Method and device for separating and recovering mercury

A technology for separation and recovery of mercury, applied in separation methods, distillation separation, chemical instruments and methods, etc., can solve problems such as thermal deterioration of phosphor powder, deterioration of brightness and other characteristics, and destruction of phosphor crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

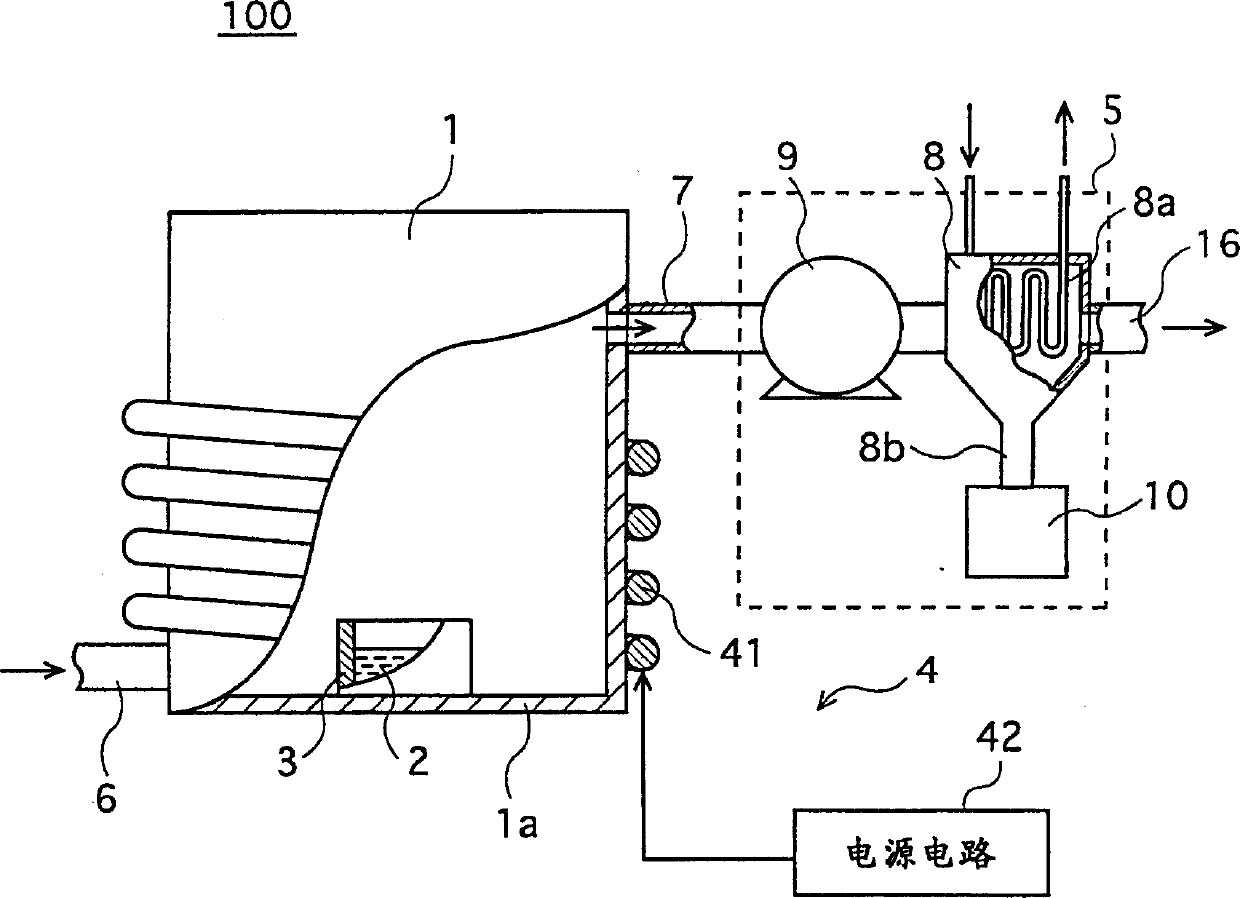

[0027] FIG. 1 is a structural diagram showing a mercury separation and recovery device 100 used in a mercury separation and recovery method according to a first embodiment of the present invention.

[0028] As shown in the same figure, this mercury separation and recovery device 100 is equipped with a cylindrical sealable metal reaction vessel 1, and the bottom of the reaction vessel 1 is arranged for containing phosphor powder containing mercury and A cylindrical distillation vessel 3 for the mixture 2 of the organic reducing agent, a heating device 4 for heating the mixture 2 in the distillation vessel 3 and vaporizing and separating mercury from the phosphor powder, and a reaction vessel 1 for absorbing and condensing Mercury Recovery of Vaporized Mercury Part 5.

[0029] The distillation vessel 3 is made of stainless steel and can be attached and detached from the bottom 1 a of the reaction vessel 1 . In addition, a pipeline 6 for feeding gases such as nitrogen and air is...

experiment example

[0049] The following will describe an experimental example for determining the effect of the method for separating and recovering mercury in the first embodiment.

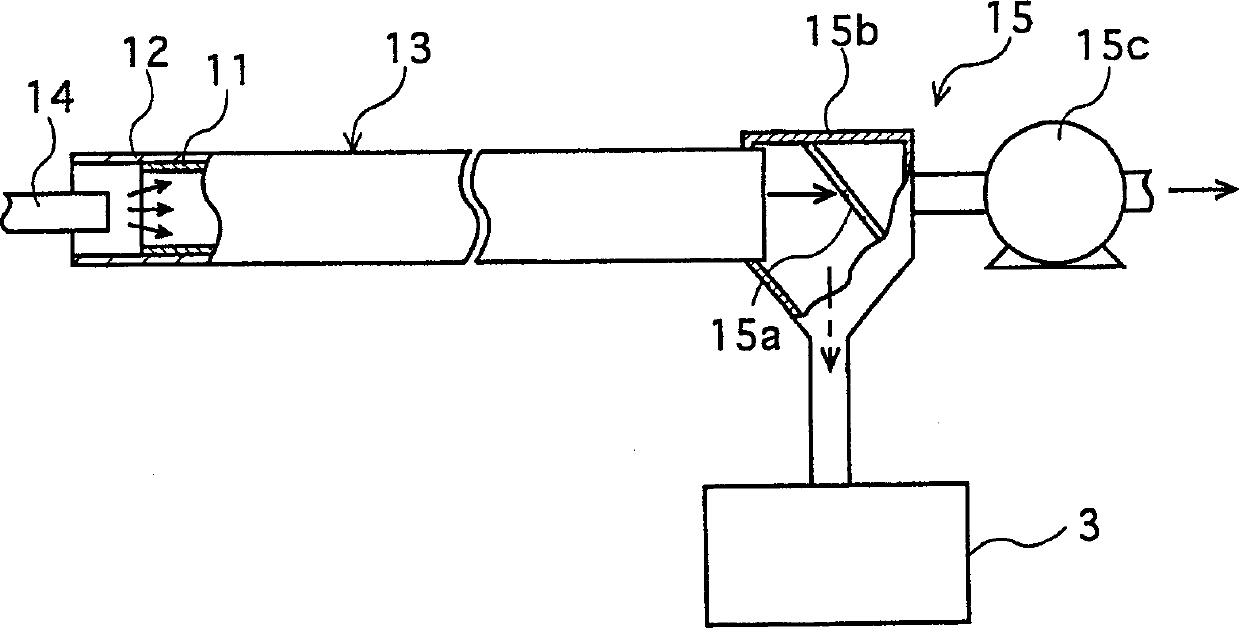

[0050] First, phosphor powder was recovered from the end-of-life straight-tube type waste fluorescent lamp 13 with a rated power of 40 W. The phosphor used in the waste fluorescent lamp 13 is made of red phosphor Y 2 o 3 : Eu, blue phosphor (SrCaBa) 5 (PO 4 ) 3 Cl:Eu, green phosphor LaPO 4 : Rare earth phosphor composed of Tb and Ce.

[0051] The amount of mercury contained in the recovered phosphor powder, that is, the phosphor powder before mercury separation (hereinafter referred to as "the phosphor powder before treatment") was 2800 μg per 2 g of the phosphor powder.

[0052] The phosphor powder before treatment was mixed into an aqueous solution in which oxalic acid was dissolved at a ratio of 0.4 g (20% by weight) of oxalic acid to 2 g of the phosphor powder to prepare a mixture A (Example 1).

[0053]...

no. 2 Embodiment approach

[0069] The following describes the mercury separation and recovery device related to the second embodiment of the present invention. Since this mercury separation and recovery device has the same structure as the mercury separation and recovery device 100 (FIG. 1) used in the mercury separation and recovery method in the first embodiment above, except that a spacer 17 made of a thermally conductive material is provided in the distillation vessel 3, structure, only the distillation vessel 3 will be described below.

[0070] Fig. 7A is a perspective view showing an example of the distillation vessel 3 in the second embodiment. As shown in the figure, a spacer member 17 composed of three stainless steel cylindrical members having different diameters is provided substantially concentrically in the distillation vessel 3 . 7B is a schematic diagram of heat conduction in the phosphor powder 20 in the distillation vessel 3 in the reaction vessel 1, and the distillation vessel 3 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com