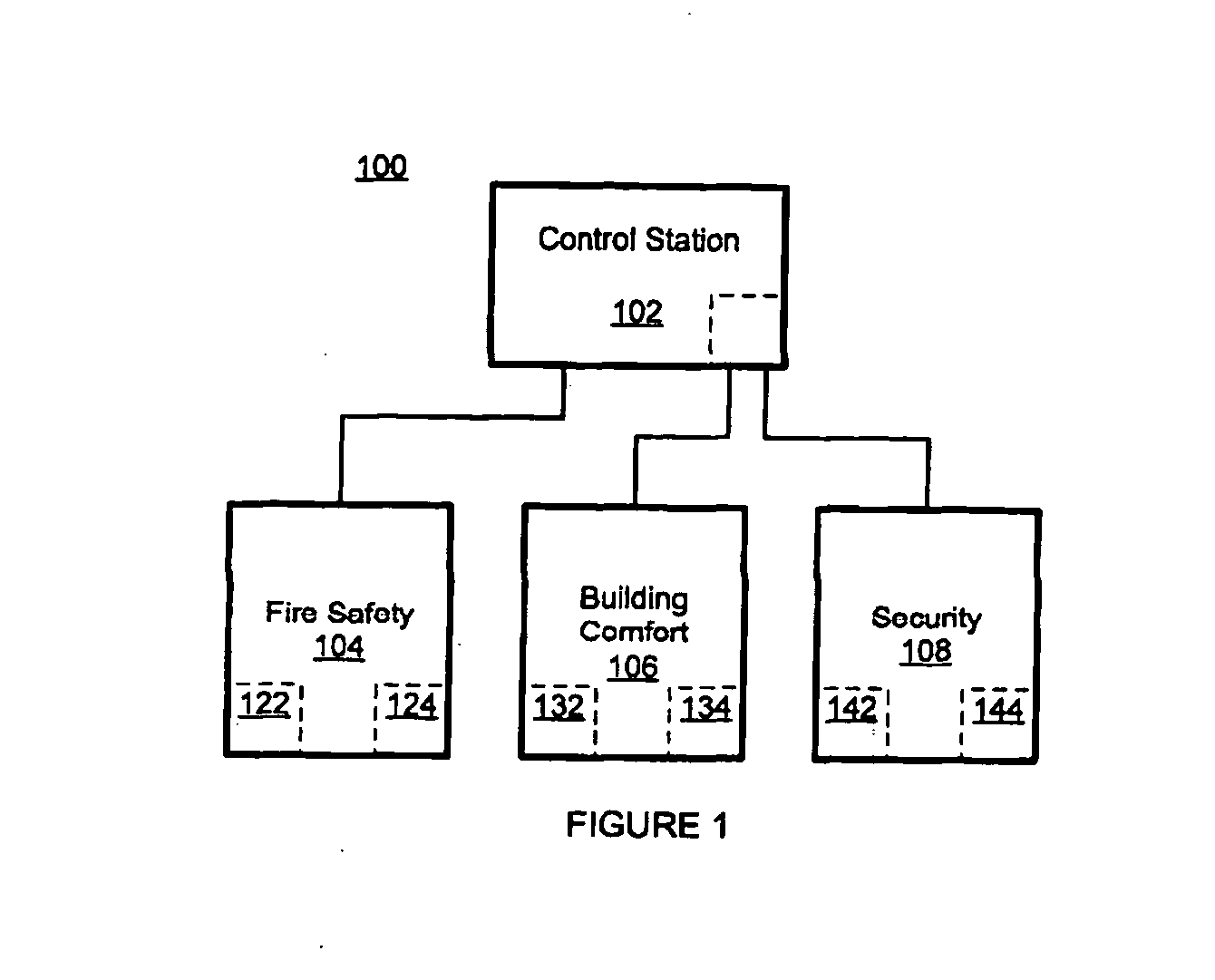

LED strobe for hazard protection systems

InactiveUS20070035255A1Preventing over-drivingEasy visual inspectionElectrical apparatusElectric light circuit arrangementEngineeringProtection system

A light-emitting diode (“LED”) based strobe may be used in automated system to provide a visual alert to occupants and / or building personnel if an emergency condition exists. A LED based strobe provides an even distribution of light having a sharp, bright pulse of light desired for emergency evacuation using lower power consumption.

Owner:SIEMENS IND INC

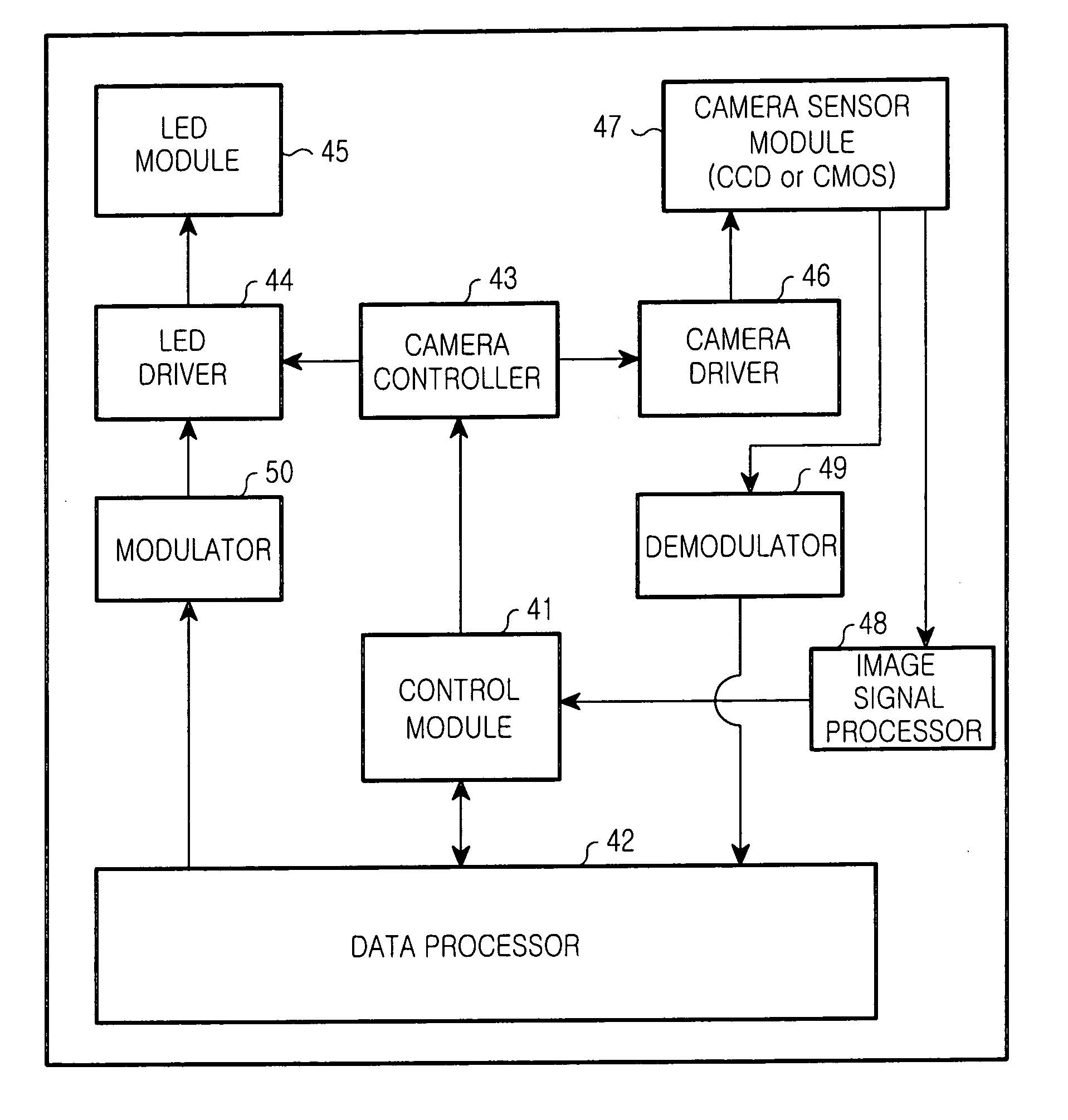

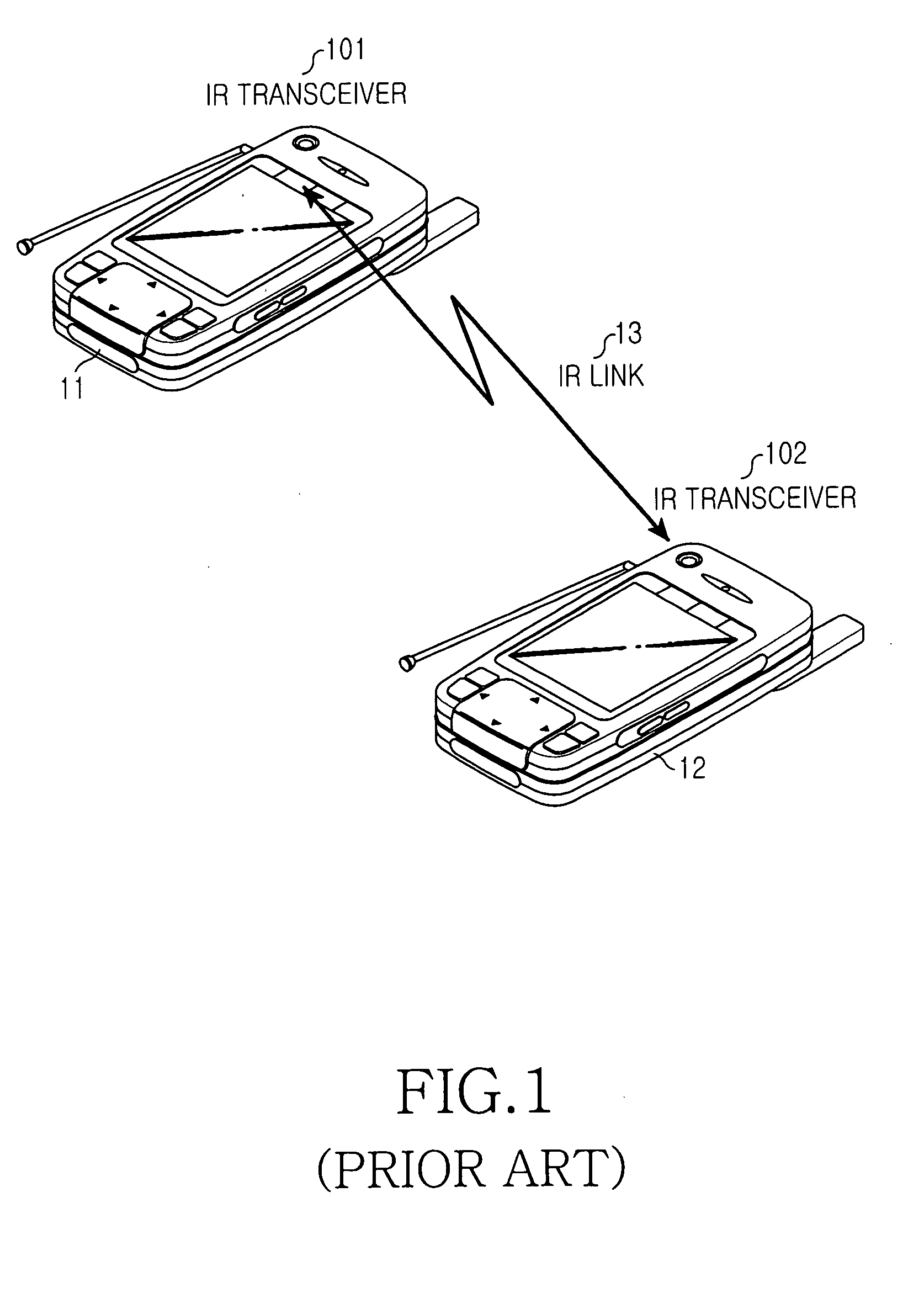

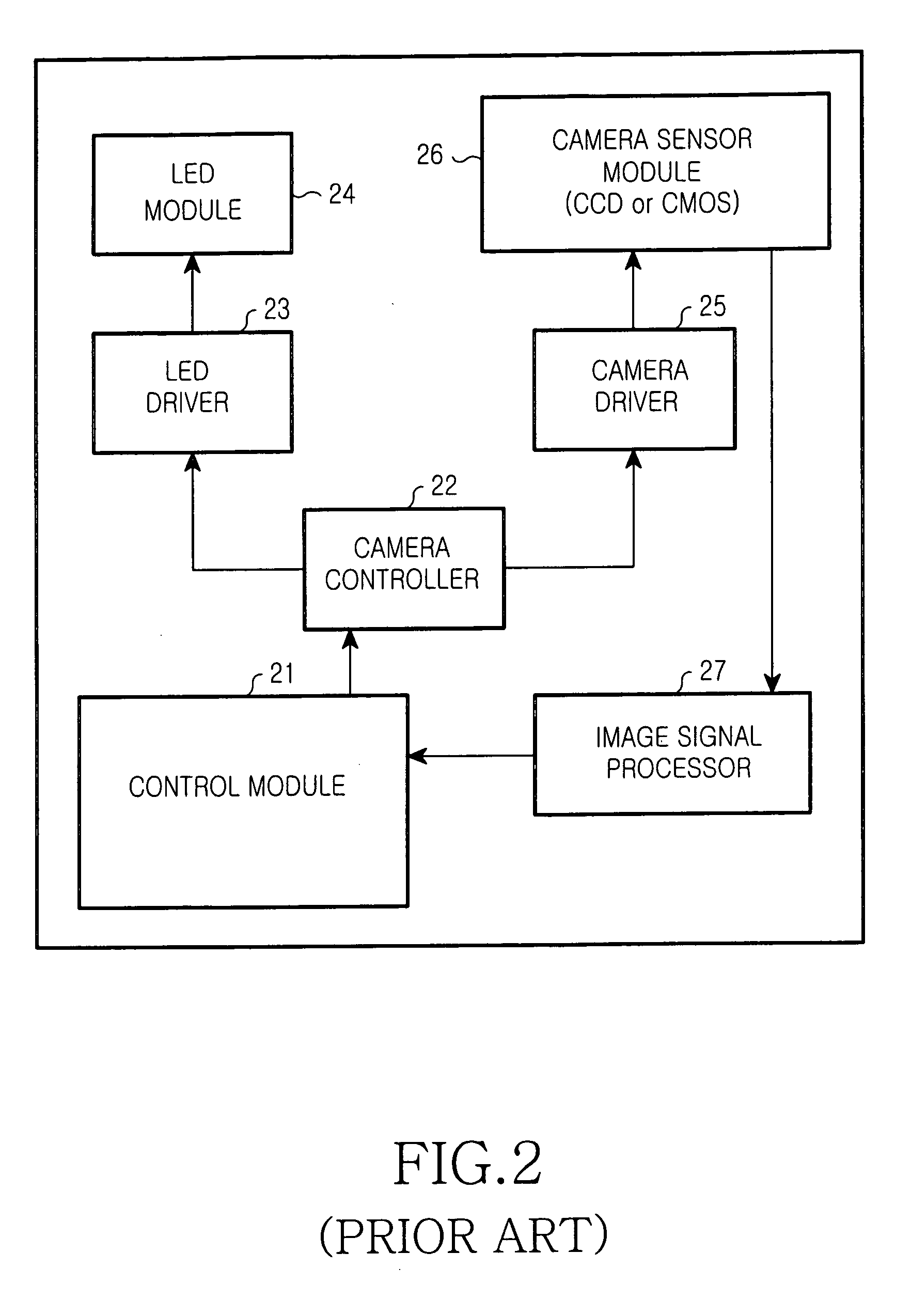

Wireless terminal for carrying out visible light short-range communication using camera device

InactiveUS20050265731A1Meet the requirementsEnhanced advantageNetwork topologiesClose-range type systemsCommunications systemComputer science

Disclosed is a wireless communication system using visible light and, more particularly, a short-range wireless communication system using a camera sensor module and a flash module mounted on a wireless terminal. The wireless terminal utilizes an LED and a camera sensor selectively for performing camera functions in a wireless terminal and as interface modules for visible light short-range communication.

Owner:SAMSUNG ELECTRONICS CO LTD

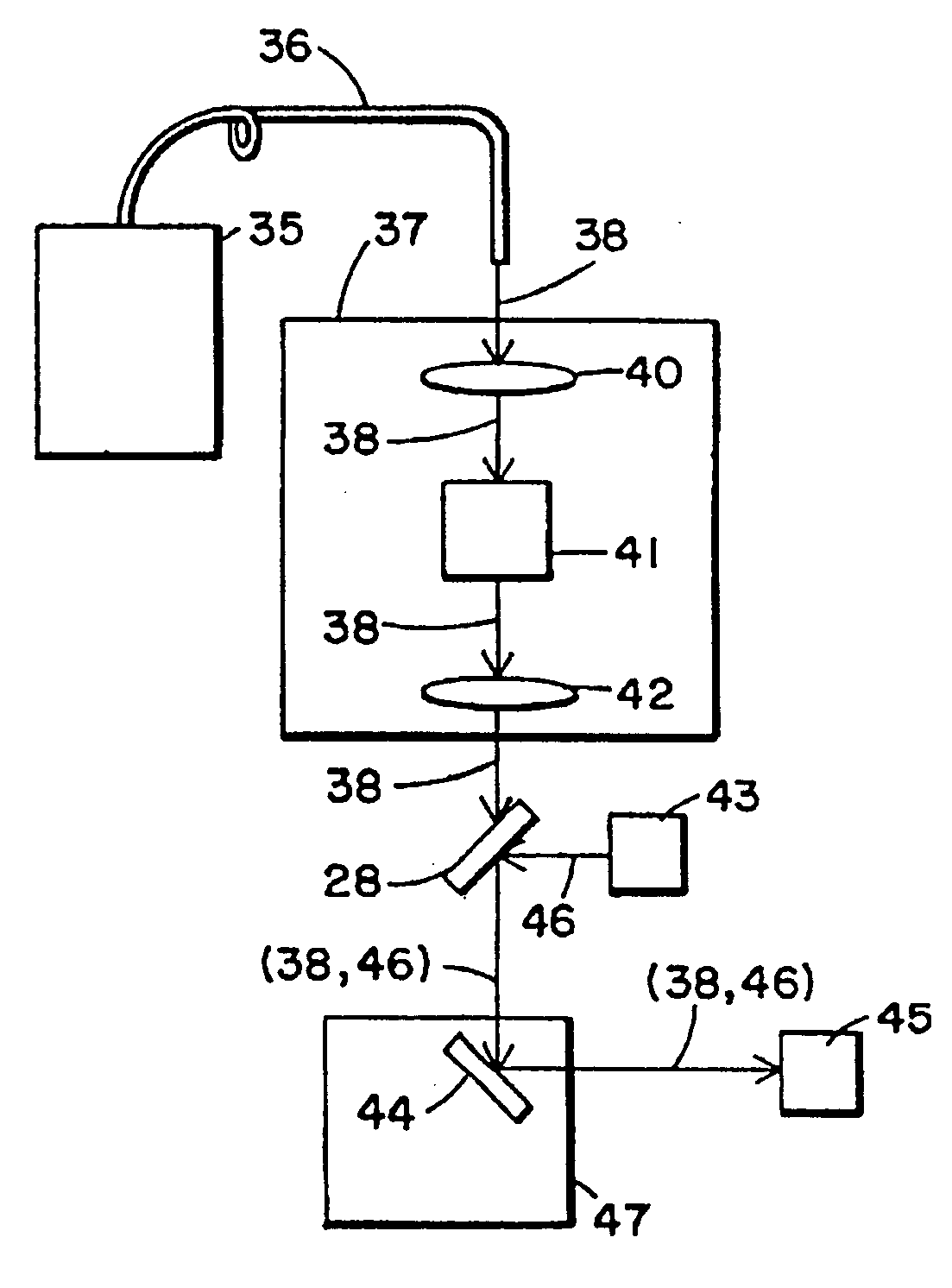

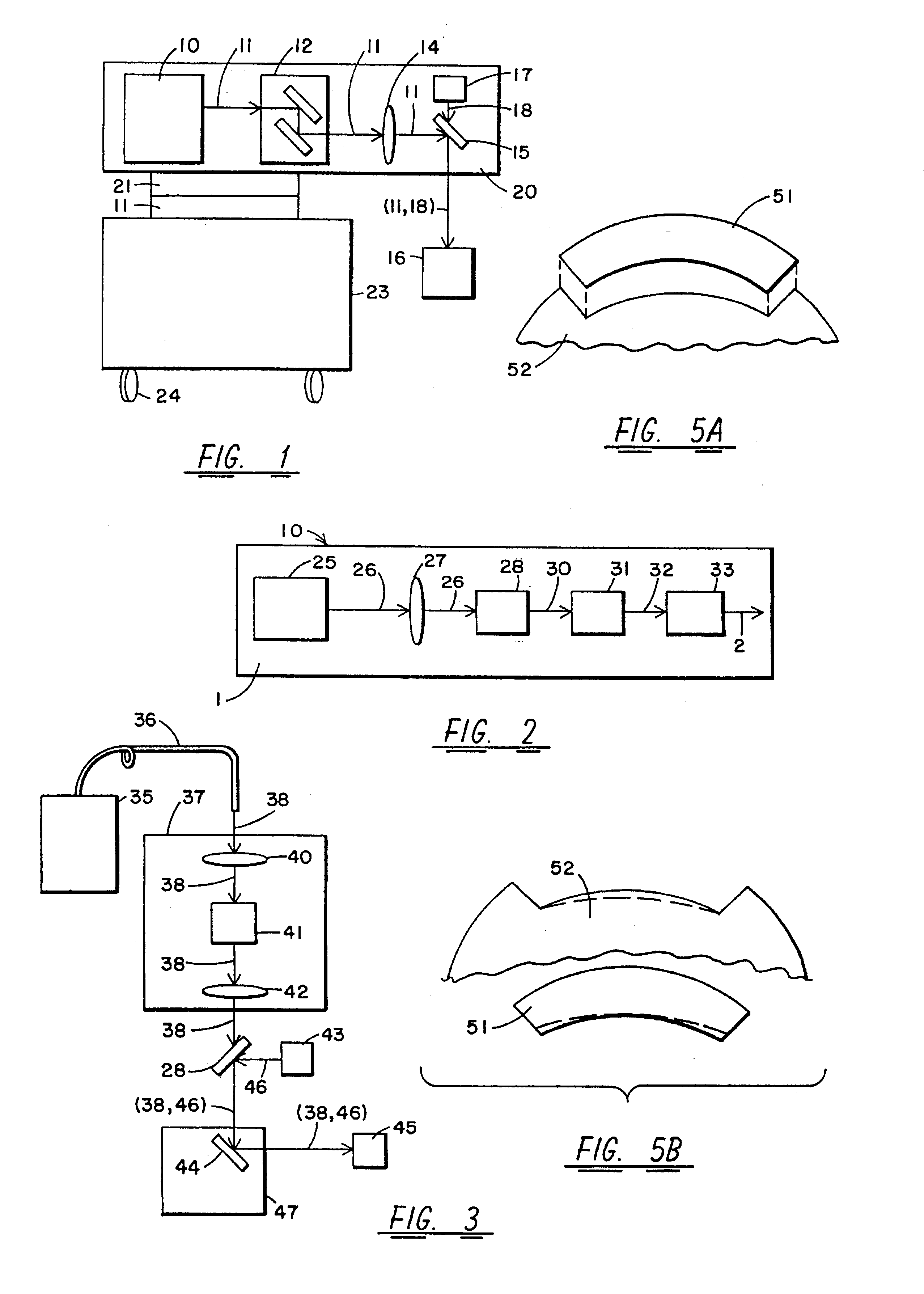

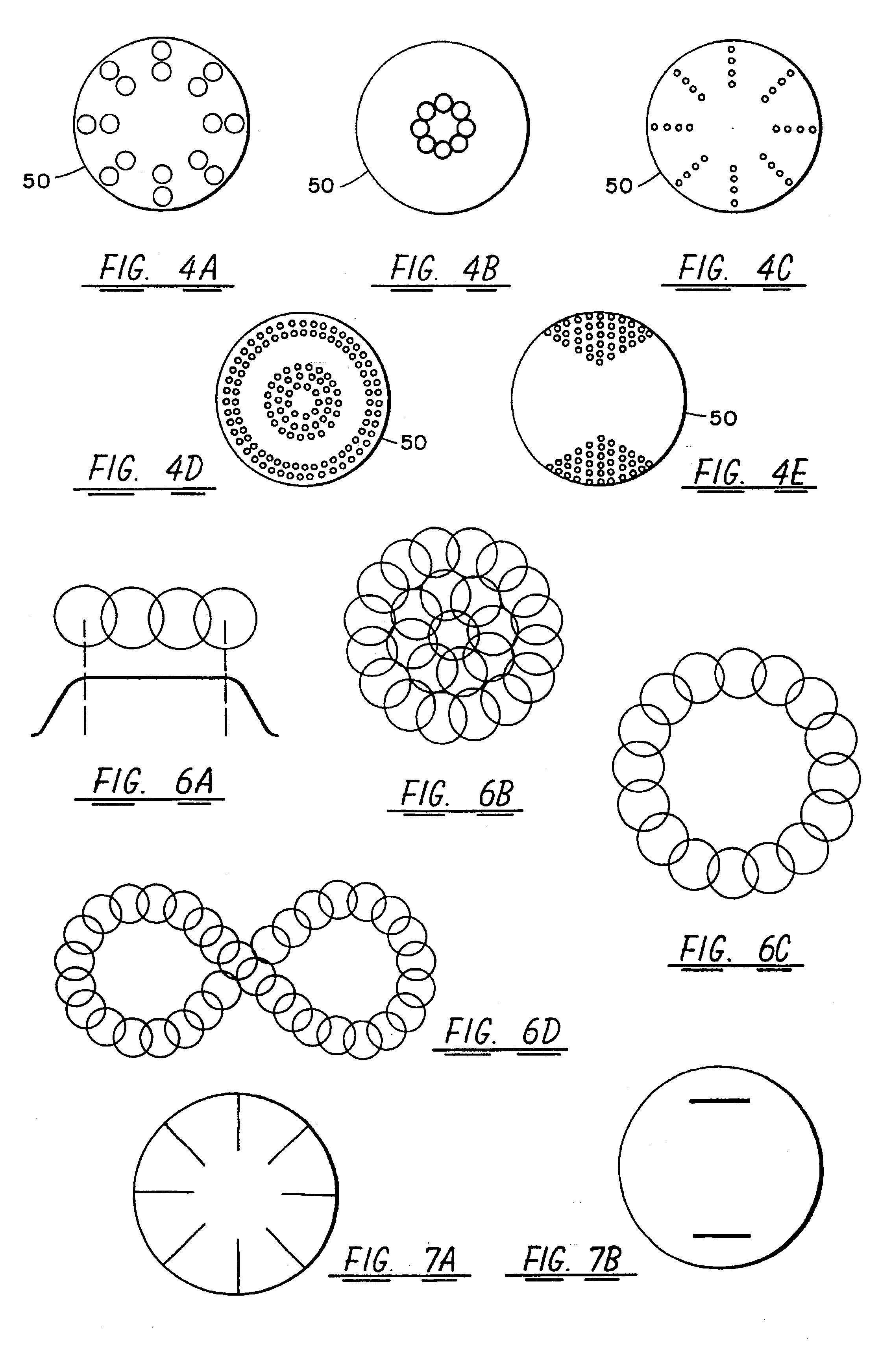

Ophthalmic surgery method using non-contact scanning laser

InactiveUSRE37504E1Low-powerLow-cost and effectiveLaser surgeryDiagnosticsSystem parametersOphthalmic surgery

A refractive laser surgery process is disclosed for using compact, low-cost ophthalmic laser systems which have computer-controlled scanning with a non-contact delivery device for both photo-ablation and photo-coagulation in corneal reshaping. The basic laser systems may include flash-lamp and diode pumped UV solid state lasers (193-215 nm), compact excimer laser (193 nm), free-running Er:glass (1.54 microns), Ho:YAG (2.1 microns), Q-switched Er:YAG (2.94 microns), and tunable IR lasers, (750-1100) nm and (2.5-3.2) microns. The advantages of the non-contact, scanning device used in the process over other prior art lasers include being safer, reduced cost, more compact and more precise and with greater flexibility. The theory of beam overlap and of ablation rate and coagulation patterns is also disclosed for system parameters. Lasers are selected with energy of (0.01-10) mJ, repetition rate of (1-10,000), pulse duration of 0.01 nanoseconds to a few hundreds of microseconds, and with spot size of (0.05-2) mm for use with refractive laser surgery.

Owner:LASERSIGHT TECH

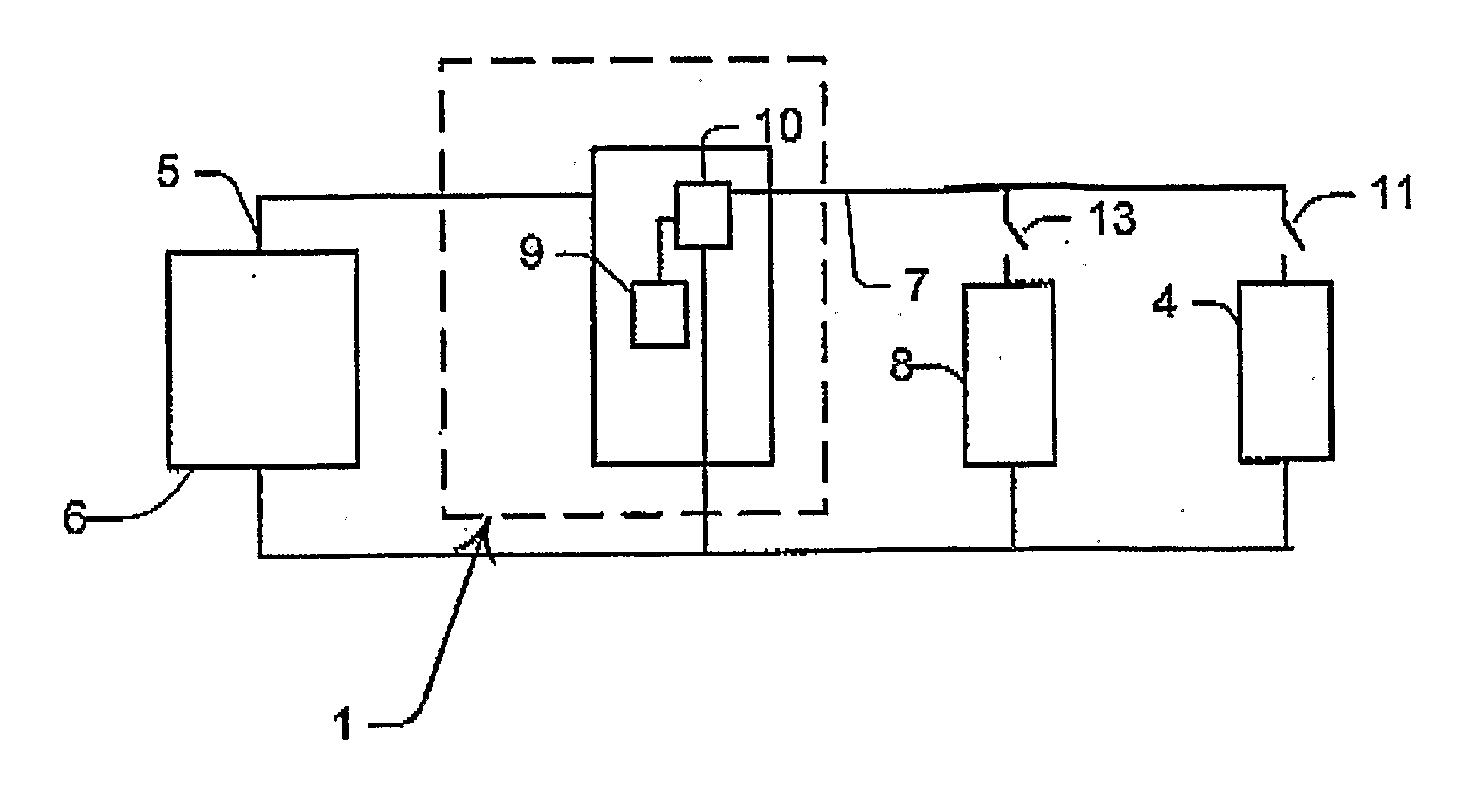

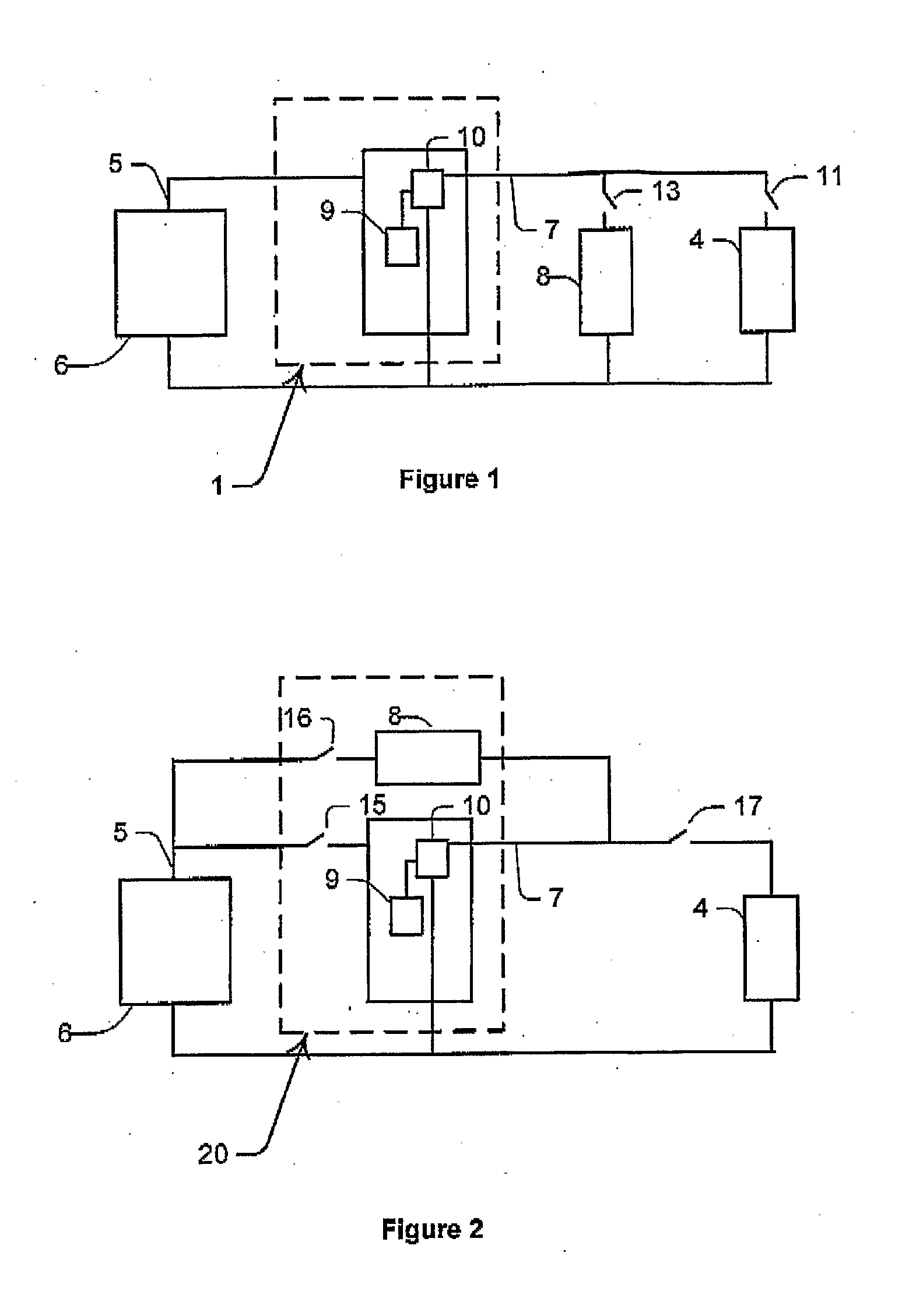

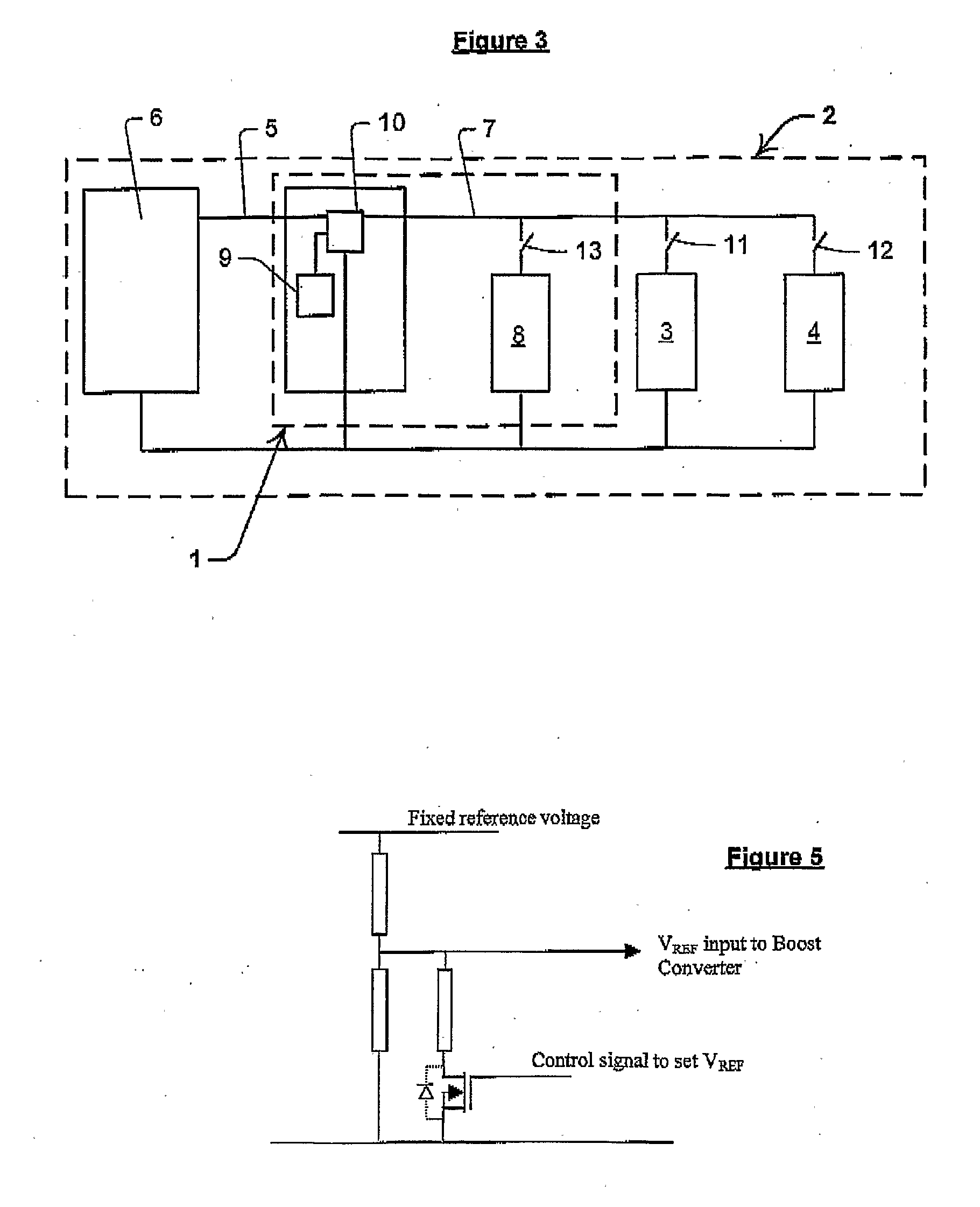

Power Supply

ActiveUS20080129219A1Reduce riskExtended run timeBatteries circuit arrangementsDc-dc conversionDriver circuitSupercapacitor

A power supply (1) for powering a load, the load being in the form of a flash driver circuit (4) for a digital camera (not shown). The power supply includes a supercapacitive device, in the form of a supercapacitor (8), for powering circuit (4). A regulator unit, in the form of an inductive regulator (10), charges supercapacitor (8).

Owner:CAP XX LTD

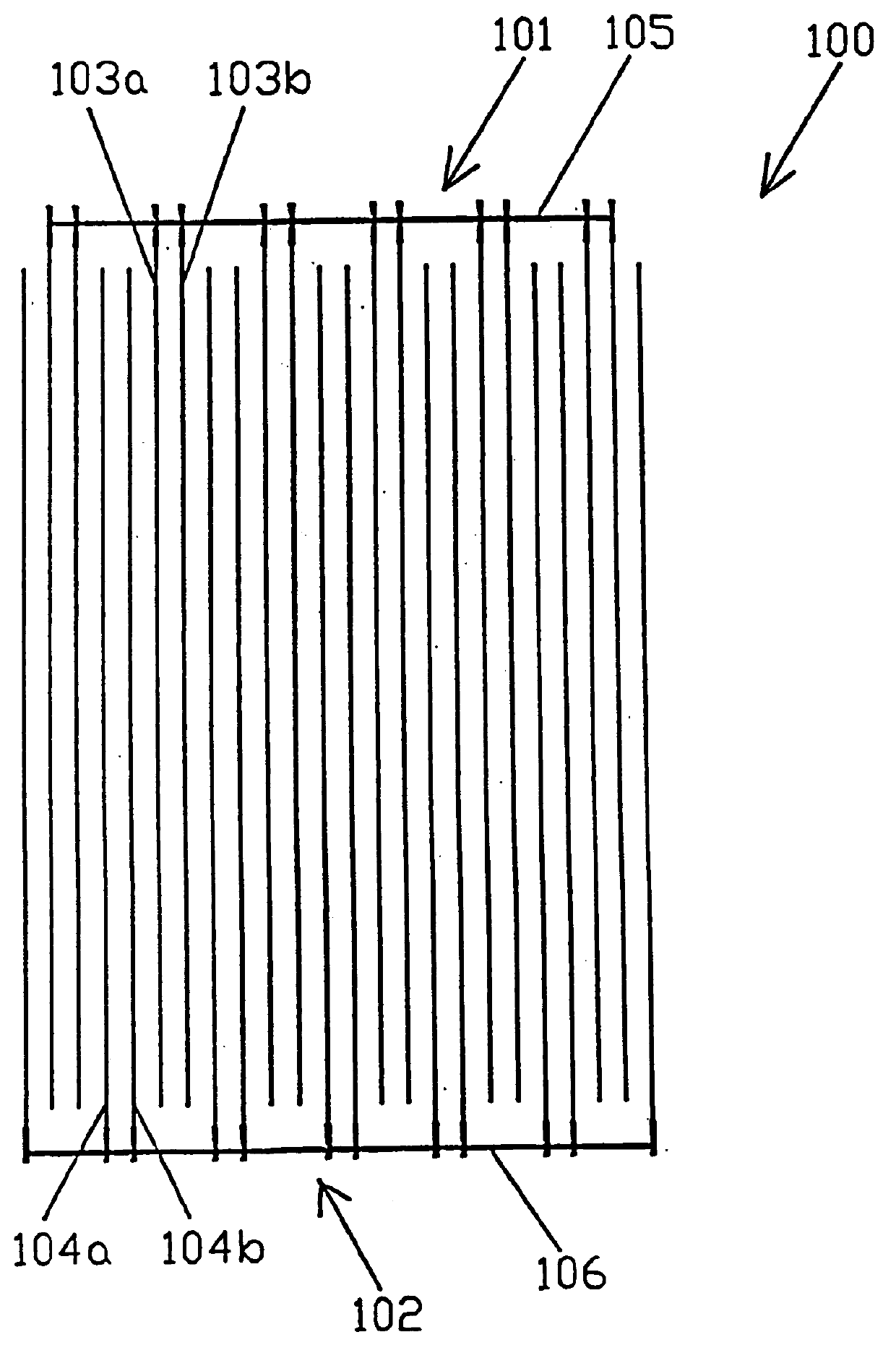

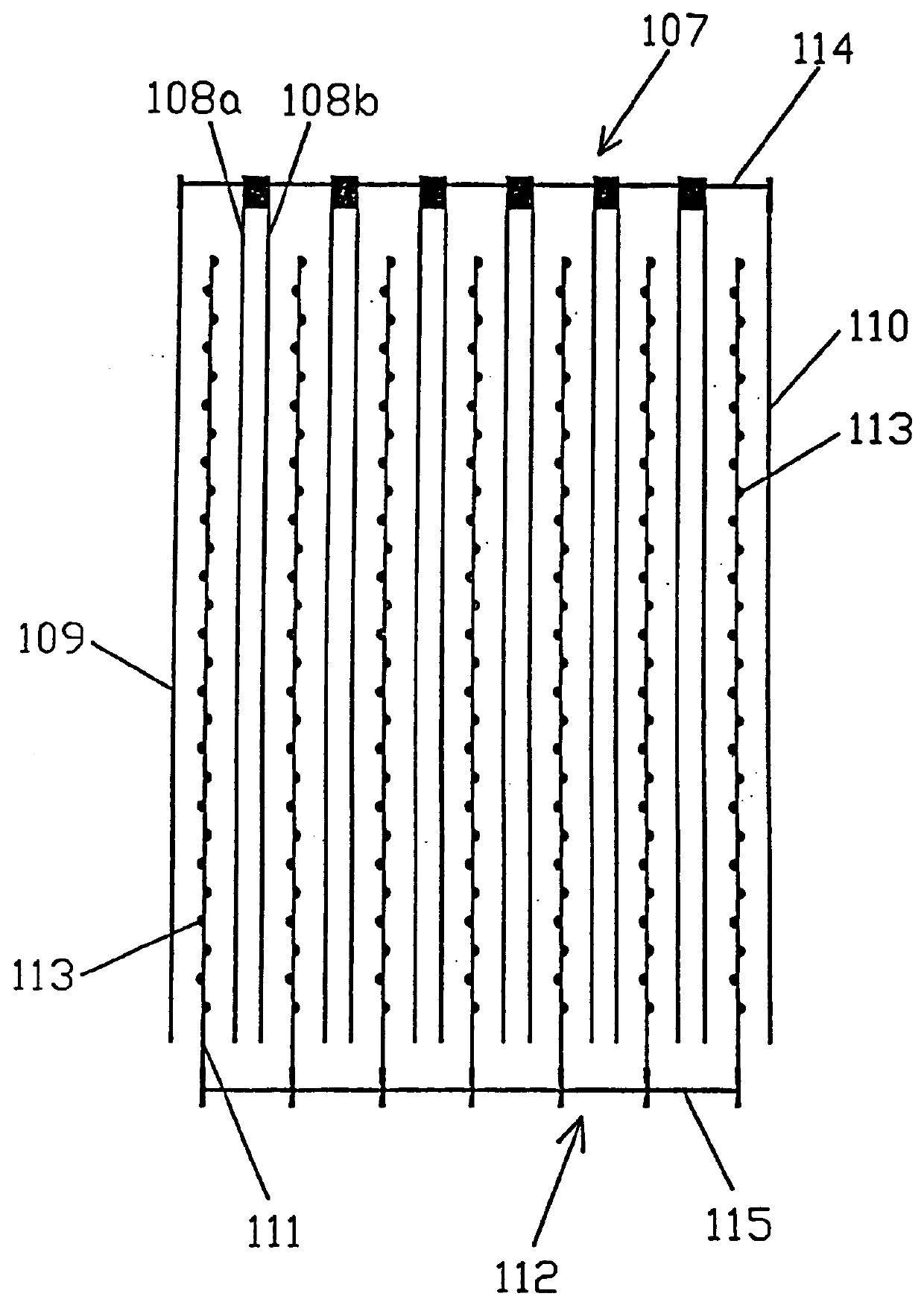

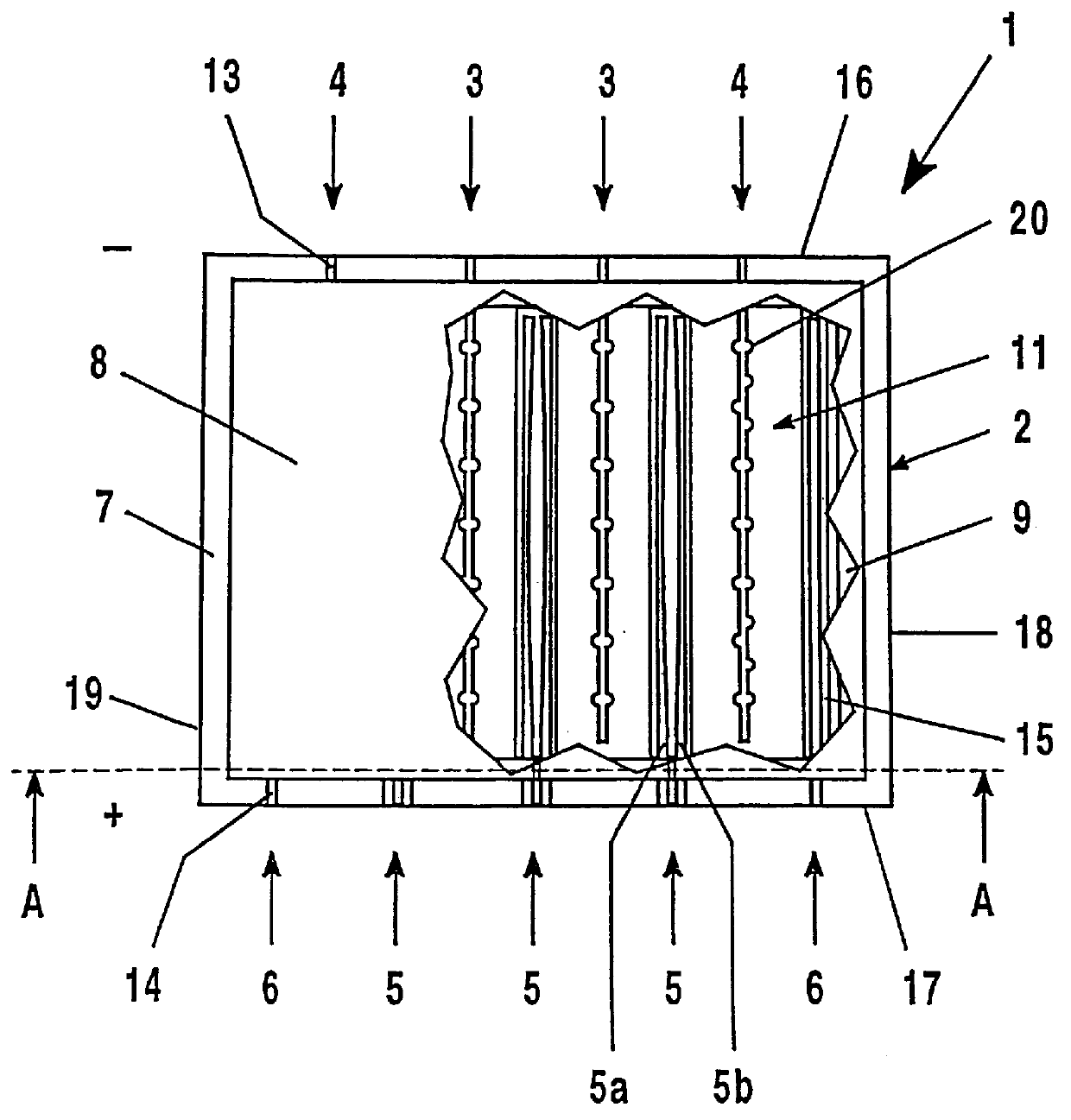

Flat fluorescent lamp with specific electrode structuring

InactiveUS6034470AReduce the numberReduce productionDischarge tube luminescnet screensLamp detailsElectrical conductorEngineering

PCT No. PCT / DE98 / 00827 Sec. 371 Date Nov. 17, 1998 Sec. 102(e) Date Nov. 17, 1998 PCT Filed Mar. 20, 1998 PCT Pub. No. WO98 / 43277 PCT Pub. Date Oct. 1, 1998A flat fluorescent lamp (1) has a discharge vessel (2) having a base plate (7), a top plate (8) and a frame (9) which are connected to one another in a gas-tight fashion by means of solder (10). Structures resembling conductor tracks function in the interior of the discharge vessel as electrodes (3-6), in the feedthrough region as feedthroughs, and in the external region as external supply leads (13; 14). Flat lamps of the most different sizes can thereby be produced simply in engineering terms and in a fashion capable of effective automation. Moreover, virtually any electrode shapes can be realized, in particular optimized with regard to a uniform luminous density with a reduced drop in luminous density towards the edges of the flat lamp. At least the anodes (5, 6) are covered in each case with a dielectric layer (15). The lamp (1) is preferably operated by means of a pulsed voltage source and serves as background lighting for LCDs, for example in monitors or driver information displays.

Owner:PATENT TREUHAND GESELLSCHAFT FUR ELECTRIC GLUEHLAMPEN MBH

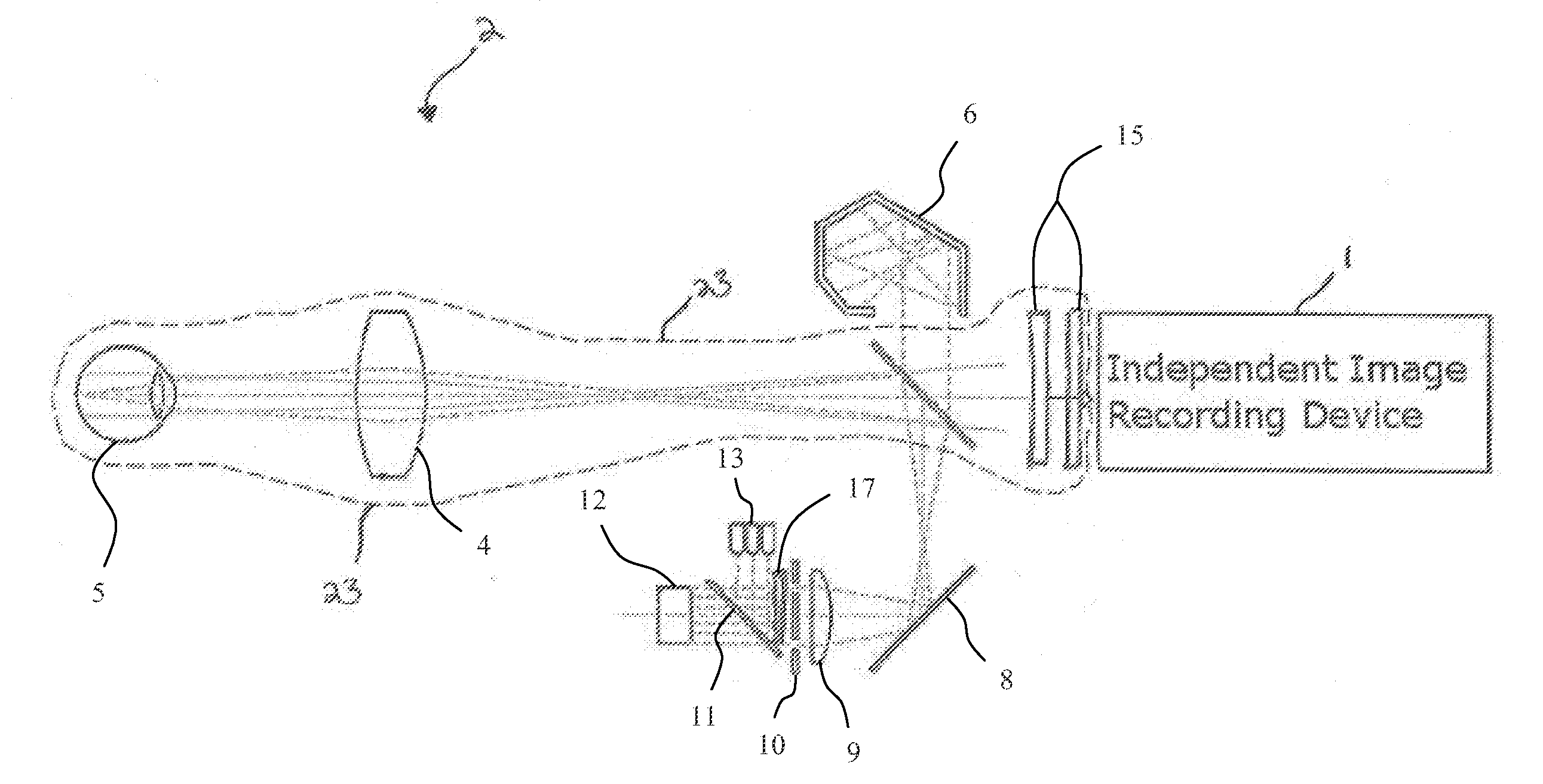

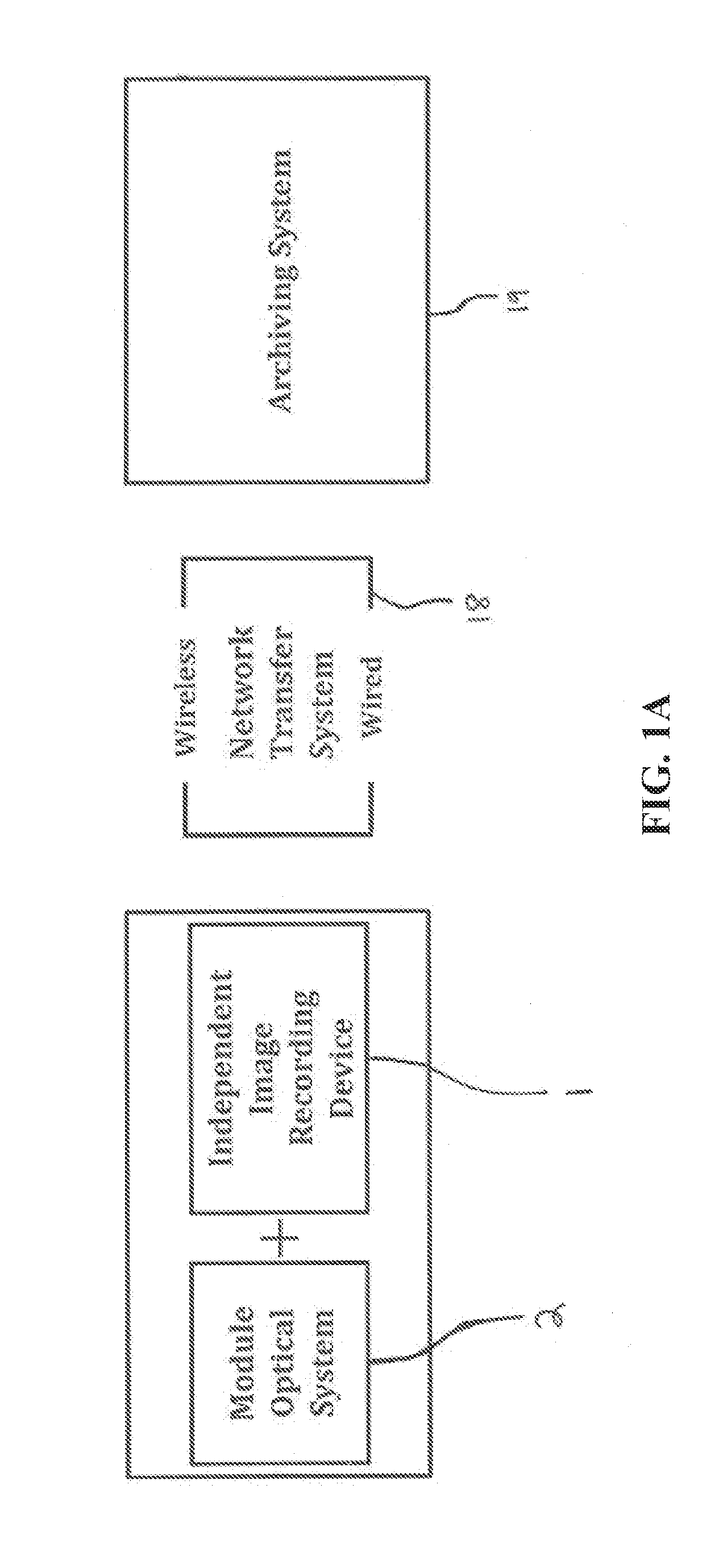

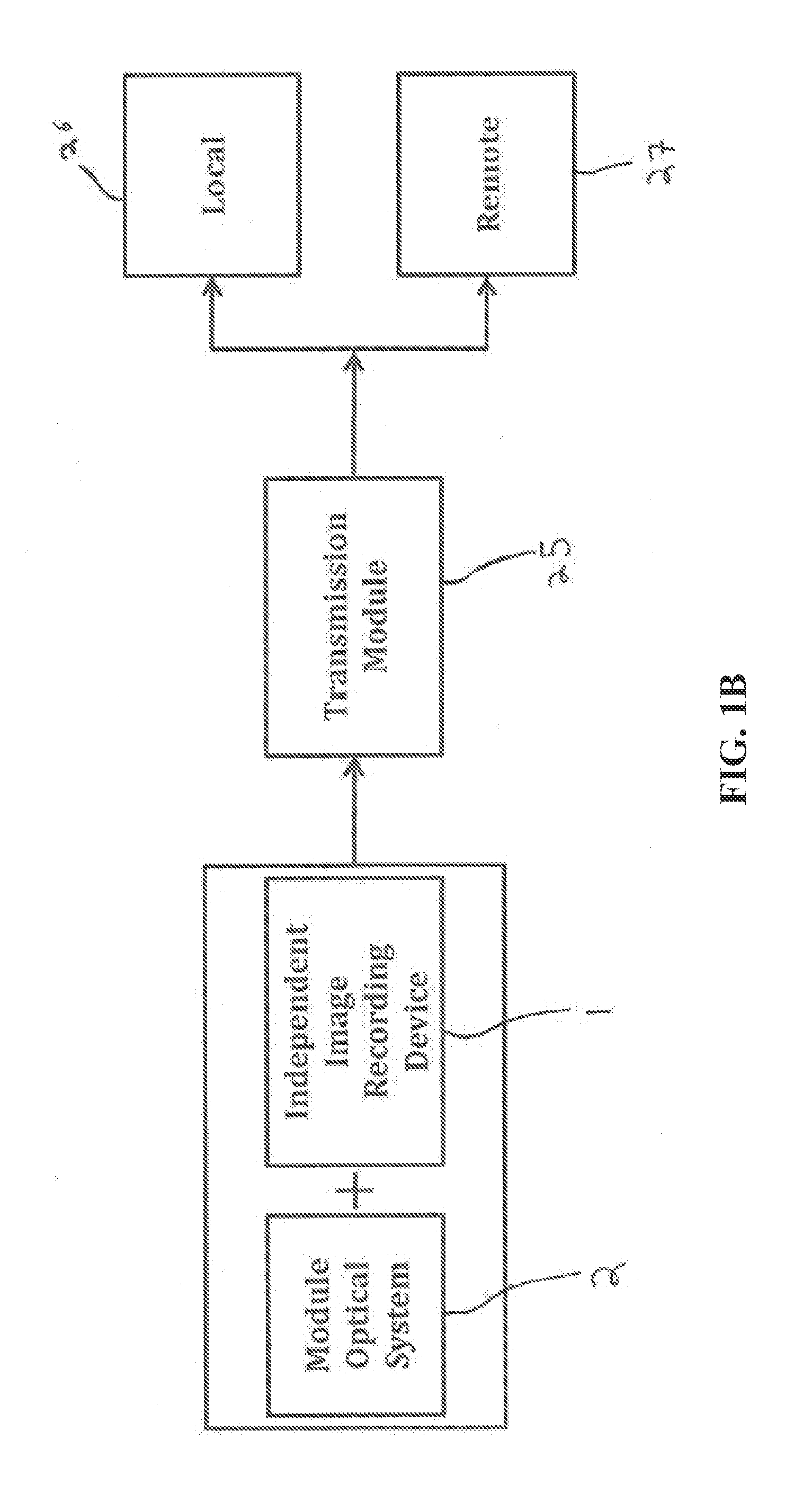

Hand-held portable fundus camera for screening photography

ActiveUS20120229617A1Low costEasy to useTelevision system detailsAcquiring/recognising eyesFundus cameraHand held

System and Method pertaining to the modification and integration of an existing consumer digital camera, for example, with an optical imaging module to enable point and shoot fundus photography of the eye. The auto-focus macro capability of existing consumer cameras is adapted to photograph the retina over an extended diopter range, eliminating the need for manual diopter focus adjustment. The thru-the-lens (TTL) auto-exposure flash capability of existing consumer cameras is adapted to photograph the retina with automatic flash exposure eliminating the need for manual flash adjustment. The consumer camera imaging sensor and flash are modified to allow the camera sensor to perform both non-mydriatic focusing of the retina using infrared illumination and standard color flash photography of the retina without the need for additional imaging sensors or mechanical filters. These modifications and integration of existing consumer cameras for fundus photography of the eye significantly improve ease of manufacture and usability over existing fundus cameras.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

Anneal of epitaxial layer in a semiconductor device

InactiveUS7416605B2From gel statePolycrystalline material growthCharge carrier mobilityDegree Celsius

An anneal of an epitaxially grown crystalline semiconductor layer comprising a combination of group-IV elements. The layer contains at least one of the group of carbon and tin. The layer of epitaxially grown material is annealed at a temperature substantially in a range of 1,000 to 1,400 degrees Celsius for a period not to exceed 100 milliseconds within 10% of the peak temperature. The anneal is performed for example with a laser anneal or a flash lamp anneal. The limited-time anneal may improve carrier mobility of a transistor.

Owner:NORTH STAR INNOVATIONS

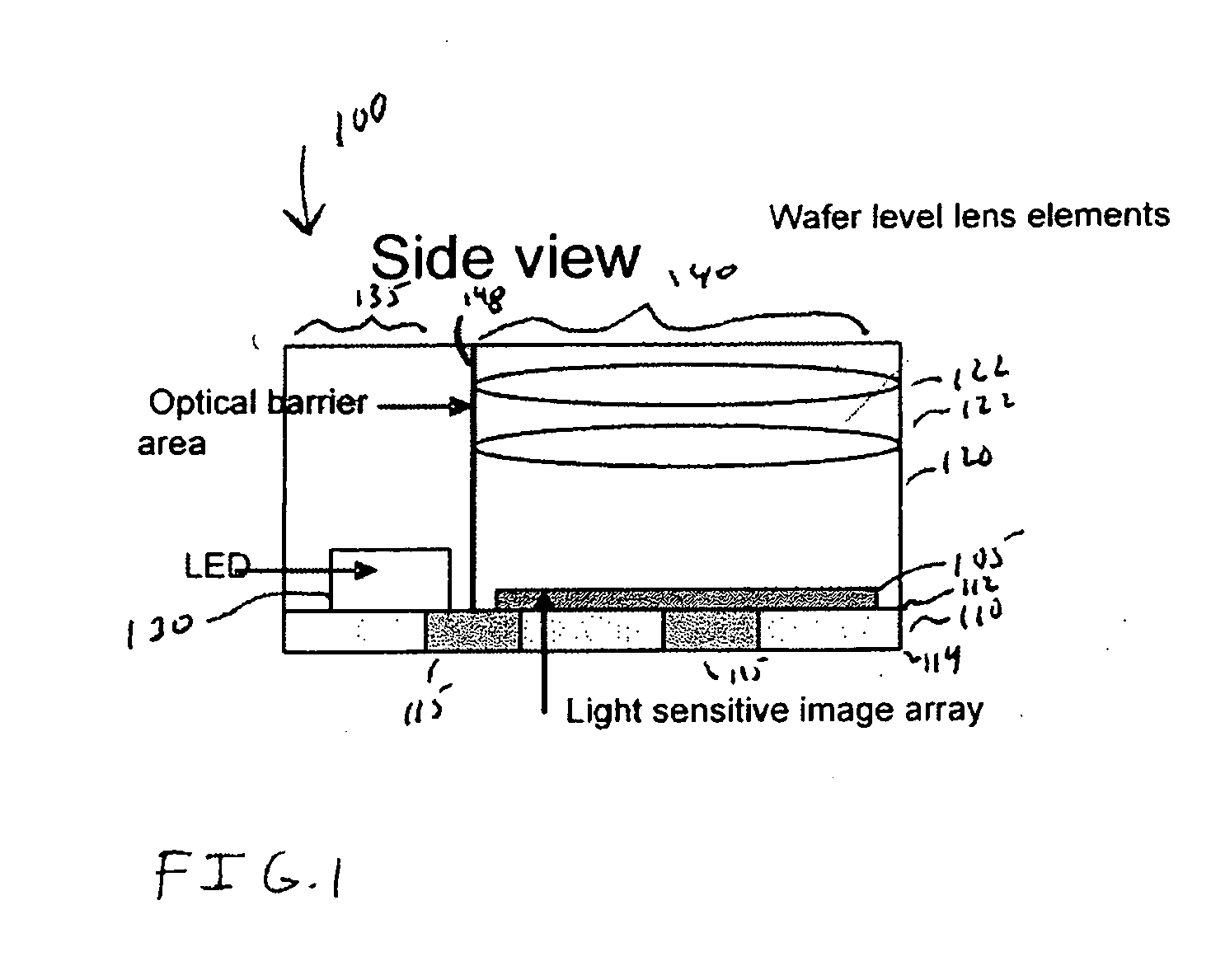

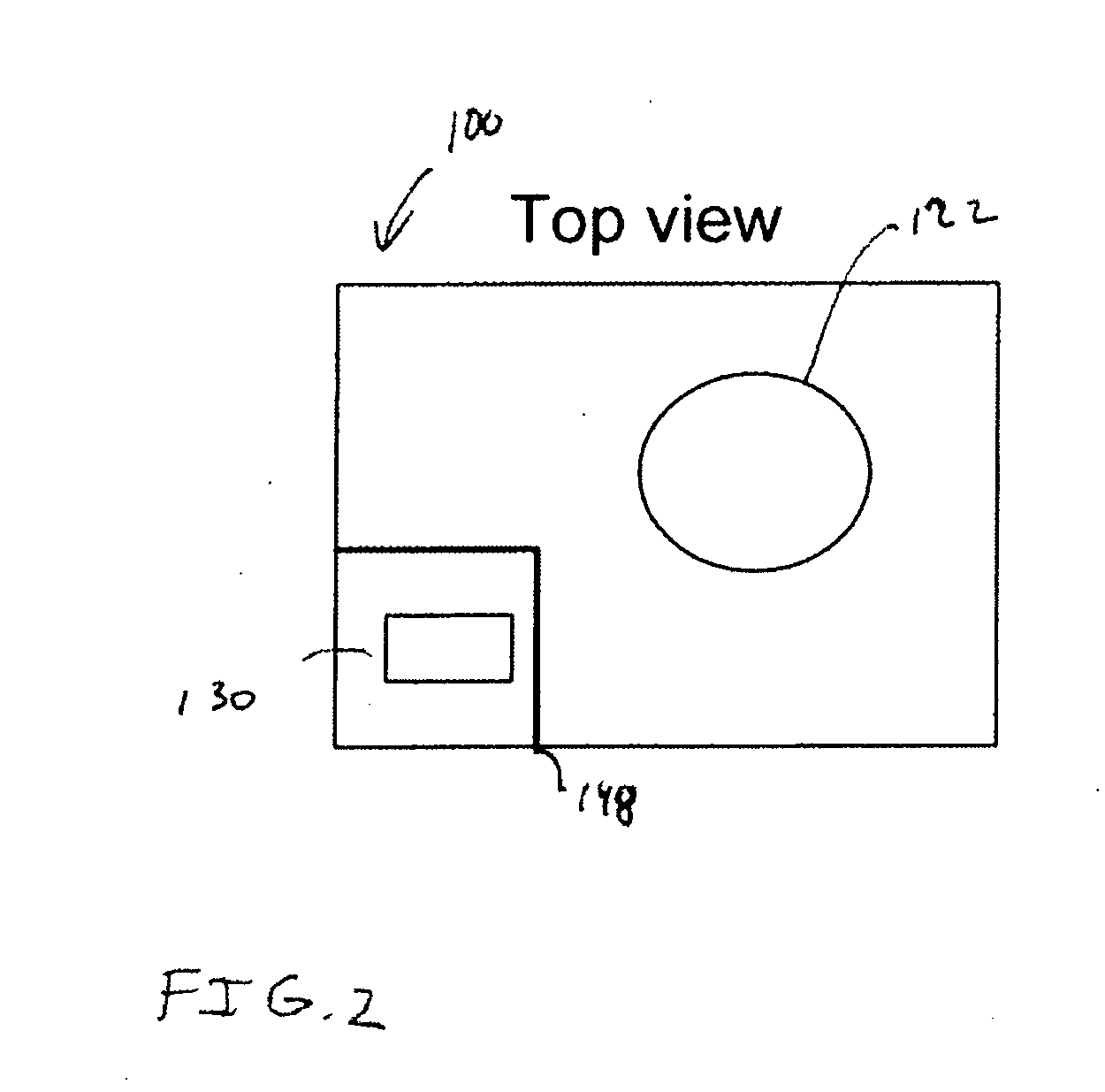

Reflowable Camera Module With Integrated Flash

ActiveUS20090153729A1Avoid strayTelevision system detailsSemiconductor/solid-state device manufacturingImaging qualityComputer module

A reflowable camera module is implemented using a Chip Scale Package (CSP). An image sensor is formed on one portion of the carrier. A light emitting diode (LED) is formed on another portion of the carrier. The LED serves as an integrated camera flash. Additional optical isolation is provided within the camera module to prevent stray light generated by the LED from degrading image quality.

Owner:OMNIVISION TECH INC

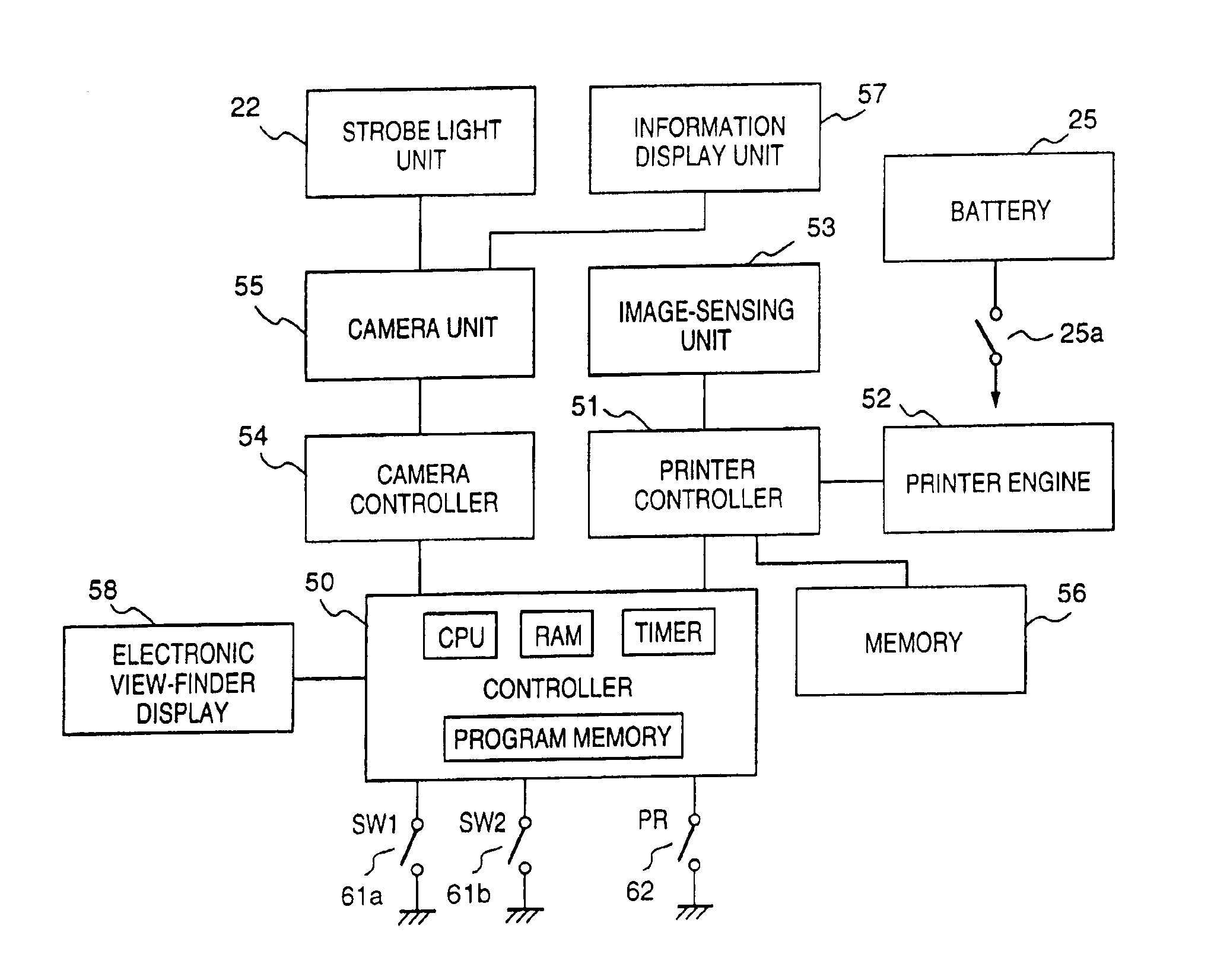

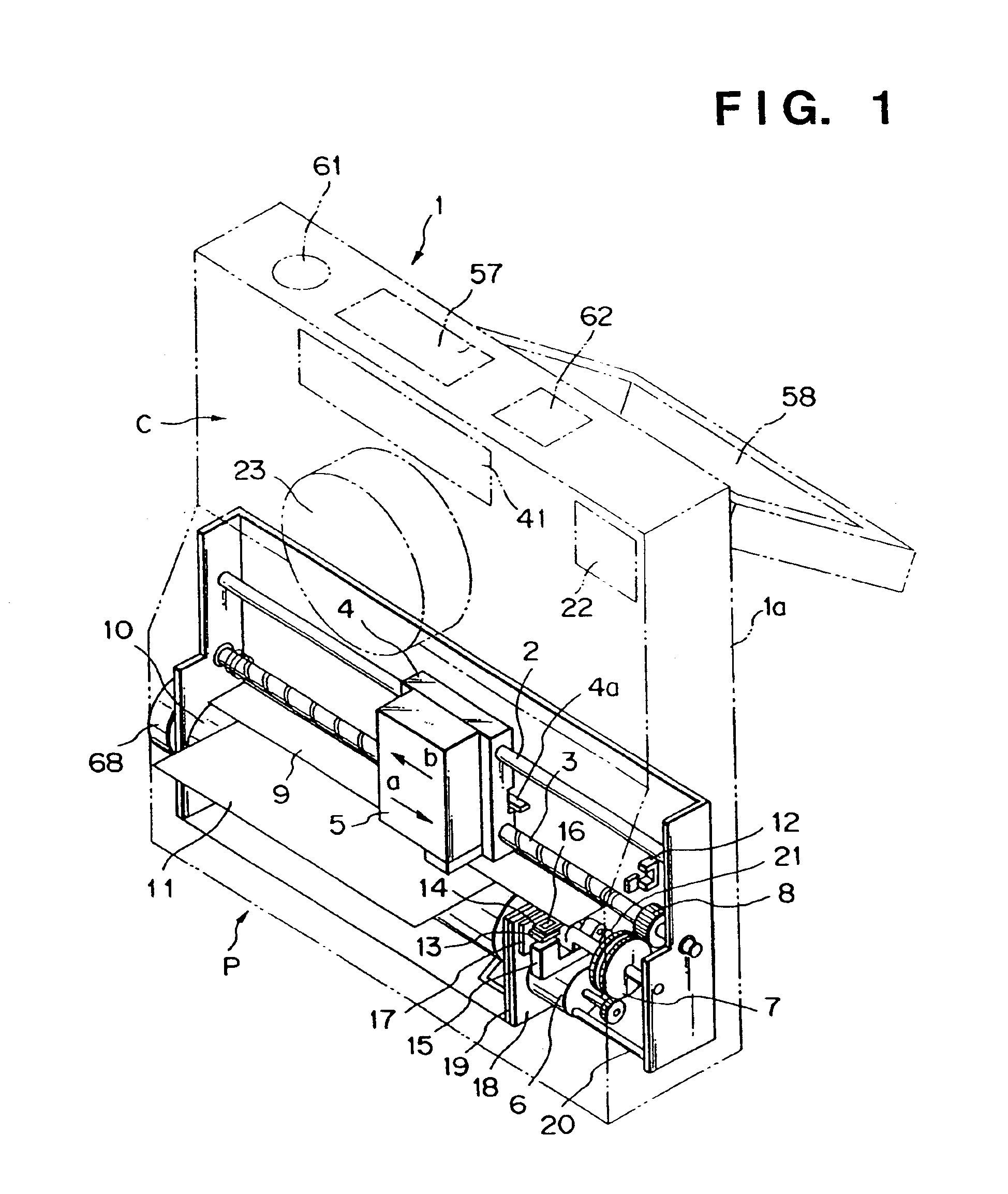

Printer-built-in image-sensing apparatus and electric-consumption control method thereof

InactiveUS6888649B2Prevents poor printoutReduce waiting timeTelevision system detailsDigitally marking record carriersElectric consumptionStrobe light

A printer-built-in image-sensing apparatus including a camera which performs image sensing with film exposure, and a printer which prints an image sensed by the camera. After a shutter button has been pressed and image sensing with strobe light emission has been performed, if printing is instructed by pressing of a print button, then electric charging a capacitor of a strobe circuit is made after the completion of the print operation. Otherwise, the charging of the capacitor is started immediately after the image sensing. In this case, even if printing is instructed during the electric charge, printing is started after completion of the electric charge. Thus, electric consumption upon print operation can be reduced and fluctuation of voltage can be suppressed.

Owner:CANON KK

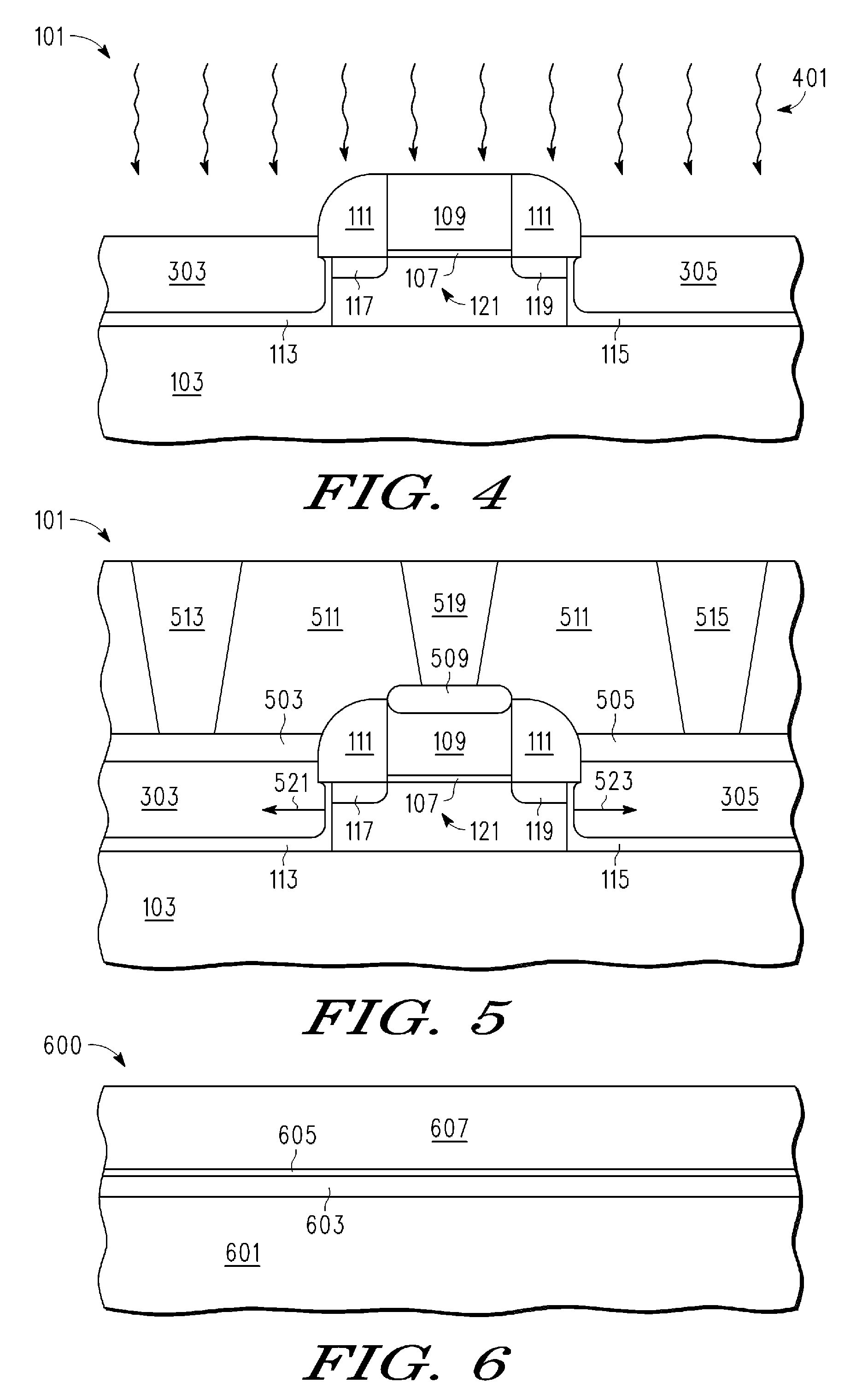

Pulse train annealing method and apparatus

InactiveUS20090120924A1Semiconductor/solid-state device manufacturingElectric heating for furnacesLaserFlash-lamp

The present invention generally describes apparatuses and methods used to perform an annealing process on desired regions of a substrate. In one embodiment, pulses of electromagnetic energy are delivered to a substrate using a flash lamp or laser apparatus. The pulses may be from about 1 nsec to about 10 msec long, and each pulse has less energy than that required to melt the substrate material. The interval between pulses is generally long enough to allow the energy imparted by each pulse to dissipate completely. Thus, each pulse completes a micro-anneal cycle. The pulses may be delivered to the entire substrate at once, or to portions of the substrate at a time. Further embodiments provide an apparatus for powering a radiation assembly, and apparatuses for detecting the effect of pulses on a substrate.

Owner:APPLIED MATERIALS INC

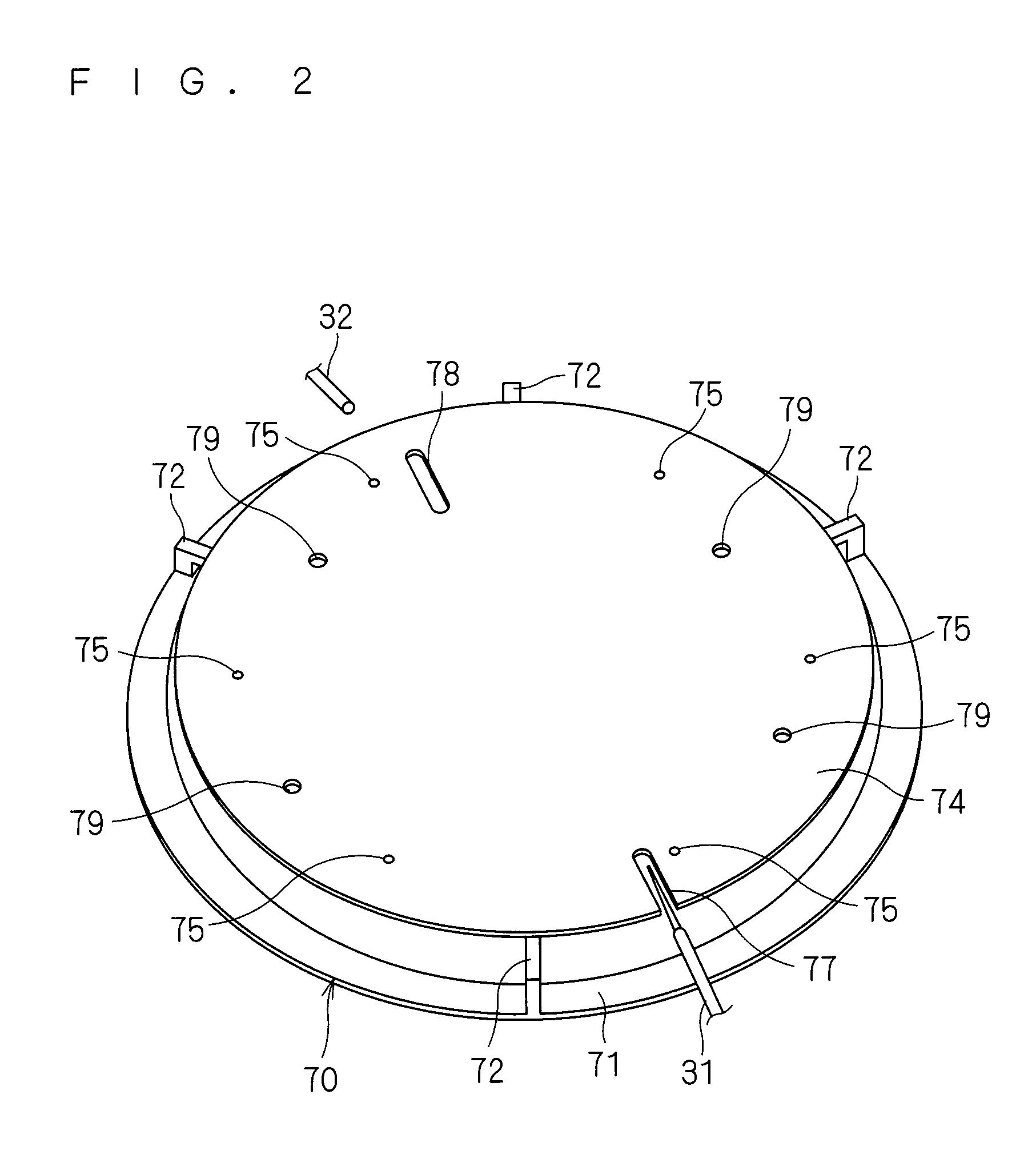

Susceptor for heat treatment and heat treatment apparatus

InactiveUS20060291835A1Avoid crackingWell formedSemiconductor/solid-state device manufacturingHigh-frequency/infra-red heating bakingSusceptorEngineering

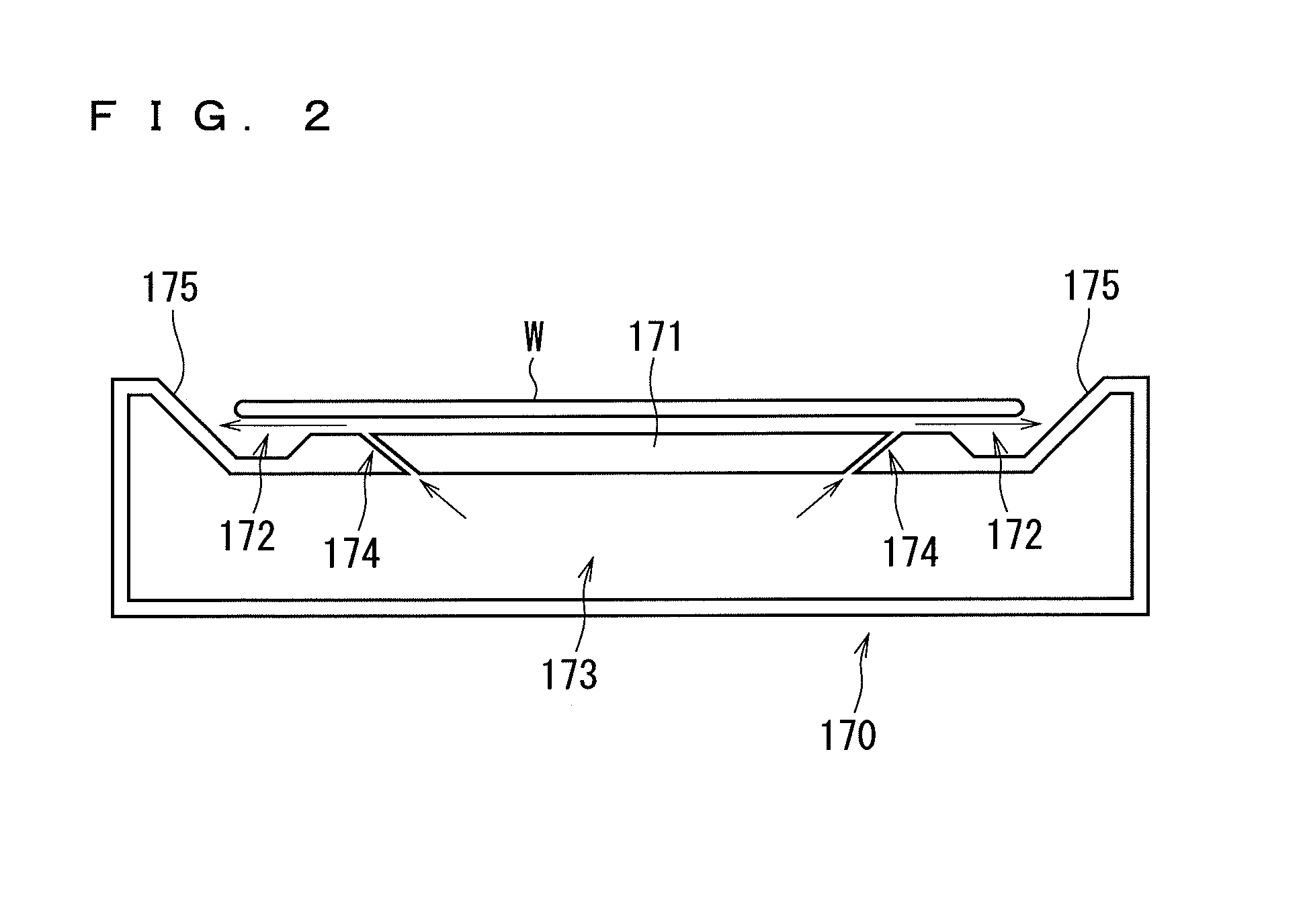

A susceptor for holding a semiconductor wafer when flash heating is performed by exposing the semiconductor wafer to a flash of light from flash lamps is formed with a recessed portion of a concave configuration having an outer diameter greater than the diameter of the semiconductor wafer, as seen in plan view. When the susceptor is viewed from above, the concave configuration of the recessed portion is greater in plan view size than the semiconductor wafer. The susceptor formed with the recessed portion holds the semiconductor wafer in such a manner that an inner wall surface of the recessed portion supports a peripheral portion of the semiconductor wafer. As a result, a gap filled with a layer of gas is formed between the lower surface of the semiconductor wafer and the upper surface of the susceptor, to prevent a crack in the semiconductor wafer when the semiconductor wafer is exposed to a flash of light from the flash lamps.

Owner:DAINIPPON SCREEN MTG CO LTD

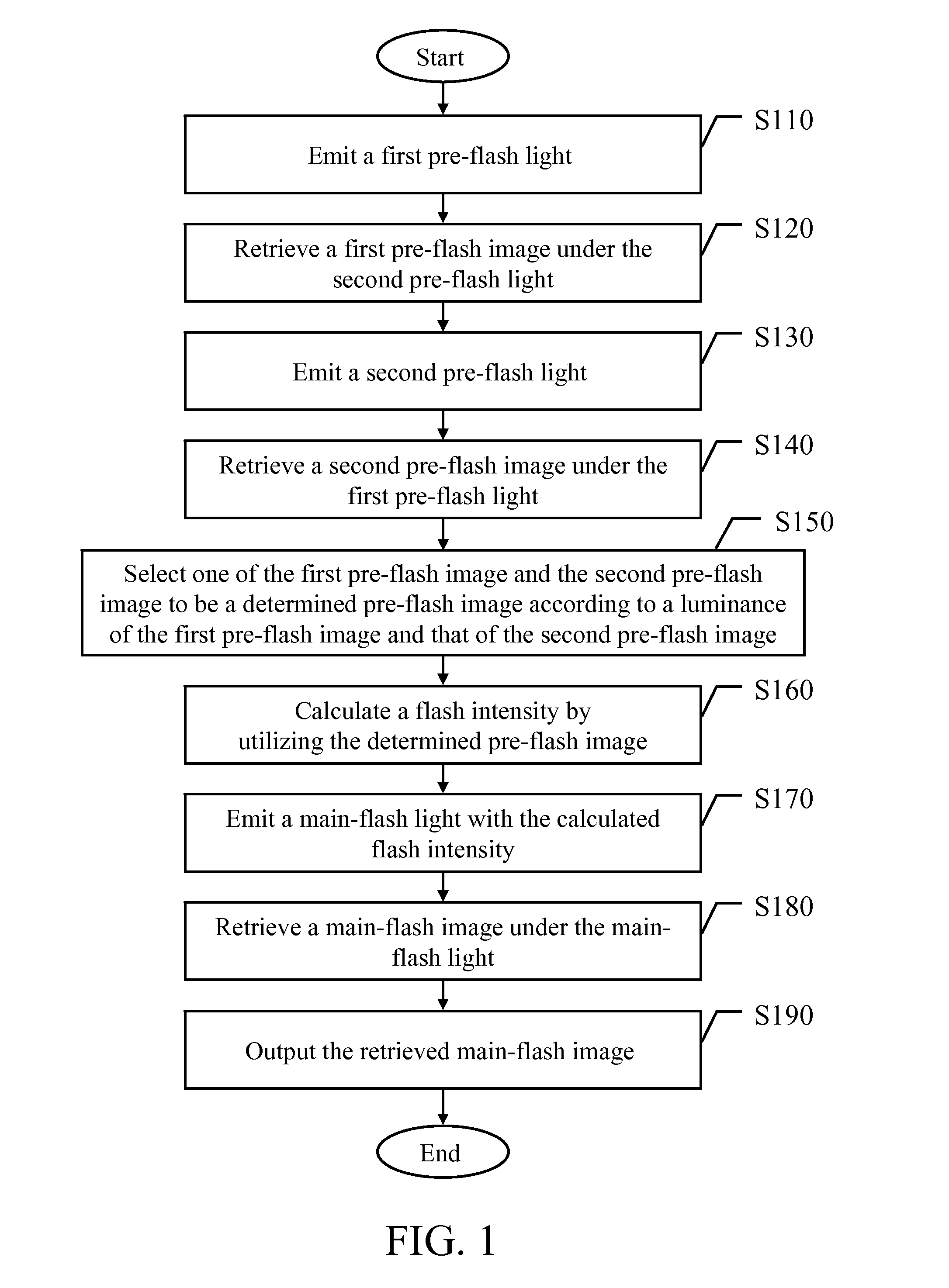

Adjusting method of flash intensity

InactiveUS20100165178A1Reduces luminance errorTelevision system detailsColor television detailsImage captureFlash-lamp

An adjusting method of flash intensity is applied in an image capture apparatus with a flash lamp, where two pre-flash images corresponding the object are retrieved under two different pre-flash lights, respectively, and then a flash intensity of main-flash light is calculated according to one of the retrieved pre-flash images, so as to retrieve a main-flash image corresponding the object under the main-flash light with the calculated main-flash light.

Owner:ALTEK CORP

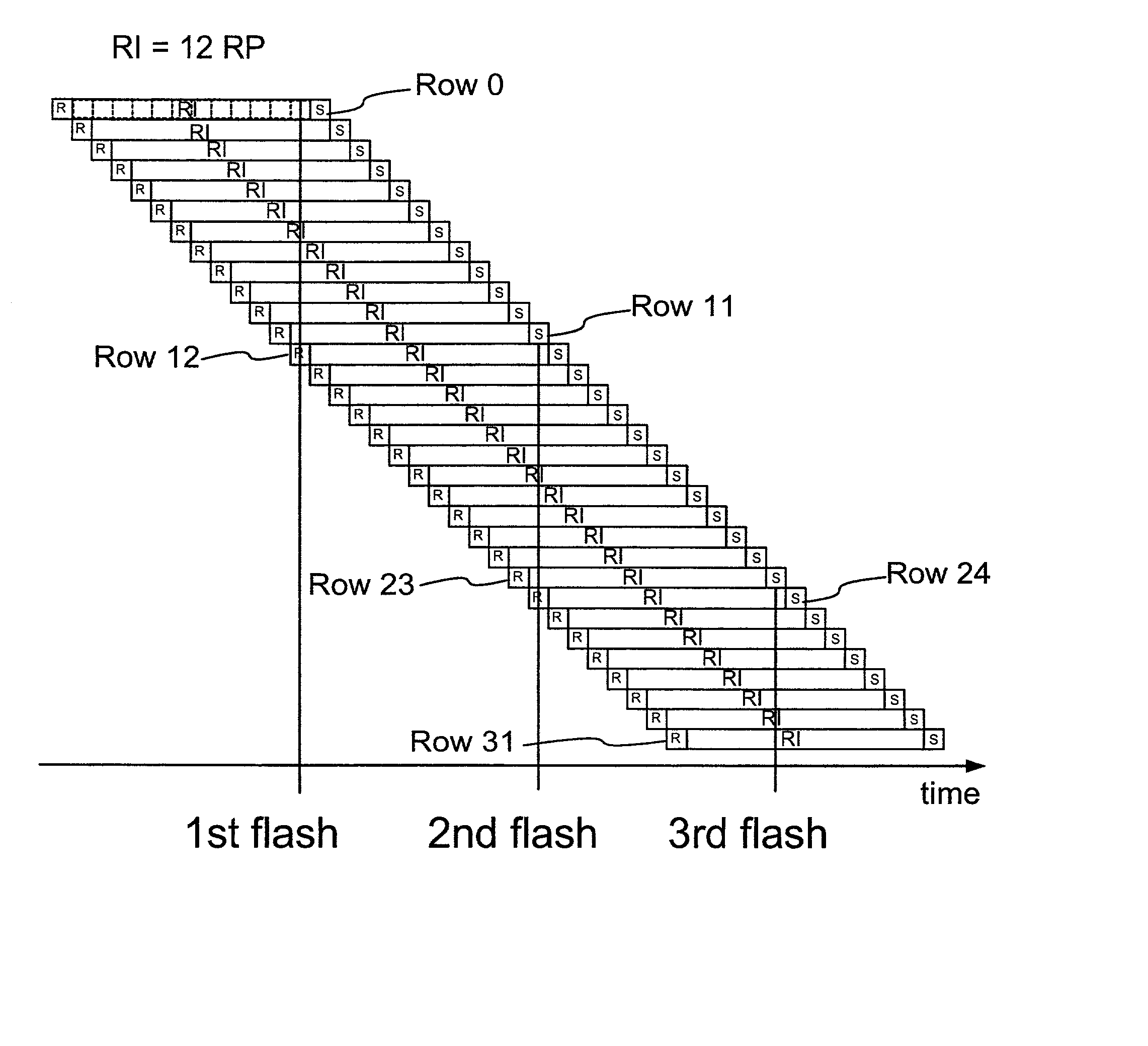

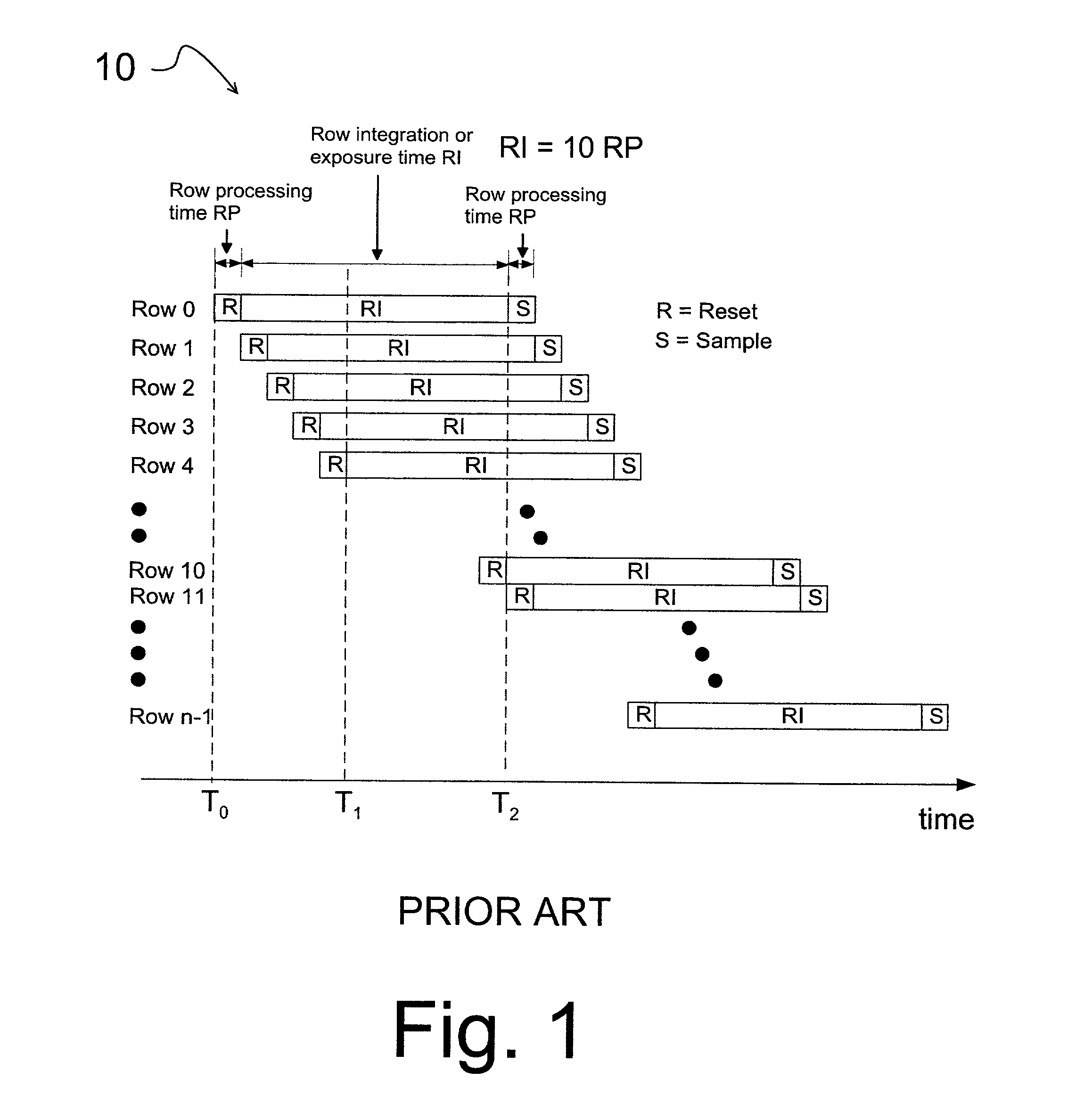

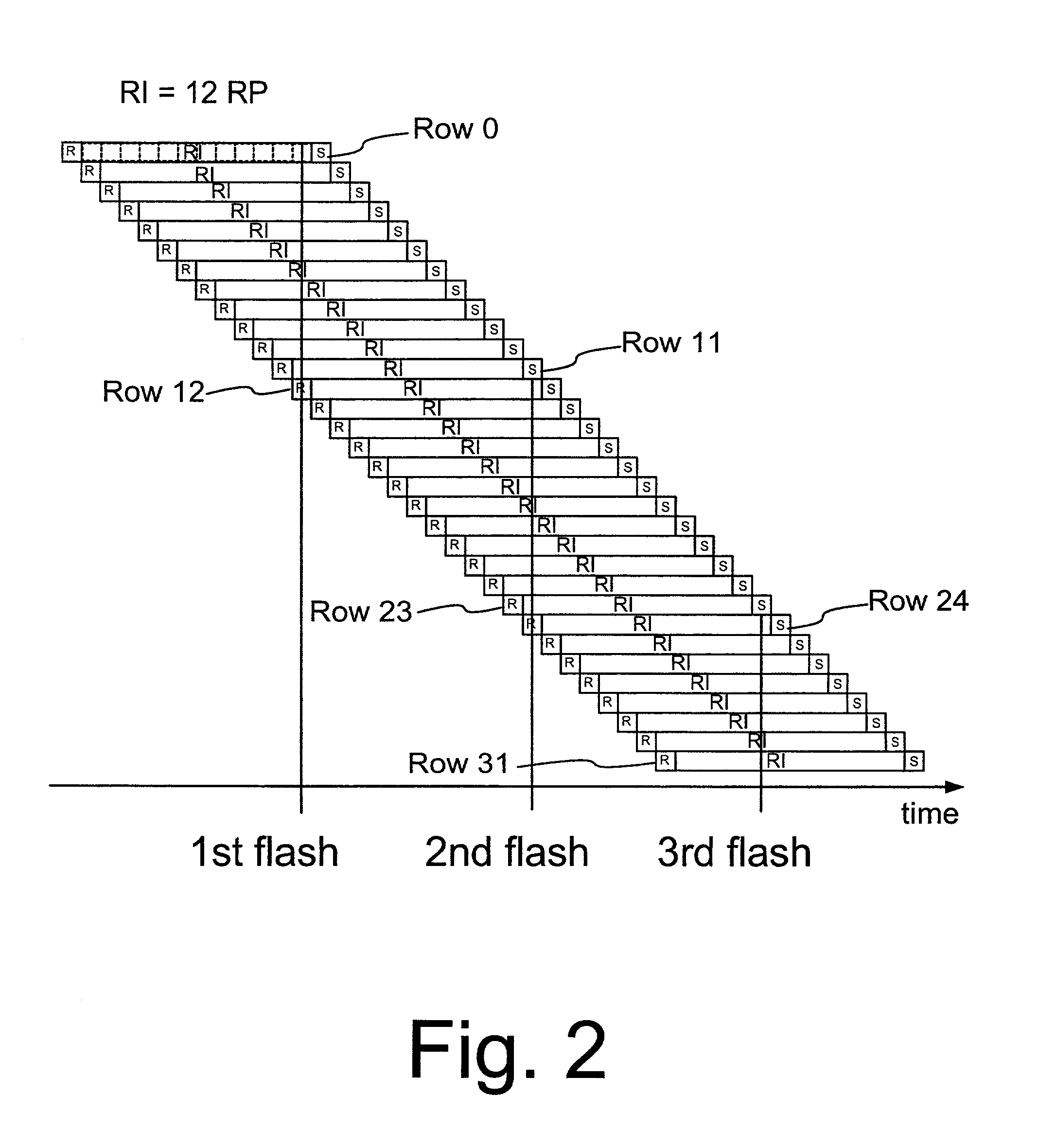

Control of a flash unit in a digital camera

ActiveUS20030007088A1Television system detailsTelevision system scanning detailsSingle flashElectronic shutter

The invention is based on a method for controlling a flashlight in connection with a digital image sensor without a mechanical shutter, wherein the exposure of the image sensor is performed in sub-areas, such as pixel rows or columns, or in another order, by using a rolling electronic shutter or the like. Thus, the exposure of said sub-areas of the image sensor takes place at least partly at different times. According to the invention, during the time of exposure of one image, i.e. substantially all the sub-areas of the image sensor, several discrete, successive flashes of the flashlight are used to achieve even exposure of the image area, which the flashes are timed in such a way that each single flash is triggered at a point of time which is common to the integration or exposure time of as many successive sub-areas of the image sensor as possible. According to the invention, the successive light flashes are also timed in such a way that one and only one flash of the flashlight occurs during the integration or exposure time of each single sub-area. By the present invention, the significant advantage is attained that the invention minimizes the number of light flashes required for one image while it also secures that each sub-area of the sensor to be exposed at a different time is illuminated as evenly as possible.

Owner:NOKIA TECHNOLOGLES OY

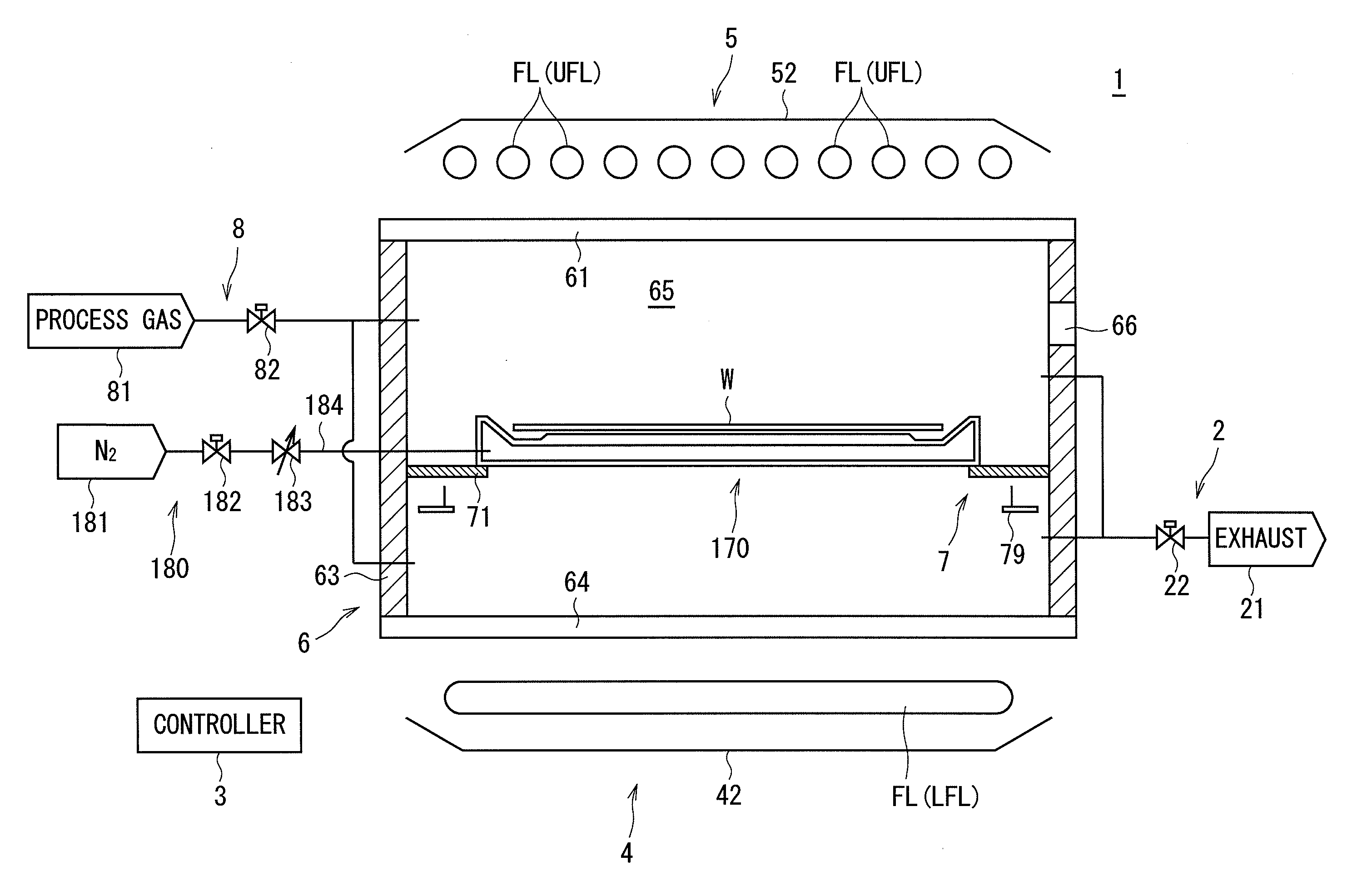

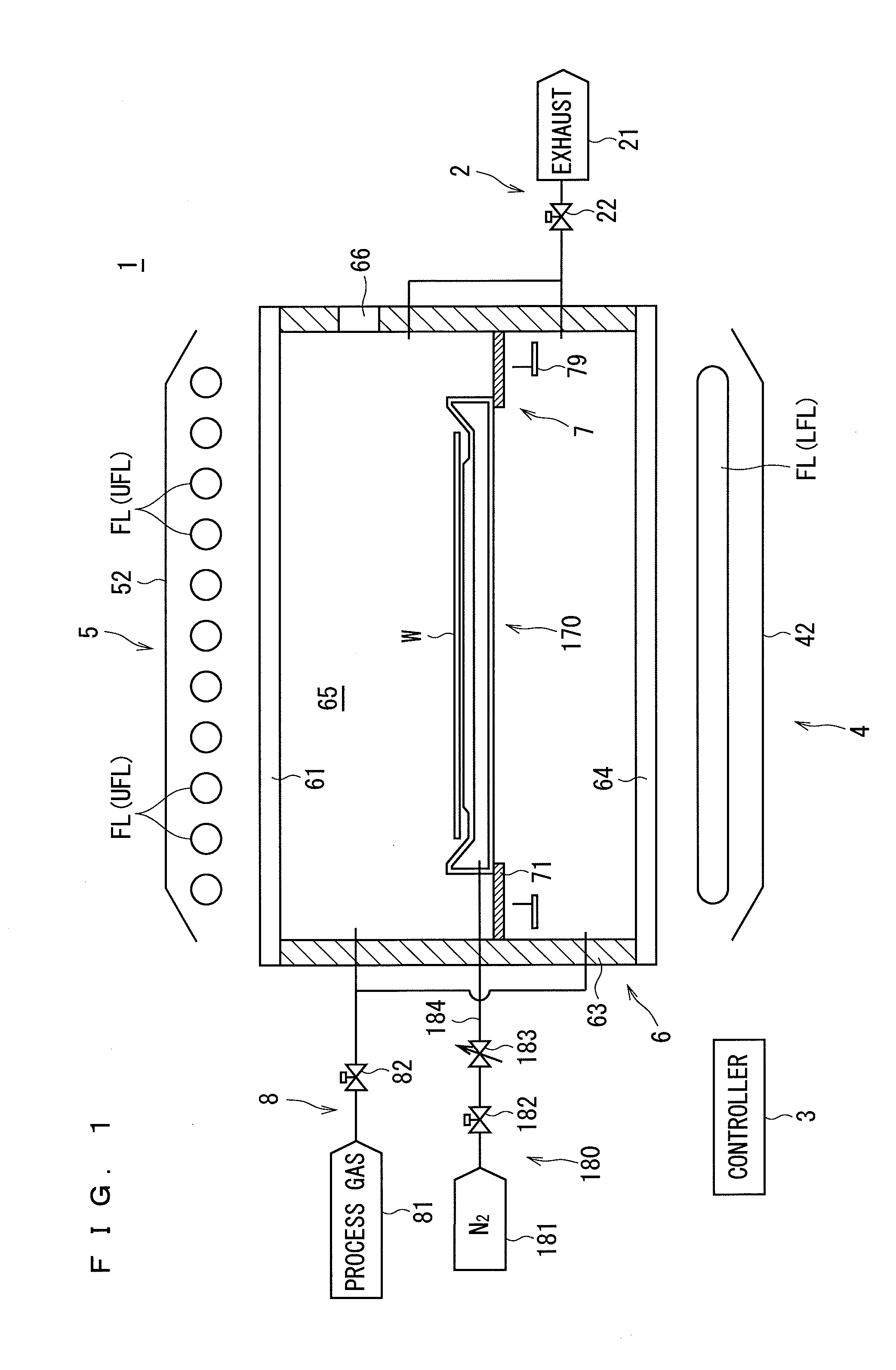

Heat treatment apparatus for heating substrate by irradiation with flashes of light, and heat treatment method

ActiveUS20130203269A1Degree of reductionAvoid crackingMuffle furnacesCharge supportsRoom temperatureEngineering

A first flash heating is performed in which a lower flash lamp irradiates a back surface of a semiconductor wafer with flashes of light, so that heat conduction from the back surface to a surface of the semiconductor wafer raises the temperature of the surface from the room temperature to an intermediate temperature. Then, a second flash heating is performed in which an upper flash lamp irradiates the surface of the semiconductor wafer with flashes of light, to raise the temperature of the surface of the semiconductor wafer from the intermediate temperature to a target temperature. Since only the irradiation with flashes of light emitted from the lower flash lamp and the upper flash lamp is used to cause the semiconductor wafer having the room temperature to reach the target temperature, all heat treatments can be completed in an extremely short time of one second or less.

Owner:DAINIPPON SCREEN MTG CO LTD

Thermal processing apparatus and thermal processing method

InactiveUS6998580B2Easy to controlDrying solid materials with heatMuffle furnacesUltimate tensile strengthIrradiation

Owner:DAINIPPON SCREEN MTG CO LTD

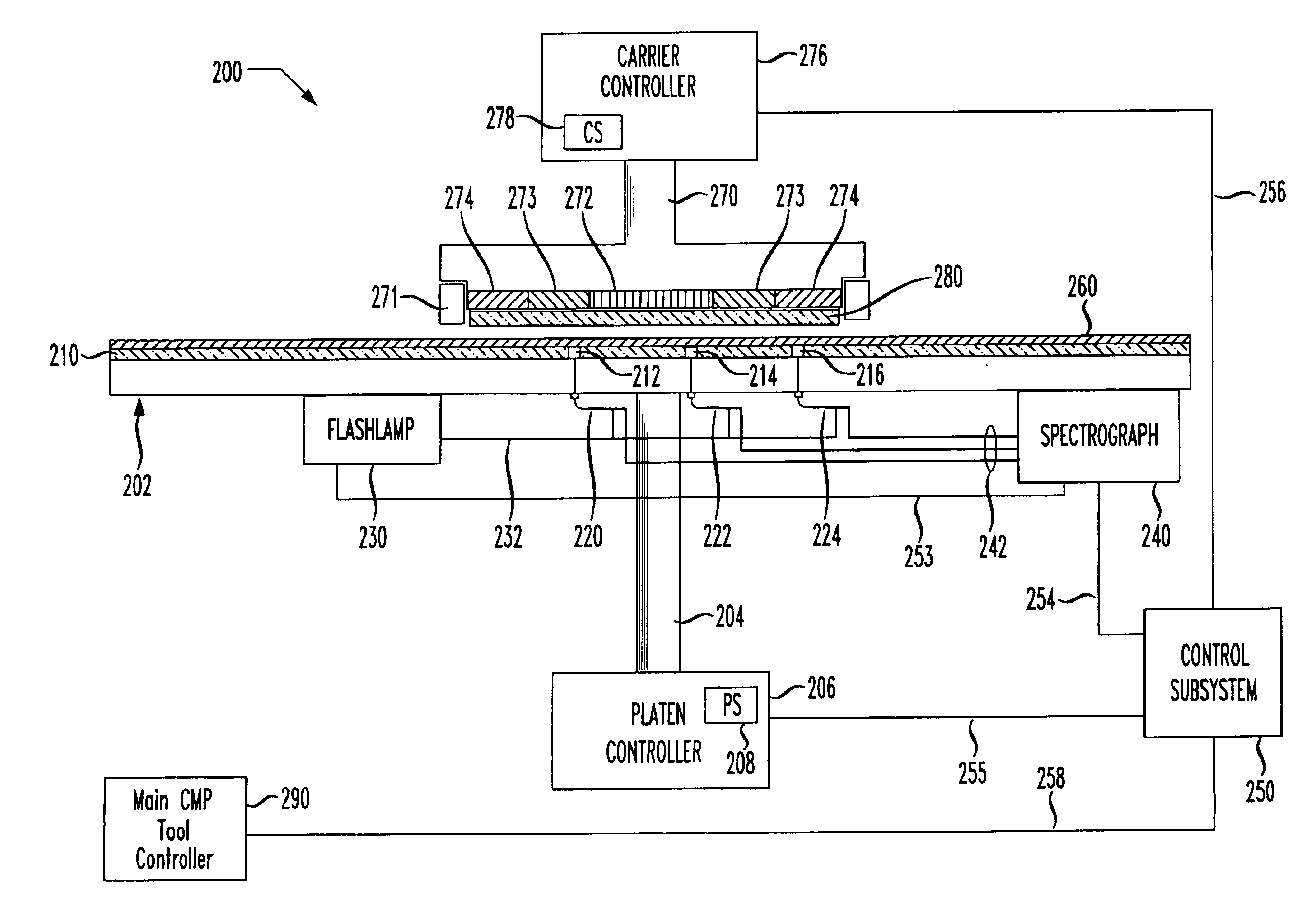

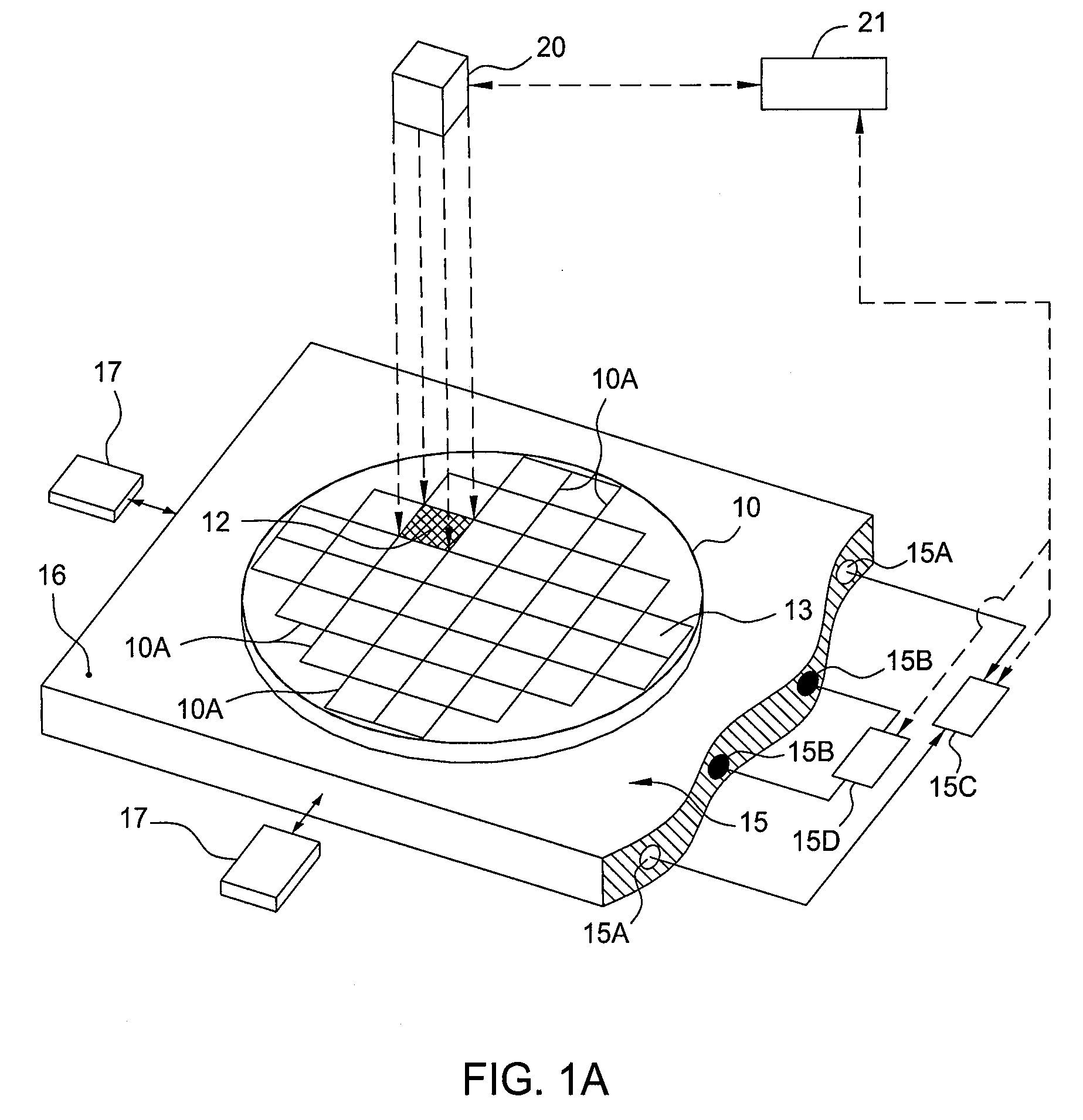

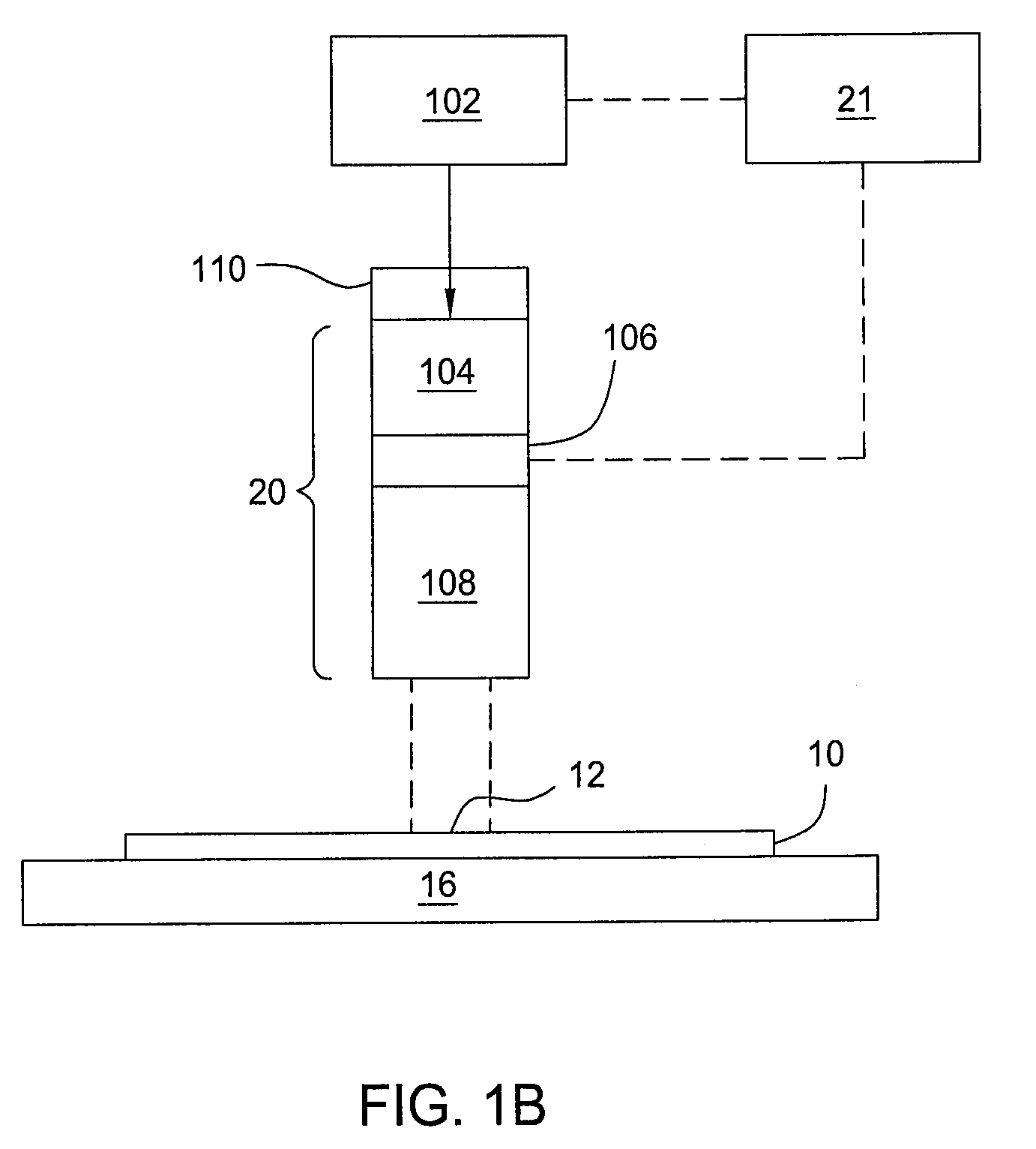

Optical closed-loop control system for a CMP apparatus and method of manufacture thereof

ActiveUS6991514B1Minimize timePolishing machinesRevolution surface grinding machinesFlash-lampEngineering

For use with a chemical mechanical polishing apparatus for polishing a semiconductor wafer having a platen, a polishing pad and a wafer carrier, an optical closed-loop control system. In one embodiment, the system includes a plurality of optical probes impacting a corresponding probe window and rigidly mountable through the platen. The system also includes a flash lamp configured to provide light to each of the plurality of optical probes and minimize an exposure time of the light onto the semiconductor wafer, a spectrograph configured to spatially image light received by each of the plurality of optical probes to a common charge-coupled device and produce real-time spectral reflectometry data therefrom. The system further includes a control subsystem configured to analyze the real-time spectral reflectometry data and determine at least one wafer state parameter therefrom, and cause the polishing to be adjusted based upon the at least one wafer state parameter.

Owner:VERITY INSTR

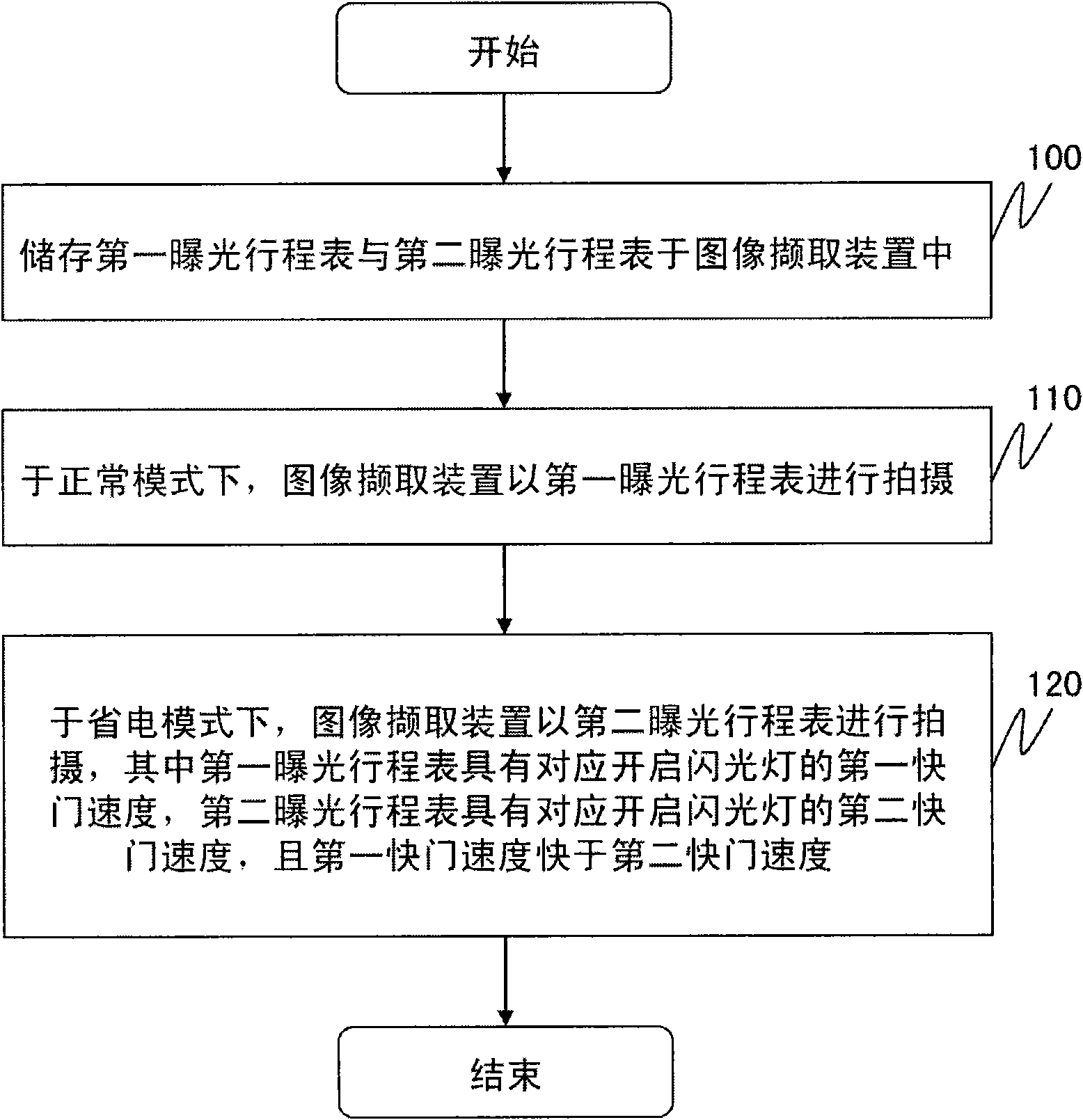

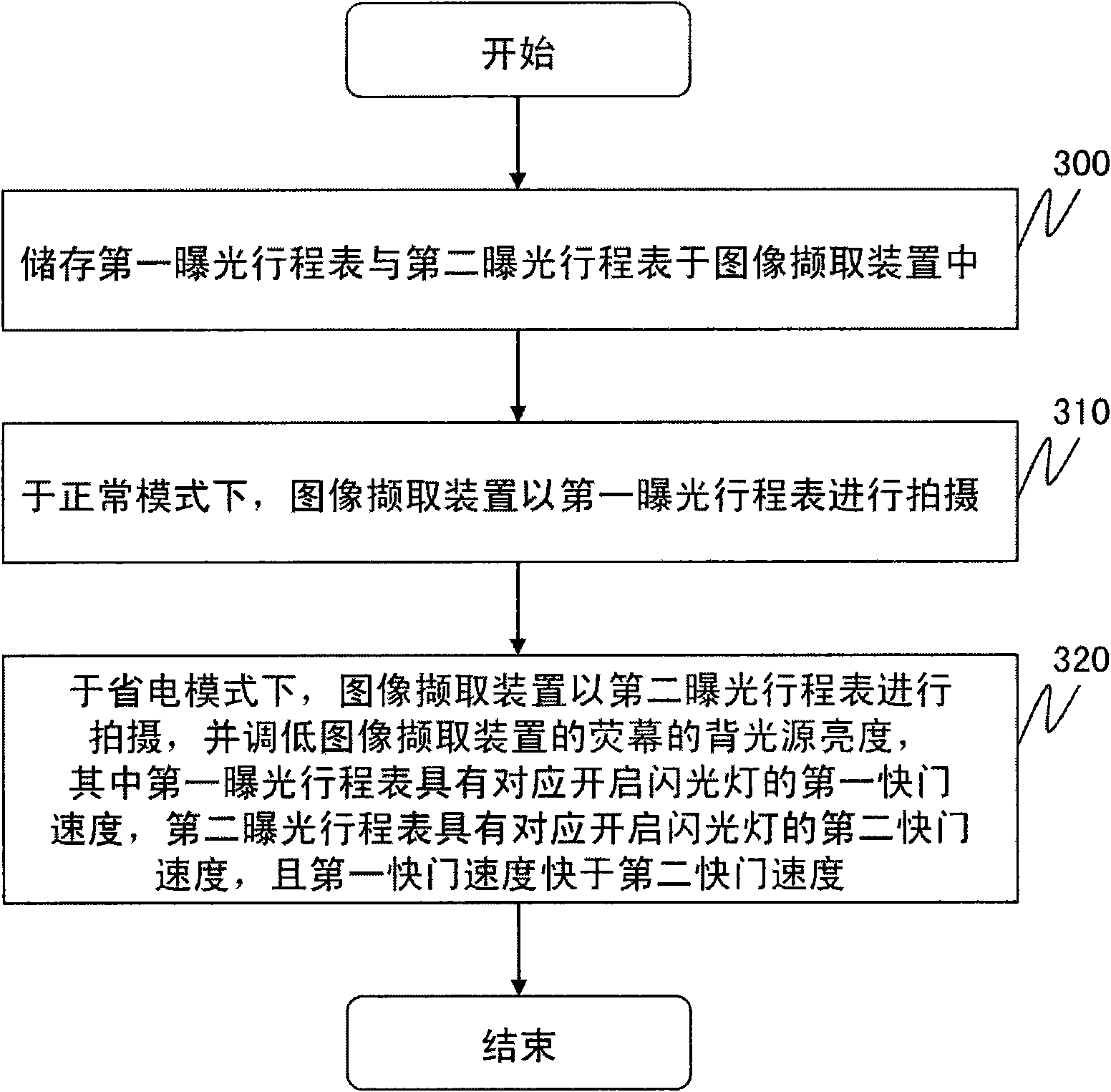

Power-saving method of image capture device

InactiveCN101959016ASave electricityExtended use timeTelevision system detailsColor television detailsComputer hardwareNormal mode

The invention discloses a power-saving method of an image capture device, which is applied to an image capture device with a flash lamp, and comprises the following steps: storing a first exposure travel table and a second exposure travel table in the image capture device; under a normal mode, shooting according to the first exposure travel table by the image capture device; and under a power-saving mode, shooting according to the second exposure travel table by the image capture device, wherein the first exposure travel table has a first shutter speed for correspondingly opening the flash lamp, the second exposure travel table has a second shutter speed for correspondingly opening the flash lamp, and the first shutter speed is faster than the second shutter speed. According to the operation mode of the image capture device, the exposure travel table of the image capture device can be adjusted by the method correspondingly, thus prolonging the service time of the image capture device.

Owner:ALTEK CORP

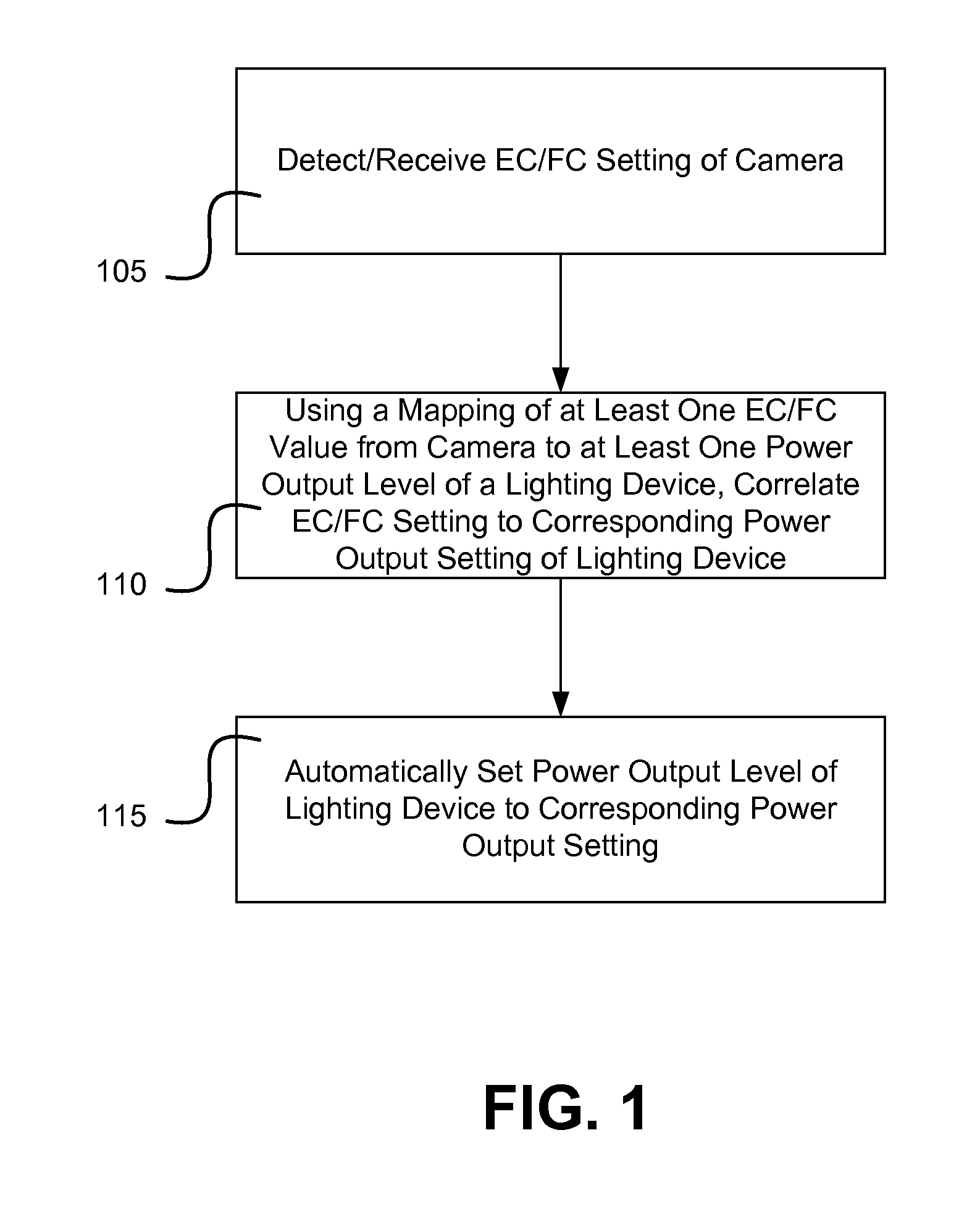

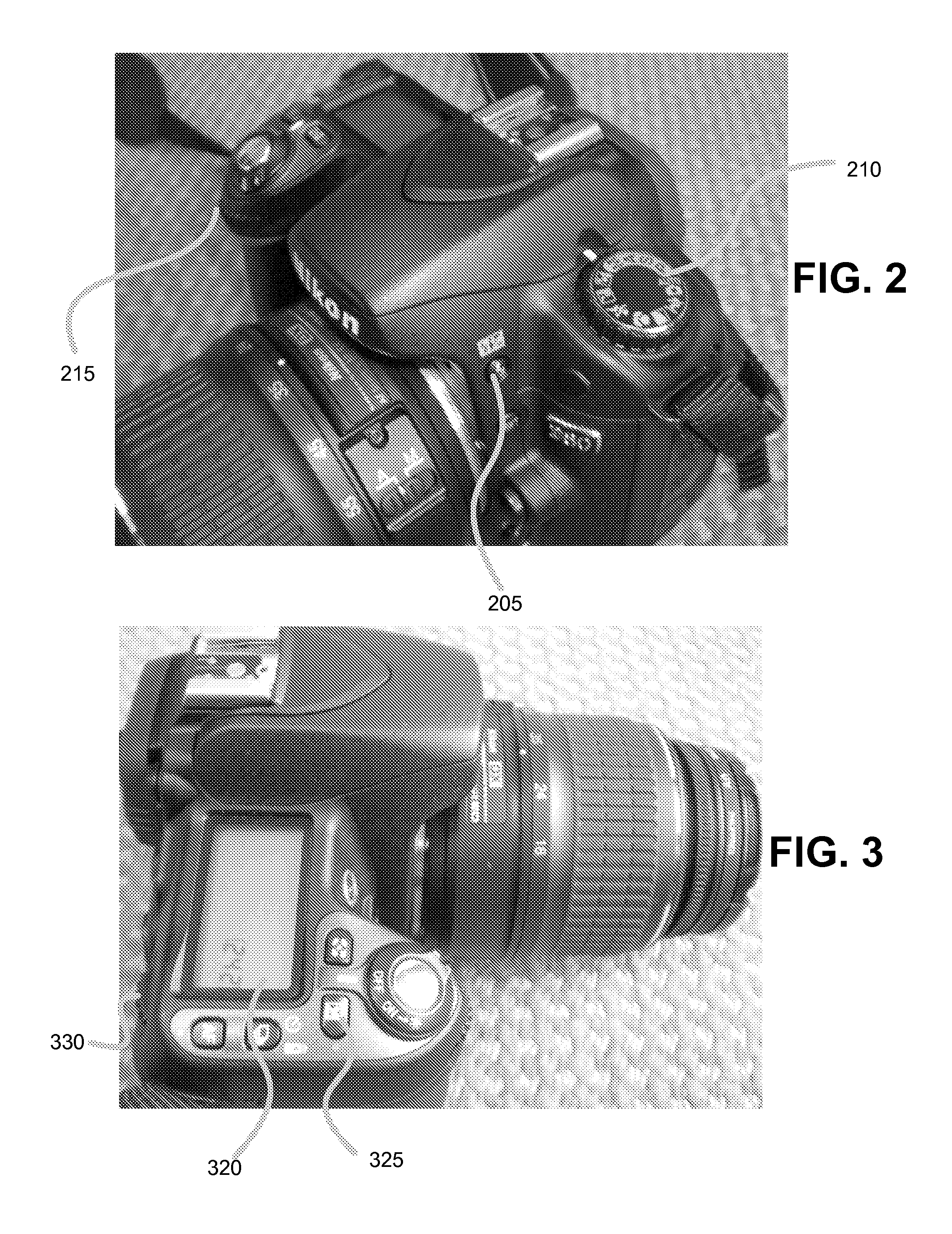

Photographic Light Output Power Control System and Method

InactiveUS20120140088A1Television system detailsColor television detailsLight equipmentPower control system

Retasking of one or more photographic exposure controls of a camera to give direct manual control of a power output level of a lighting device by mapping a dynamic range of a photographic exposure compensation control of the camera to a dynamic range of a power output level of the lighting device. In another example, mapping is used in automatic tracking of changes in ISO and / or aperture of a camera to a power output level of a lighting device. In one example, automatic tracking of power control can be provided to lighting devices (such as studio strobes) that do not usually have access to automated power control from a camera.

Owner:LAB PARTNERS ASSOC INC

Heat treatment apparatus for heating substrate by exposing substrate to flash light

InactiveUS20090175605A1Suppresses temperature changesPrevent treatment failureSemiconductor/solid-state device manufacturingHigh-frequency/infra-red heating bakingElectrical resistance and conductanceSusceptor

A semiconductor wafer to be treated is placed in a horizontal position on a holding plate held by a susceptor. Six bumps are mounted upright on the upper surface of the holding plate. The semiconductor wafer is supported by the six bumps in point contacting relationship, and is held at a distance ranging from 0.5 mm to 3 mm from the upper surface of the holding plate. Light is directed from halogen lamps onto the semiconductor wafer held by the holding plate to preheat the substrate until the temperature of the semiconductor wafer is increased up to a predetermined temperature. Thereafter, flash light is directed from flash lamps onto the semiconductor wafer. A thin gas layer lying between the back surface of the semiconductor wafer and the upper surface of the holding plate acts as a resistance to suppress the motion of the semiconductor wafer, thereby preventing a crack in the semiconductor wafer.

Owner:DAINIPPON SCREEN MTG CO LTD

Flash lamp drive circuit

The invention provides a power supply or drive circuit for a pulsed flashlamp which utilizes a two-core component having common windings as both an inductor for arc mode drive and for breakdown triggering of the lamp. Discharge of a capacitor through the inductor and lamp is controlled by a high-speed semiconductor switch which is turned on and off by a suitable control, current flowing from the inductor through a one-way path including the lamp when the switch is off. The control maintains the ratio of the power variation through the lamp to the average power through the lamp substantially constant. The controls may also be utilized to control output pulse shape. Novel protective features are also provided for circuit components during turn on periods for the switch.

Owner:PALOMAR MEDICAL TECH

Pulse train annealing method and apparatus

ActiveUS20090121157A1Semiconductor/solid-state device manufacturingRadiation therapyPulse sequenceLaser

The present invention generally describes apparatuses and methods used to perform an annealing process on desired regions of a substrate. In one embodiment, pulses of electromagnetic energy are delivered to a substrate using a flash lamp or laser apparatus. The pulses may be from about 1 nsec to about 10 msec long, and each pulse has less energy than that required to melt the substrate material. The interval between pulses is generally long enough to allow the energy imparted by each pulse to dissipate completely. Thus, each pulse completes a micro-anneal cycle. The pulses may be delivered to the entire substrate at once, or to portions of the substrate at a time. Further embodiments provide an apparatus for powering a radiation assembly, and apparatuses for detecting the effect of pulses on a substrate.

Owner:APPLIED MATERIALS INC

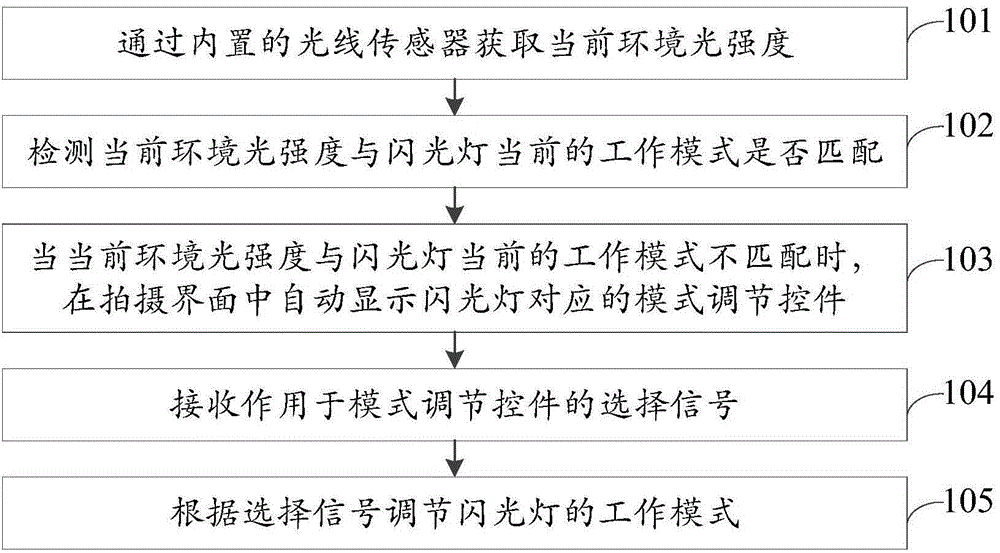

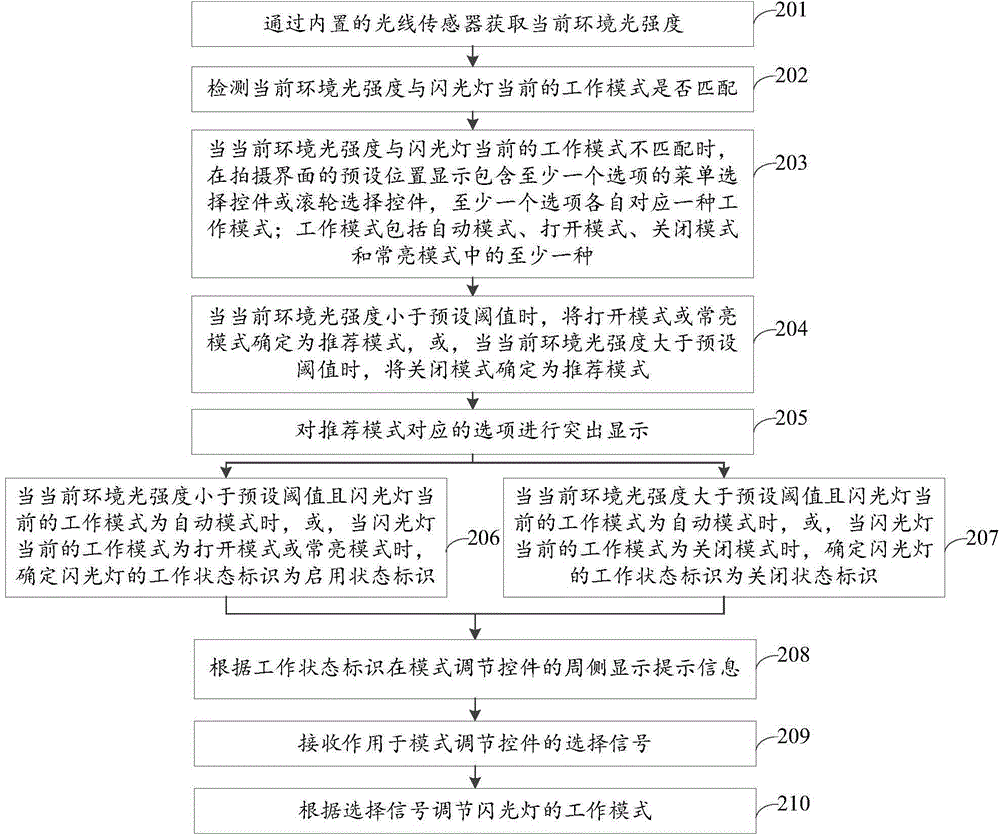

Method and device for regulating mode

ActiveCN106210550AEasy to controlSolve the problem of low control and control efficiencyTelevision system detailsColor television detailsLine sensorWork pattern

The invention discloses a method and a device for regulating a mode, which belong to the field of intelligent devices. The method comprises steps: current ambient light intensity is acquired through a built-in light sensor; whether the current ambient light intensity is matched with the current working mode of a flash lamp is detected; when the current ambient light intensity is not matched with the current working mode of the flash lamp, a mode regulation control corresponding to the flash lamp is automatically displayed in a shooting interface; a selection signal acting on the mode regulation control is received; and according to the selection signal, the working mode of the flash lamp is regulated. Automatic pop-up of the mode regulation control corresponding to the flash lamp is realized through a terminal, the user can directly select a flash lamp working mode, and the control efficiency is improved.

Owner:XIAOMI INC

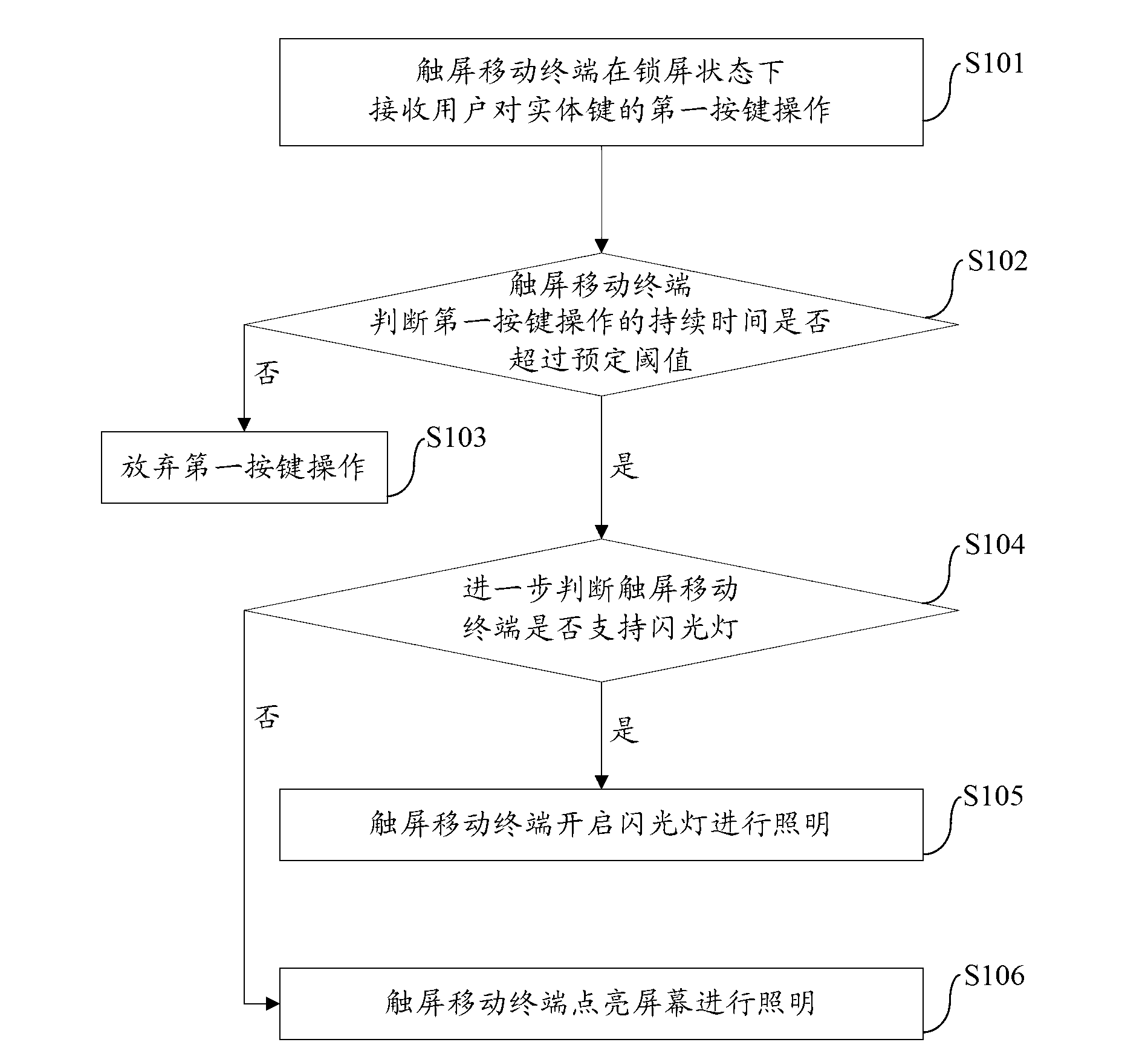

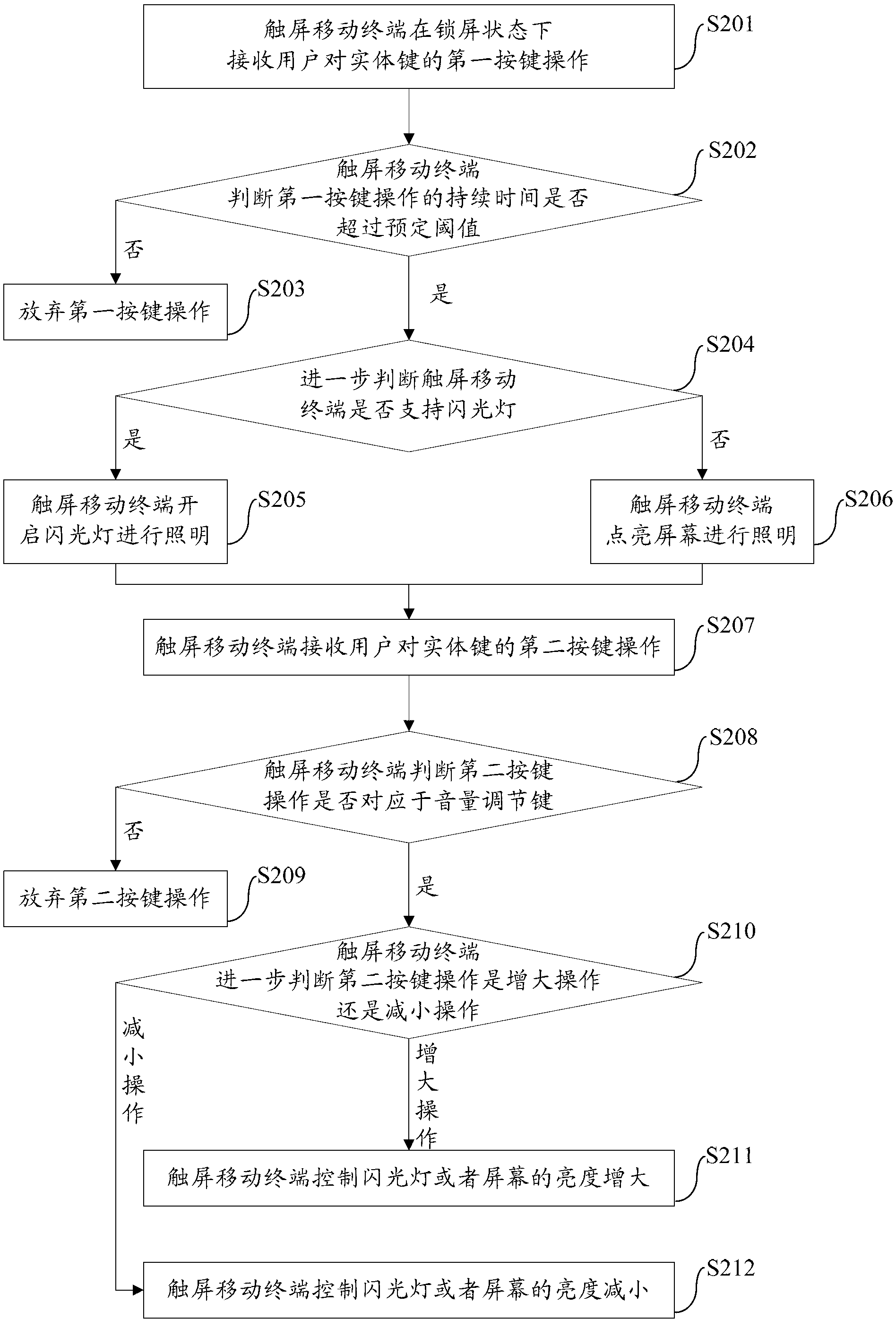

Touch screen mobile terminal and quick illumination-starting method and quick illumination-starting system thereof

ActiveCN103019567AShorten the timeImprove experienceInput/output processes for data processingKey pressingComputer terminal

The invention provides a quick illumination-starting method and a quick illumination-starting system for touch screen mobile terminals and a touch screen mobile terminal, wherein the method includes the following steps: the touch screen mobile terminal receives the first key operation of an entity key by a user under a screen-locked state; the touch screen mobile terminal judges whether the duration of the first key operation exceeds a predetermined threshold value; if so, whether the touch screen mobile terminal supports a flash lamp is further judged; if so, then the touch screen mobile terminal switches on the flash lamp for illumination; and if not, then the touch screen mobile terminal lights up the screen for illumination. According to the method of the embodiment of the invention, the flash lamp can be switched on or the screen can be lit up without requiring the unlocking of the screen and the starting of an illumination control program as long as the entity key is pressed for a while, so that the operation process is simplified, consequently, the time of illumination starting by the user is saved, moreover, operation is convenient and quick, and the experience of users is good.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

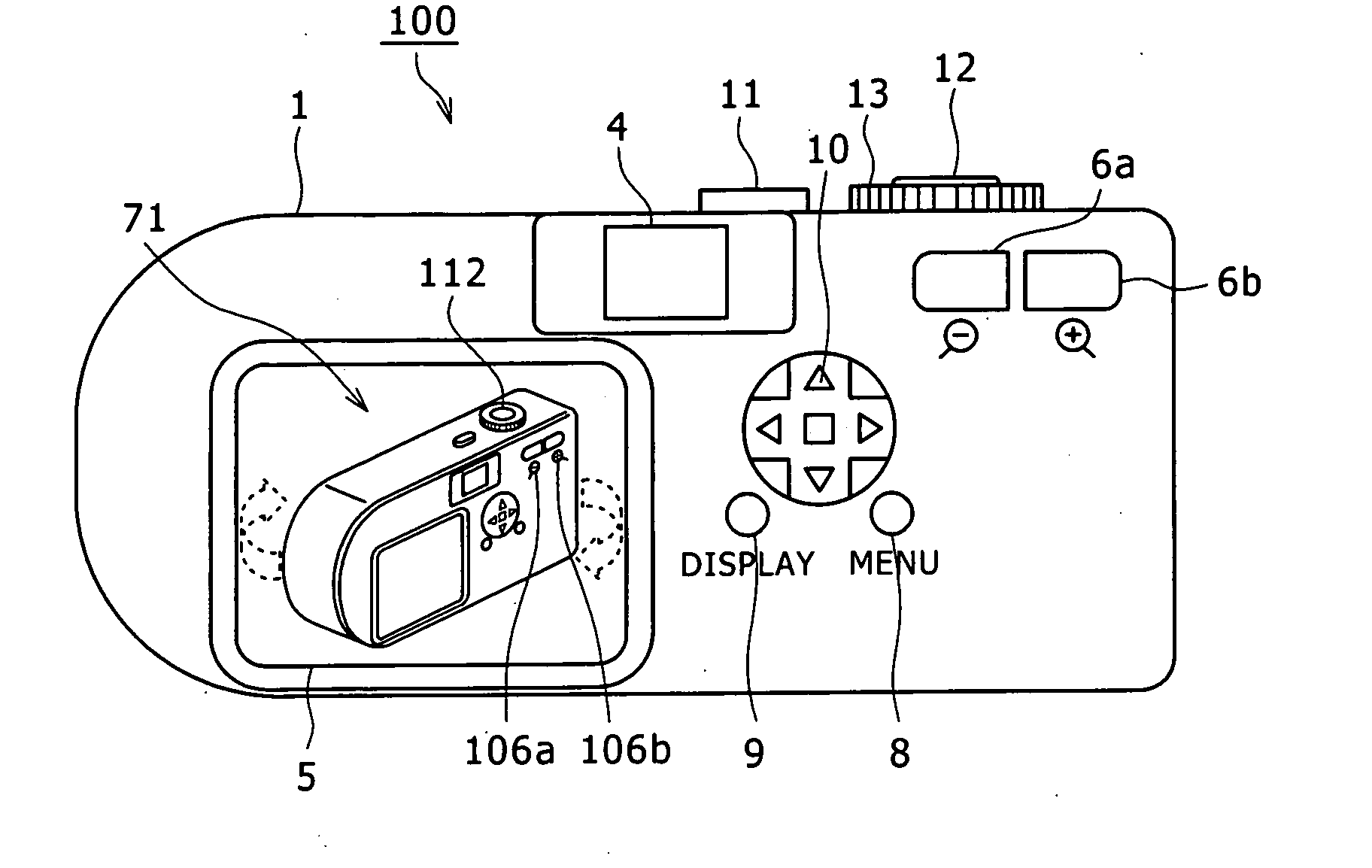

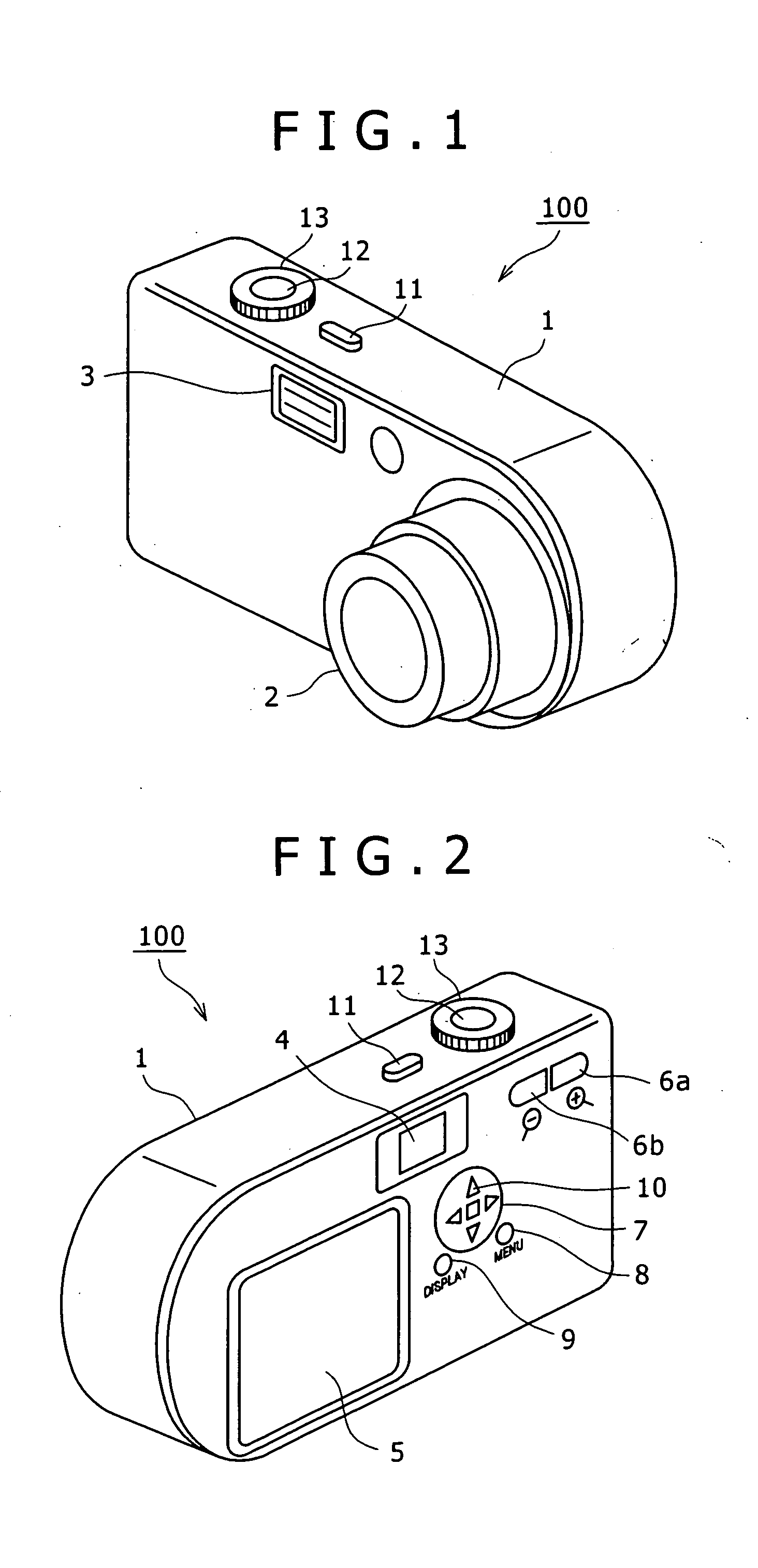

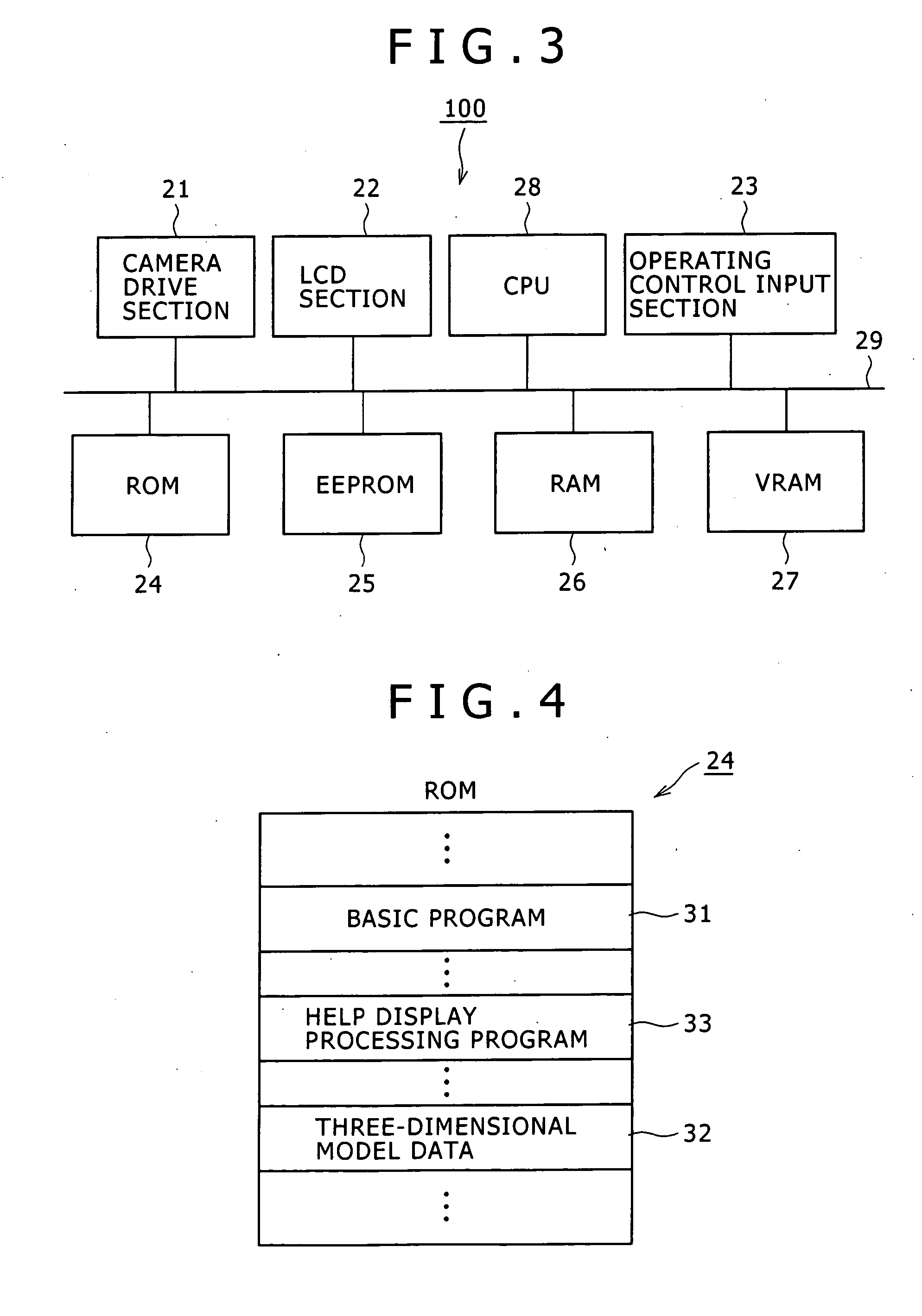

Electronic device and its operation explanation display method

InactiveUS20060170687A1Amount of memory can be minimisedQuantity minimizationTelevision system detailsColor television detailsOperating instructionAnimation

Disclosed is an electronic device / apparatus capable of displaying an animation that varies with internal settings and minimizing the amount of memory use for handling information for animation generation. When a shutter button (12) is pressed in a help display mode, flash ON / OFF setup information (52) stored in an EEPROM (25) is referenced. If the value of the flash ON / OFF setup information is ON, a three-dimensional animation in which a flash (104) on a three-dimensional model (71) emits light is created and displayed in accordance with three-dimensional model data. If, on the other hand, the value is OFF, a three-dimensional animation in which the flash (104) on the three-dimensional (71) model does not emit light is displayed. Consequently, the user can recognize visually and intuitively the difference among various digital camera (100) motions that vary with system settings.

Owner:SONY CORP

Heat treatment apparatus heating substrate by irradiation with light

ActiveUS20090067823A1Set freeDomestic stoves or rangesDrying solid materials with heatPower flowIrradiation

A capacitor, a coil, a flash lamp, and a switching element such as an IGBT are connected in series. A controller outputs a pulse signal to the gate of the switching element. A waveform setter sets the waveform of the pulse signal, based on the contents of input from an input unit. With electrical charge accumulated in the capacitor, a pulse signal is output to the gate of the switching element so that the flash lamp emits light intermittently. A change in the waveform of the pulse signal applied to the switching element will change the waveform of current flowing through the flash lamp and, accordingly, the form of light emission, thereby resulting in a change in the temperature profile for a semiconductor wafer.

Owner:DAINIPPON SCREEN MTG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com