Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

171results about "Tube/lamp material recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

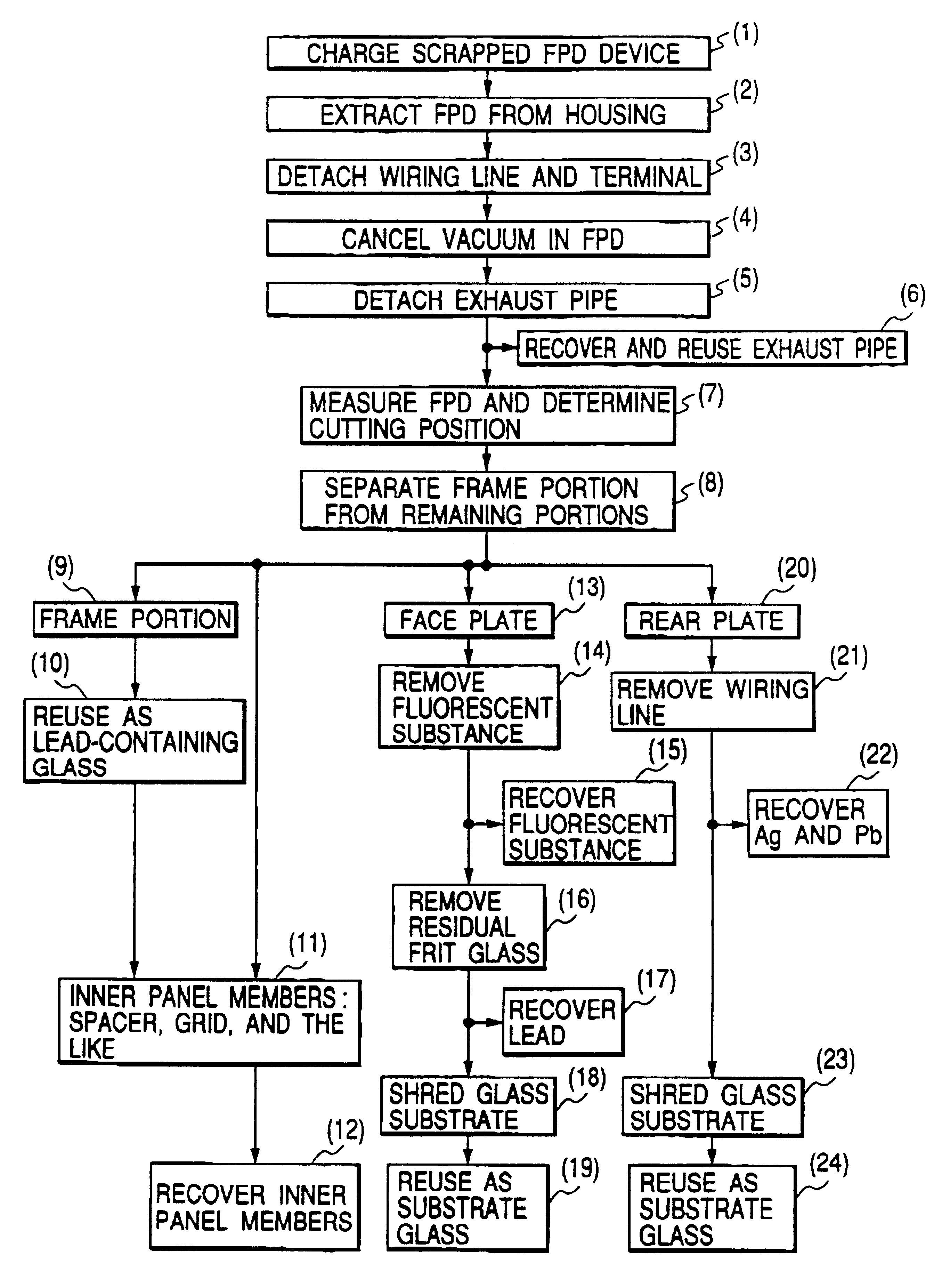

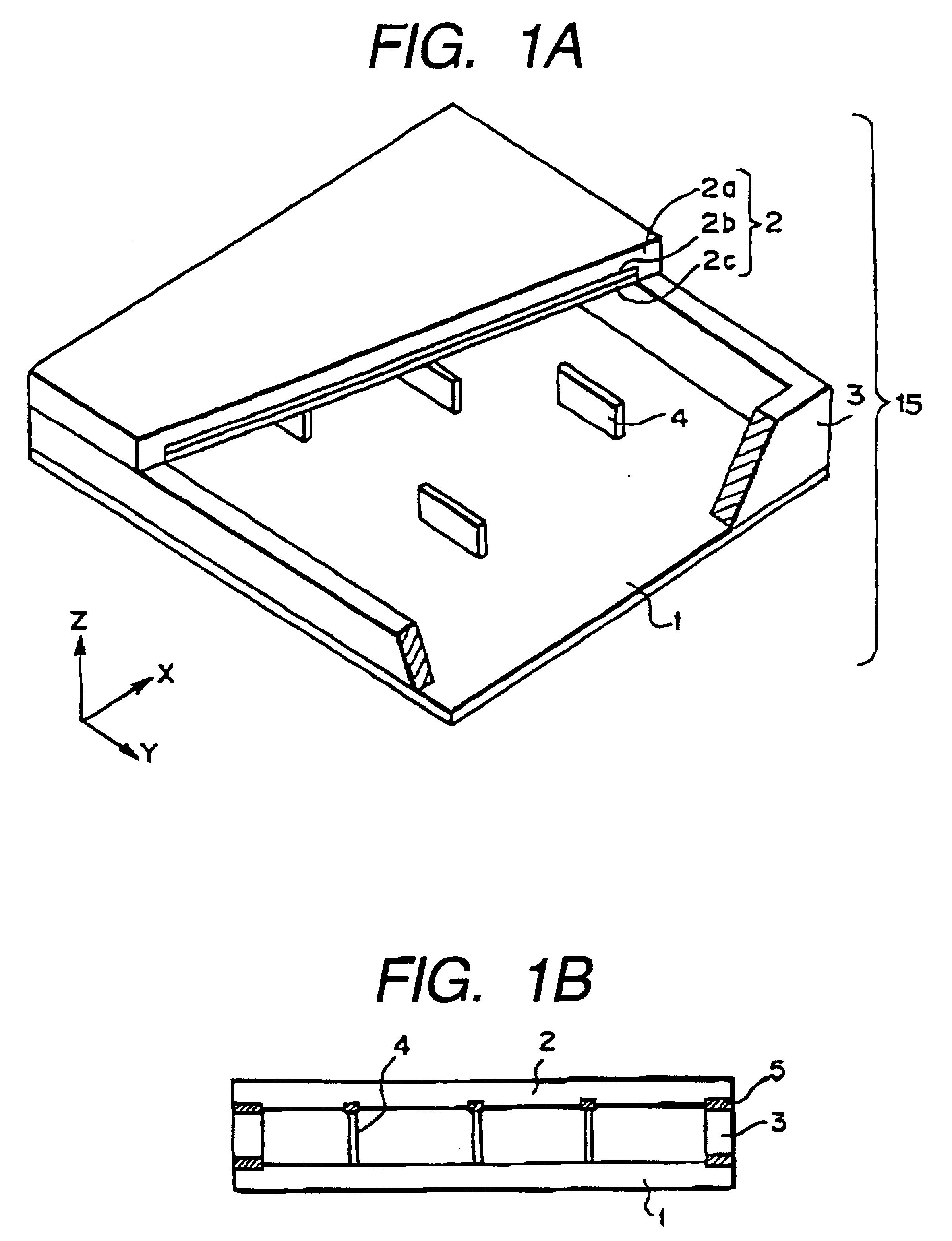

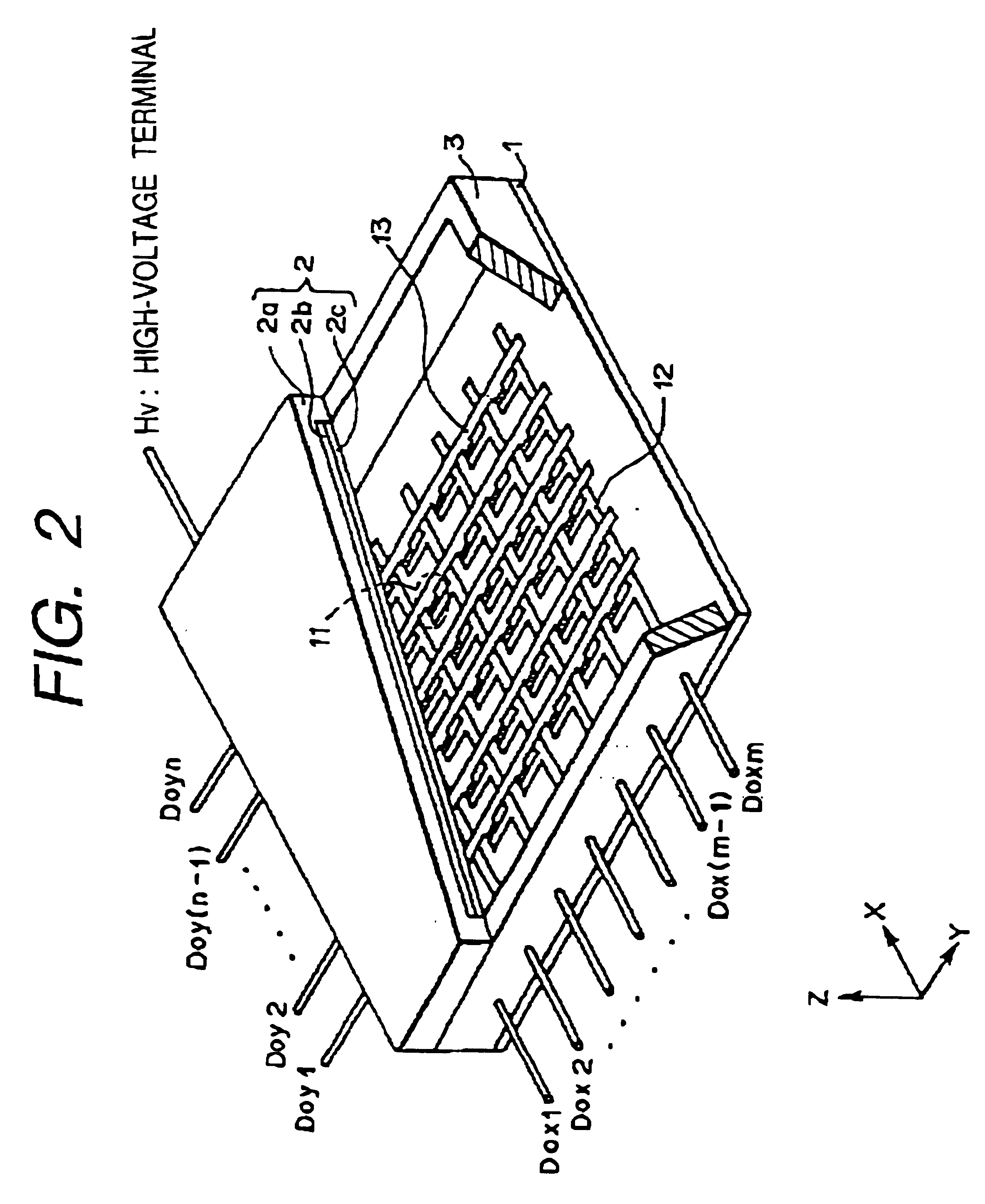

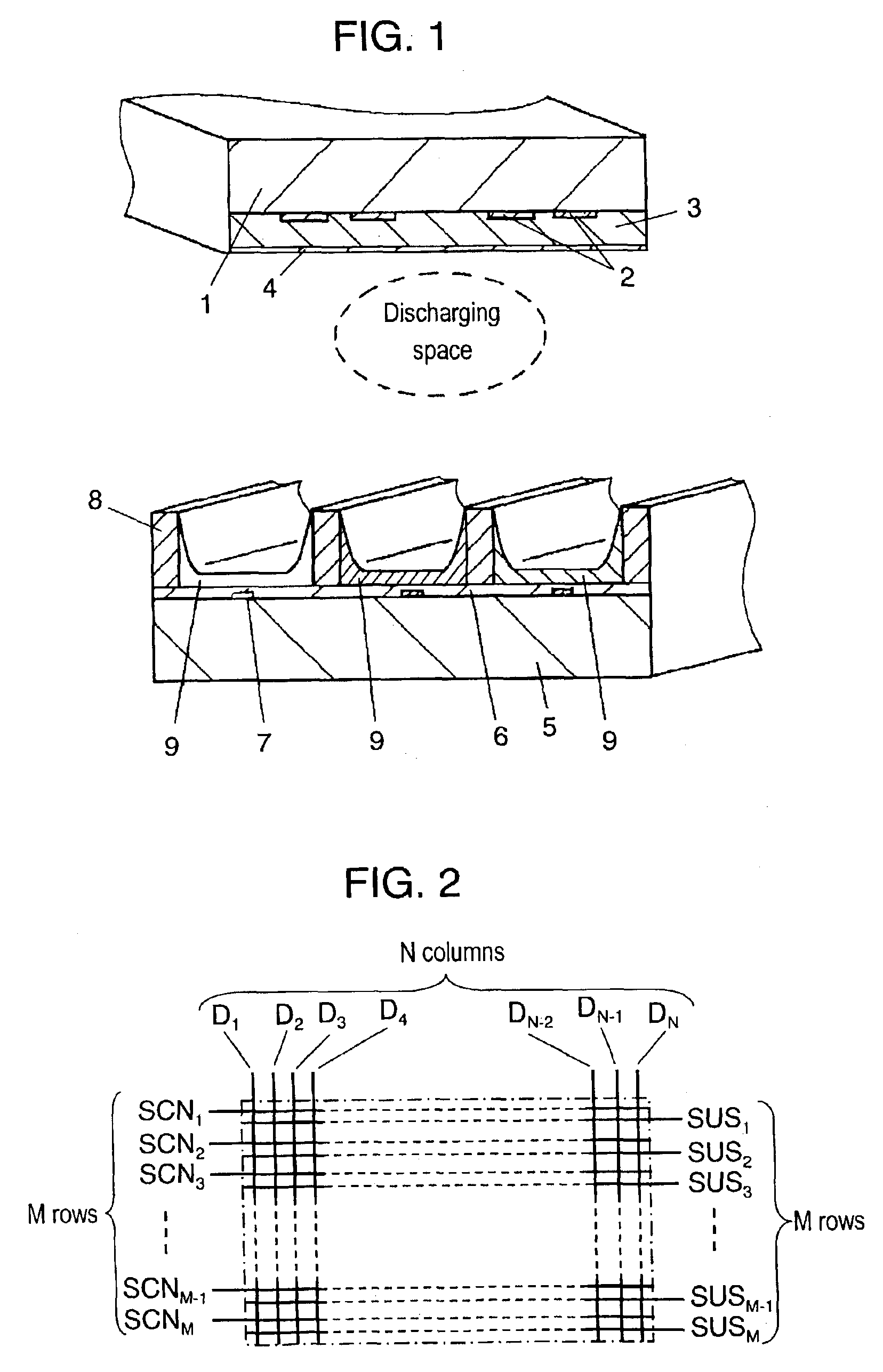

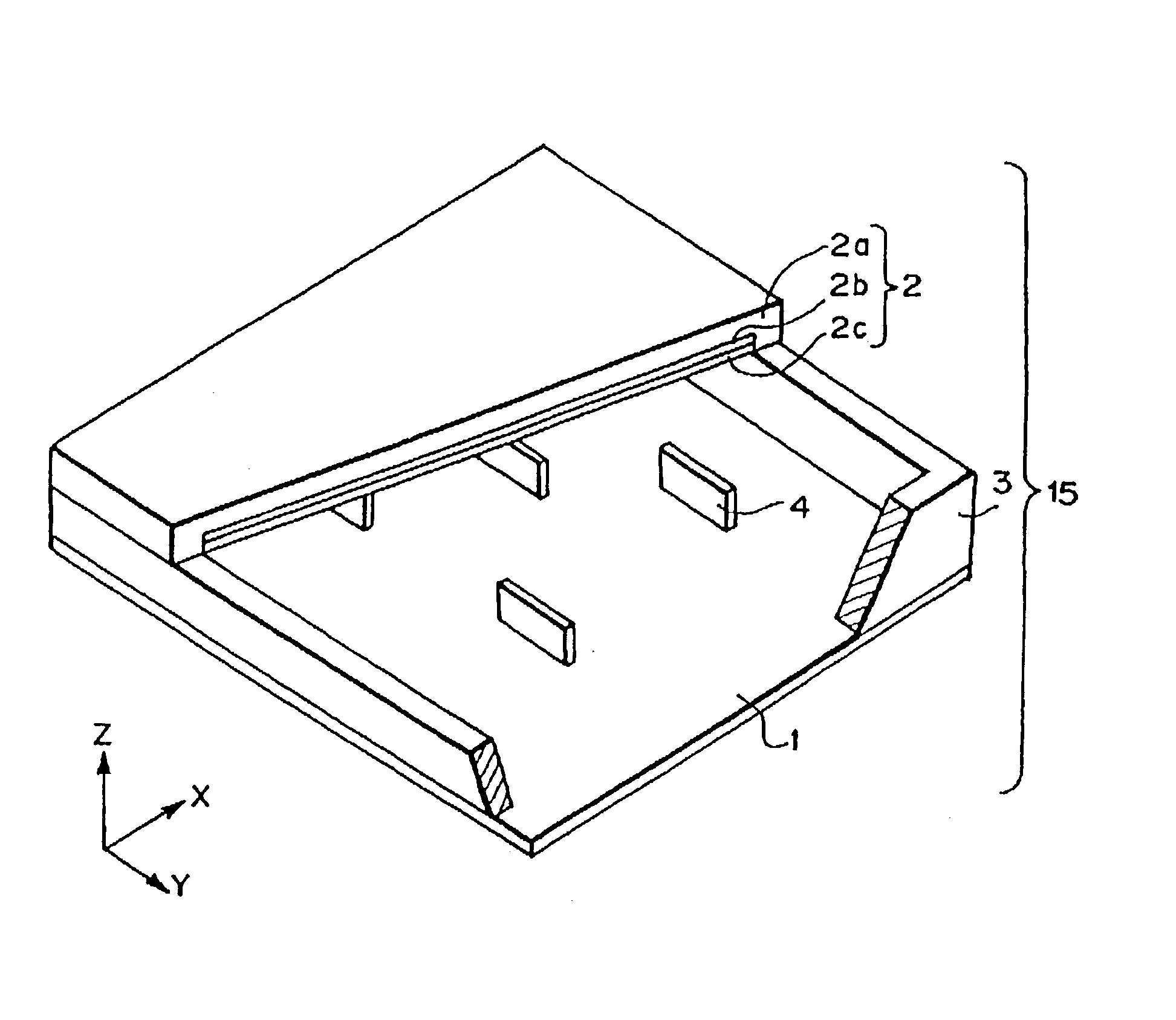

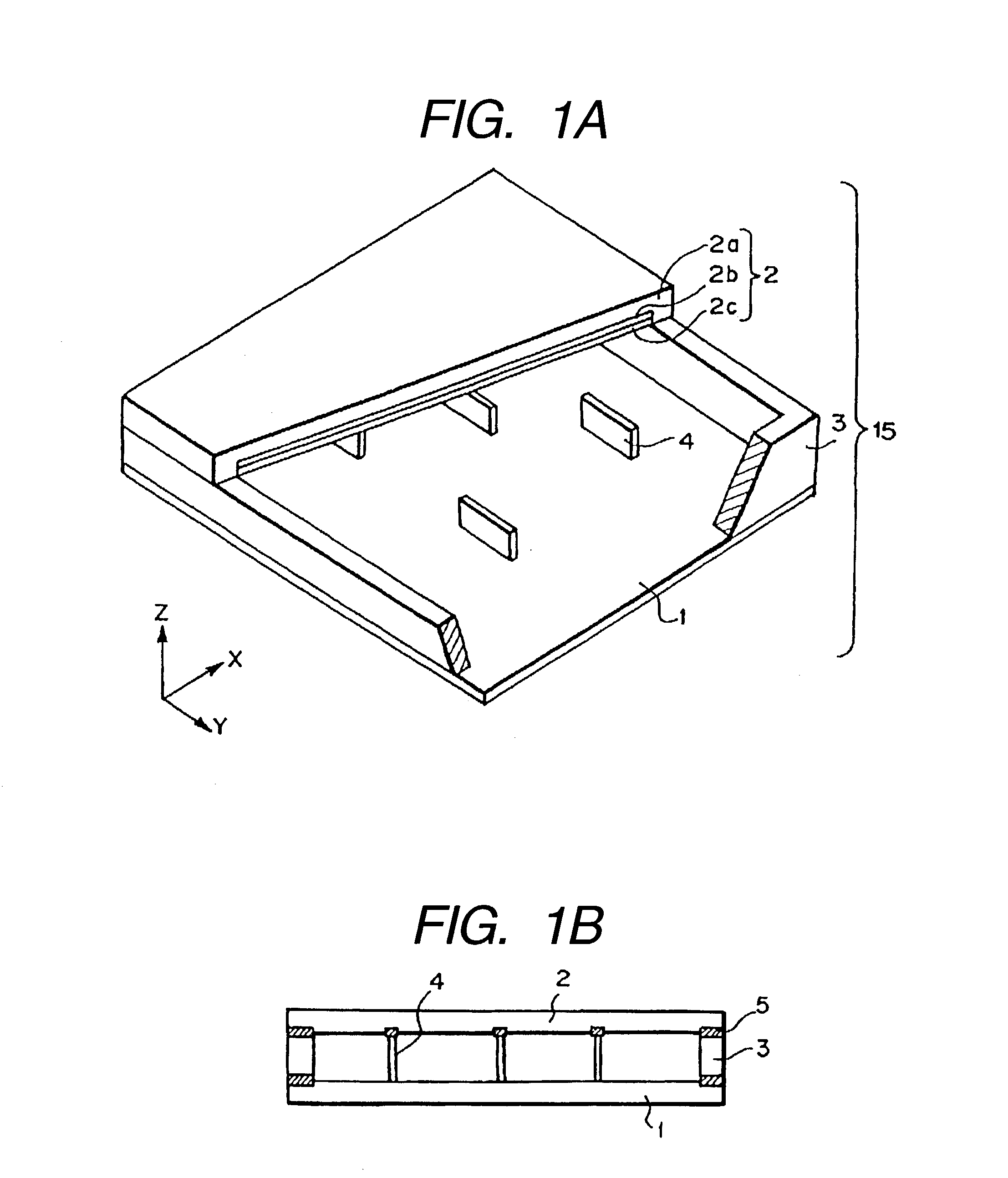

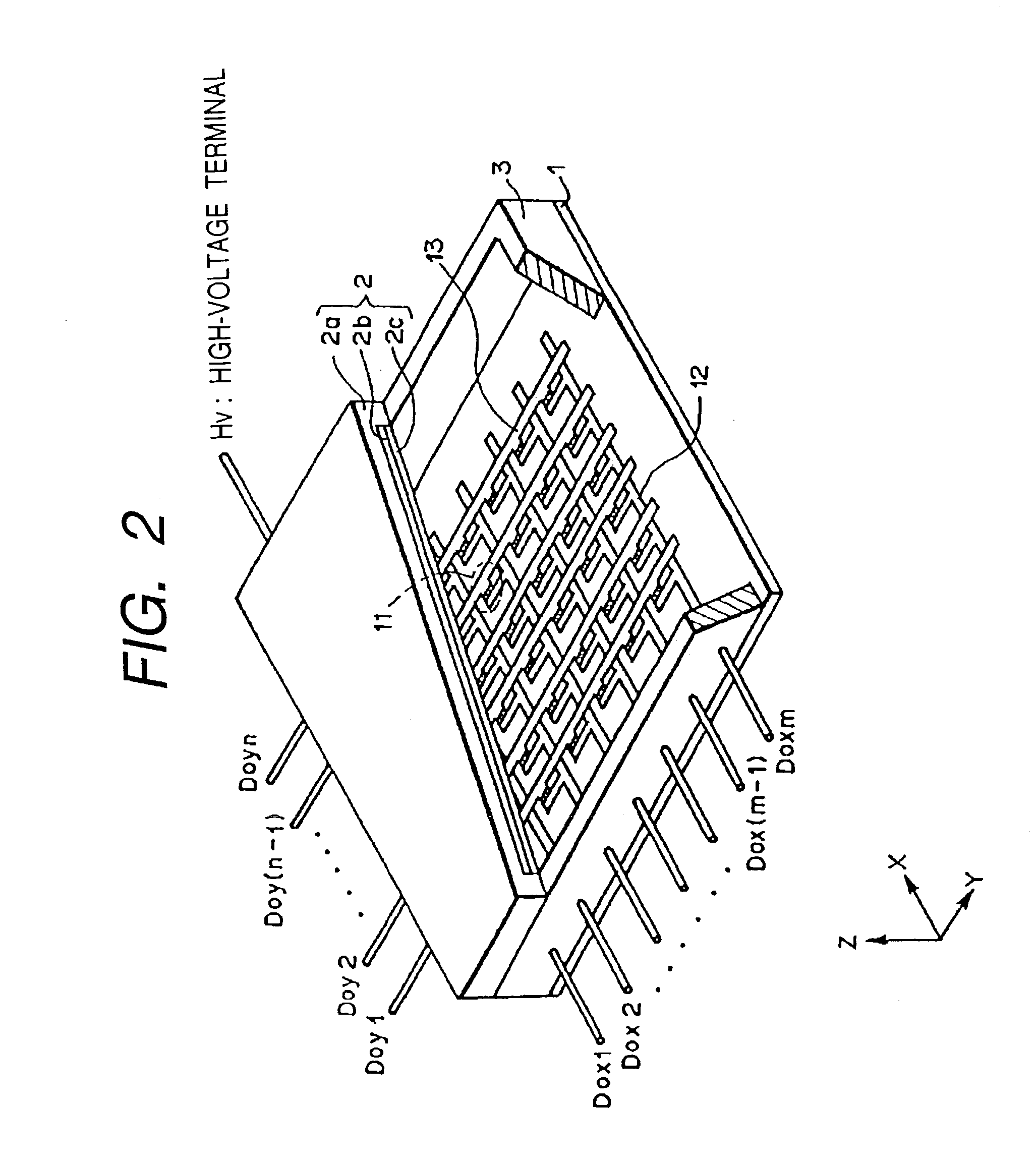

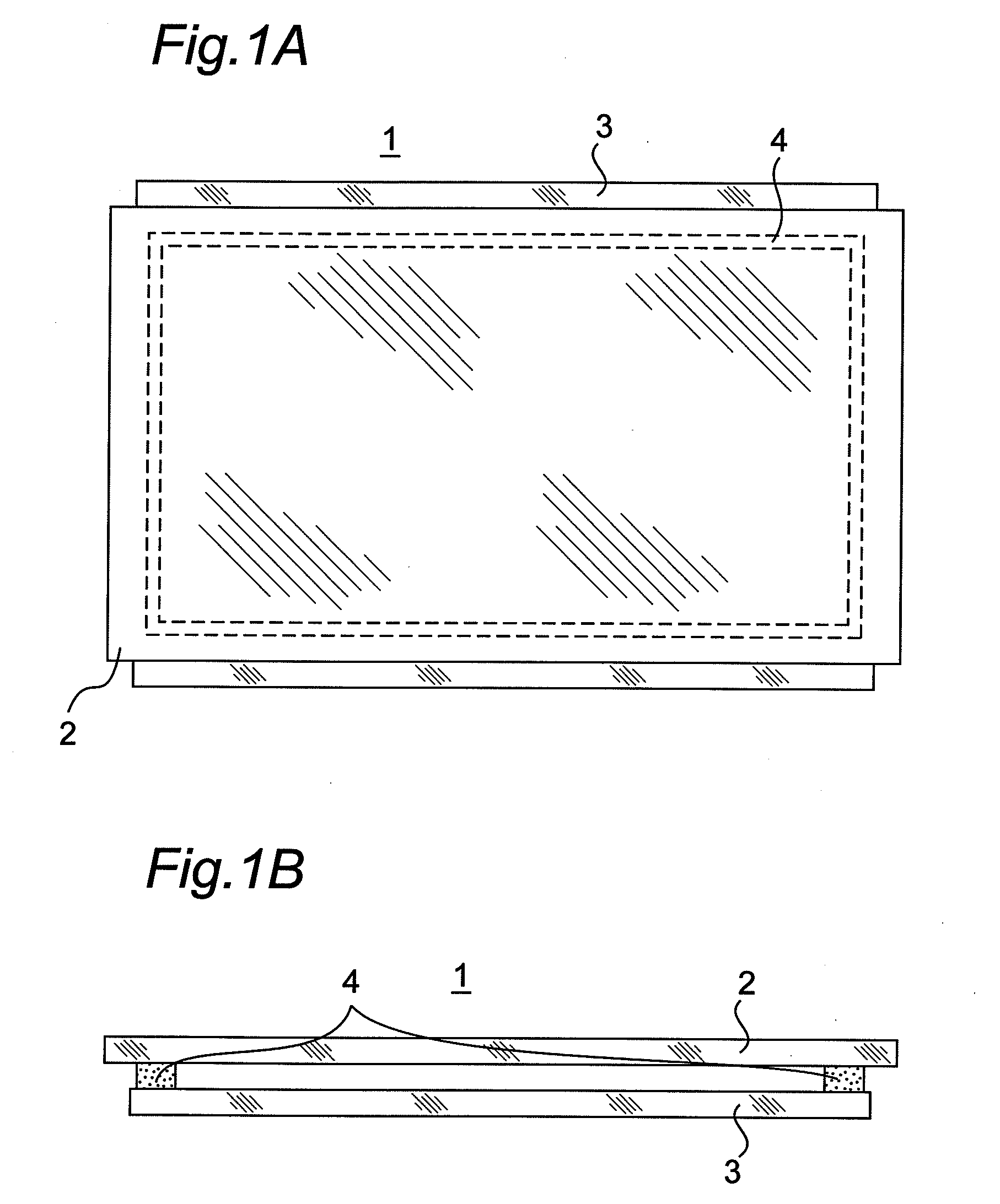

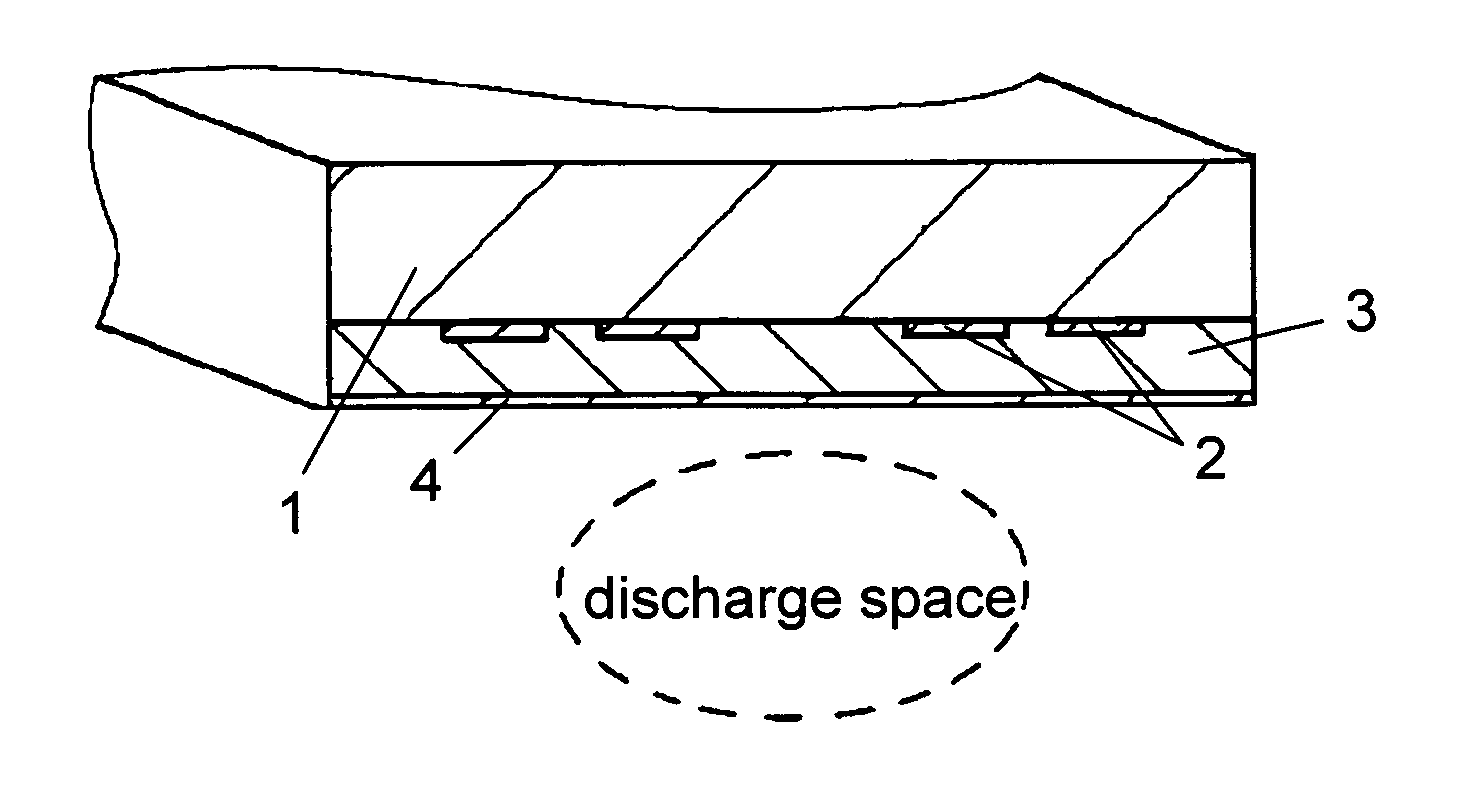

Image display apparatus, disassembly processing method therefor, and component recovery method

InactiveUS6632113B1No pressureAvoid secondary damageElectric discharge tubesGlass recyclingRecovery methodFrit

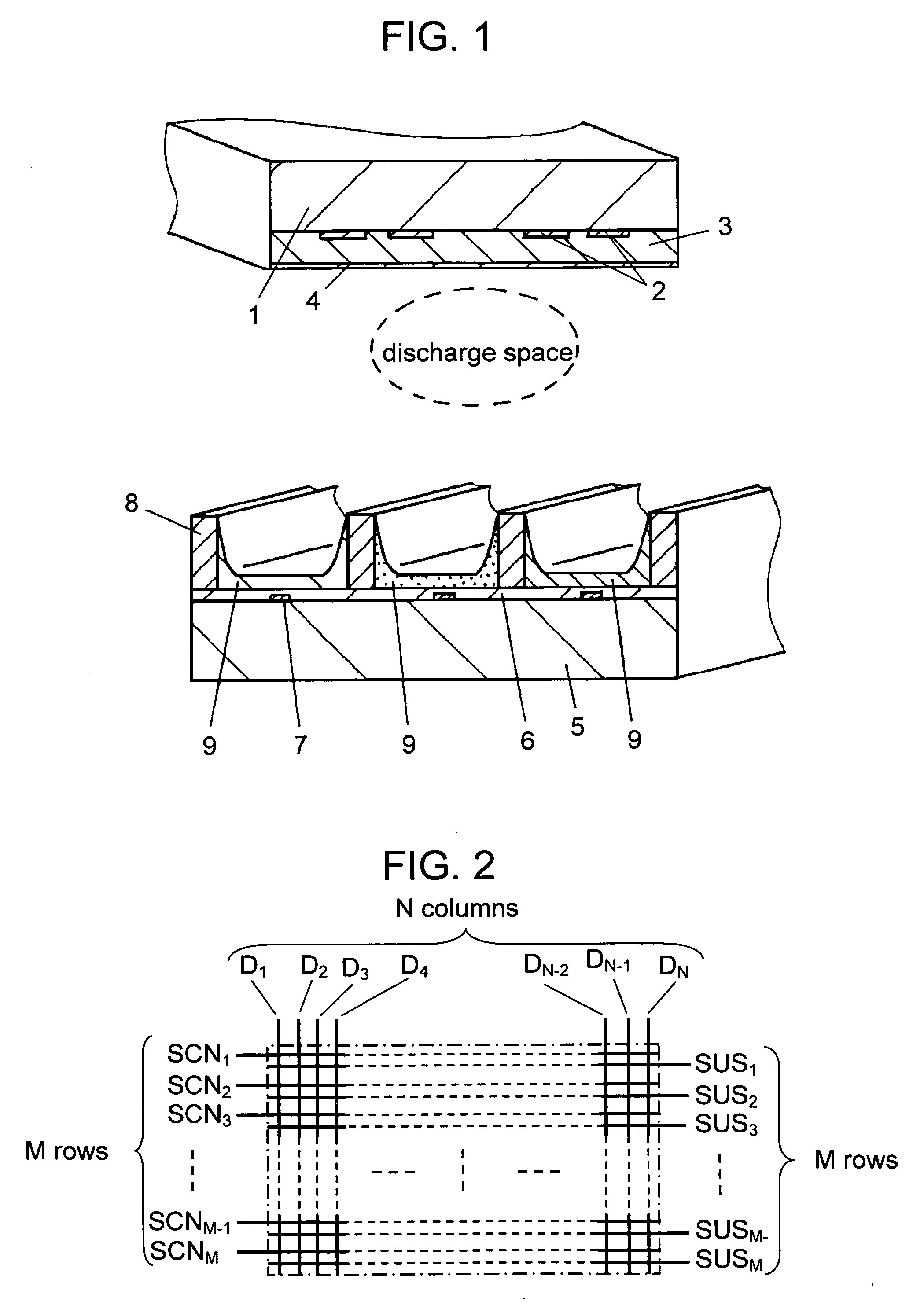

To reuse glass used in a flat panel display, processing suitable for global environment such as processing of separating a lead component must be realized. A disassembly processing method for a flat panel display having a structure in which a face plate and rear plate mainly containing glass are airtightly joined via a frame with frit glass is characterized by including the step of separating the face plate and rear plate joined with the frit glass. The separation step is characterized by separating the face plate and rear plate by cutting, dissolution, or melting.< / PTEXT>

Owner:CANON KK

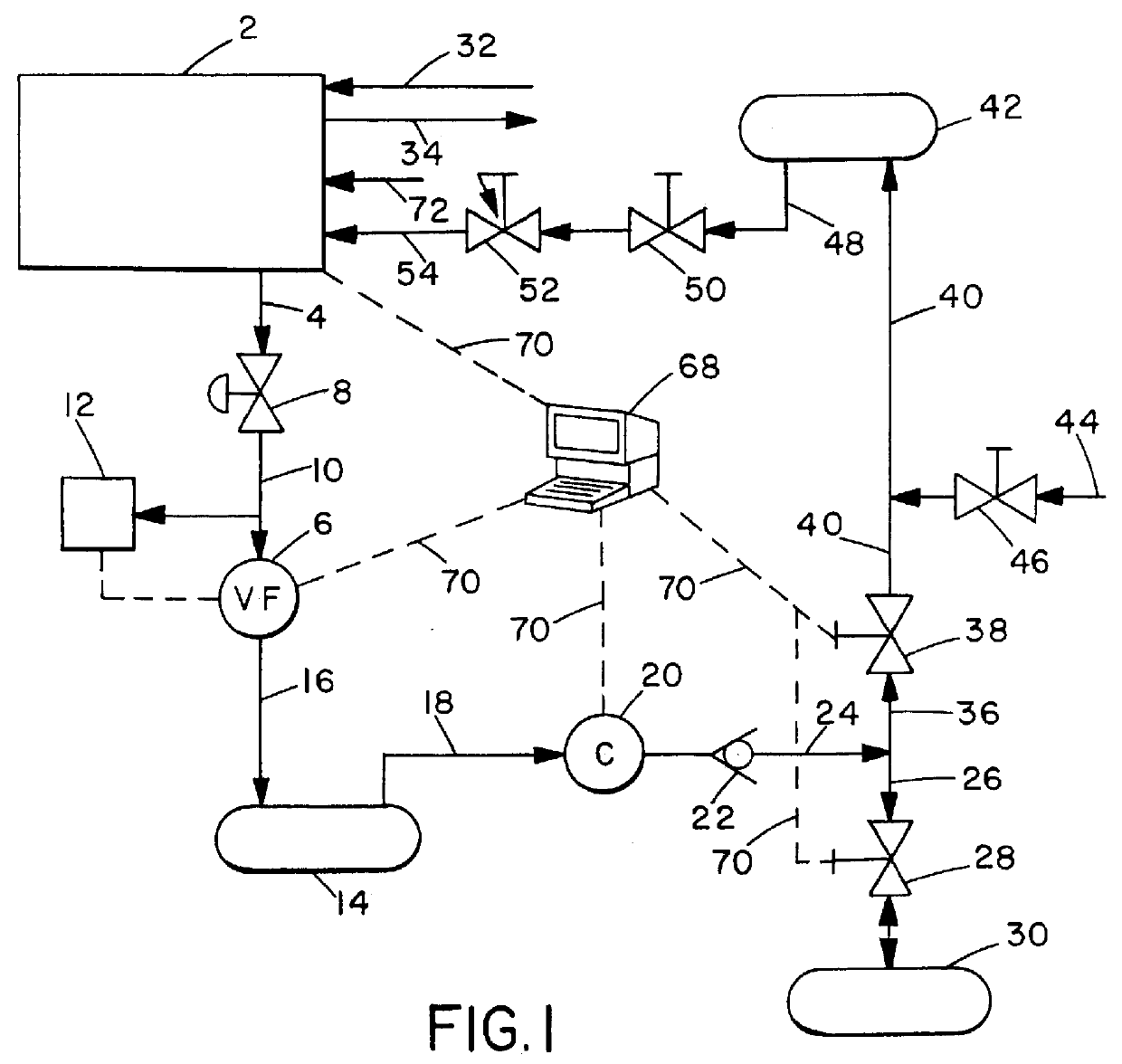

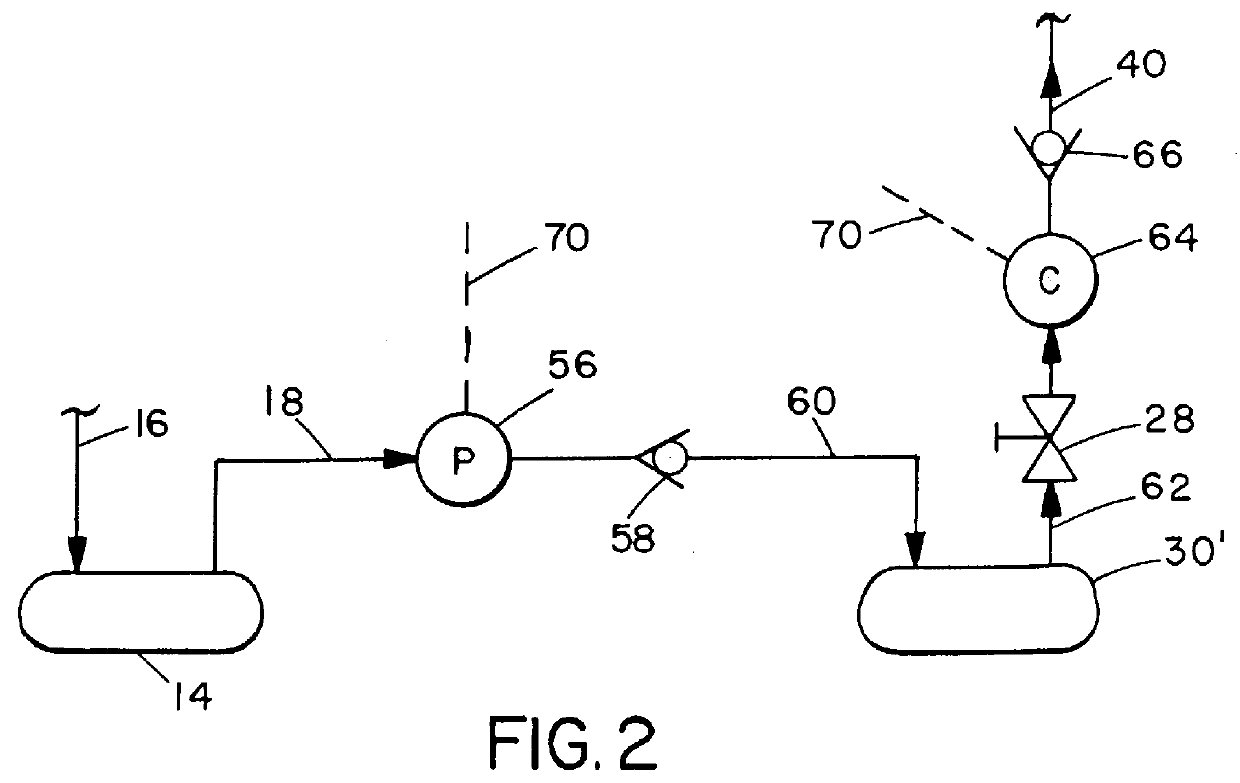

Method for recovery and reuse of gas

A gas recovery and reuse / recycle method is disclosed which can readily and economically recover valuable and / or environmentally hazardous gases from a manufacturing or chemical process and then return the gas to the process for reuse, and repeat this many times without significant contamination or degradation of the gas or the produced products. All gas transport, compression and storage equipment is designed and maintained so that it is non-contaminating to the process gas. Commonly the process gas will be a Group VIII gas, preferably He, Ne, Kr or Xe, or a gas which comprises a hazard to the ambient environment or beings therein, such as a carbon oxide gas, a halocarbon gas, an acid-precursor gas, a biologically hazardous gas, or a radioactive gas.

Owner:ENTEGRIS INC

Nanostructured sorbent materials for capturing environmental mercury vapor

InactiveUS20110049045A1Precise positioningAvoid contactMaterial nanotechnologyGas treatmentFluorescenceSorbent

The present invention is a method and material for using a sorbent material to capture and stabilize mercury. The method for using sorbent material to capture and stabilize mercury contains the following steps. First, the sorbent material is provided. The sorbent material, in one embodiment, is nano-particles. In a preferred embodiment, the nano-particles are unstabilized nano-Se. Next, the sorbent material is exposed to mercury in an environment. As a result, the sorbent material captures and stabilizes mercury from the environment. In the preferred embodiment, the environment is an indoor space in which a fluorescent has broken.

Owner:BROWN UNIVERSITY

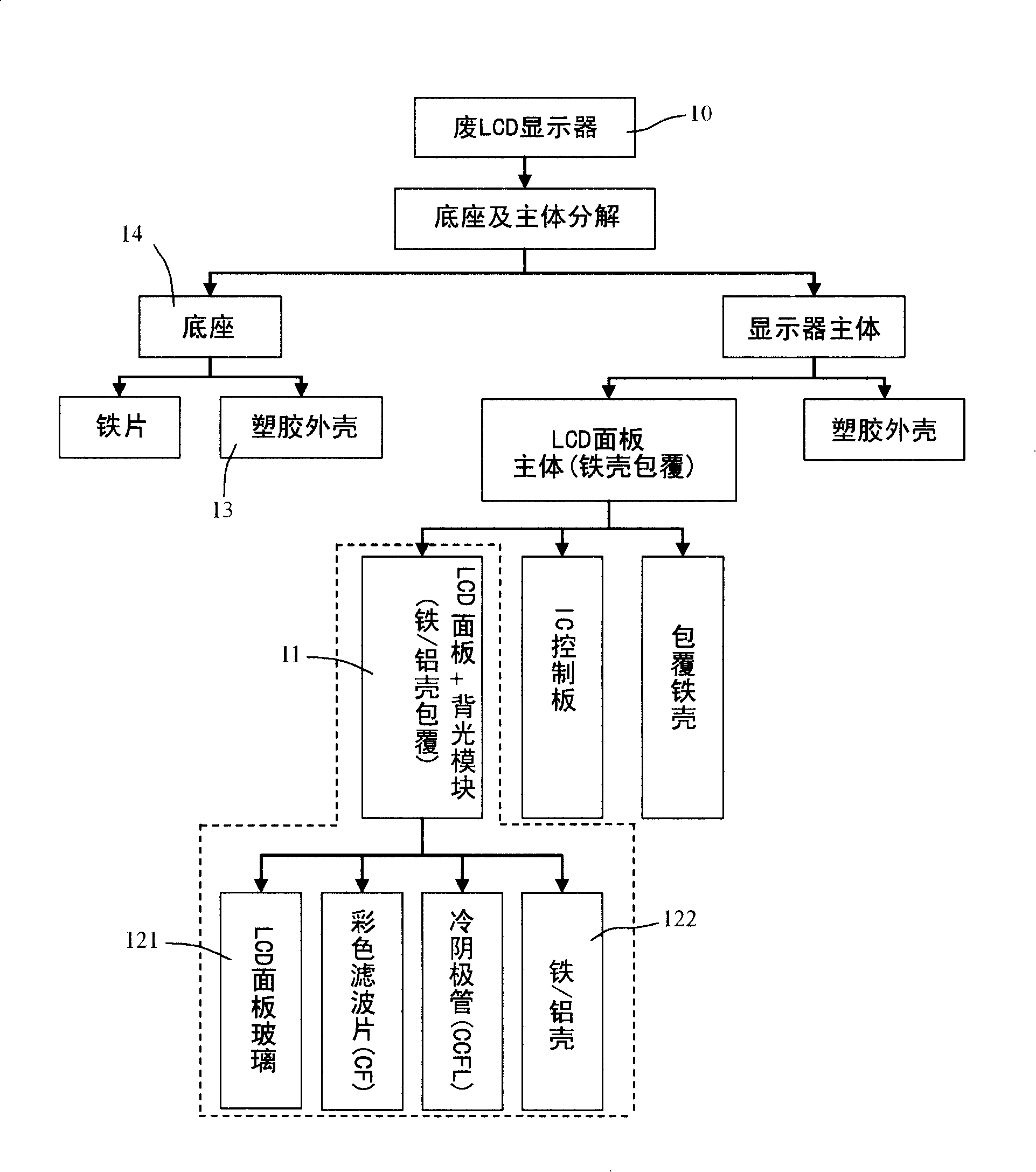

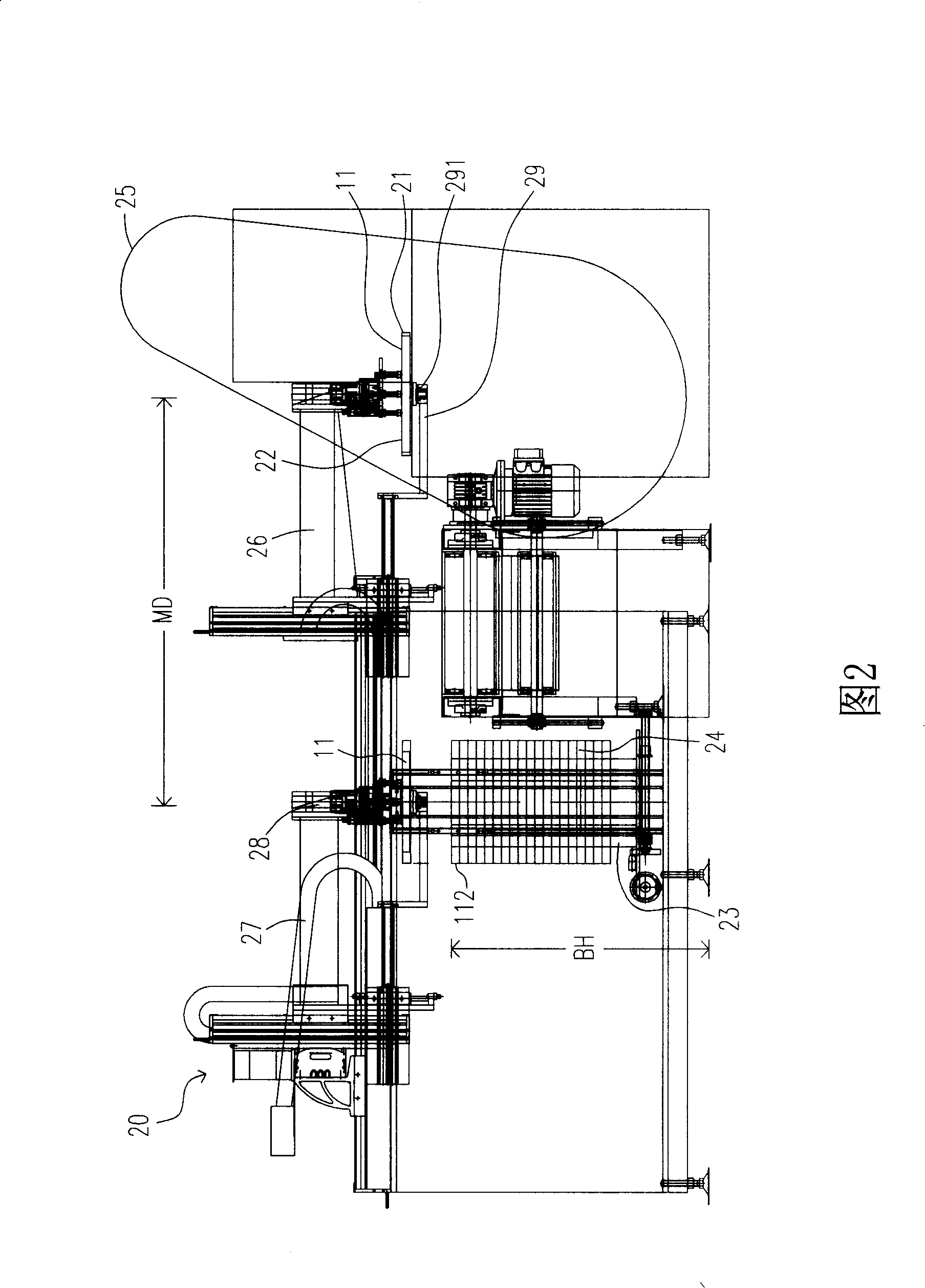

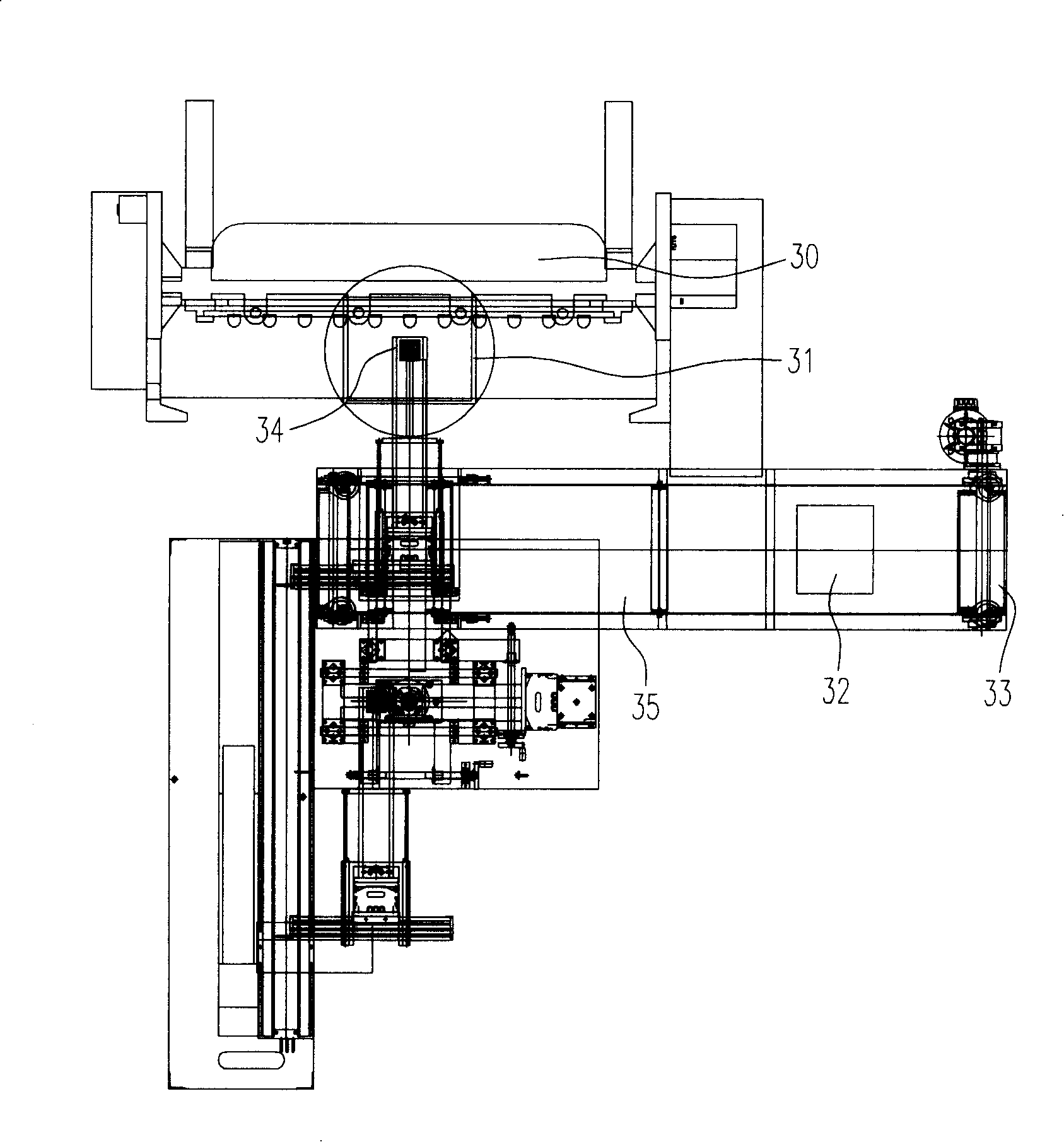

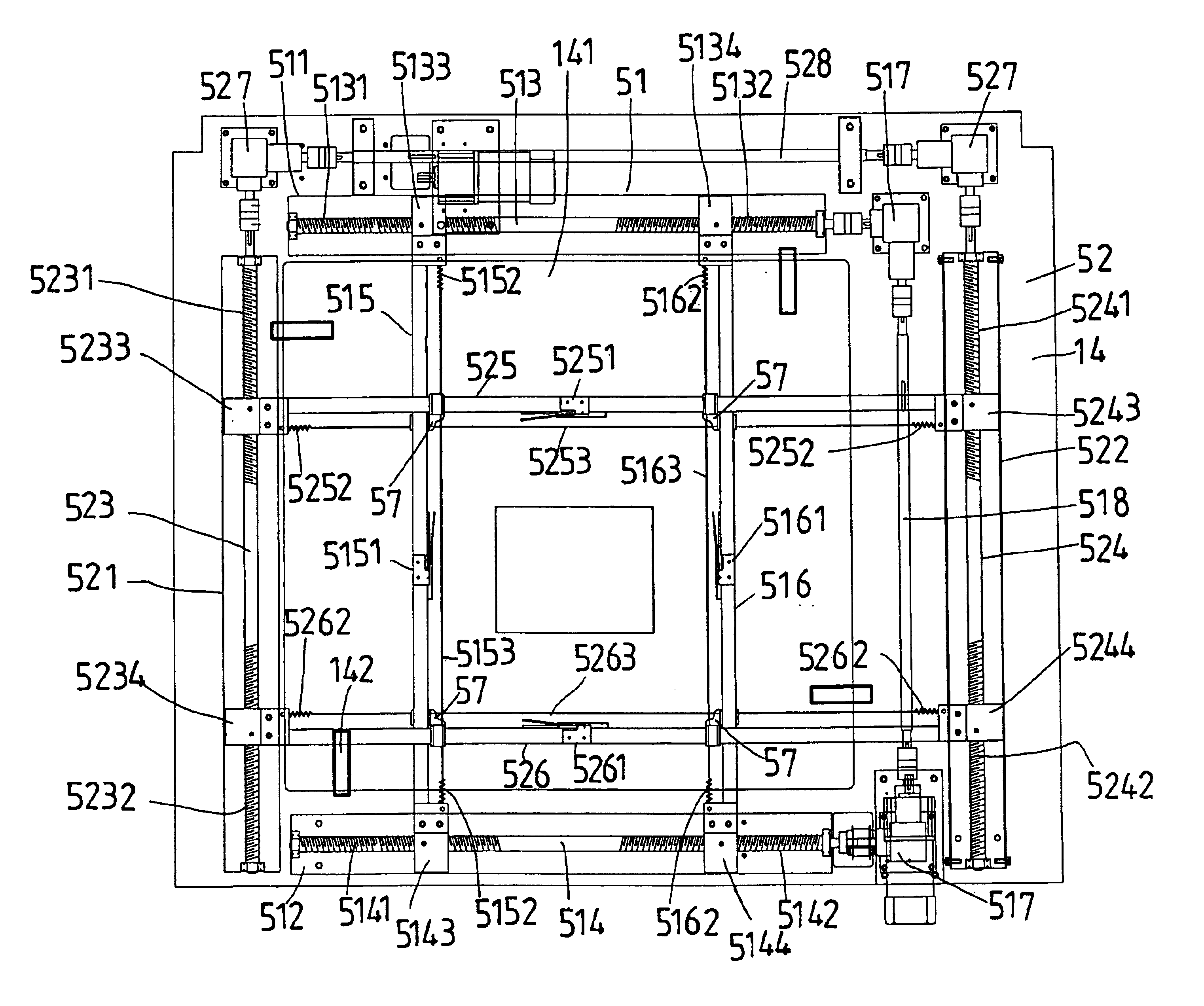

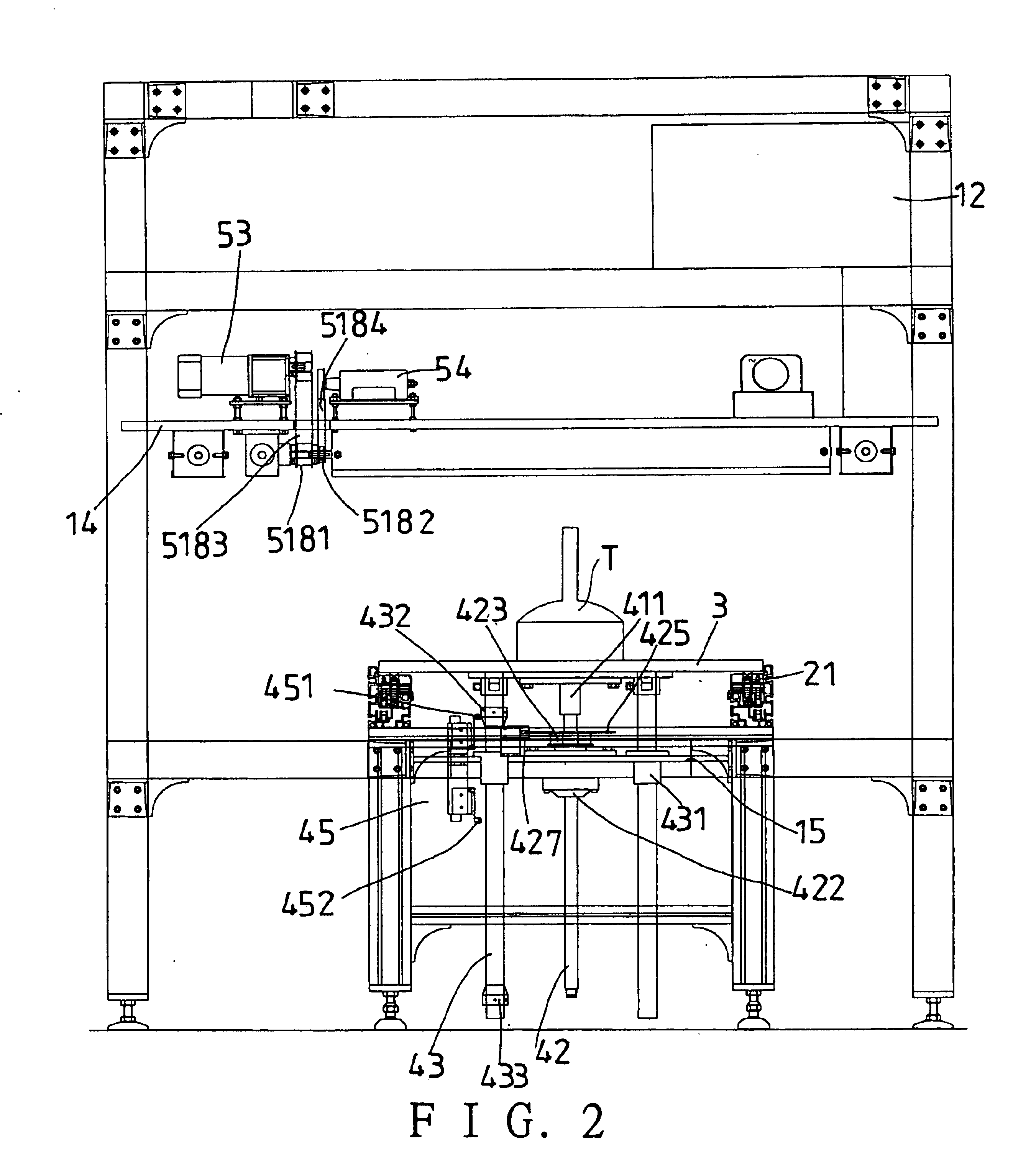

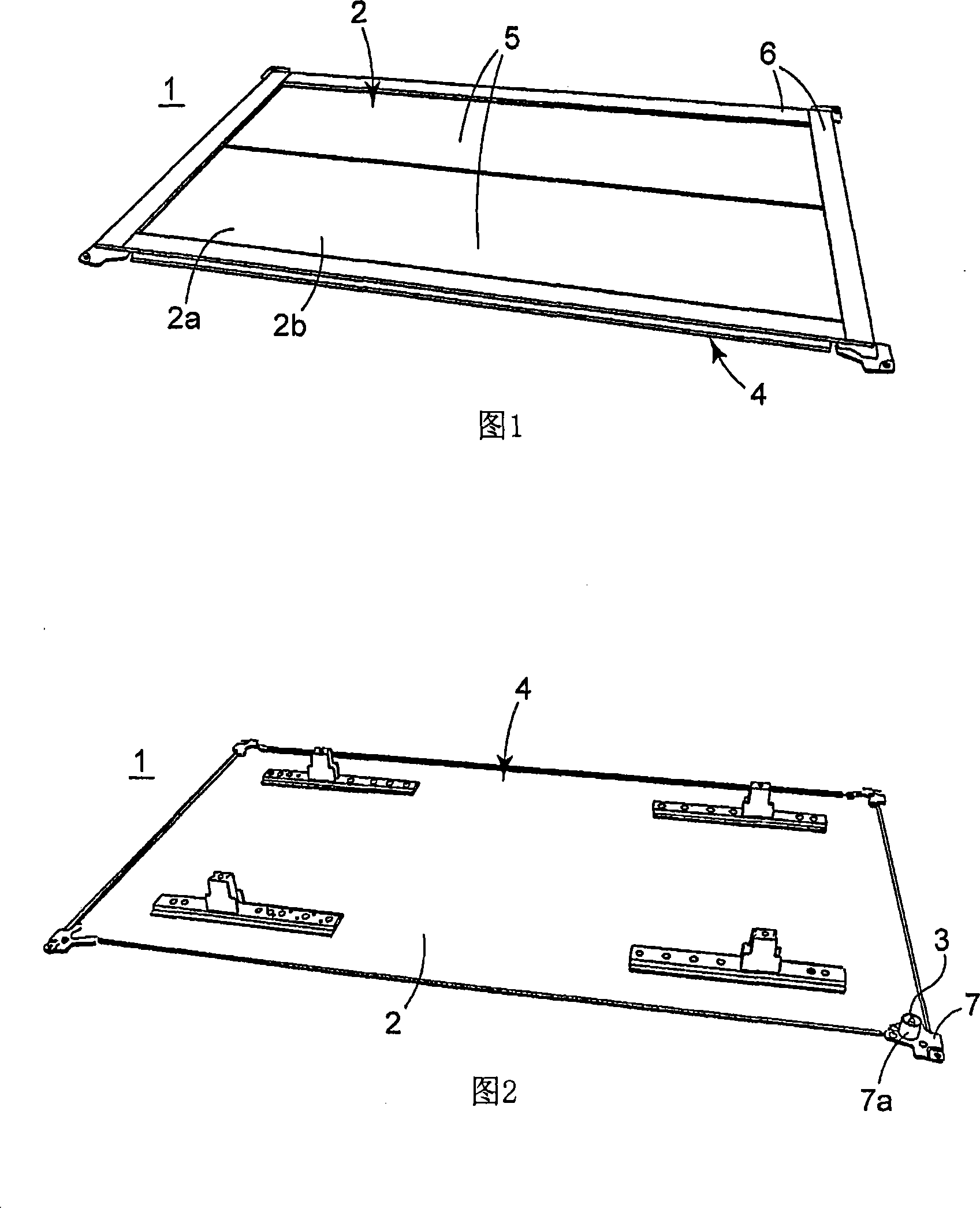

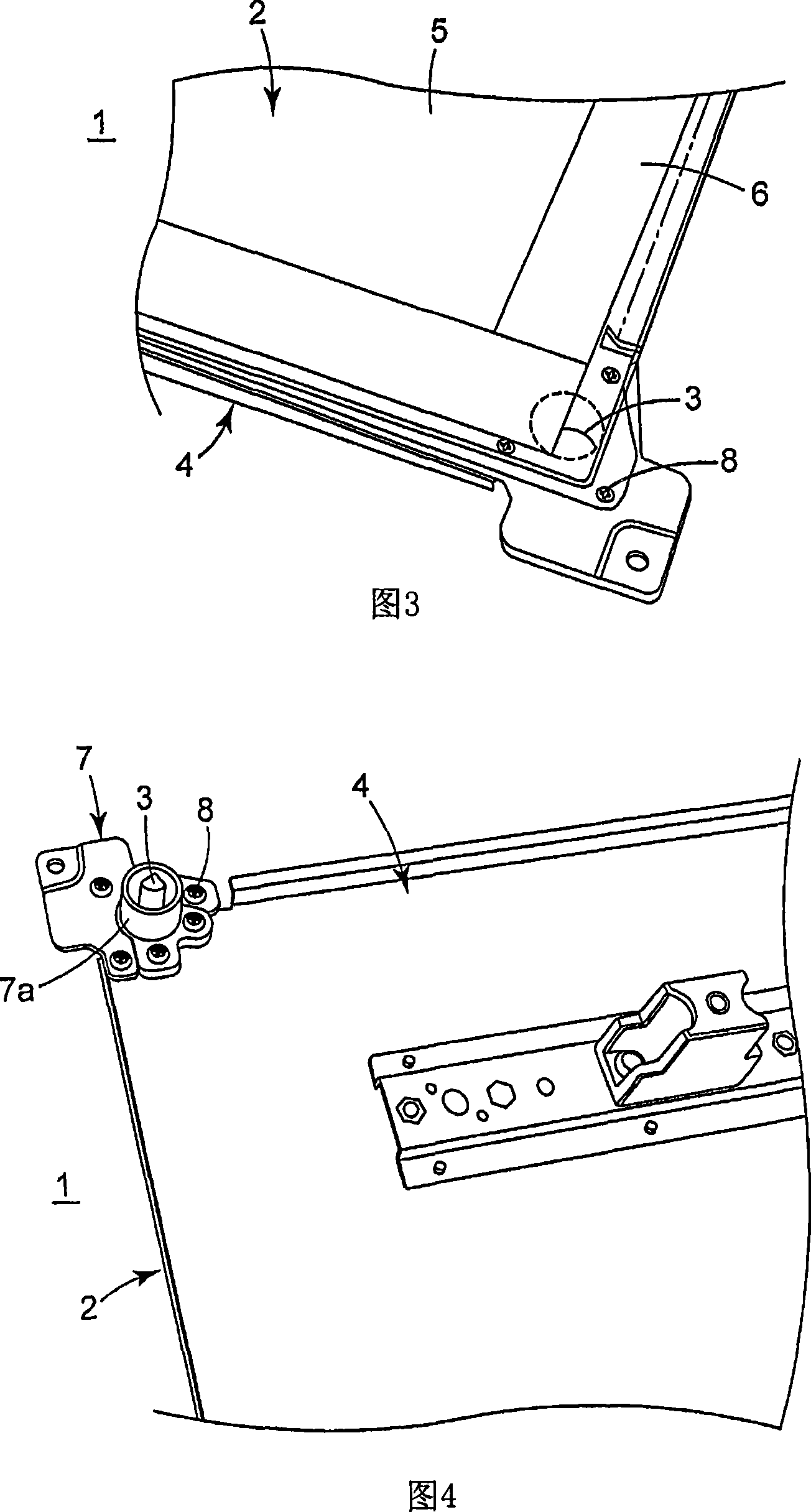

Method and device for detaching reclaimed liquid crystal display

InactiveCN101209453AShorten the timeWith automatic lifting functionSolid waste disposalShearing machinesLiquid-crystal displayEngineering

The invention relates to a disassembly method for recycling a liquid crystal display (LCD) and a device thereof. The steps of the method comprise: a panel of the liquid crystal display is provided; a first side of the panel is positioned; the first side of the panel is cut; a first rotation of the panel is carried out and a second side of the panel is cut, thus being beneficial to sorting a first material and a second material of the panel. The invention is mainly characterized in that an automatic edge-cutting device is adopted to cut the structure at the assembly part of the LCD panel so as to ensure that resources and items made of different materials in the panel are separated from each other and lay a foundation for the followed sorting and recycling of resources and deal with the situation that large quantity of LCD appears in future. In addition, compared with the traditional method which adopts manpower and power-driven tools, the method of the invention saves time consumption nearly 10 times.

Owner:IND TECH RES INST

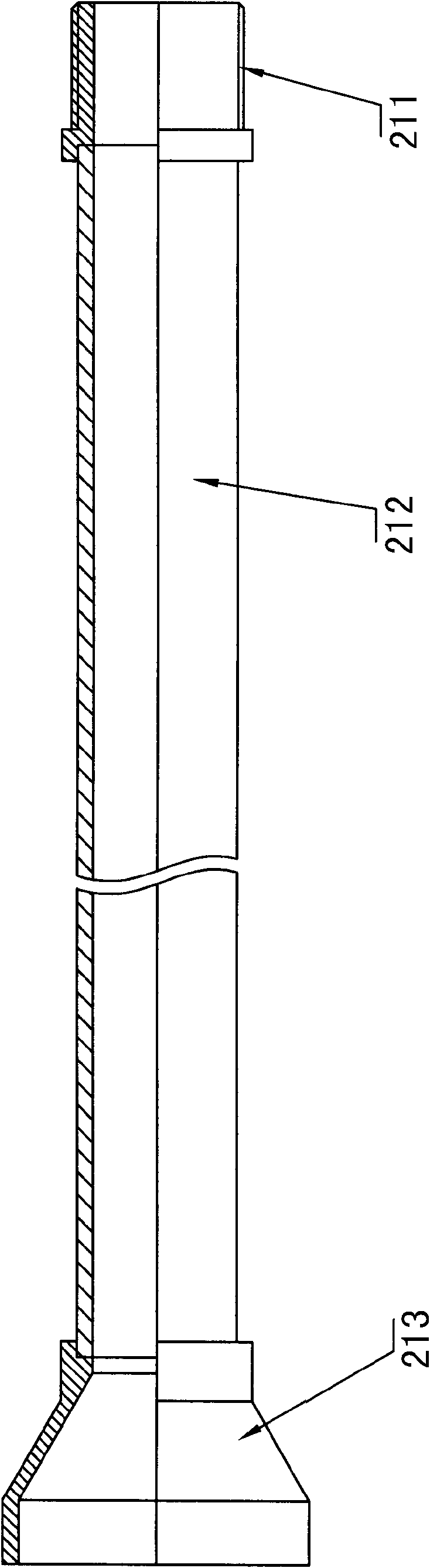

Automatic picture tube cutting machine

An automatic picture tube cutting machine is provided. The machine includes a transporting mechanism for transporting a tray carrying a picture tube into a moving-up-and-down base, which automatically adjusts the vertical position of the picture tube based upon its size. The machine also includes a positioning and cutting device wherein a plurality of clamp units cooperatively set tungsten heating filaments in contact with the picture tube to circumscribe that picture tube at a preset cutting height. Upon heating via the tungsten heating filaments and subsequent cool water quenching, the picture tube is broken at its circumscribed portion into separated front and rear stages.

Owner:YEH NENG KUEI

Removal of lead from solid materials

InactiveUS20150050199A1Minimal costTin compoundsSolvent extractionMaterials scienceCathode Ray Tube Display

A leaching composition that substantially removes lead from solid materials and a method of using said composition. Preferably, the concentration of lead in the solid materials following processing is low enough that the solid materials can be reused and / or disposed of at minimal cost to the processor. Preferably, the solid materials comprise glass, such as cathode ray tube glass.

Owner:ENTEGRIS INC

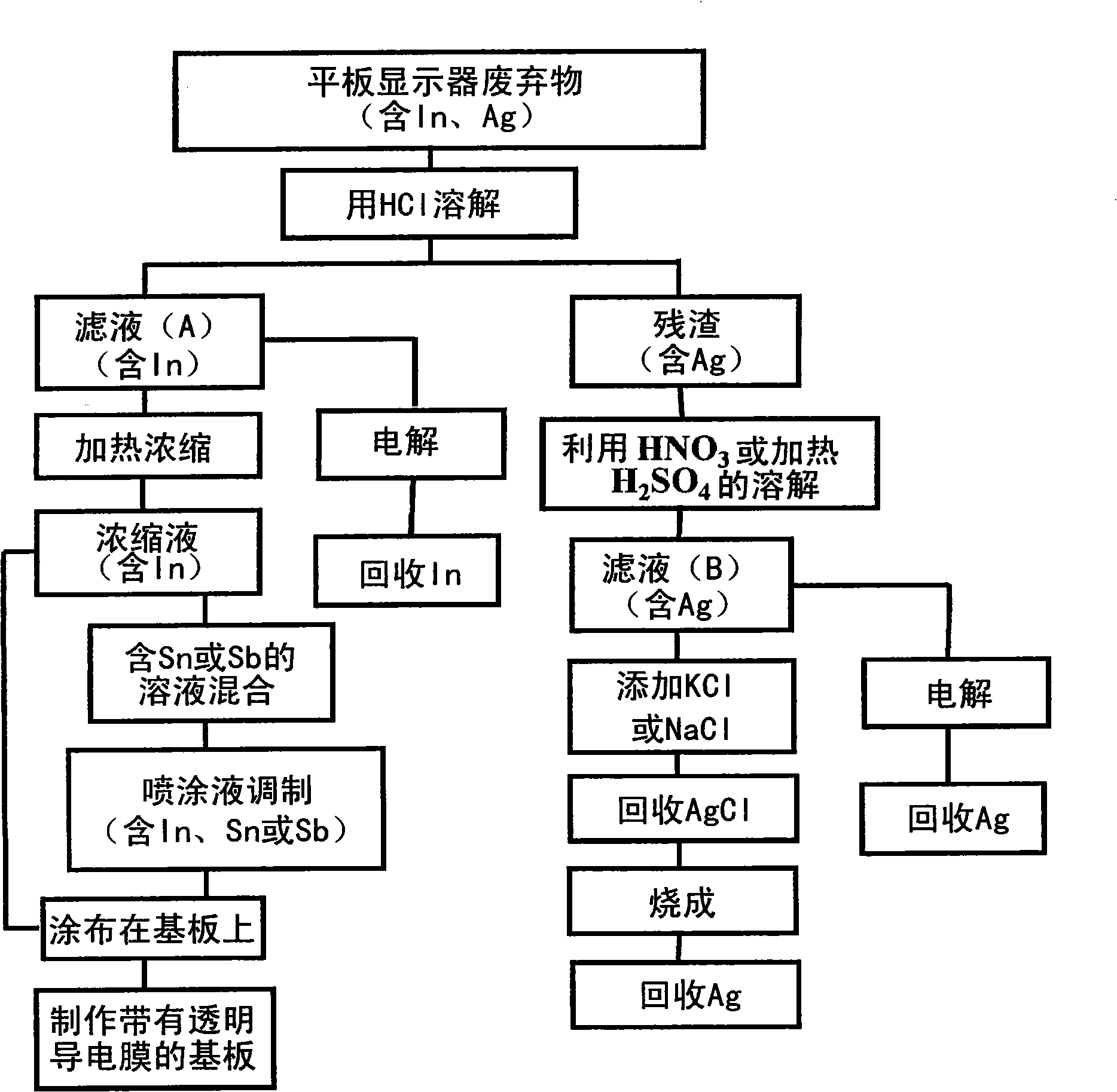

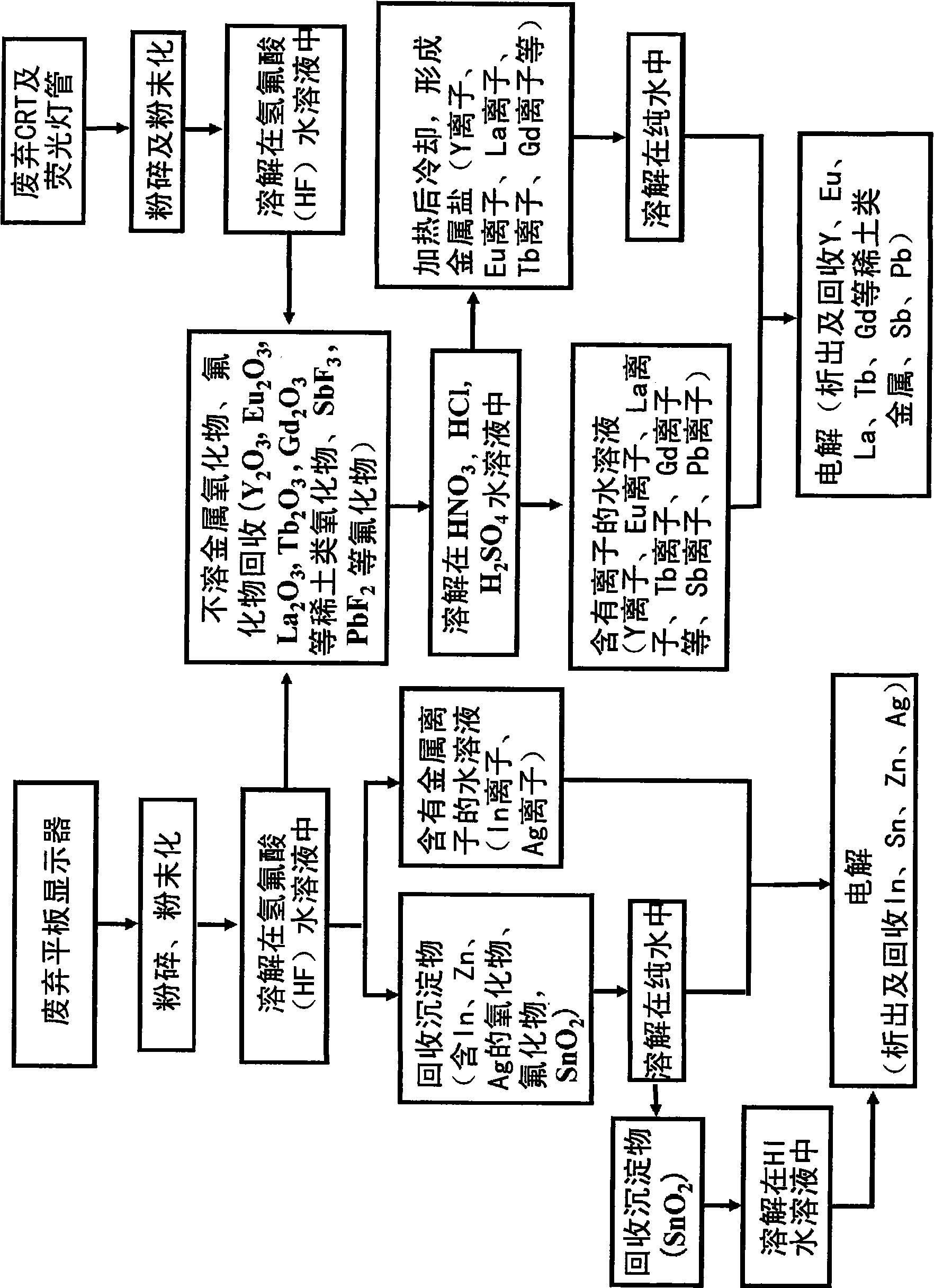

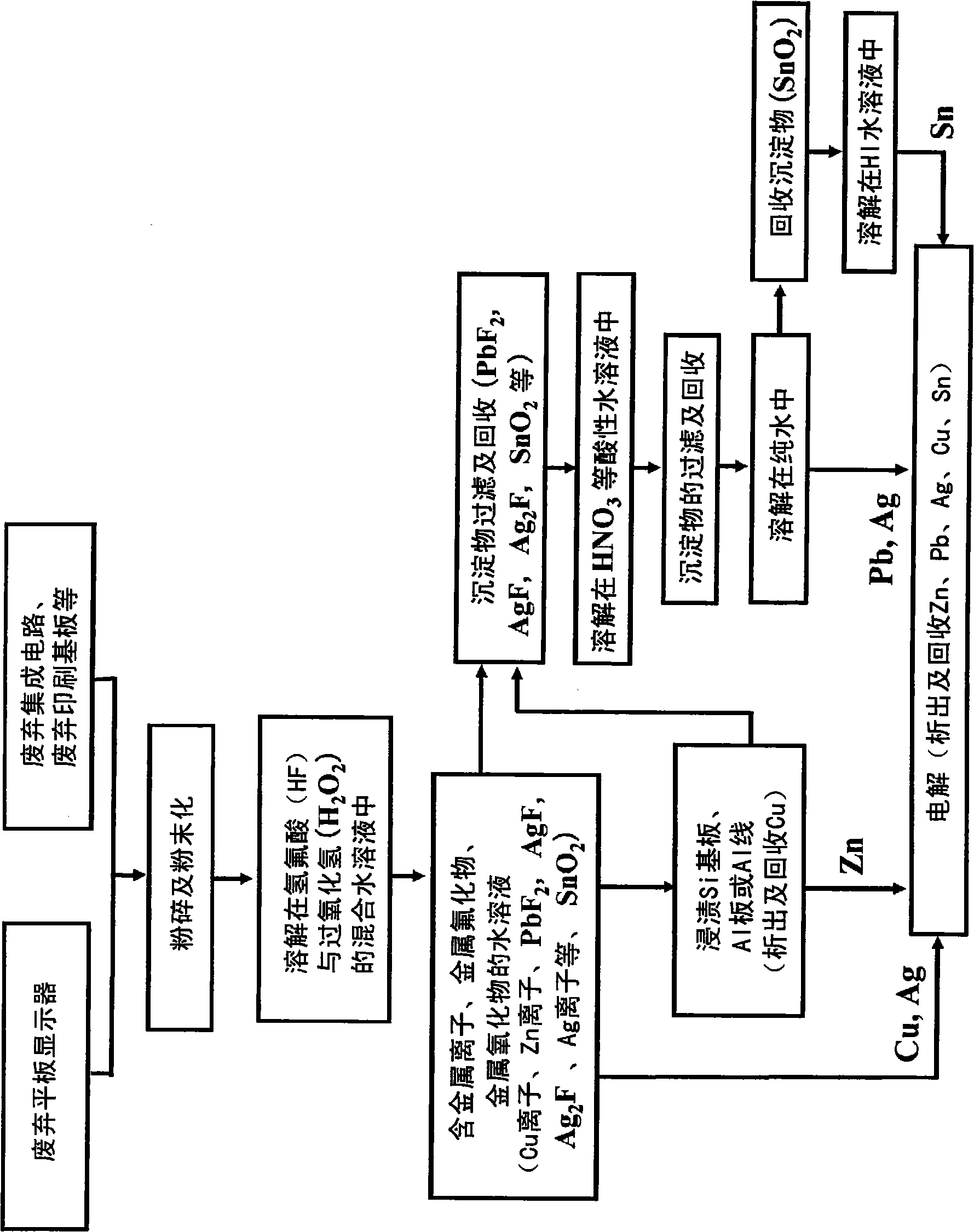

Method of recycling useful metal

Owner:SHIBAURA INST OF TECH

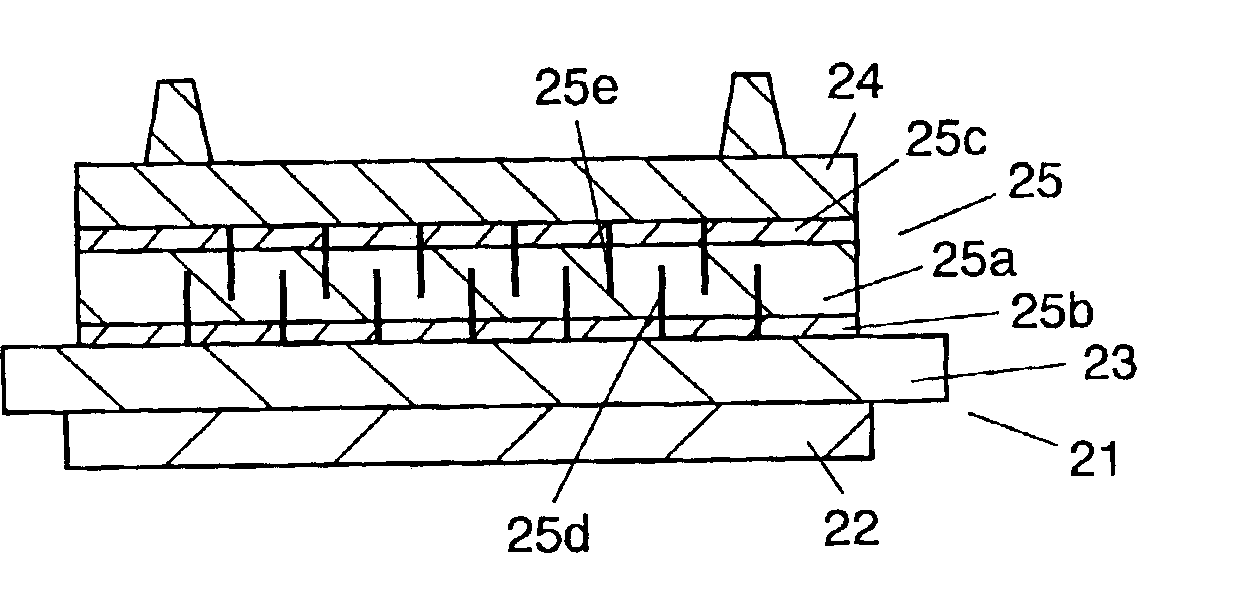

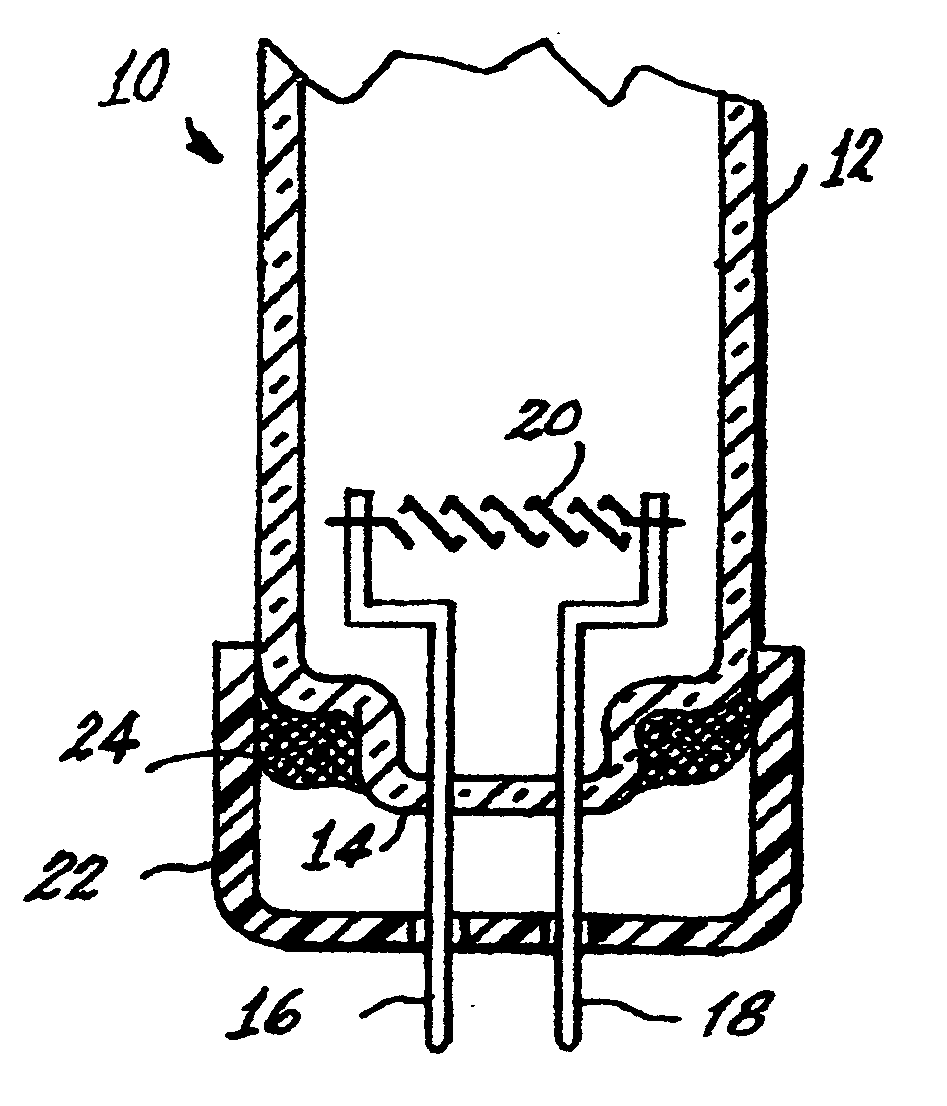

Manufacturing method and dismantling method for plasma display device

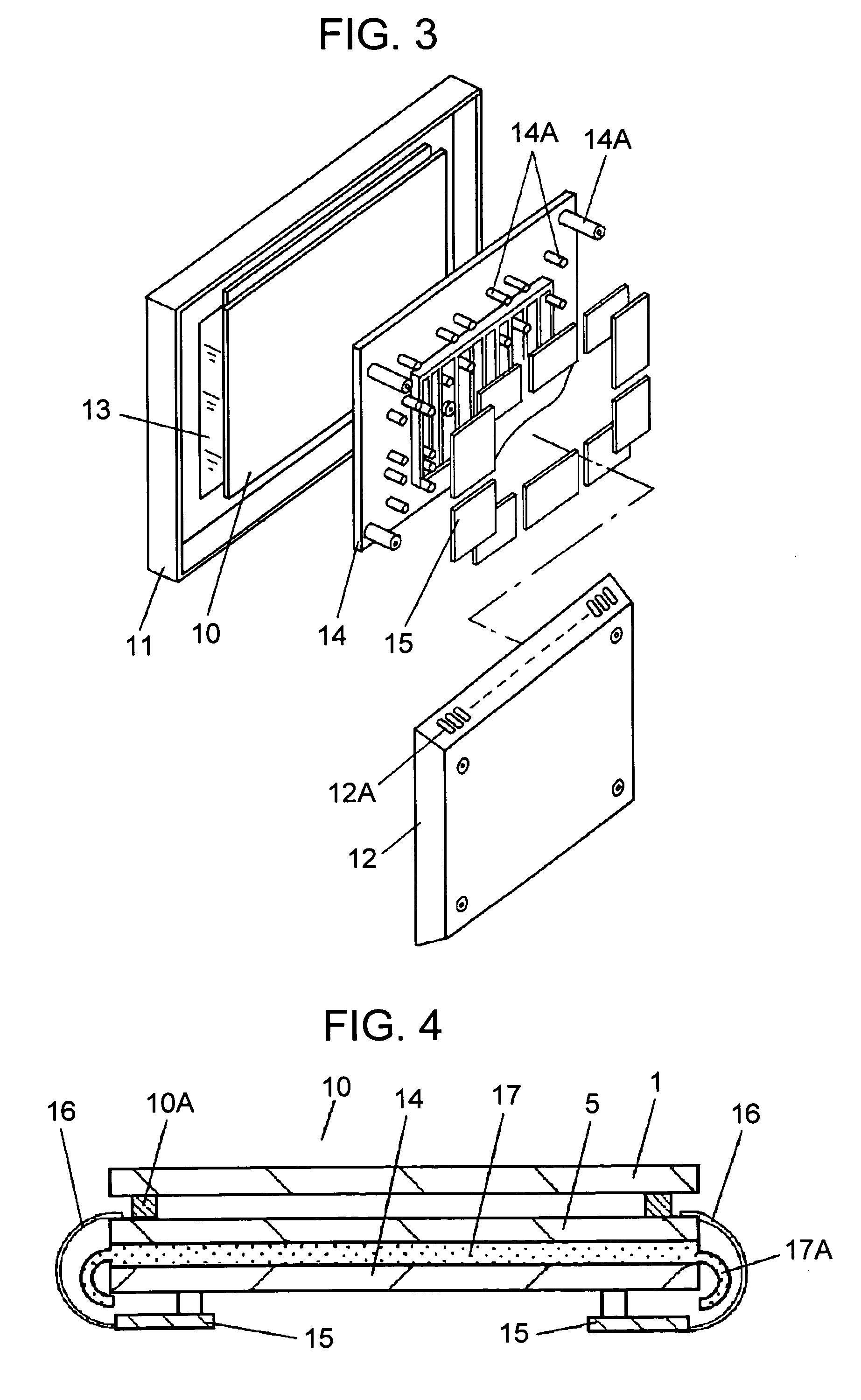

InactiveUS6979243B2Easy to separateEfficient conductionLamination ancillary operationsDischarge tube luminescnet screensDisplay deviceEngineering

A manufacturing method and dismantling method of a plasma display device are disclosed. These methods can bond a panel to a holder reliably, and can separate the panel and holder easily upon scrapping a plasma display device. The manufacturing method comprises steps of: (a) bonding one of adhesive layers, which are provided on both surfaces of an adhesive sheet consisting of a porous insulating sheet, to a panel holder, to bond a rear surface of a panel to the holder, and (b) bonding another adhesive layer to a rear surface of the panel. And, the dismantling method comprises the step of separating the panel from the holder by cutting the porous insulating sheet of the adhesive sheet.

Owner:PANASONIC CORP

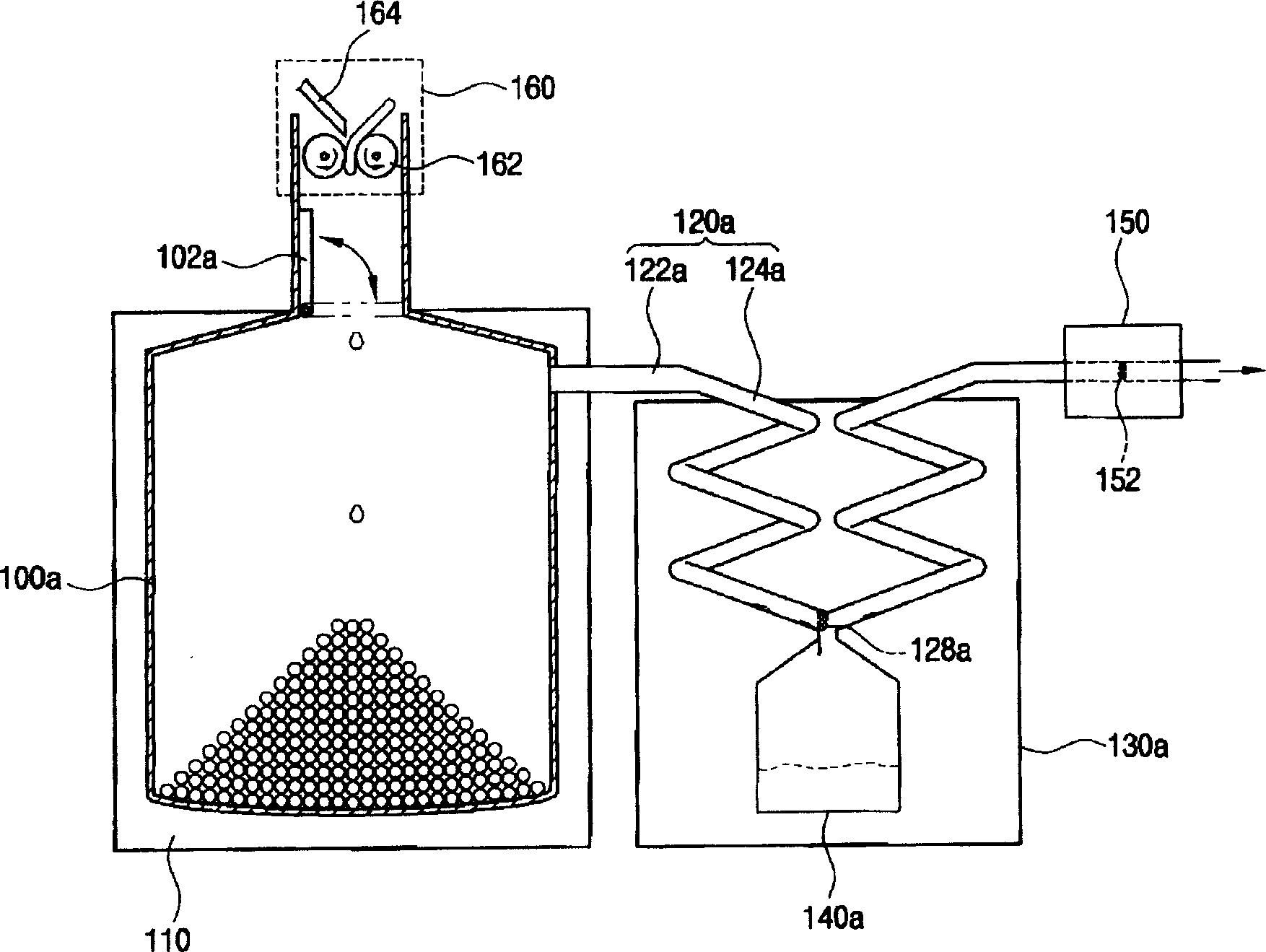

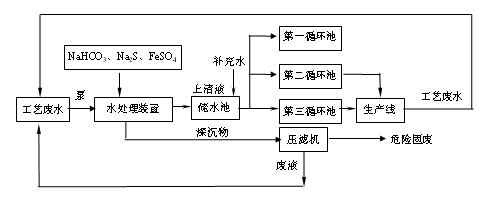

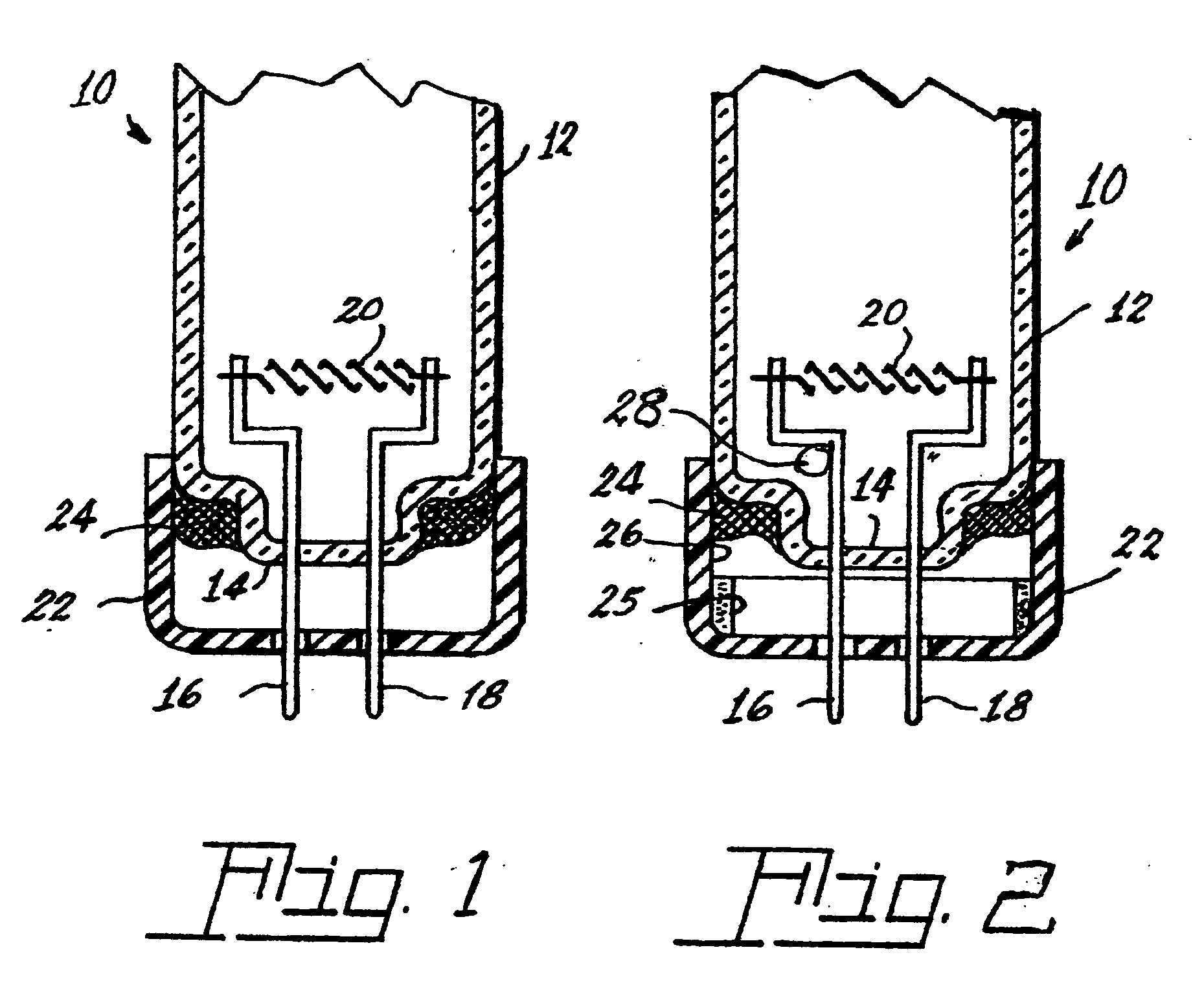

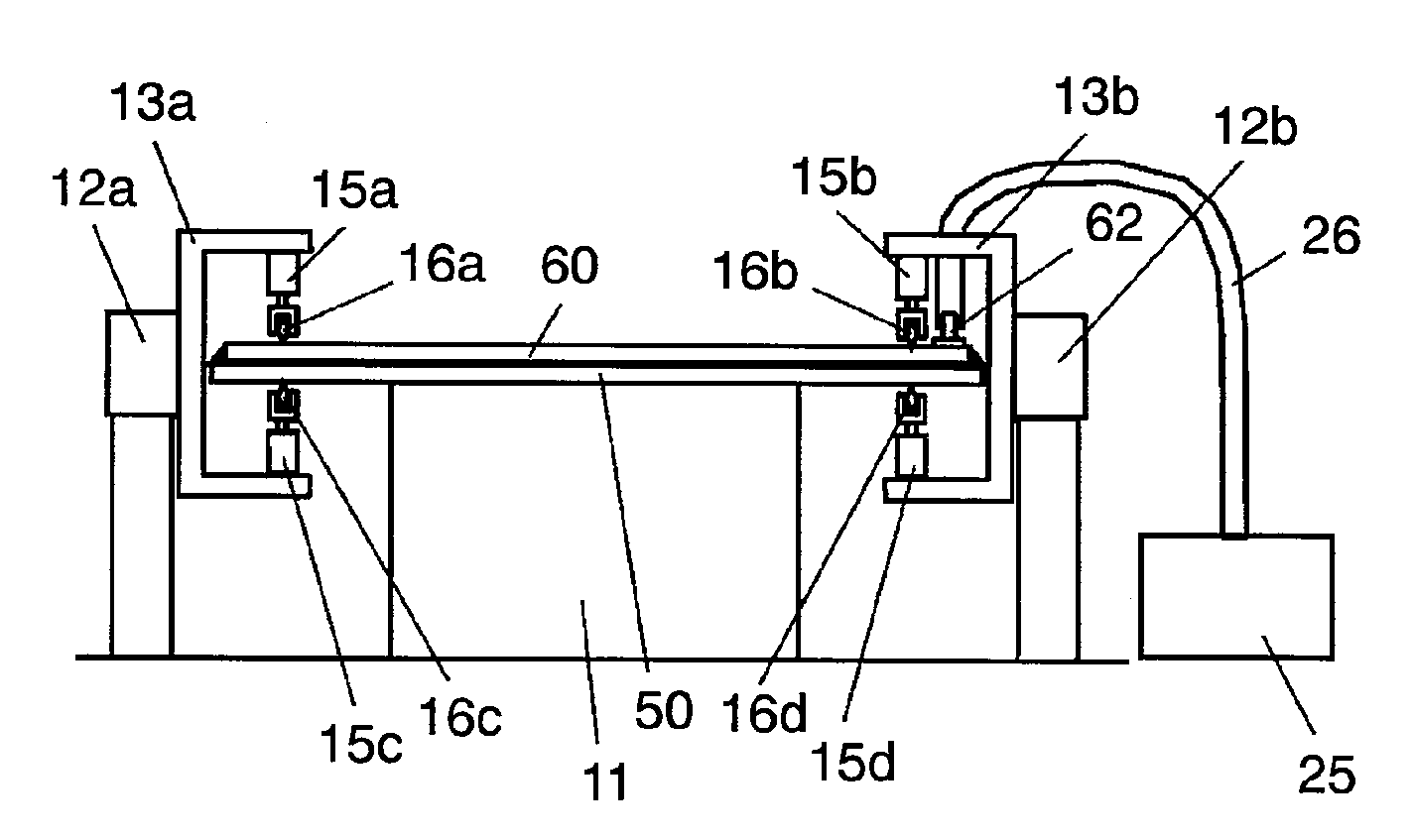

Resource recycle method for waste tubes

InactiveCN101604606AEfficient recyclingLow costGlass recyclingSolid waste disposalRecovery methodReverse current

The invention relates to a resource recycle method for waste tubes, and the technique method is as follows: pouring the waste tubes into a crusher for crushing under the negative pressure; delivering the mixture after crushing into a material receiving box; sucking the waste gas into a condensing system by an exhaust fan arranged on the top of the material receiving box for separating mercury and fluorescent powder; wherein, mercury can be recycled by a vacuum heater; the glass after crushing and the metal materials are sent to a magnetic separator for separating the glass from the metal; the separated metal is sent to a washing machine for recycling the metal by third-stage reverse current spraying washing. The invention can effectively recycle the fluorescent powder, mercury and metal, thus realizing up-to-standard discharge of waste water, waste liquid and waste gas.

Owner:HUIZHOU DINGCHEN IND DEV

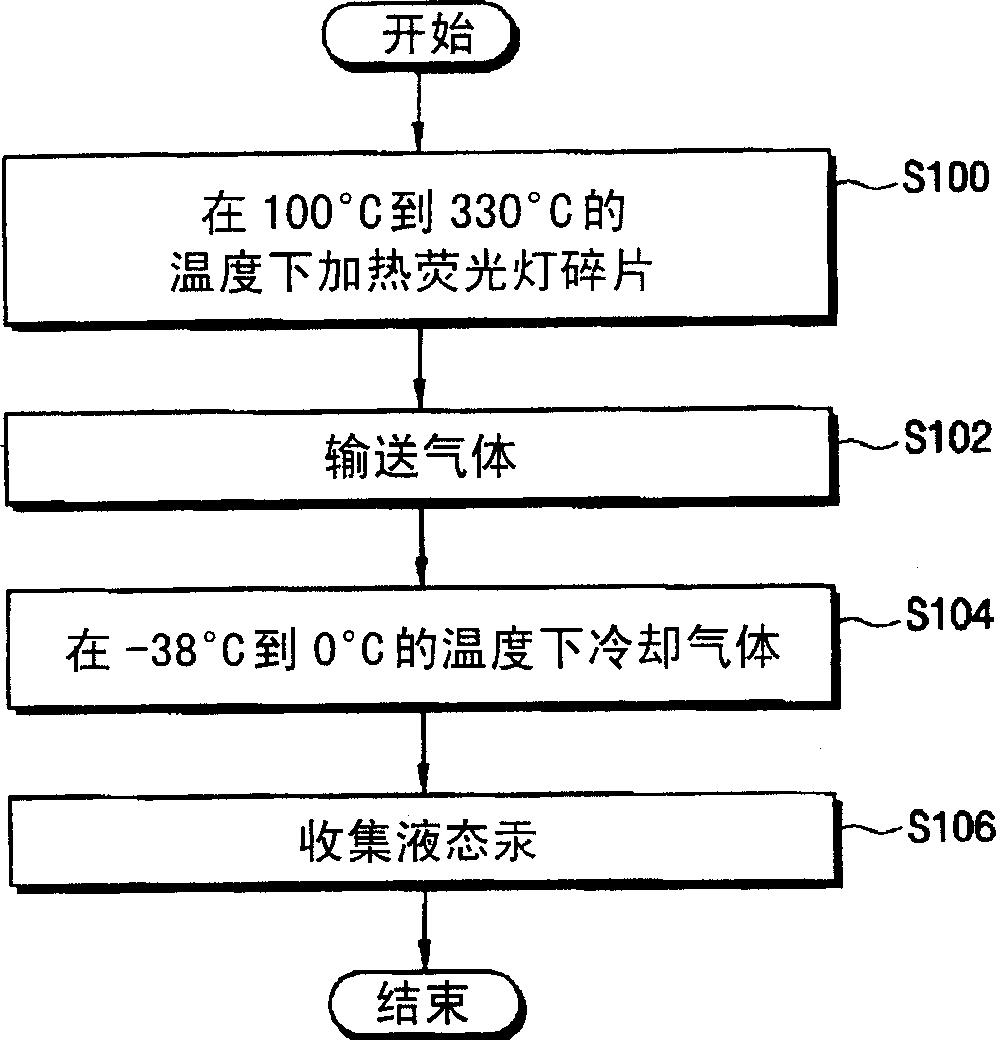

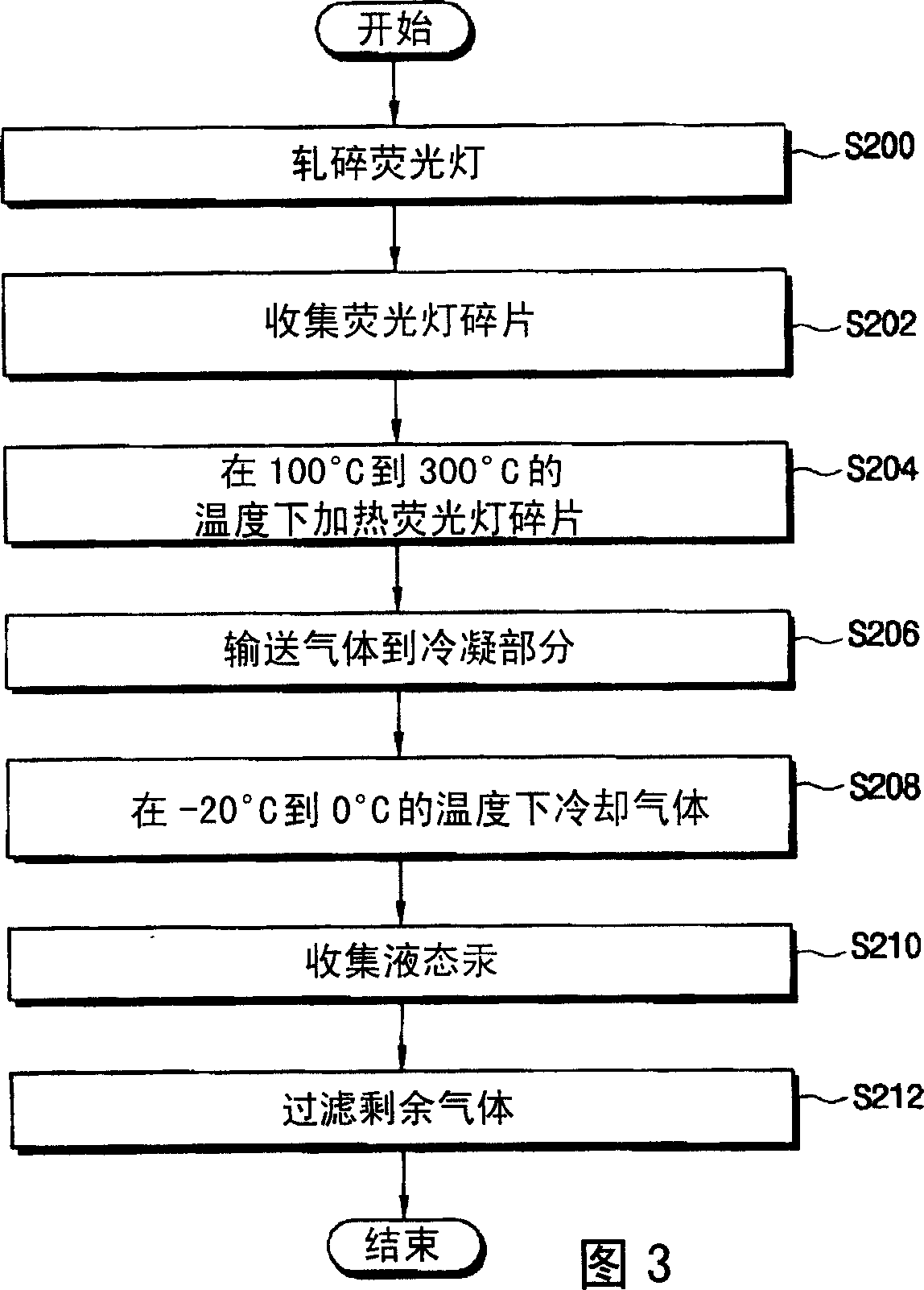

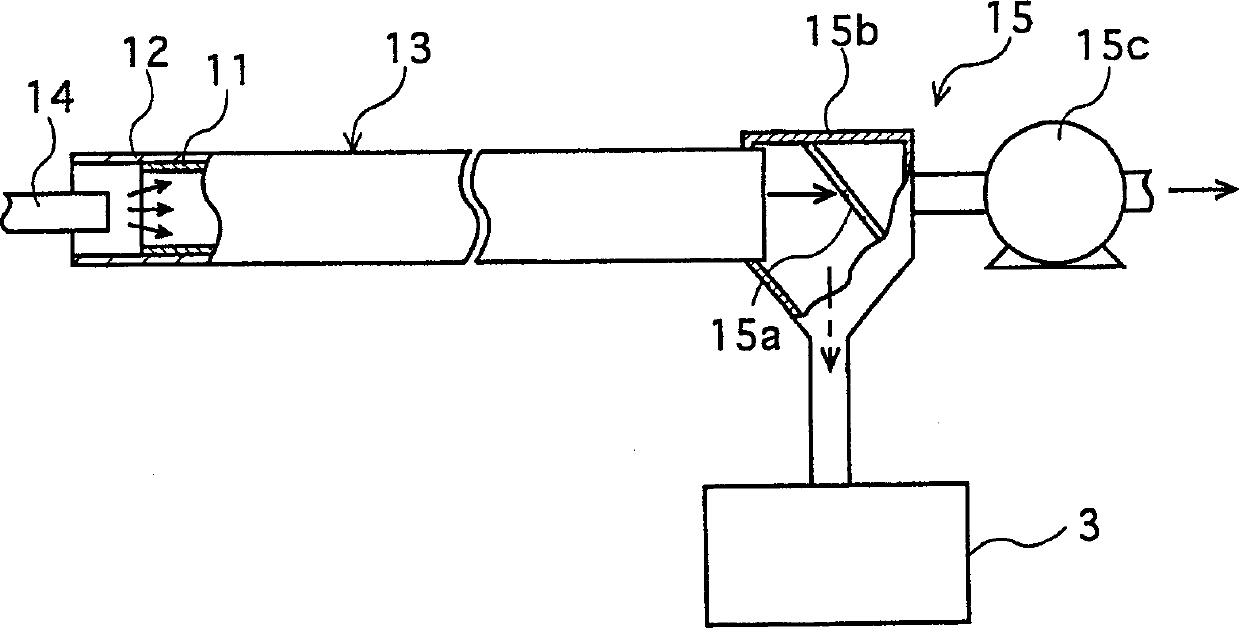

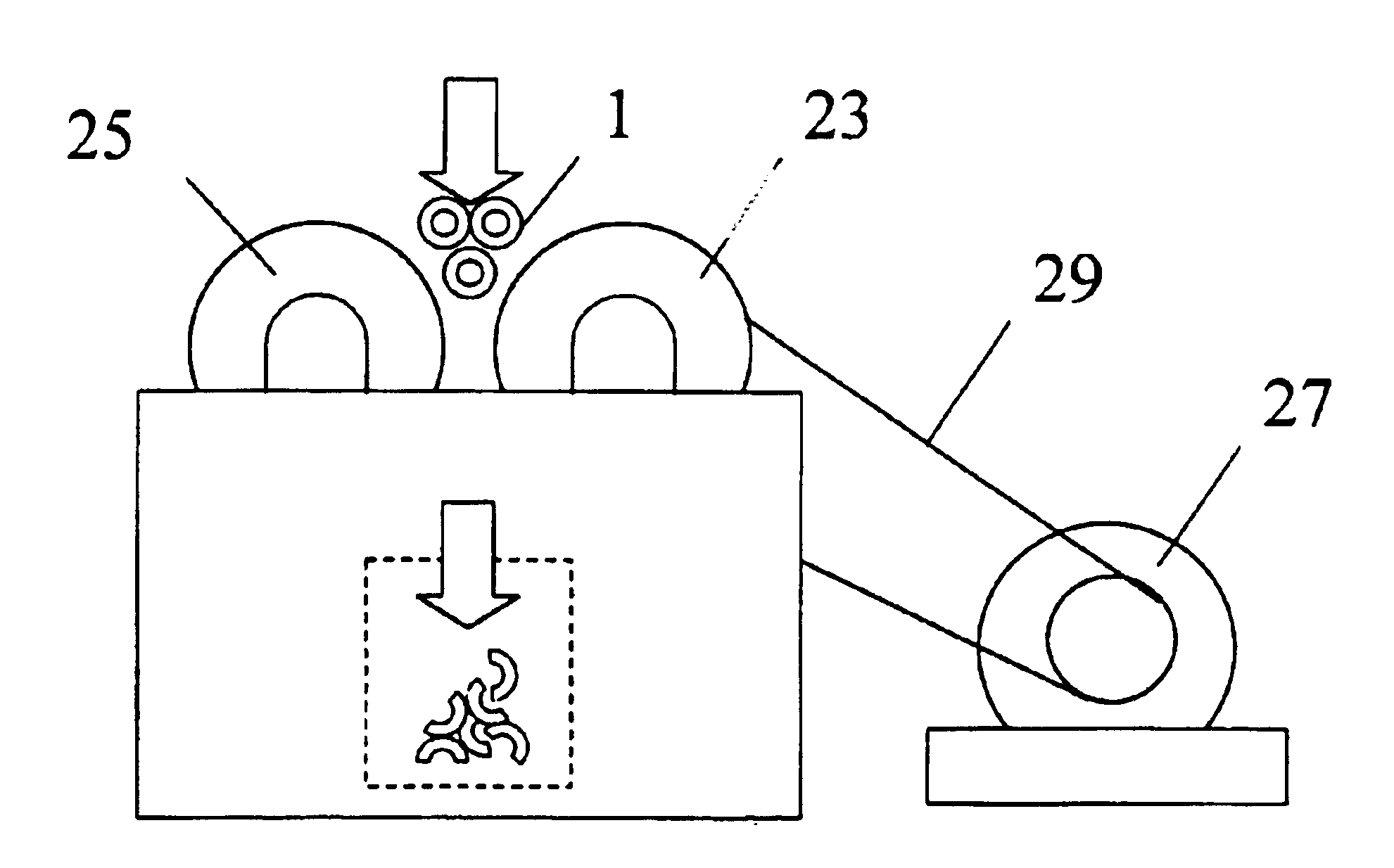

Method of recycling fluorescent lamp

InactiveCN1902723ASmall sizeReduce consumptionTransportation and packagingSolid waste disposalPhysical chemistryFluorescent lamp

In an eco-friendly method of recycling a fluorescent lamp capable of reducing energy consumption and a recycling apparatus for performing the recycling method, broken pieces of fluorescent lamps are heated at a temperature of about 100 DEG C to about 330 DEG C to form a gas containing a mercury vapor. The gas containing the mercury vapor is cooled at a temperature of about -38 DEG C to about 0 DEG C to form a liquid mercury. The liquid mercury is collected. Therefore, the broken pieces of the fluorescent lamps are heated at the temperature no higher than the boiling point of mercury so that an energy consumption and a size of the recycling apparatus are decreased, and a probability for the recycling apparatus to malfunction may also be decreased.

Owner:SAMSUNG ELECTRONICS CO LTD

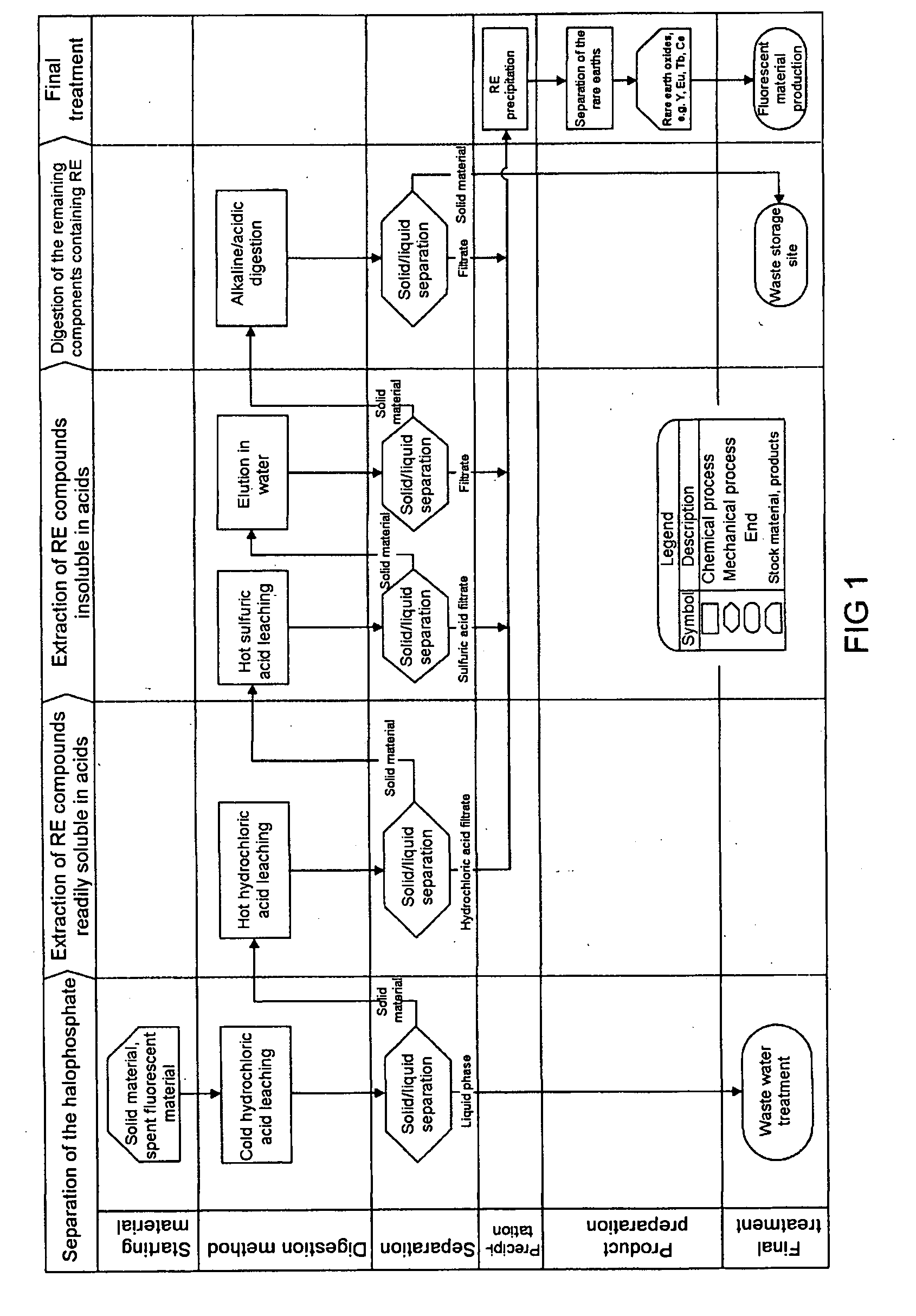

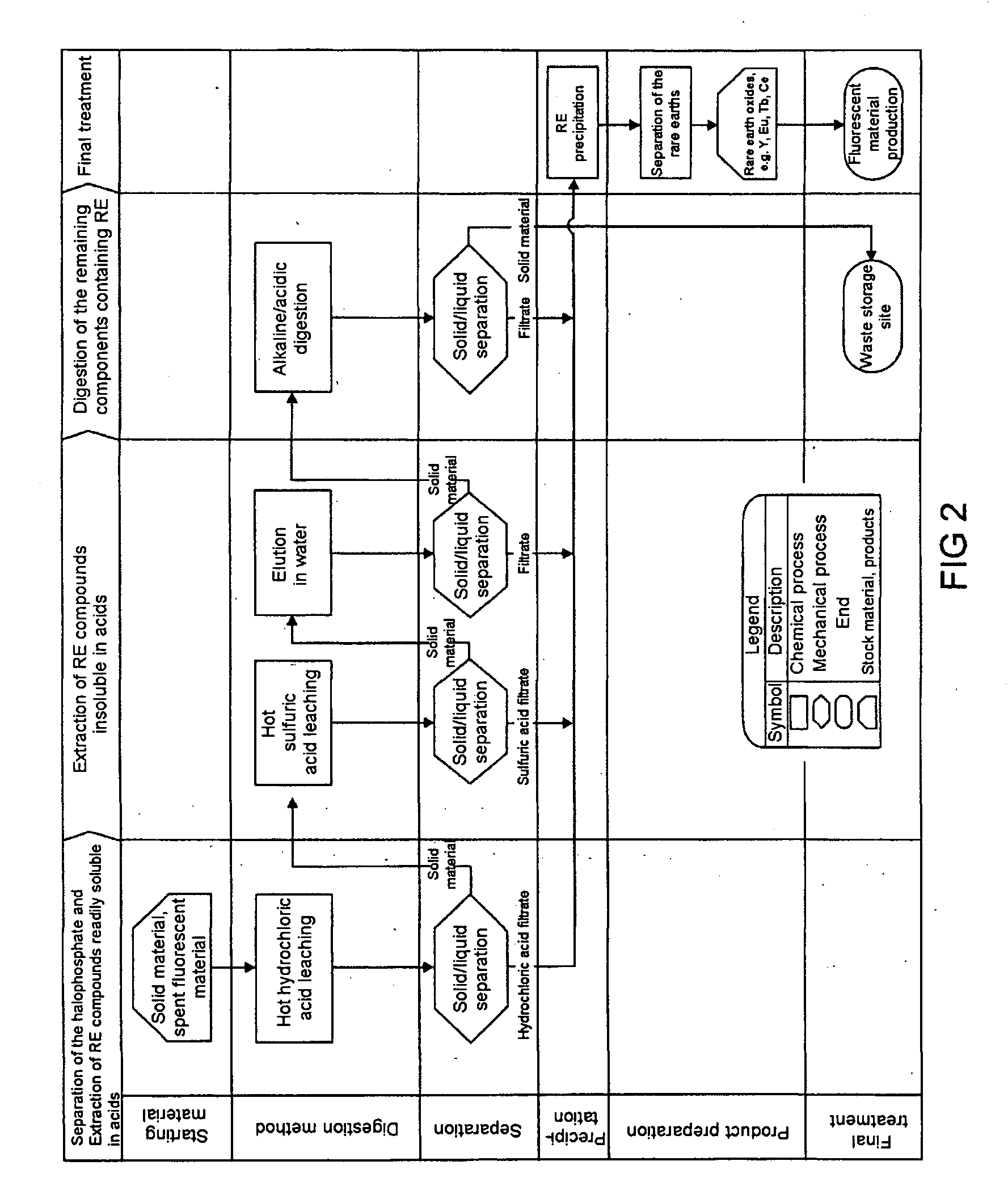

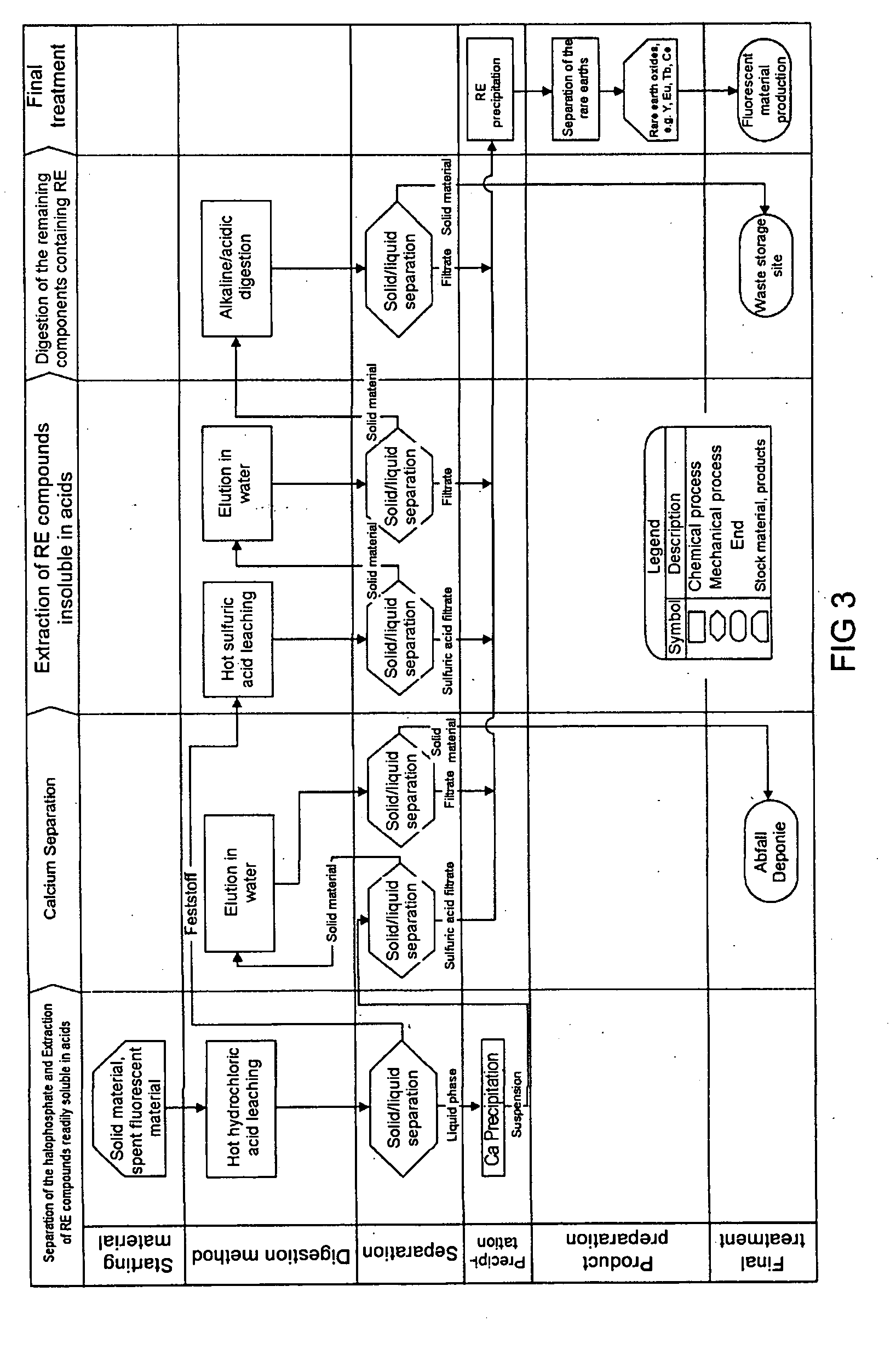

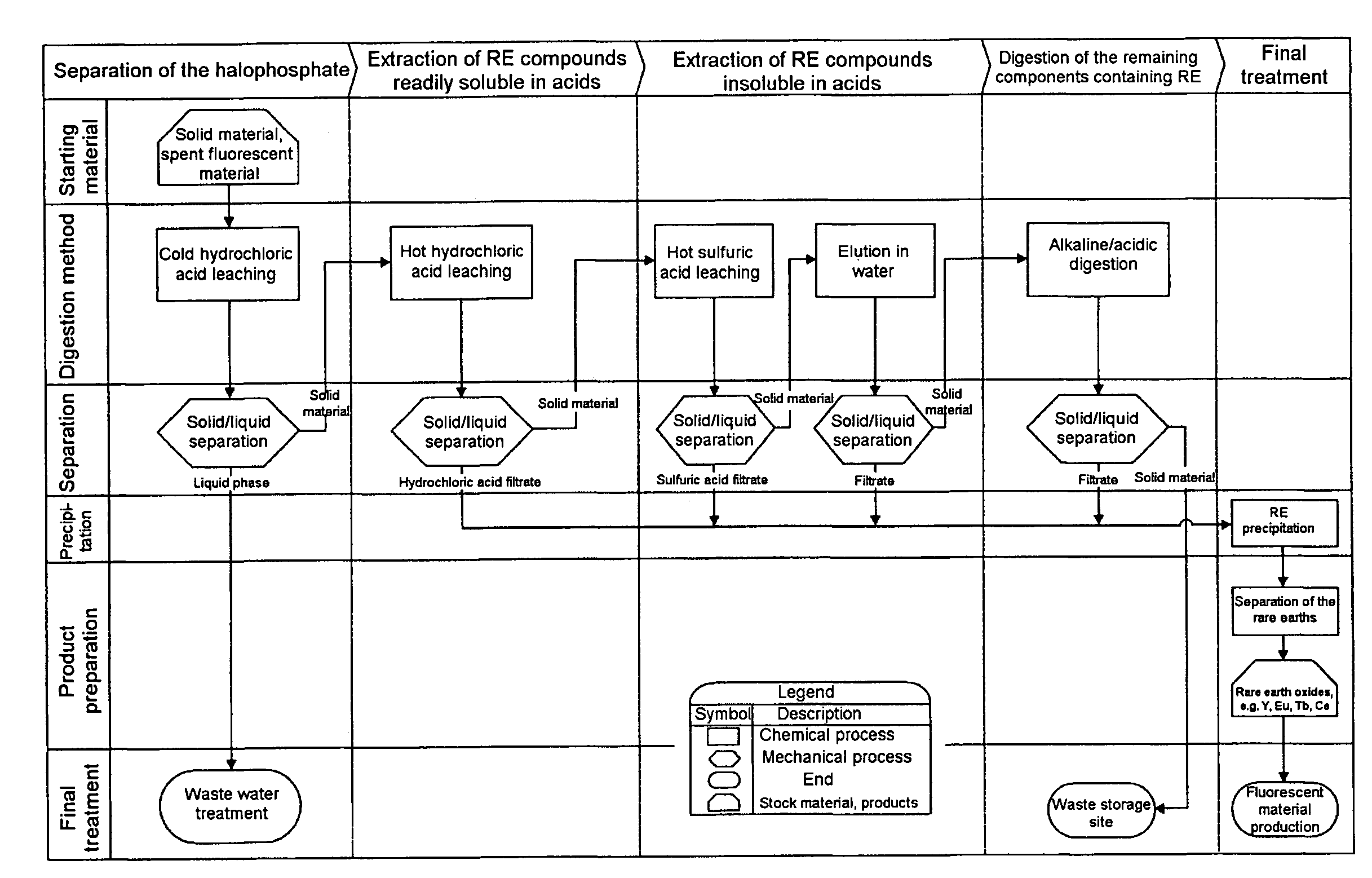

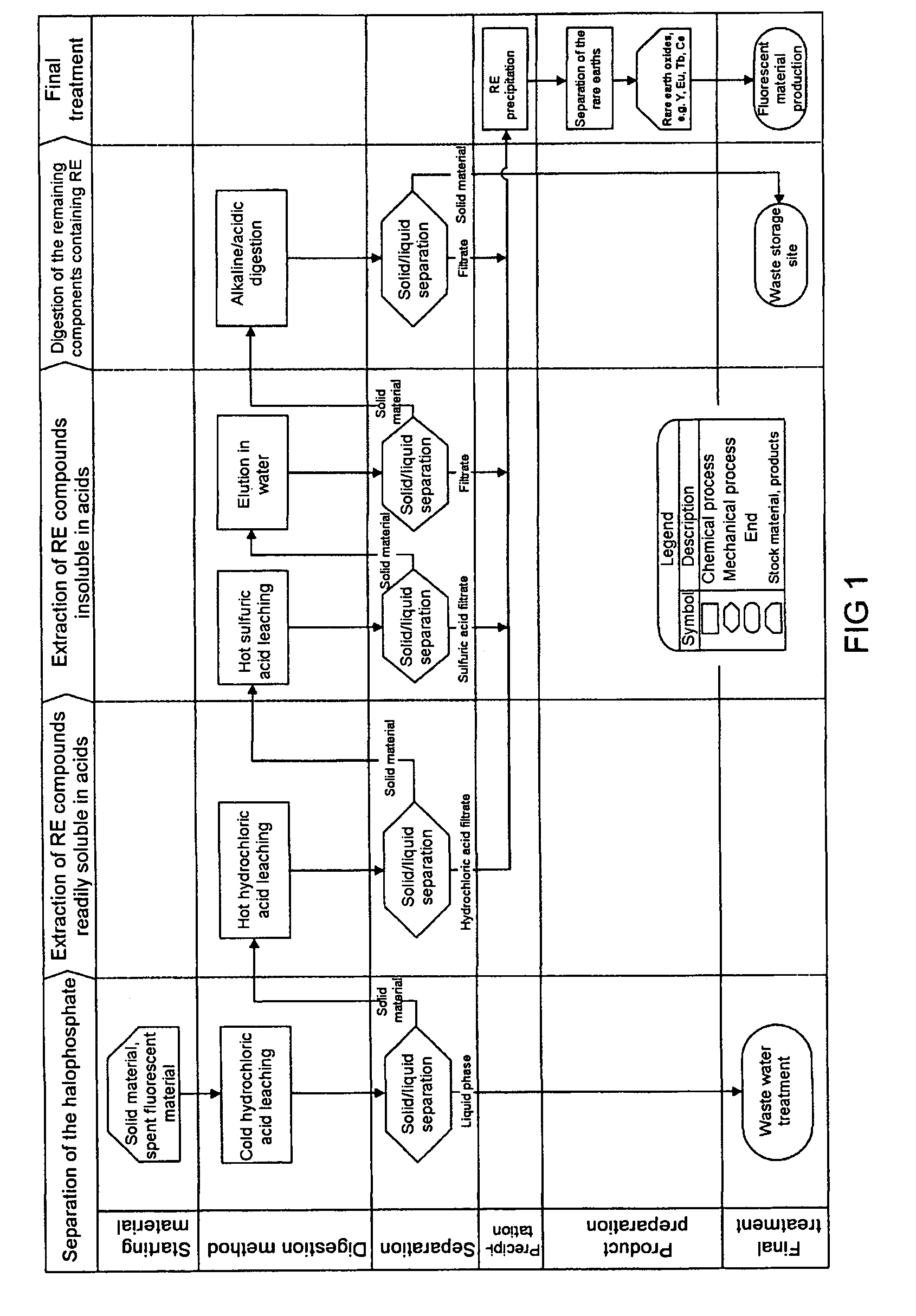

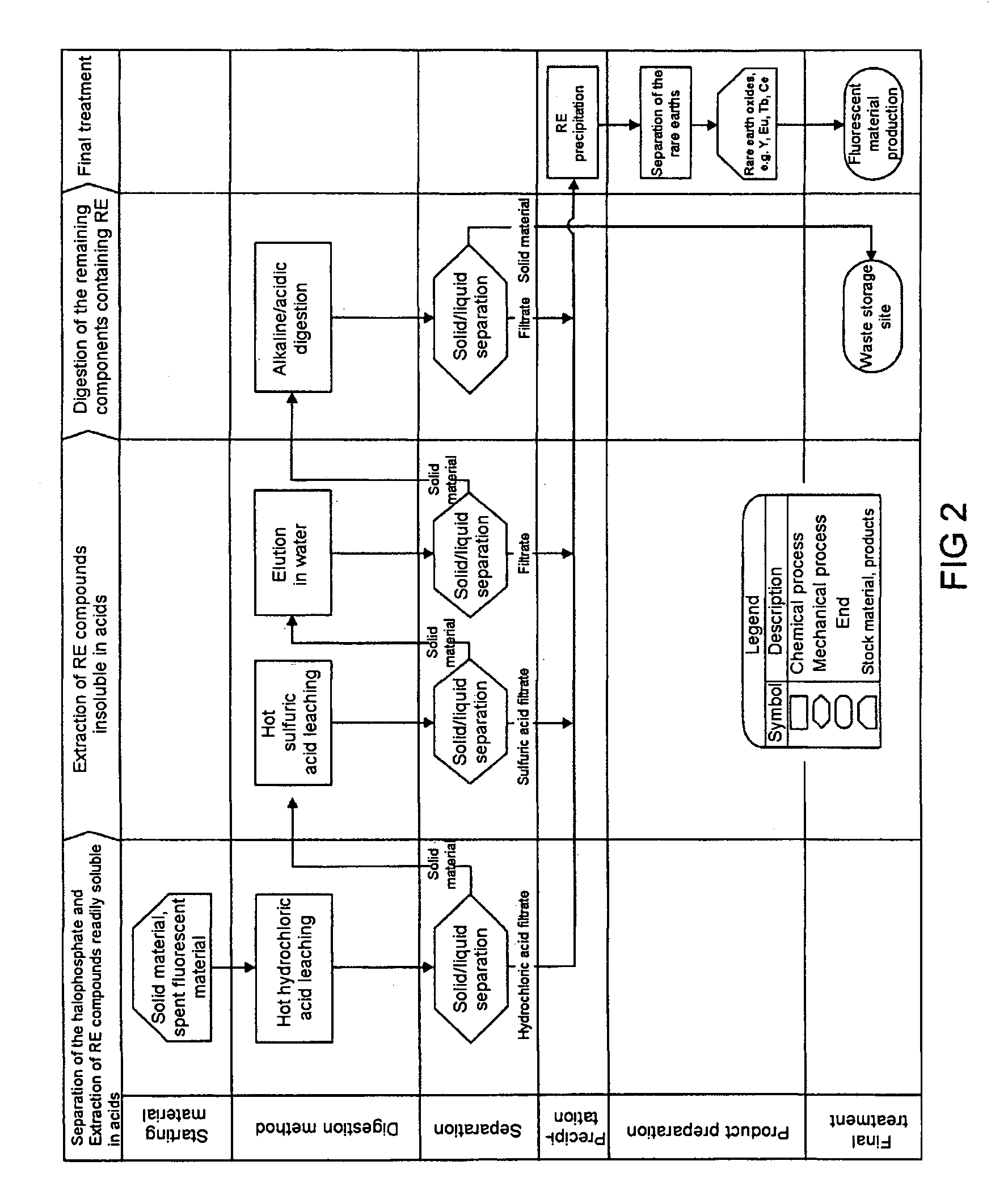

Method for Recovery of Rare Earths from Fluorescent Lamps

InactiveUS20090162267A1Reduce overall mass and volumeReduce disposalRare earth metal compoundsLuminescent compositionsAluminateRare-earth element

Method for recovery of rare earths from fluorescent lamps. The method comprises six steps. The individual process steps are: Mechanical separation of coarse components. Separation of the halophosphate. Extraction in acids of easily soluble rare-earth fluorescent substances (mainly Y, Eu-oxide) Extraction in acids of rare-earth fluorescent substances which dissolve with difficulty (for example rare-earth phosphates) Breakdown of the remaining components which contain rare earths (for example rare-earth-aluminates) Final treatment.

Owner:OSRAM GMBH

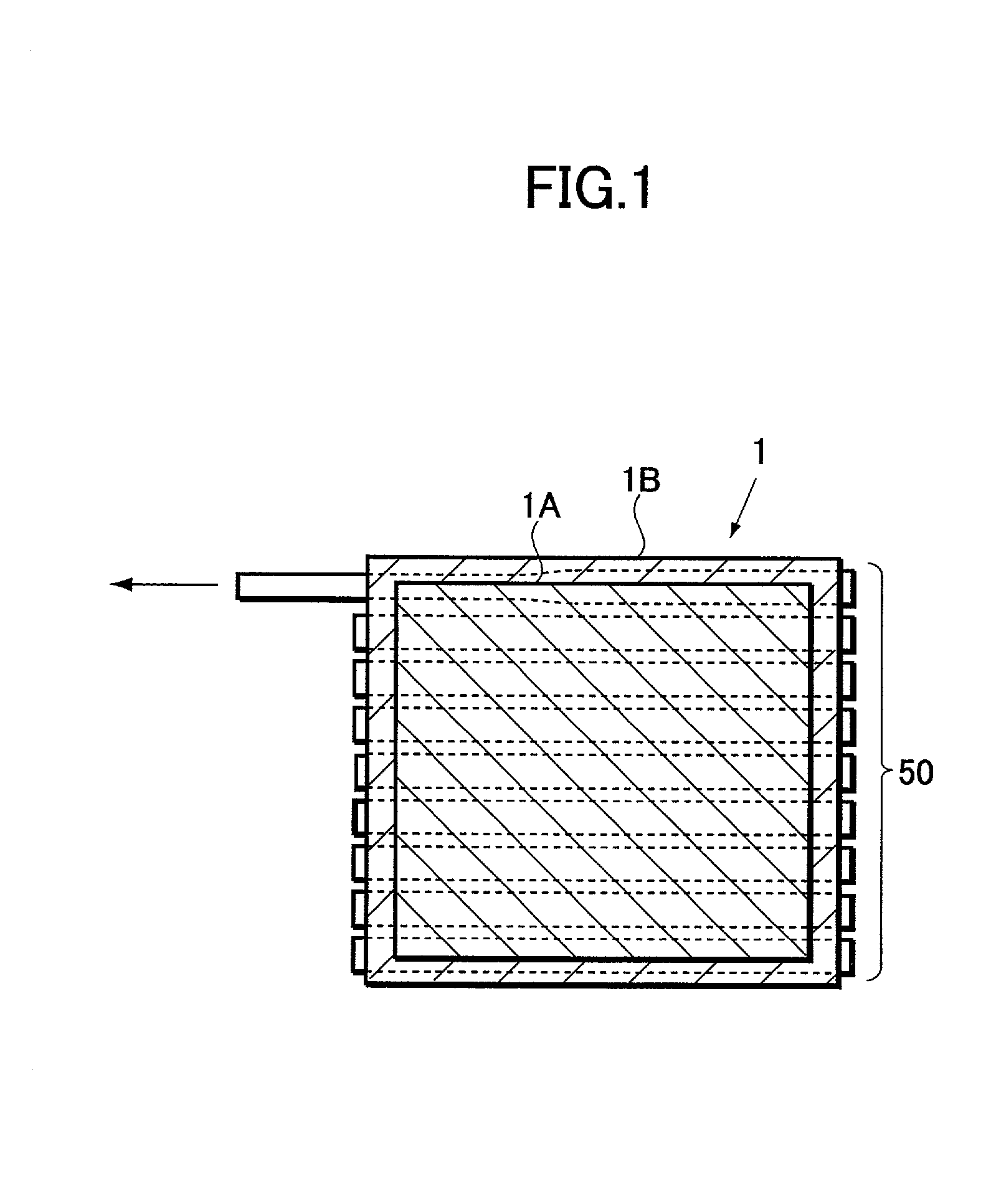

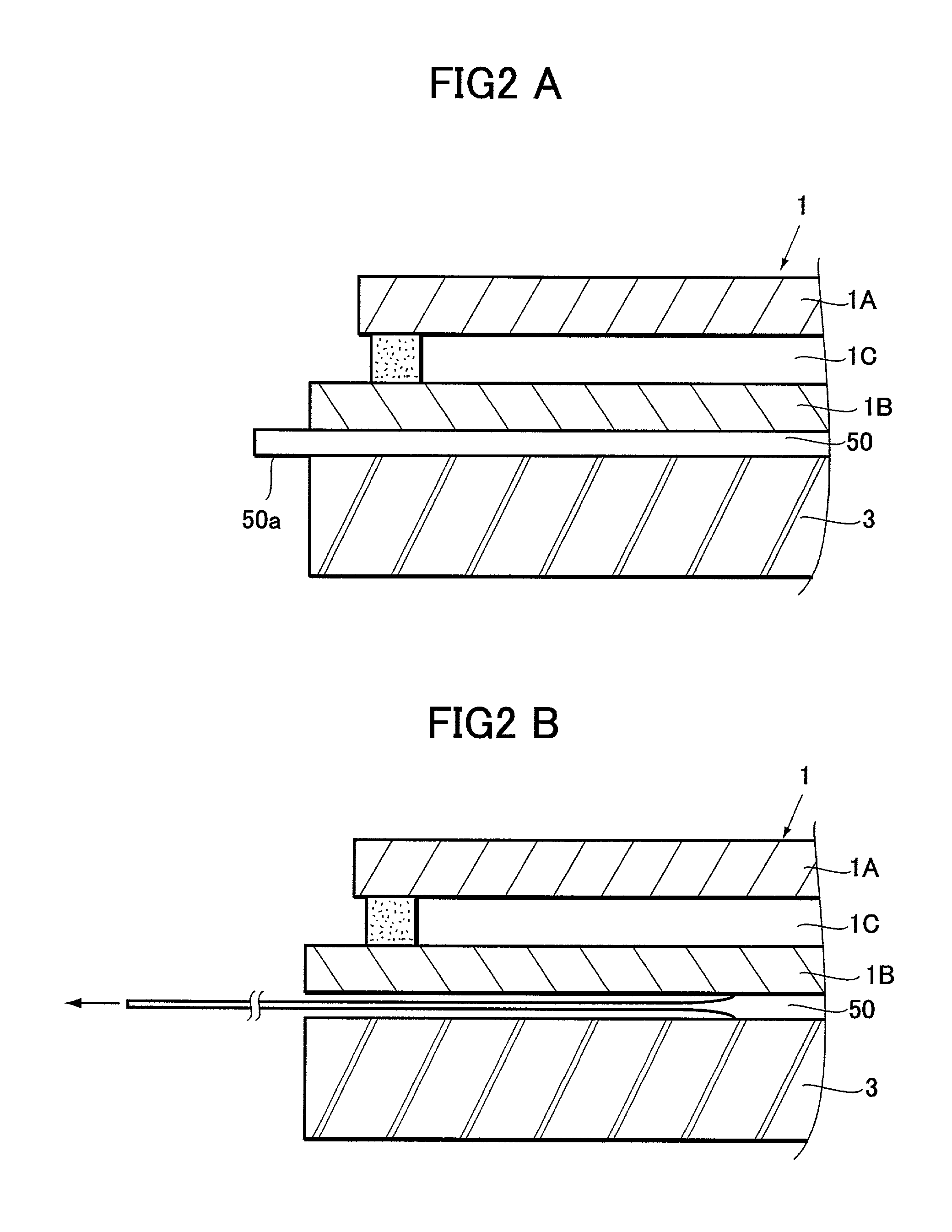

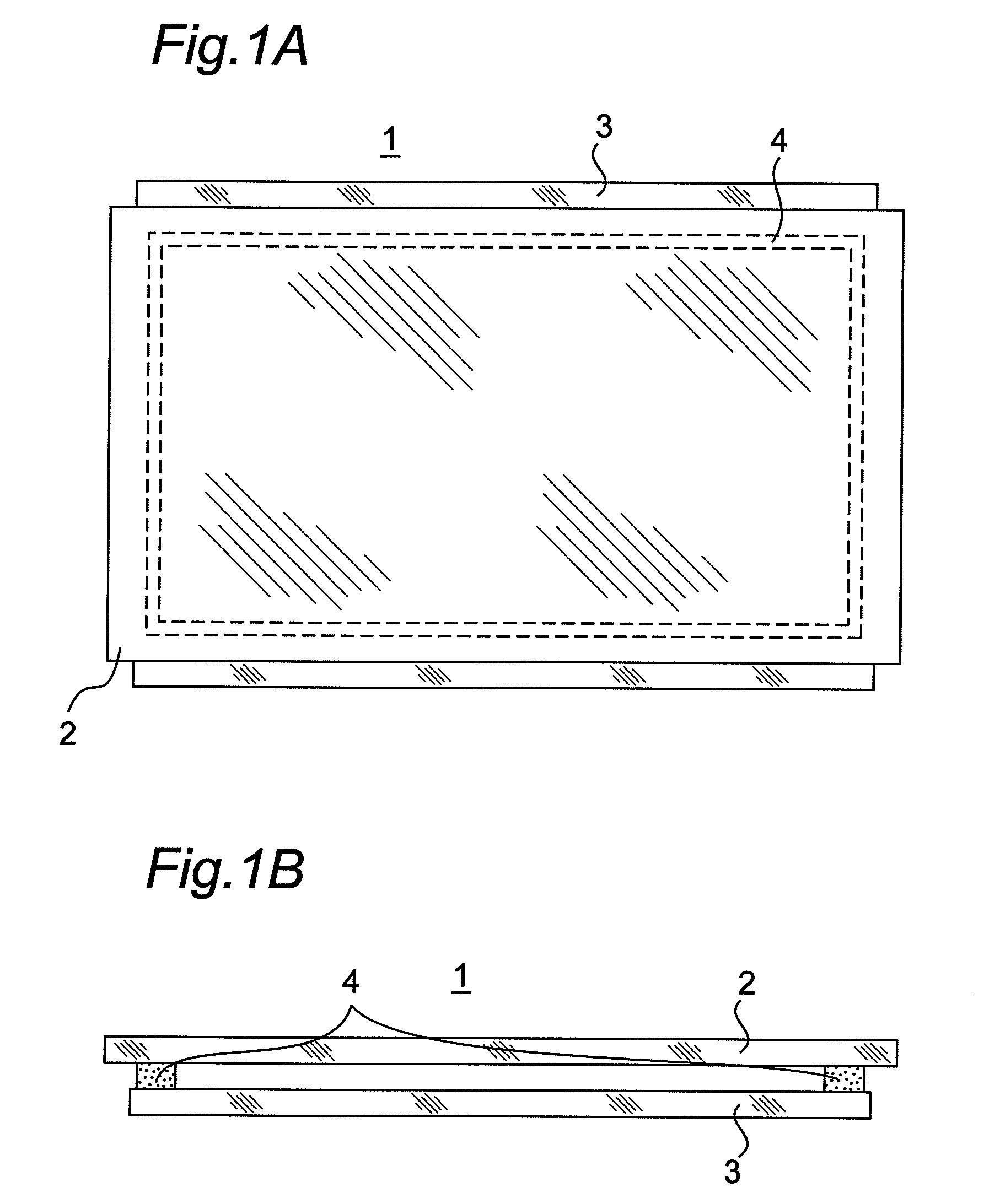

Image display apparatus, disassembly processing method therefor, and component recovery method

InactiveUS20040002276A1Easy to useEfficient reuseElectric discharge tubesGlass recyclingRecovery methodFrit

To reuse glass used in a flat panel display, processing suitable for global environment such as processing of separating a lead component must be realized. A disassembly processing method for a flat panel display having a structure in which a face plate and rear plate mainly containing glass are airtightly joined via a frame with frit glass is characterized by including the step of separating the face plate and rear plate joined with the frit glass. The separation step is characterized by separating the face plate and rear plate by cutting, dissolution, or melting.

Owner:CANON KK

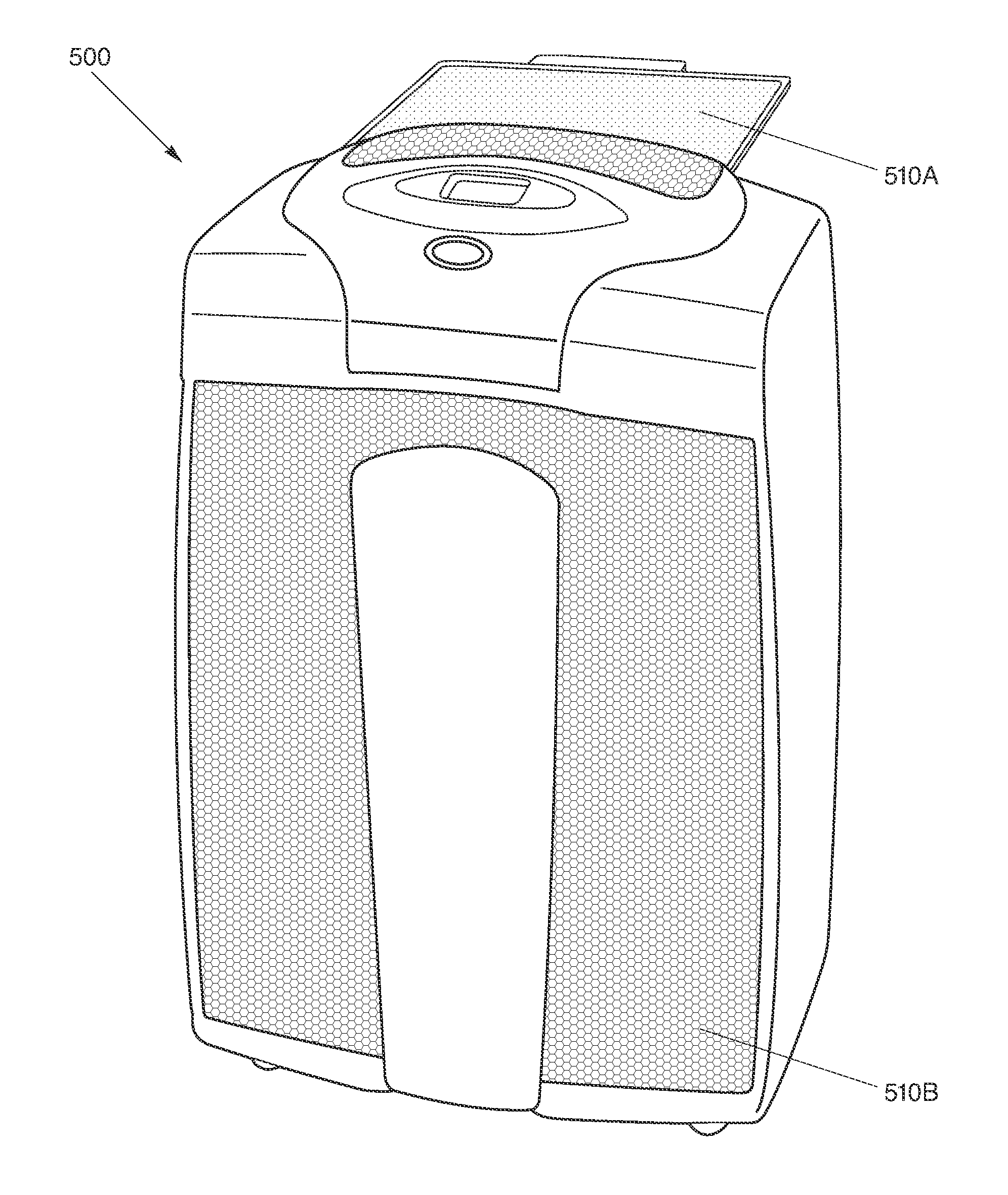

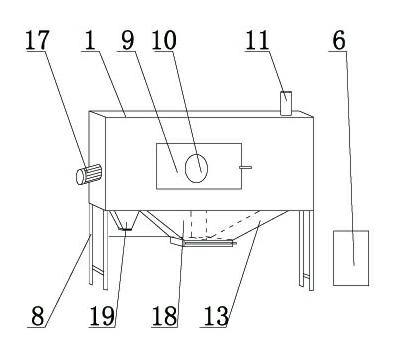

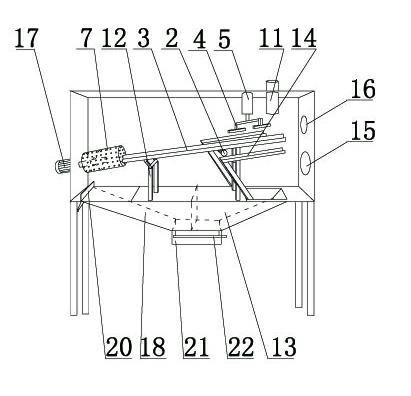

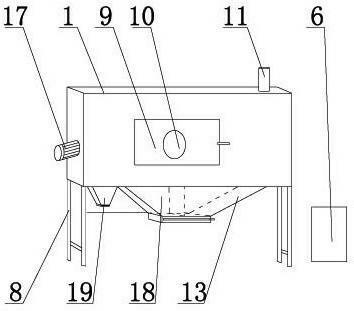

Multifunctional separator for recycling of waste fluorescent lamps

InactiveCN102489449ASimple structureImprove work efficiencyGlass recyclingSolid separationPulp and paper industryMechanical equipment

The invention relates to a multifunctional separator for recycling of waste fluorescent lamps and belongs to the technical field of mechanical equipment for recycling of fluorescent lamps. The multifunctional separator comprises a separator shell, a vibrating groove, an electromagnet, a rotating air cylinder, a filter sieve and the like, wherein a feeding cylinder is arranged at the top of the separator shell; the rotating air cylinder is arranged at the top in the separator shell; the electromagnet is arranged on a piston of the air cylinder; the vibrating groove is formed below the feeding cylinder and the electromagnet; a fan port is arranged at one end of the vibrating groove; and the filter sieve is arranged at the other end of the vibrating groove. By adoption of the vibrating groove, the filter sieve and the electromagnet, broken materials can be separated quickly. The multifunctional separator solves the problem that waste materials are recycled difficultly because the conventional broken materials can not be separated effectively and quickly. When the broken materials are separated, fluorescent powder contained in the broken materials enters a fluorescent powder collecting device from a fluorescent powder collecting port to be collected, so that the environmental pollution is avoided and the multifunctional separator is particularly applicable to recycling of the waste fluorescent lamps.

Owner:荆州市大明灯业有限公司

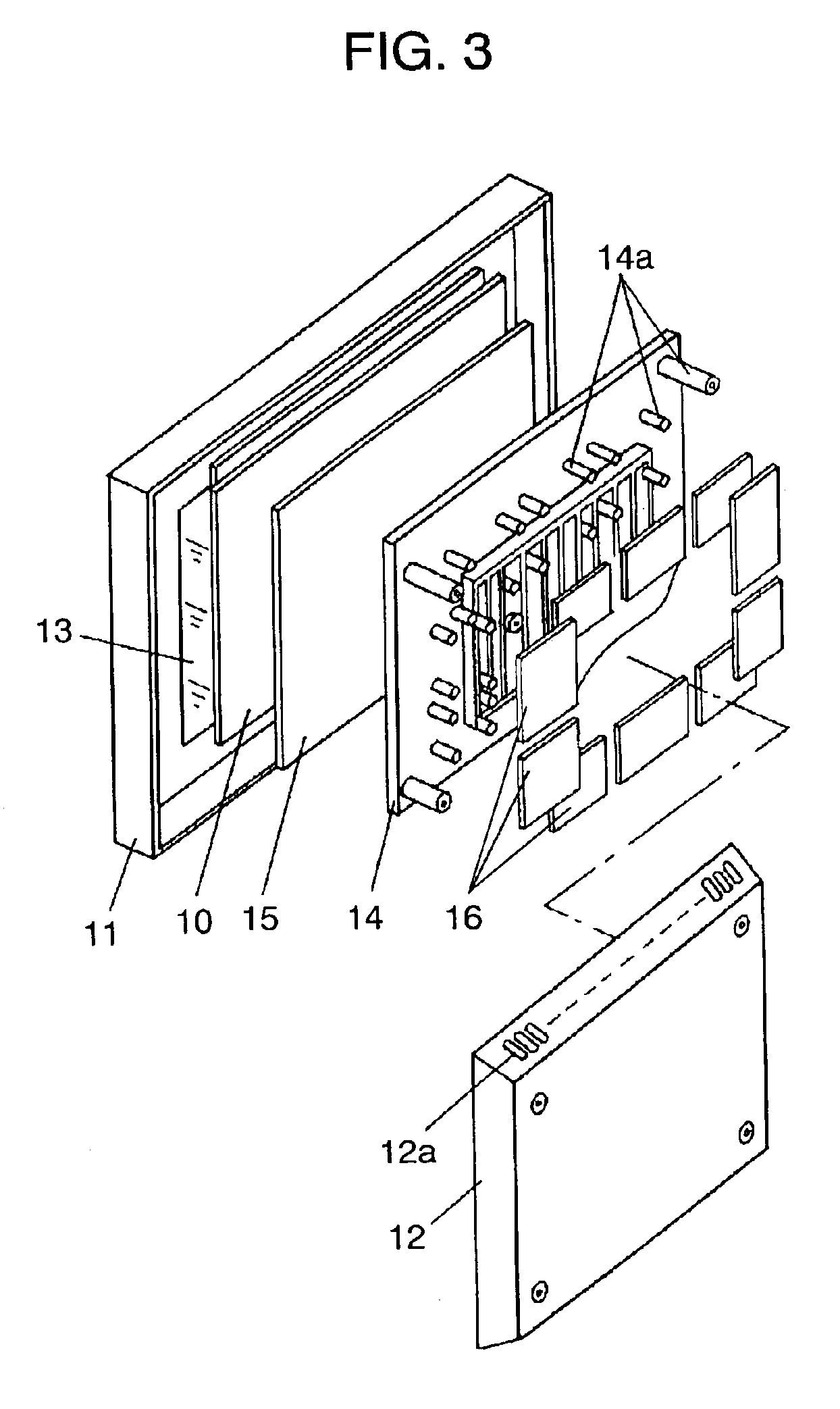

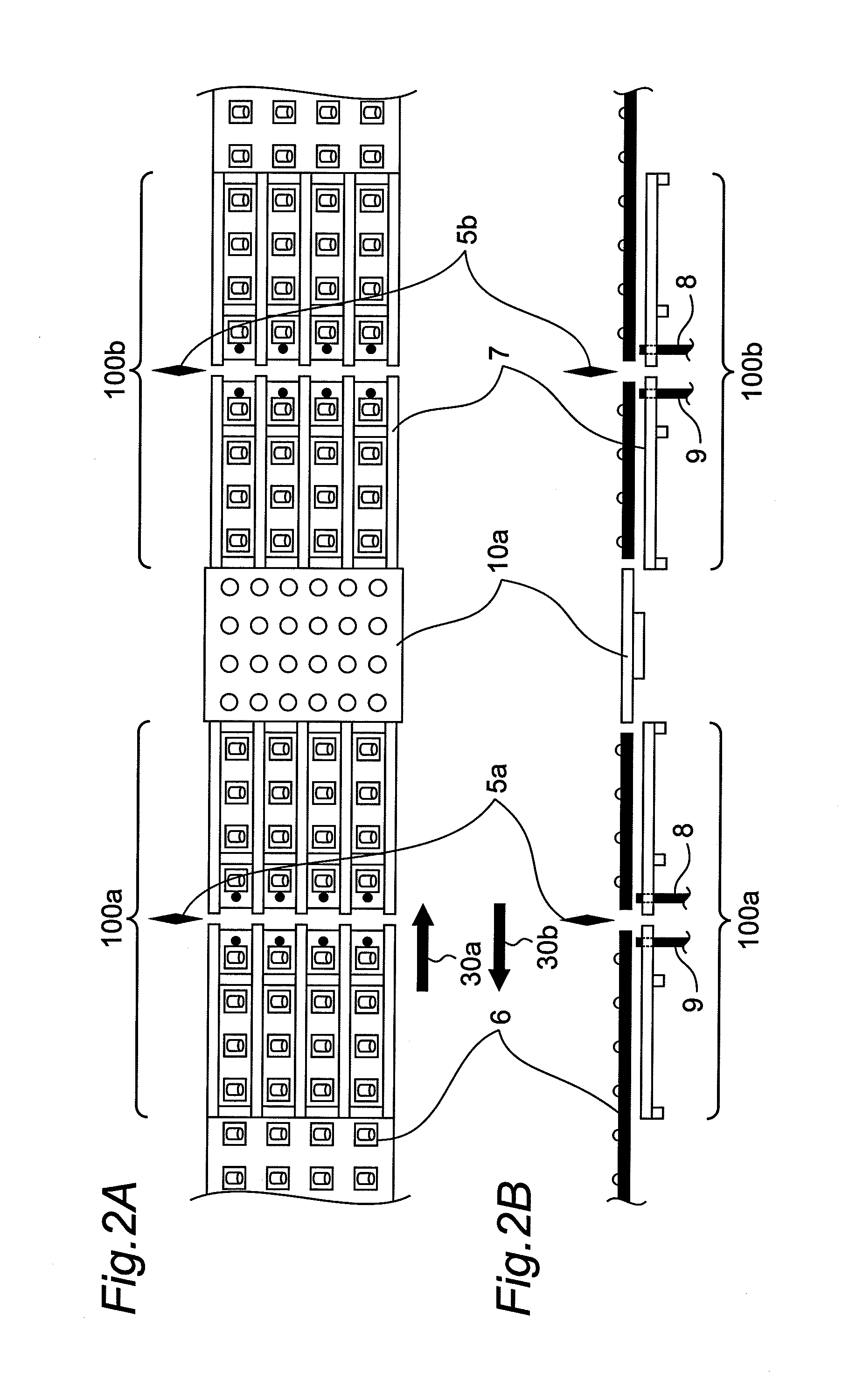

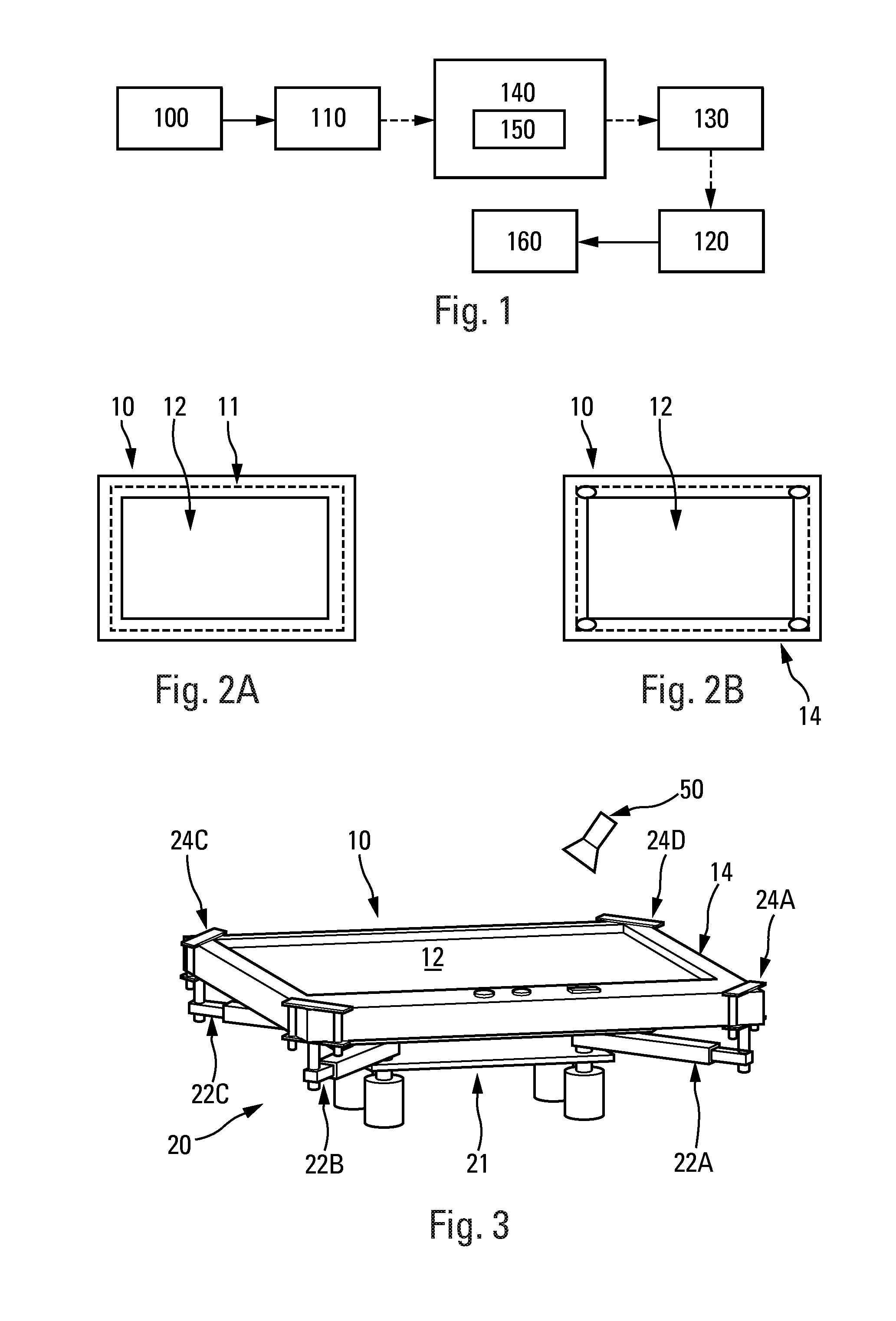

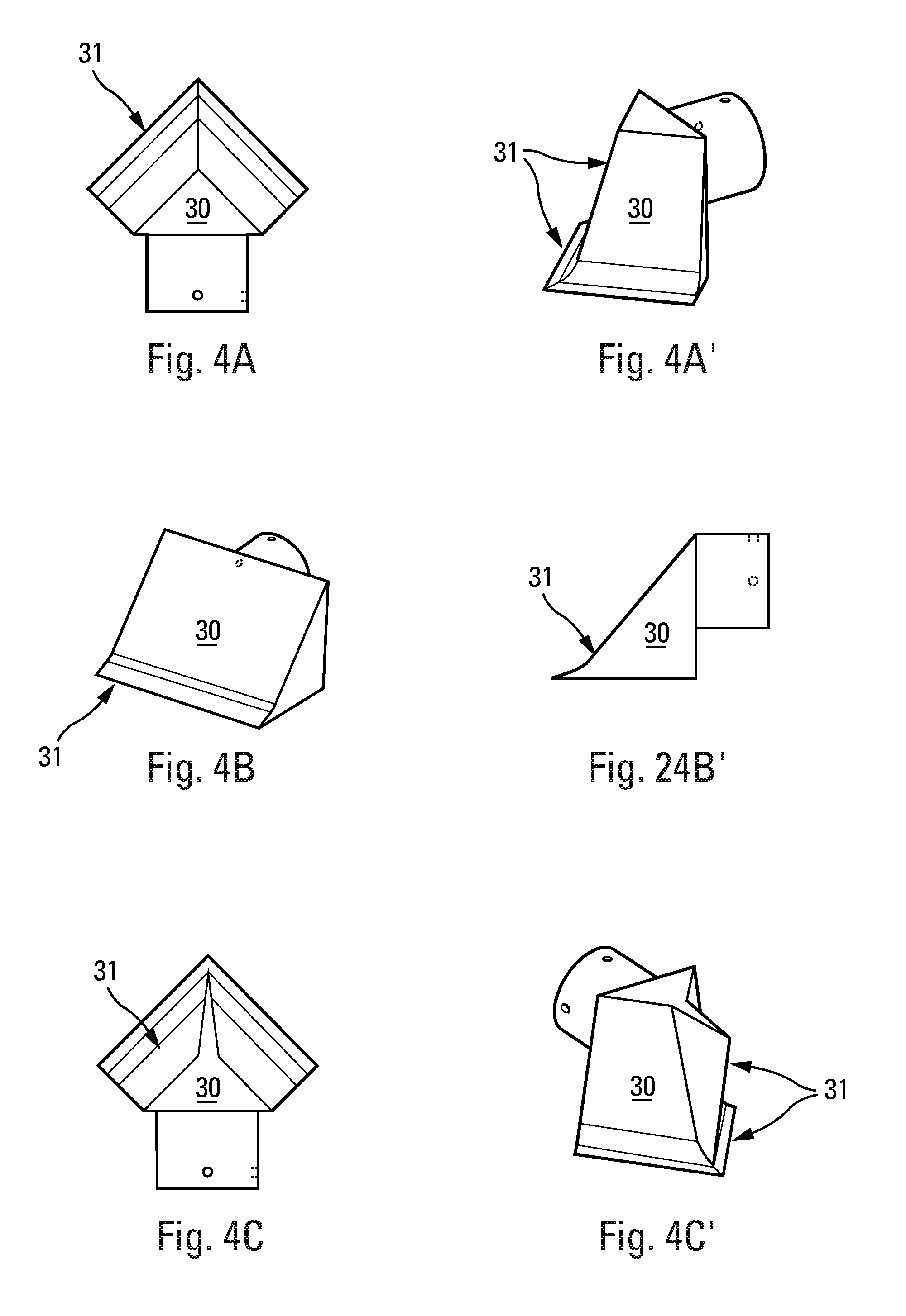

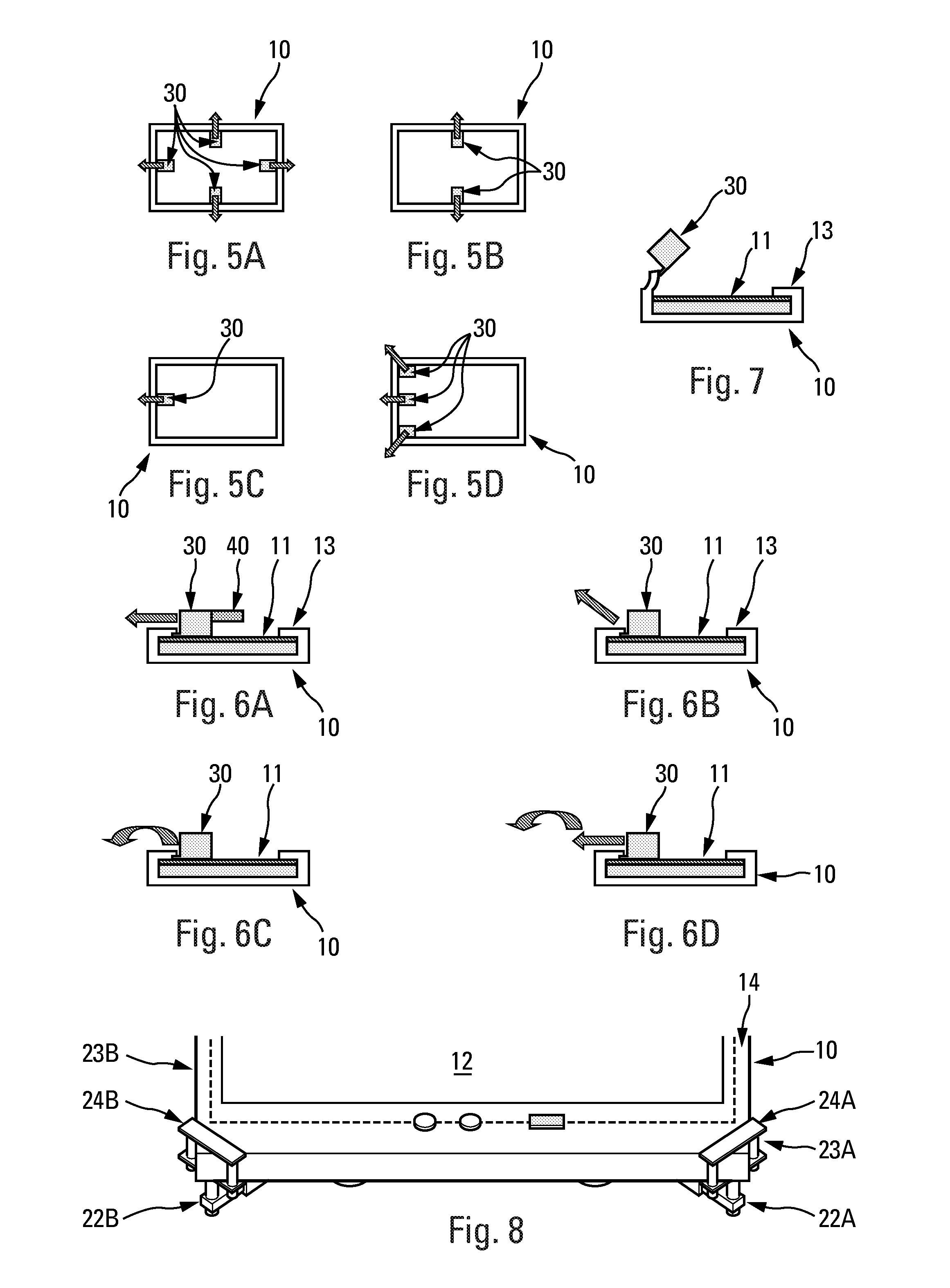

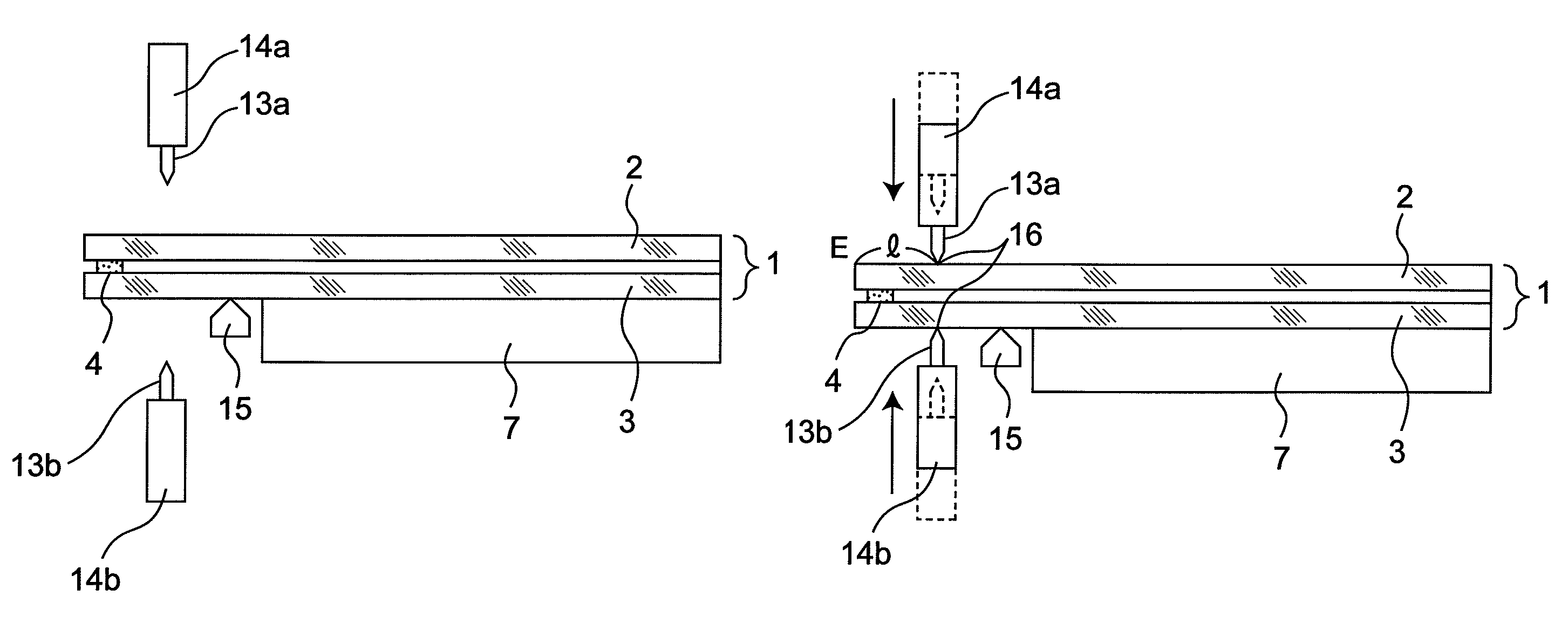

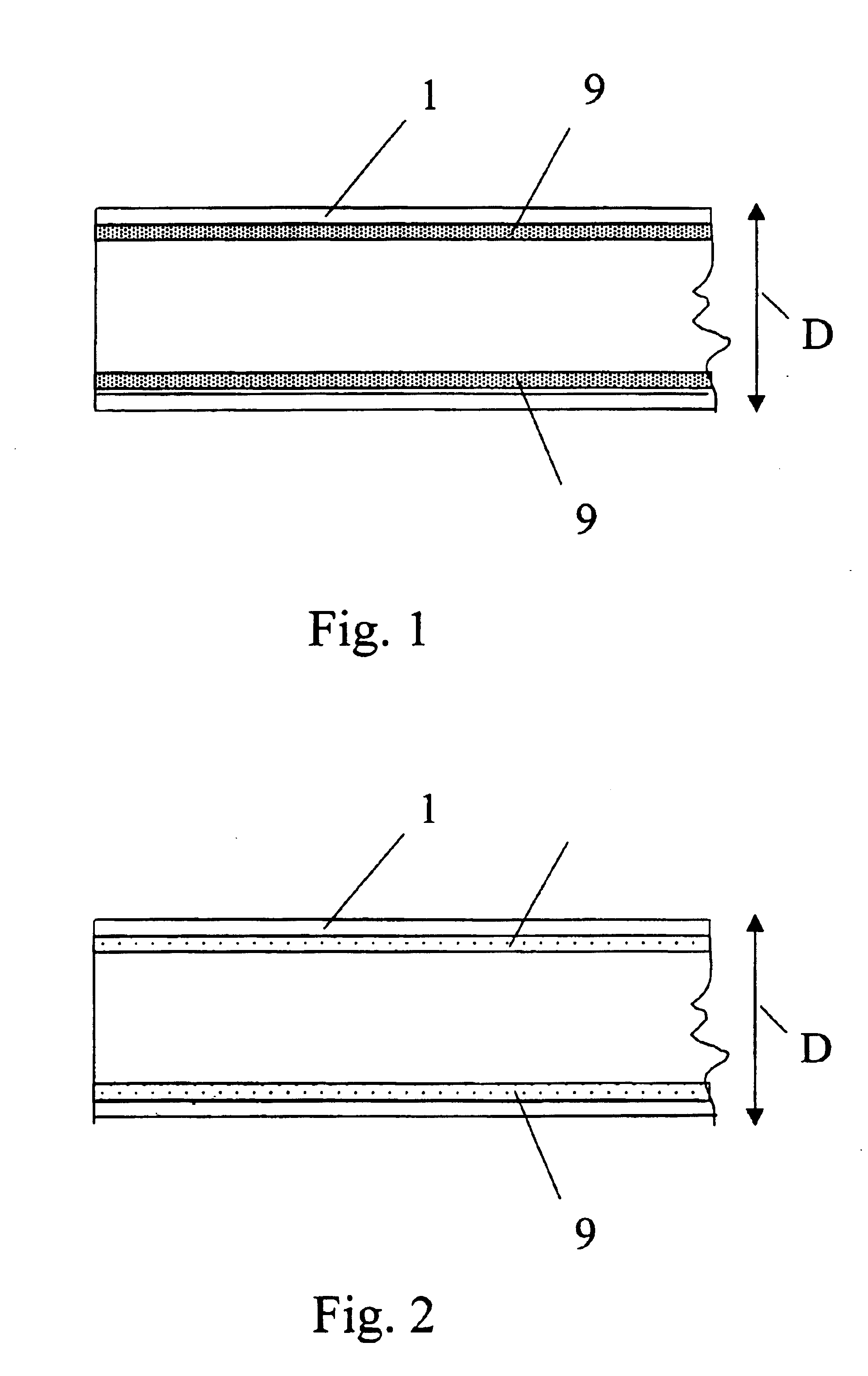

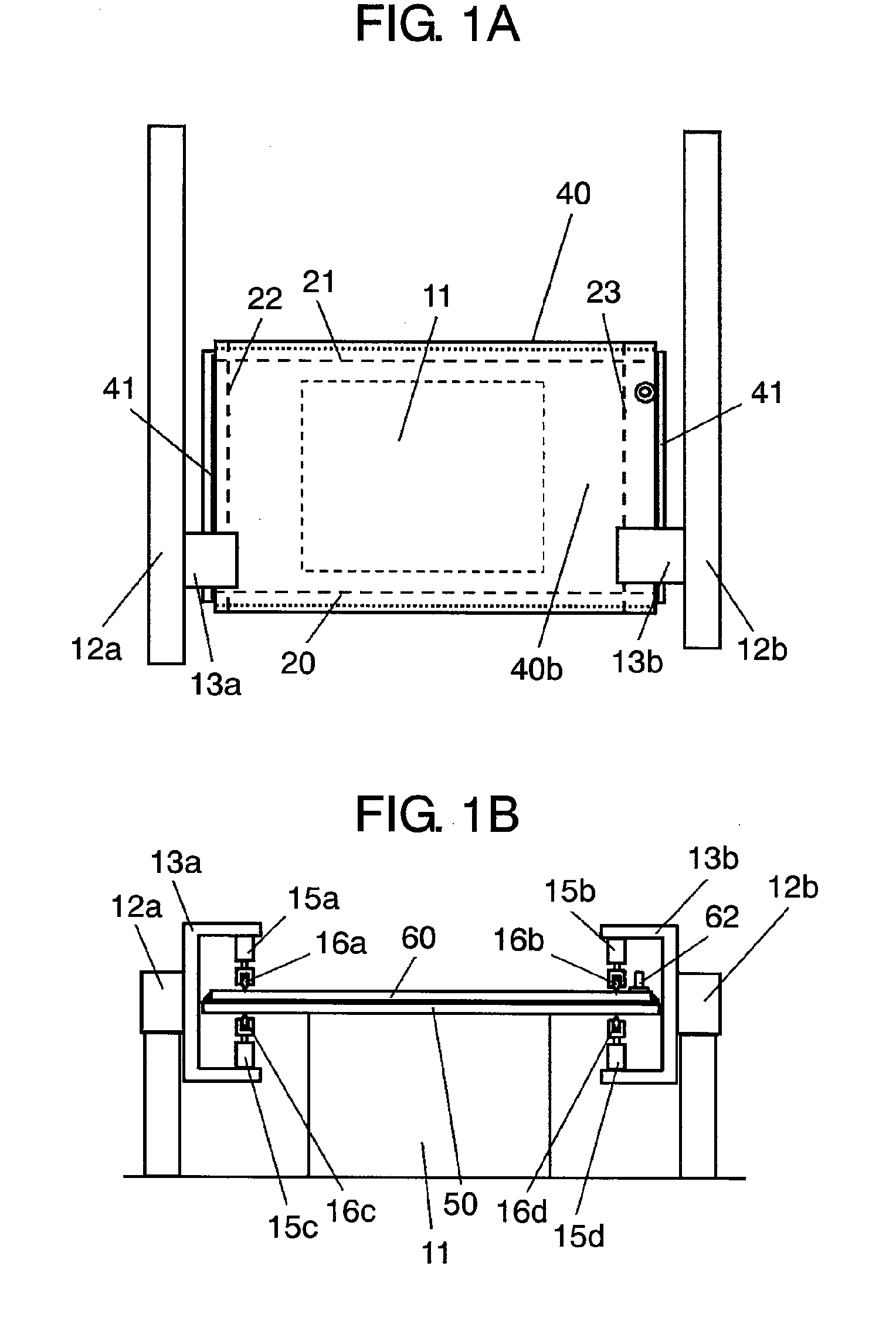

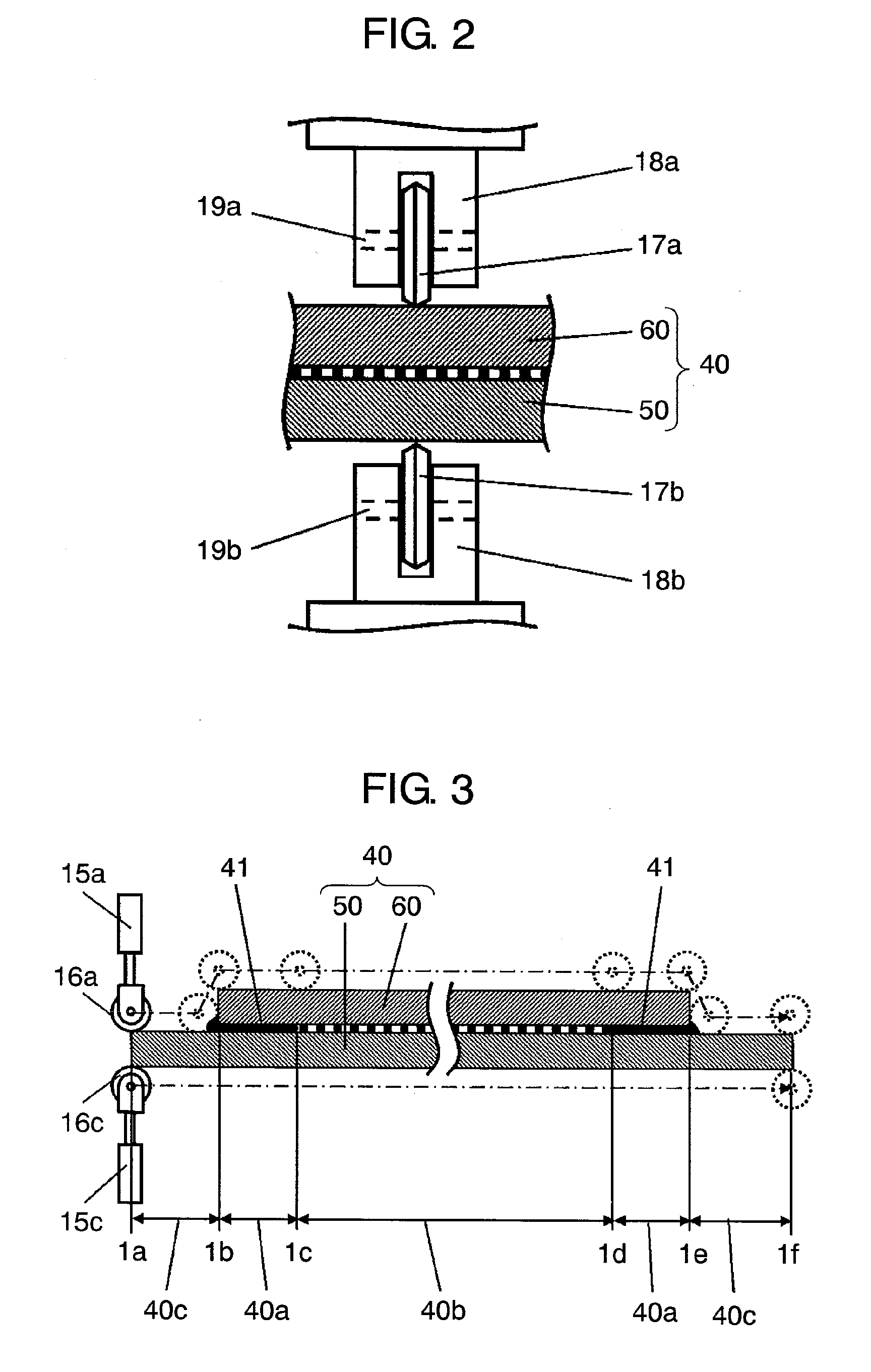

Glass cutting apparatus, glass-substrate disassembling apparatus, glass-substrate disassembling system, glass cutting method, and glass-substrate disassembling method

InactiveUS20100288101A1Simple methodInexpensive apparatusConveyorsGlass recyclingEngineeringGlass sheet

A glass cutting apparatus (101) includes a pair of cutters (13a, 13b) installed oppositely to each other in such a way as to sandwich, therebetween, a glass plate with surfaces of the glass plate thereof being along a vertical direction; a first pressing unit (14a) which presses one of the cutters to one of the surfaces of the glass plate in a horizontal direction with a pressing force P; a second pressing unit (14b) which is placed oppositely to the first pressing unit and presses the other one of the cutters to the other surface of the glass plate in the horizontal direction with the pressing force P; and a moving unit (20) which moves the pair of cutters pressing the glass plate with the pressing force P.

Owner:PANASONIC CORP

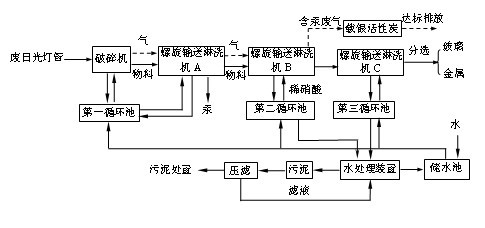

Mobile waste lamp tube safety recycling processing method and device thereof

InactiveCN102693890ASolve recycling difficultiesAvoid breakingGlass recyclingSolid waste disposalActivated carbonProduct gas

The invention discloses a mobile waste lamp tube safety recycling processing method. Main processes of the method are as follows: a waste lamp tube goes into a sealed material barrel from a feed inlet and is broken, broken glass is collected in the material barrel, dust generated in a breaking process is removed through a two-stage filtering device, mercury-containing gas is adsorbed through sulfur containing activated carbon and is discharged safely. The invention also discloses a mobile waste lamp tube safety recycling processing device used for realizing the above method. The recycling processing device of the invention is small and flexible and can be flexibly moved to each community, institution, school, and office building to carry out onsite recycling, a problem of difficult tube recycling is solved, transportation cost is reduced at the same time, and dangers of breaking and mercury emission of the tube in a transportation process are avoided.

Owner:BEIJING JINYU MANGROVE ENVIRONMENTAL PROTECTION TECH

Method for at least partially deconstructing a flat display screen

ActiveUS20140170923A1Avoid attenuationSolid waste disposalElectroluminescent light sourcesEngineering

Owner:VEOLIA PROPRETE

Display apparatus

InactiveUS20020127363A1Easy to operateSimple processLayered productsSolid cathode detailsEngineeringUltimate tensile strength

An effortless peeling operation is provided with maintaining the adhesion area required between a display panel and a chassis, which allows a disassembling operation for recycling and a parts replacement operation to be simplified. A plasma display apparatus includes a plurality of double-faced adhesive tapes 50 interposed between and adhering to the back surface of a display panel 1 and a chassis 3 for attaching the chassis 3 to the display panel 1. The double-faced adhesive tape 50 used has an adhesive strength smaller than a peel force produced by strain in a width direction caused by tension in a longitudinal direction, and the tape 50 is pulled in the longitudinal direction for peeling.

Owner:PIONEER DISPLAY PROD CORP

Method for recovery of rare earths from fluorescent lamps

InactiveUS7976798B2Reduce overall mass and volumeReduce disposalRare earth metal compoundsLuminescent compositionsAluminatePhosphate

Method for recovery of rare earths from fluorescent lamps. The method comprises six steps. •The individual process steps are: Mechanical separation of coarse components. •Separation of the halophosphate. •Extraction in acids of easily soluble rare-earth fluorescent substances (mainly Y, Eu-oxide) •Extraction in acids of rare-earth fluorescent substances which dissolve with difficulty (for example rare-earth phosphates) •Breakdown of the remaining components which contain rare earths (for example rare-earth-aluminates) •Final treatment.

Owner:OSRAM GMBH

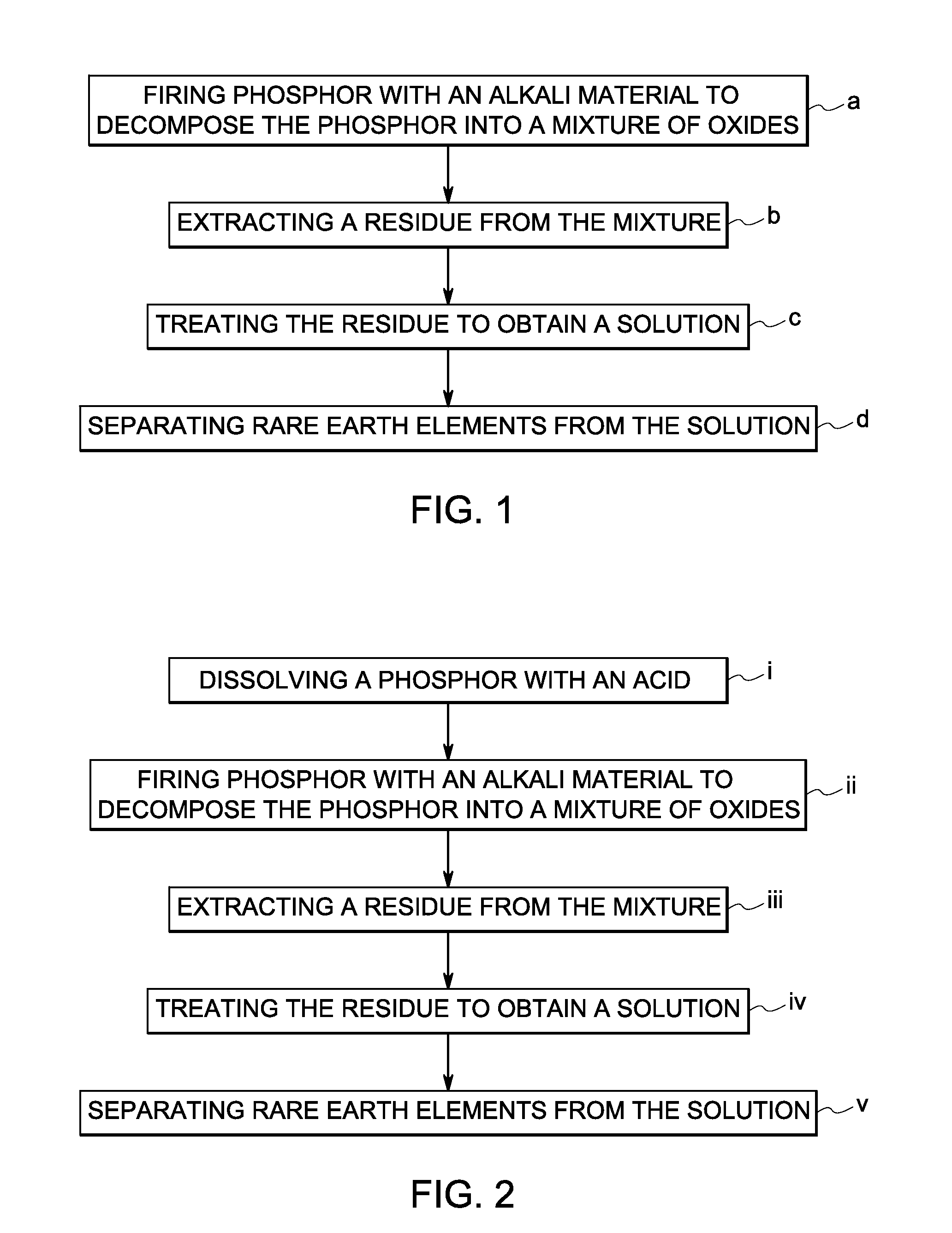

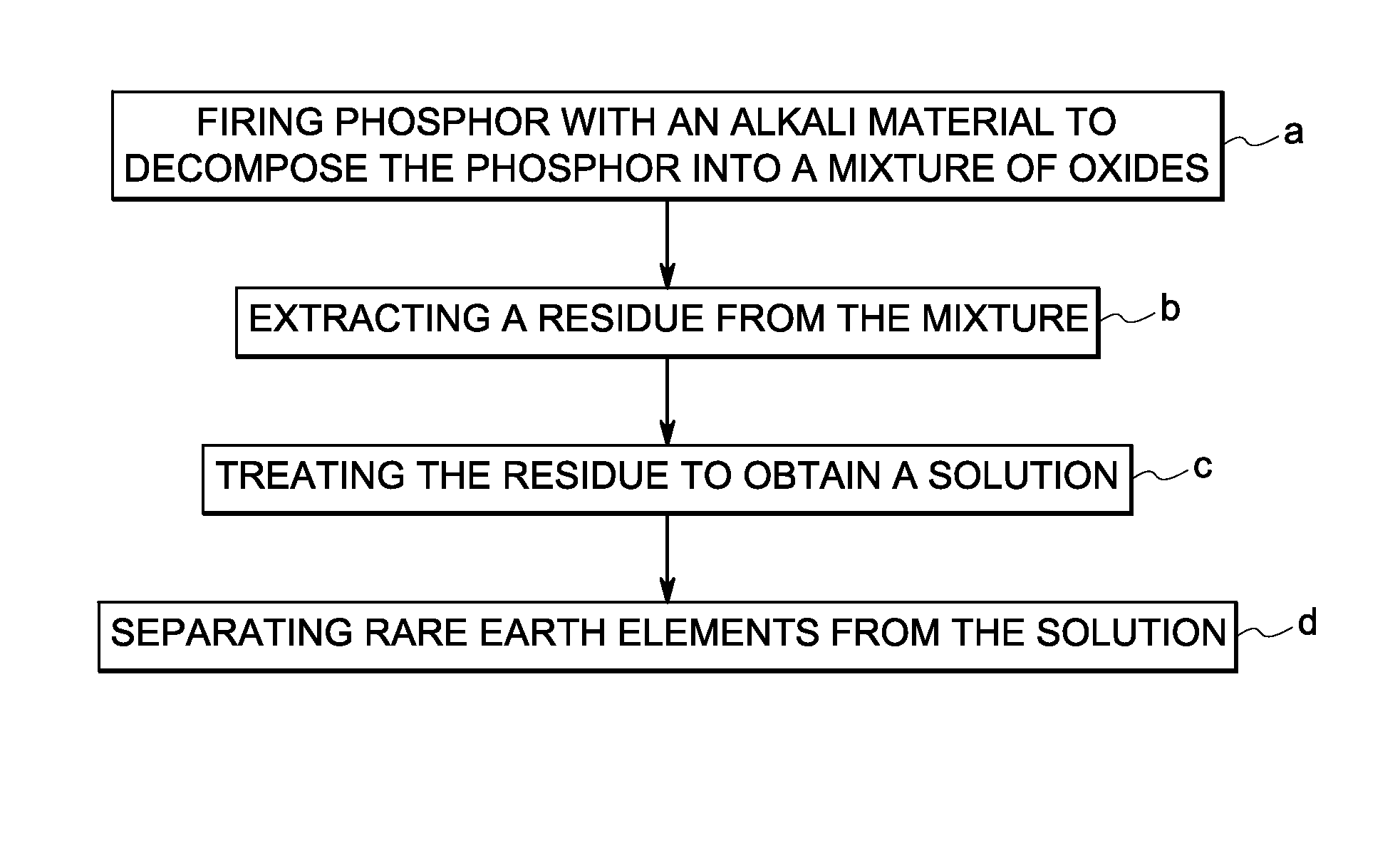

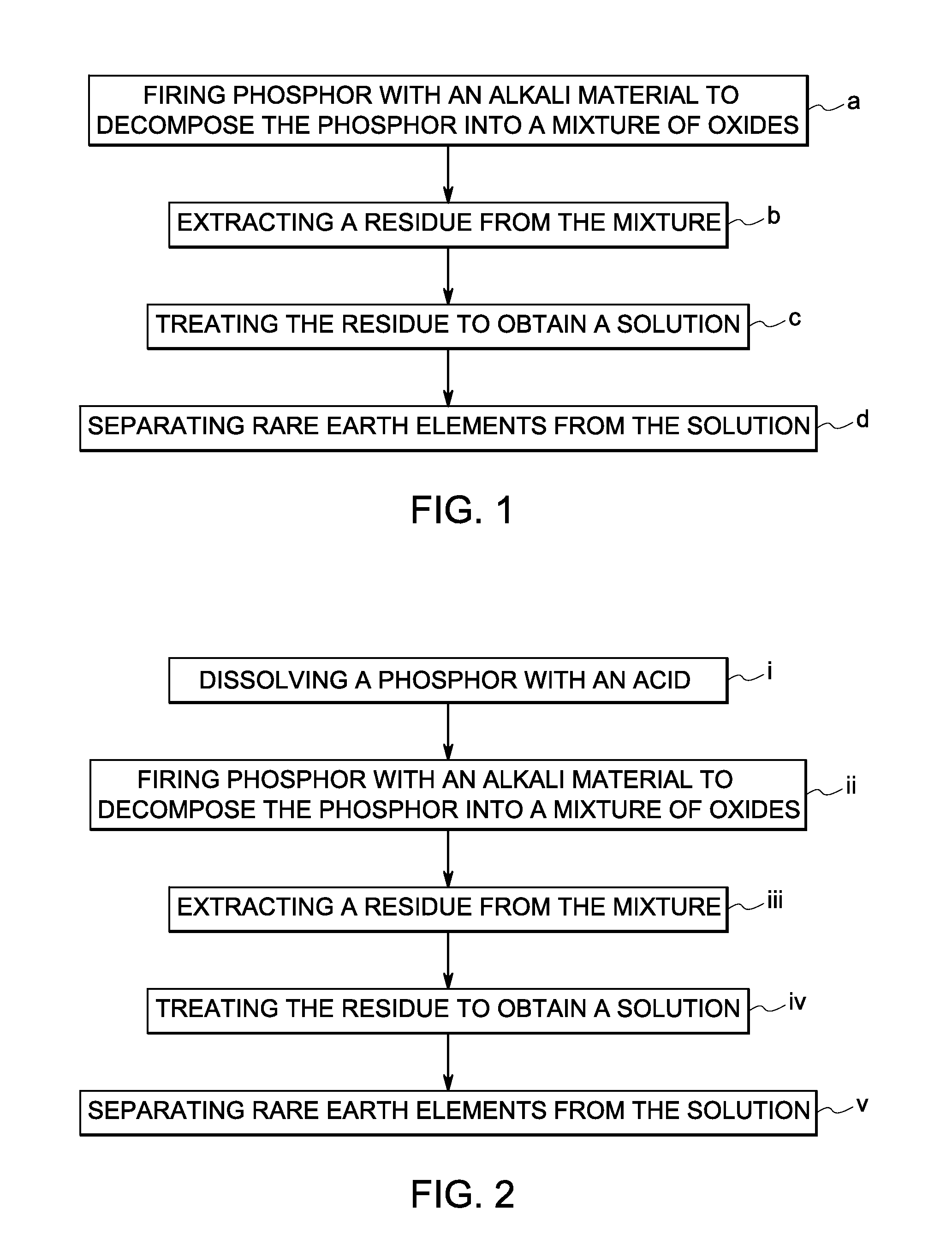

Rare earth recovery from fluorescent material and associated method

A method of recovering a rare earth constituent from a phosphor is presented. The method can include a number of steps (a) to (d). In step (a), the phosphor is fired with an alkali material under conditions sufficient to decompose the phosphor into a mixture of oxides. A residue containing rare earth oxides is extracted from the mixture in step (b). In step (c), the residue is treated to obtain a solution, which comprises rare earth constituents in salt form. Rare earth constituents are separated from the solution in step (d).

Owner:GENERAL ELECTRIC CO

Innocent treatment method for mercury-containing waste tube

ActiveCN102110560ALow costAvoid Volatile PollutionGlass recyclingElectronic waste recyclingActivated carbonSulfur

The invention relates to the improvement on an innocent treatment method for a mercury-containing waste tube. The method is characterized by comprising the following steps of: crushing the waste tube in water; performing at least three processes of washing, namely water washing, dilute nitric acid washing and water washing on the crushed tube in turn; separating and removing mercury on tube fragments; separating tube head metal from glass fragments through magnetic separation, wherein the whole treatment process is linked up in an airtight way and is performed in a sealed state; performing air draft guidance on gas emitted from the water surface under negative pressure; performing water and dilute nitric acid drip washing; and filtering and separating the mercury by using silver-carried activated carbon or sulfur-carried activated carbon, and discharging. The method has a simple and practical process, is energy saving, is suitable for automatic operation, and has the advantages of lowcost, simple and practicable process and the like; and by the method, the mercury is not released to the outside, and automatic treatment can be realized.

Owner:YIXING SUNAN SOLID WASTE TREATMENT

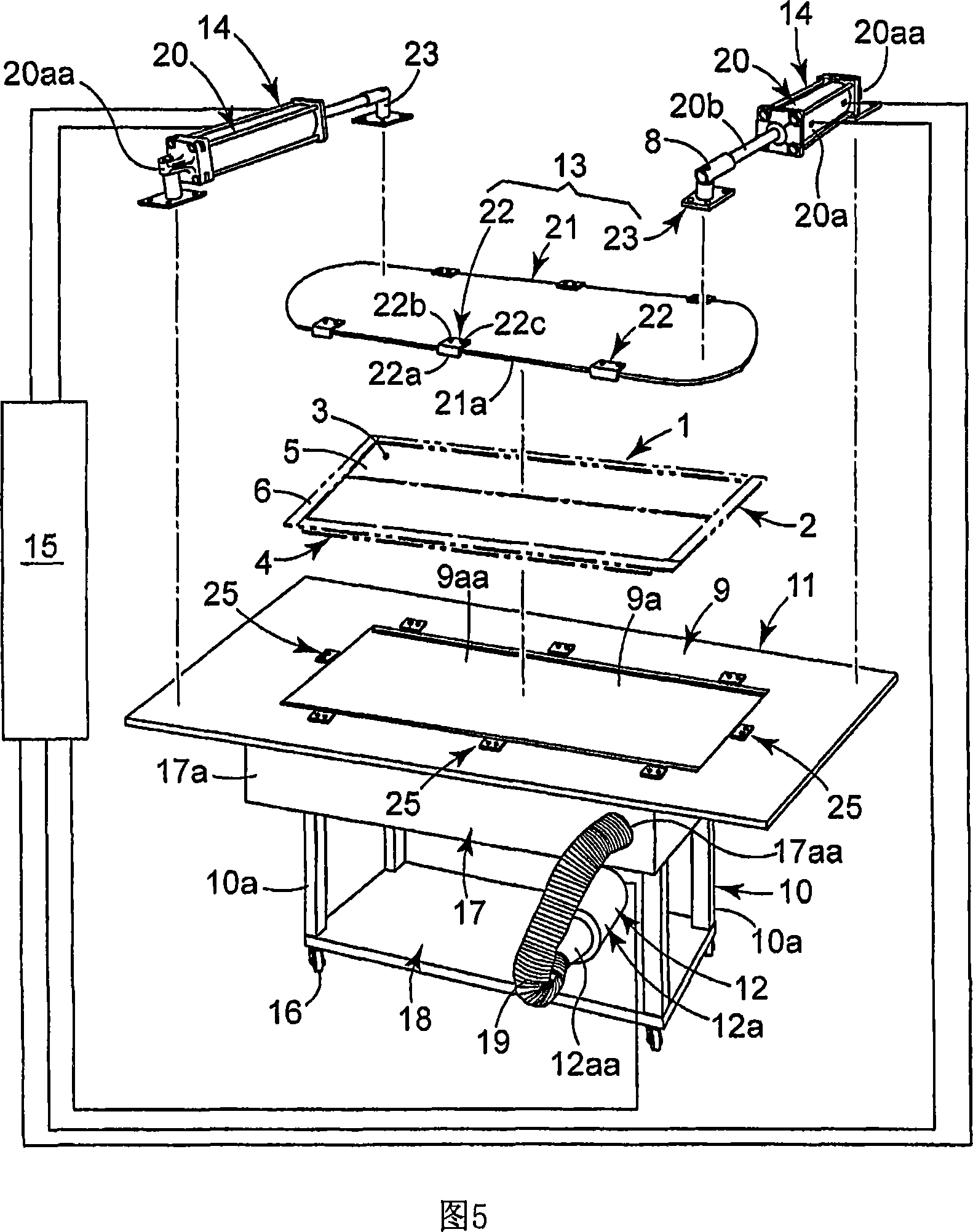

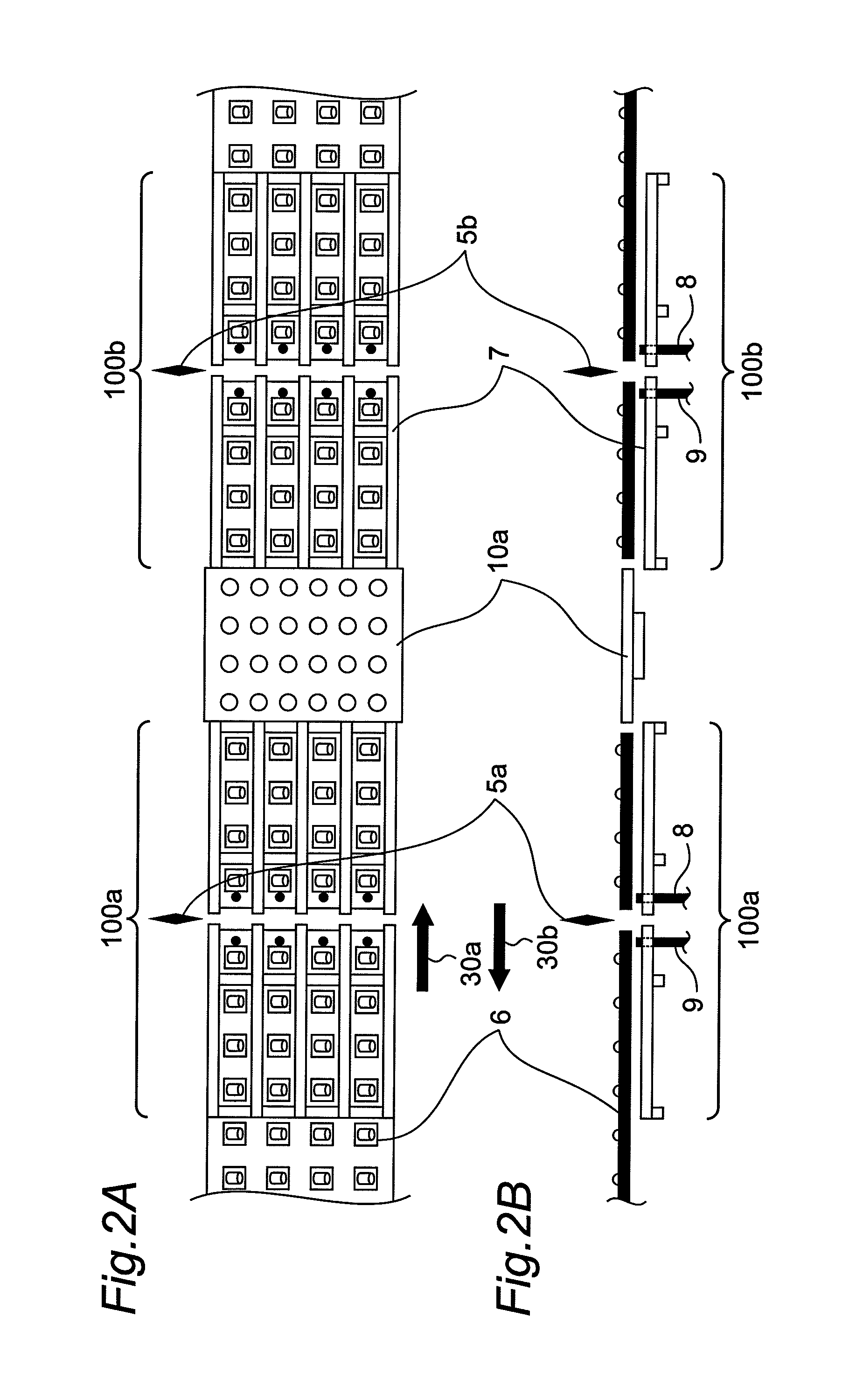

Separation apparatus for pdp panel assembly and method for controlling the same

InactiveCN101233595AConvenience Recycling OnlyEasy to recycleGas-filled discharge tubesGlass recyclingEngineeringActuator

The present invention generally relates to a separation device for separating a PDP glass panel and an aluminum frame from a PDP (Plasma Display Panel) assembly (ie, an assembly composed of a PDP glass panel and an aluminum frame) and a control method thereof. The separation device includes: a workbench including an upper plate and a support portion supporting the upper plate (which supports the plasma display panel assembly), the PDP glass panel can be connected to the aluminum frame through a thermally conductive pad or an adhesive tape medium, and can be connected through the upper plate. At least a portion of the plate restricts the horizontal movement of the aluminum frame; a heater unit is provided on one side of the workbench for heating the plasma display panel assembly on the workbench; an actuator is mounted to the upper plate of the workbench At least two parts, a separation force can be applied to the PDP glass panel of the plasma display panel assembly through a shock absorbing member medium; and a control panel, which is electrically connected to the heater unit and the actuator.

Owner:3M INNOVATIVE PROPERTIES CO

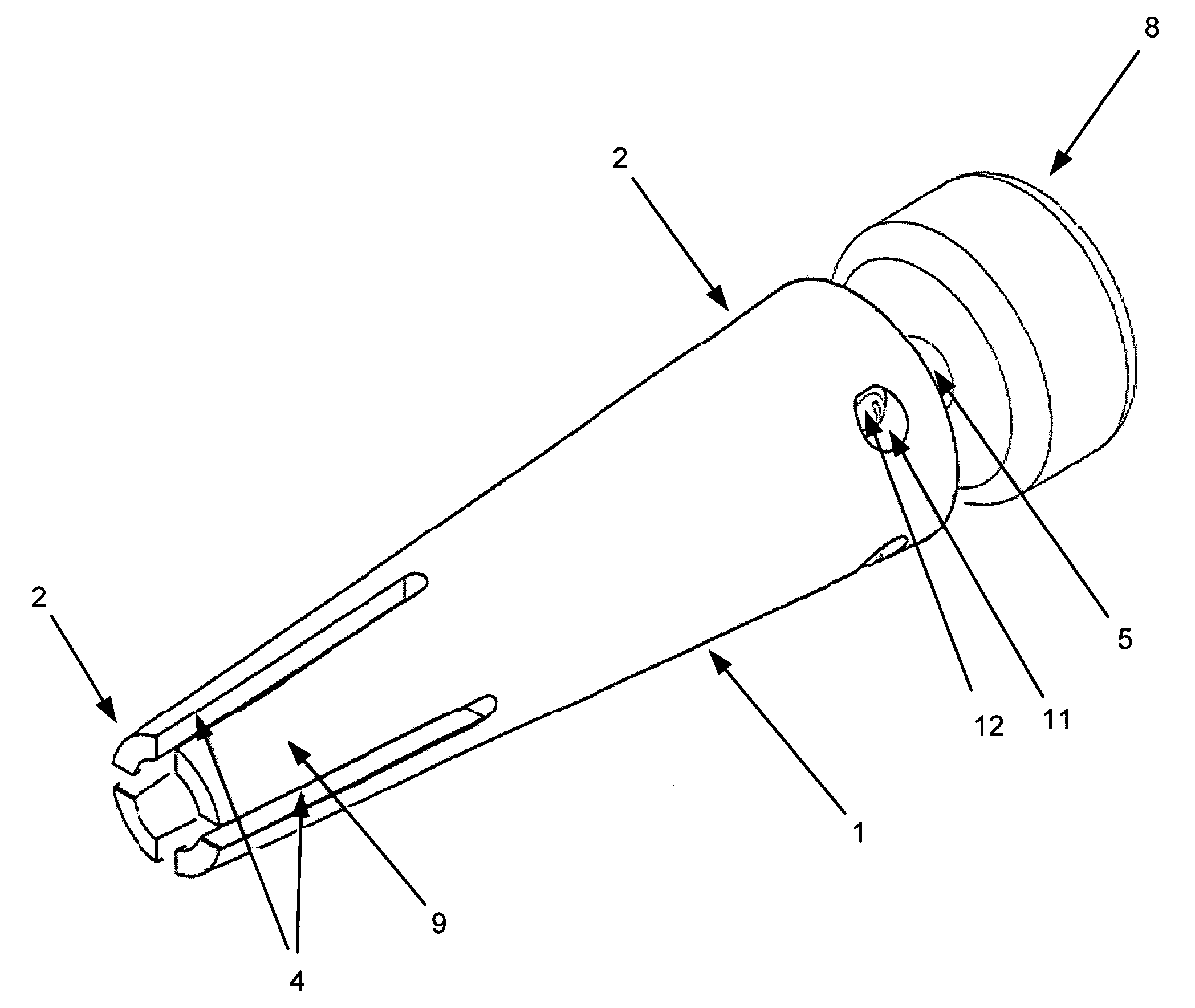

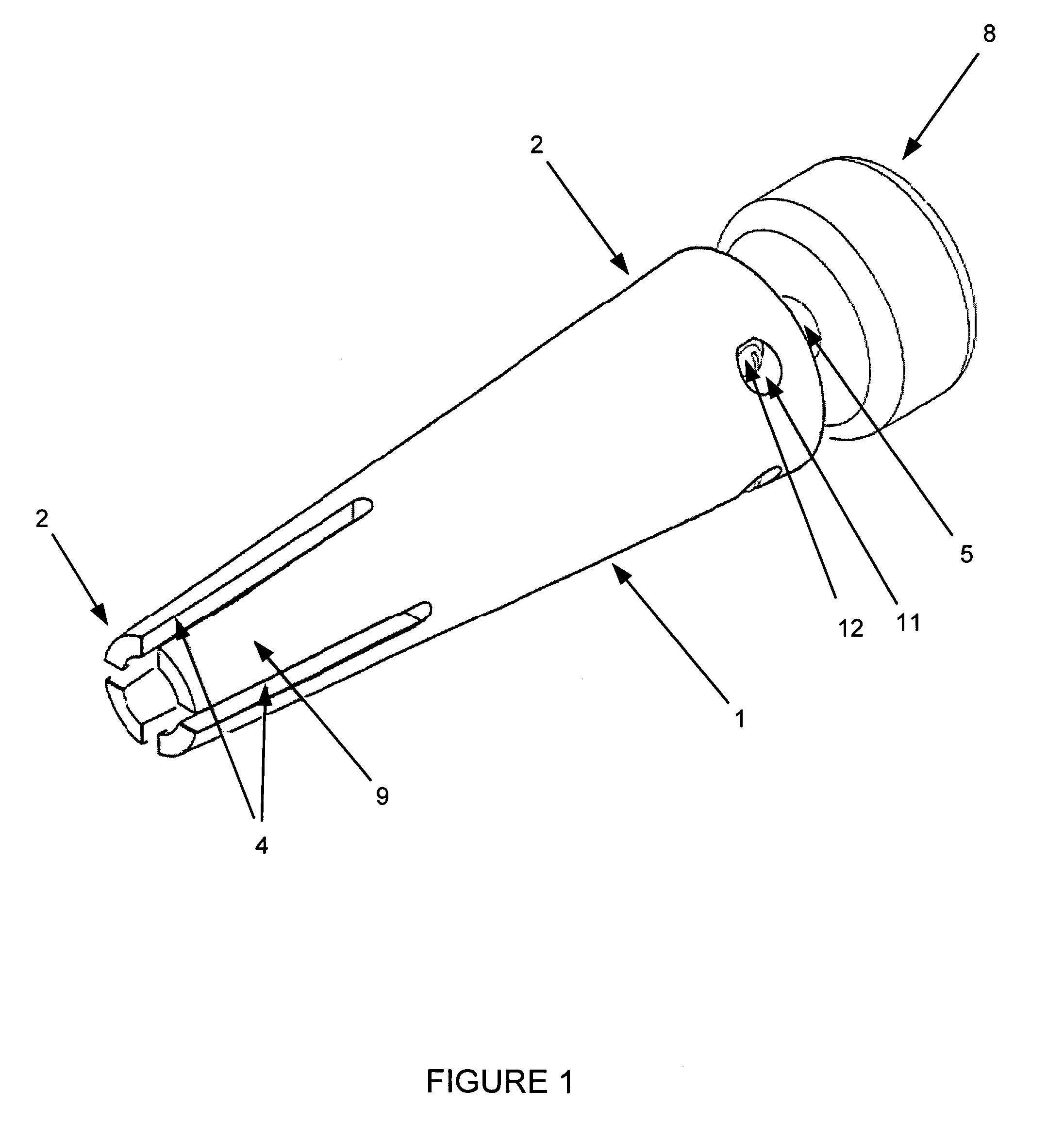

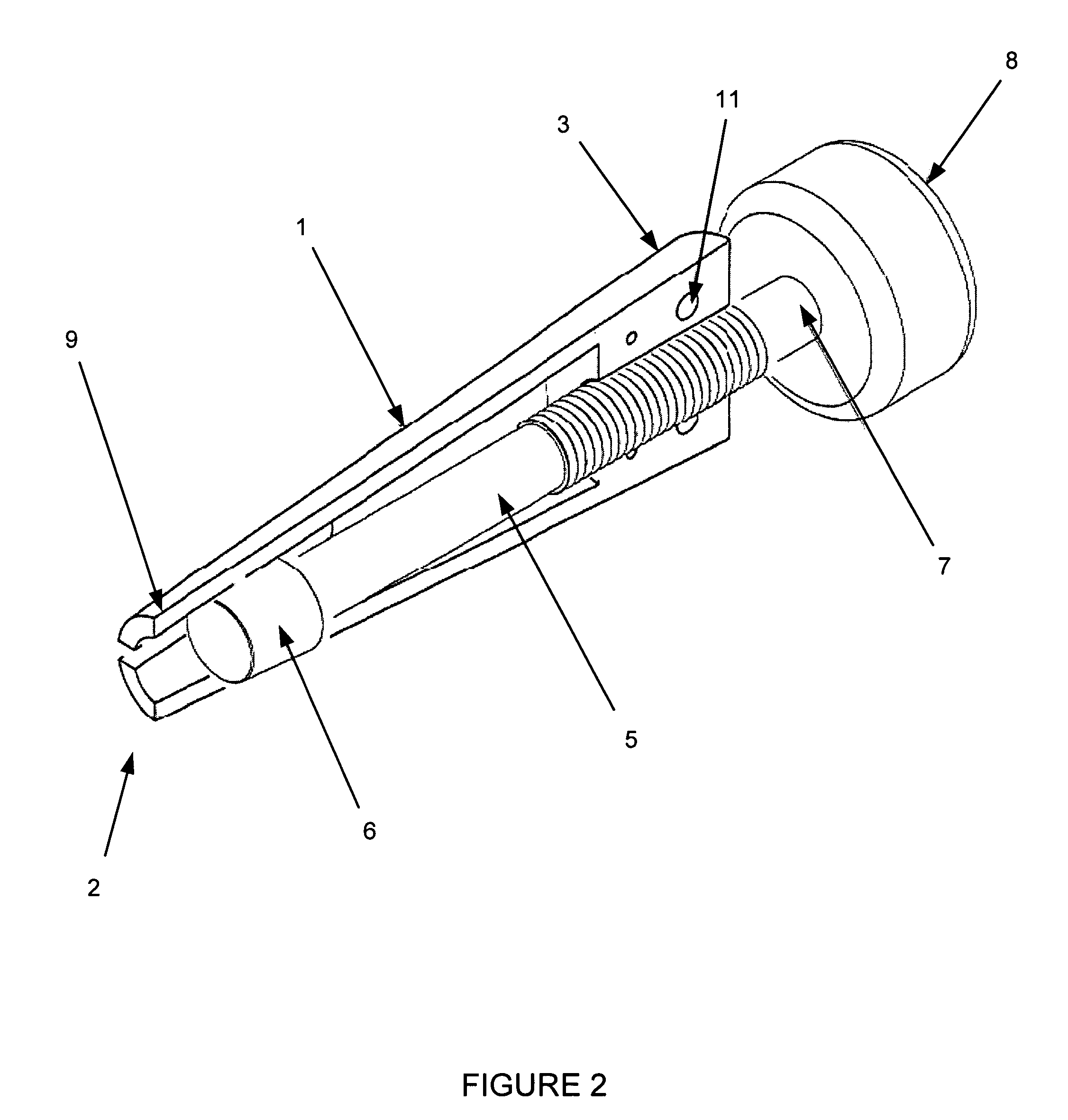

Light bulb base extractor

A device for the extraction of the base of a broken light bulb from the socket without further breakage of any remaining glass or deformation of the bulb base member or the socket. A hollow elongated conical cylinder with a series of slots or slits at the apex of the cone is inserted into a light bulb base. A threaded cylindrical rod is screwed into threads inside the conical cylinder, causing the apex of the cone to expand and engage the inside of the light bulb base. When securely engaged, the entire device is turned to cause the light bulb base to be come disengaged from the light socket.

Owner:SCEARCE THOMAS R

Method of manufacturing plasma display device

InactiveUS20060005922A1Electrical apparatus contructional detailsSurface layering apparatusAdhesivePlasma display

Here disclosed is a method of manufacturing a plasma display device in which a panel is easily separated from a holding plate if the separation is required. In the method of manufacturing a plasma display device having a panel, in which a pair of substrates having transparency at least on the front side is oppositely disposed so that discharge space and discharge cells are formed between the substrates, and a metallic holding plate that supports the panel via a thermal conductive member, the present invention employs a thermal conductive member made of a pull-to-remove adhesive. The adhesive is applied to the panel or the holding plate, and the panel and the holding plate are put together. After that, the adhesive is cured by application of pressure and heat.

Owner:PANASONIC CORP

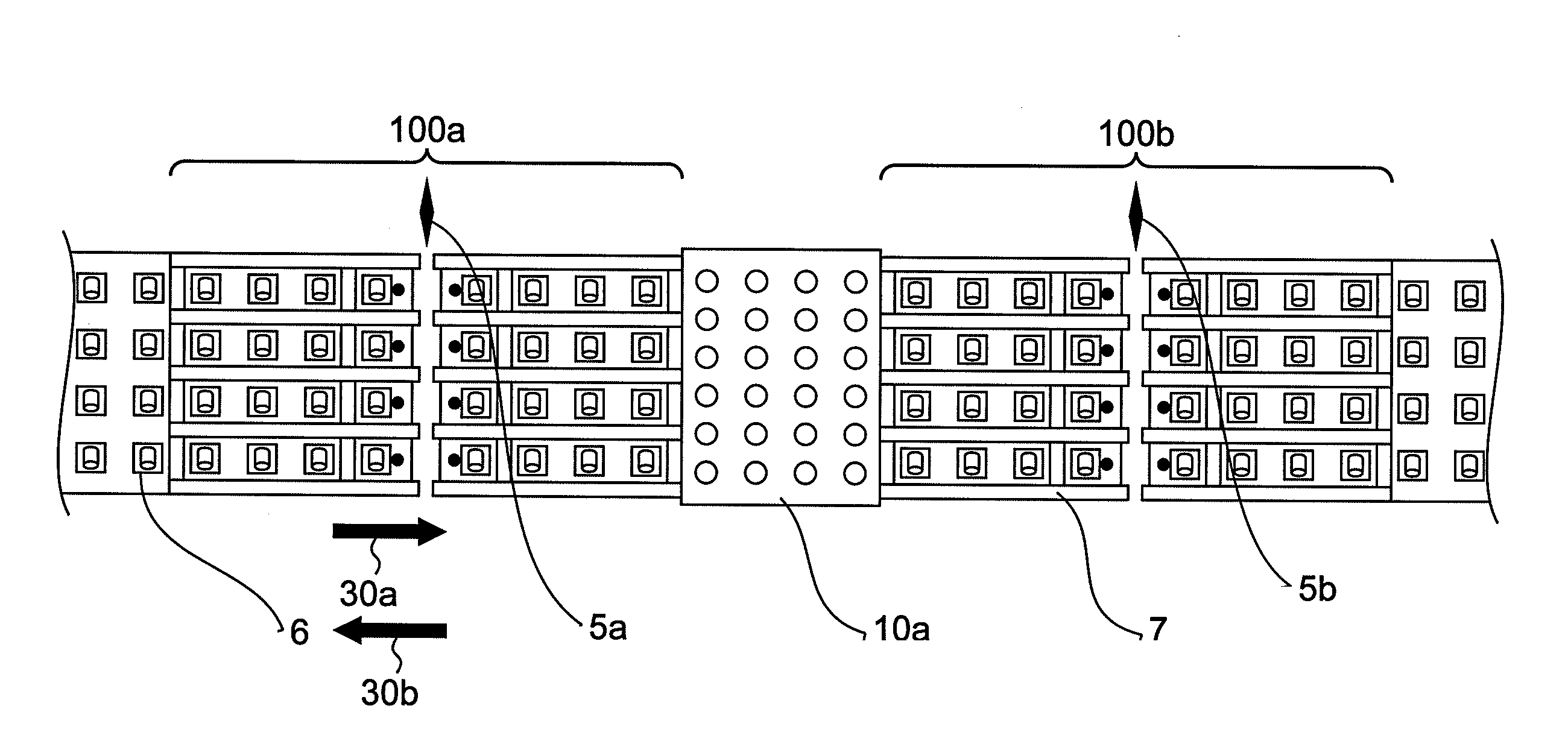

Glass cutting apparatus, glass-substrate disassembling apparatus, glass-substrate disassembling system, glass cutting method, and glass-substrate disassembling method

InactiveUS8621738B2Simple methodInexpensiveContainer making machineryConveyorsGlass sheetVertical orientation

A glass cutting apparatus (101) includes a pair of cutters (13a, 13b) installed oppositely to each other in such a way as to sandwich, therebetween, a glass plate with surfaces of the glass plate thereof being along a vertical direction; a first pressing unit (14a) which presses one of the cutters to one of the surfaces of the glass plate in a horizontal direction with a pressing force P; a second pressing unit (14b) which is placed oppositely to the first pressing unit and presses the other one of the cutters to the other surface of the glass plate in the horizontal direction with the pressing force P; and a moving unit (20) which moves the pair of cutters pressing the glass plate with the pressing force P.

Owner:PANASONIC CORP

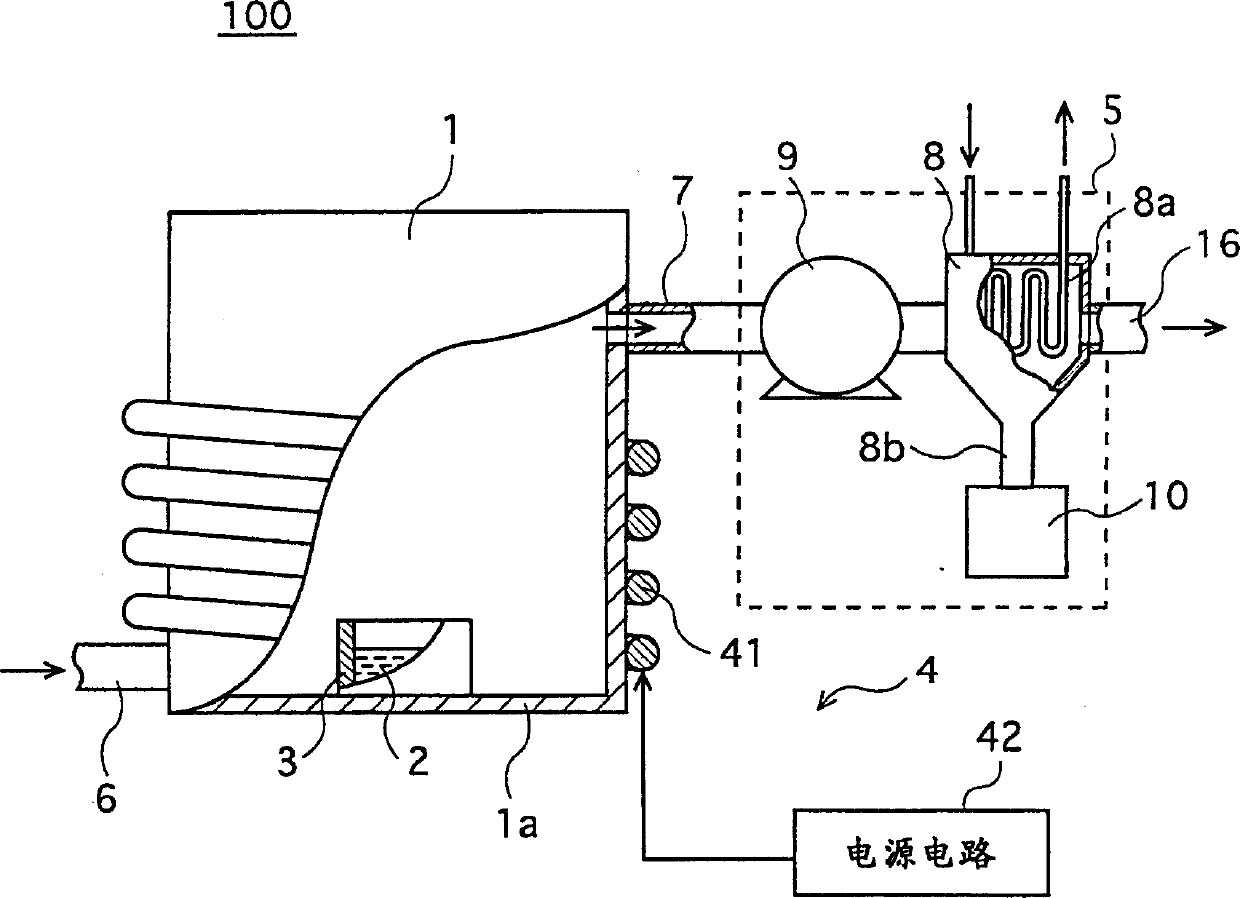

Method and device for separating and recovering mercury

InactiveCN1379430APrevents deterioration of characteristics such as brightnessFacilitate vaporization separationSolid waste disposalDistillation separationRecovery methodPhosphor

The invention relates to a method and device for separating and recovering mercury. By cutting off both ends of a lamp tube of a waste fluorescent lamp and peeling off a phosphor film formed on the inner surface of the lamp tube, phosphor powder containing mercury is recovered. Adding an organic reducing agent to the recovered phosphor powder and heating it to perform dry heating reduction treatment to vaporize and separate mercury from the phosphor powder. This vaporized mercury is condensed and recovered.

Owner:PANASONIC CORP

Rare earth recovery from fluorescent material and associated method

A method of recovering a rare earth constituent from a phosphor is presented. The method can include a number of steps (a) to (d). In step (a), the phosphor is fired with an alkali material under conditions sufficient to decompose the phosphor into a mixture of oxides. A residue containing rare earth oxides is extracted from the mixture in step (b). In step (c), the residue is treated to obtain a solution, which comprises rare earth constituents in salt form. Rare earth constituents are separated from the solution in step (d).

Owner:GENERAL ELECTRIC CO

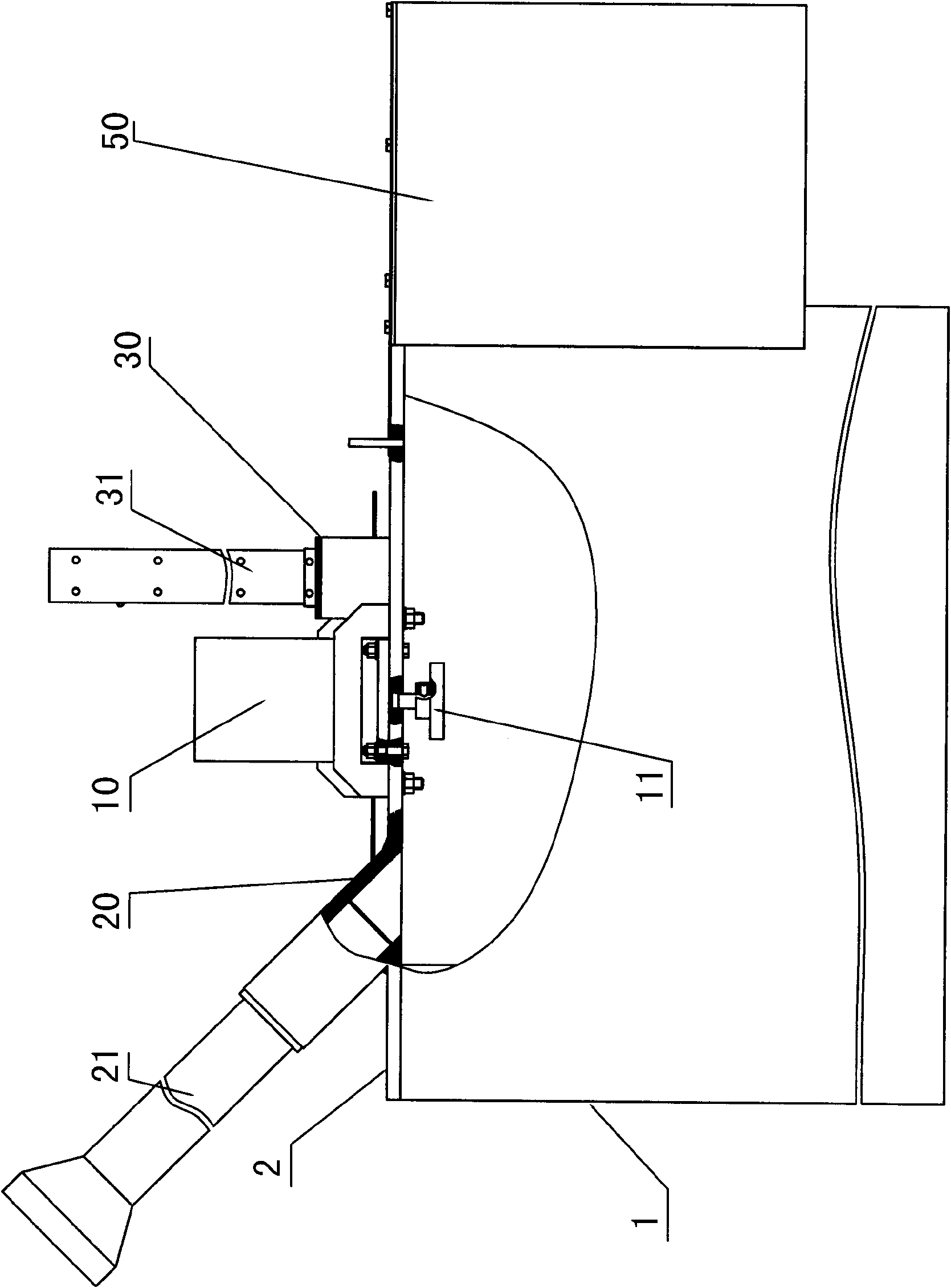

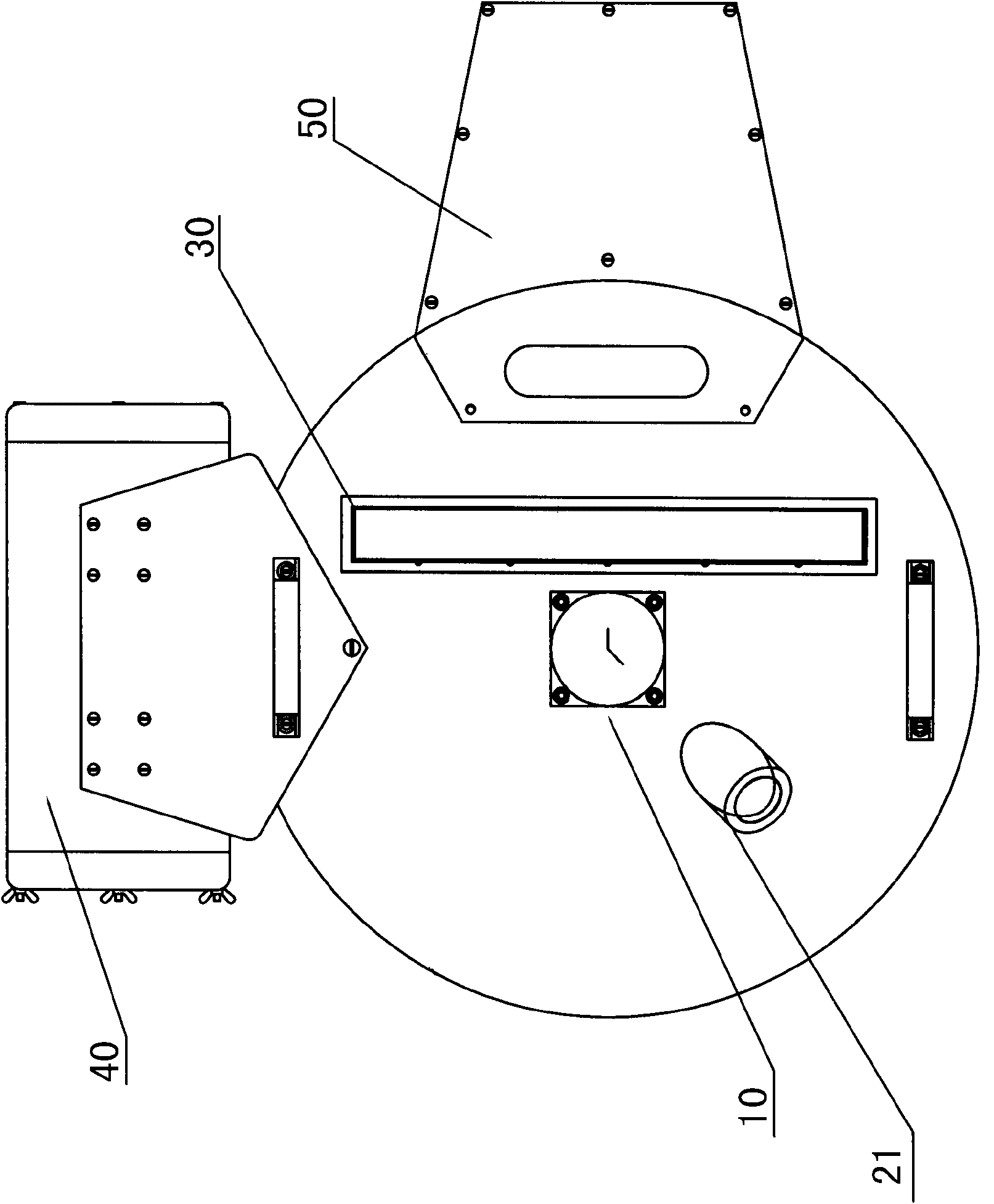

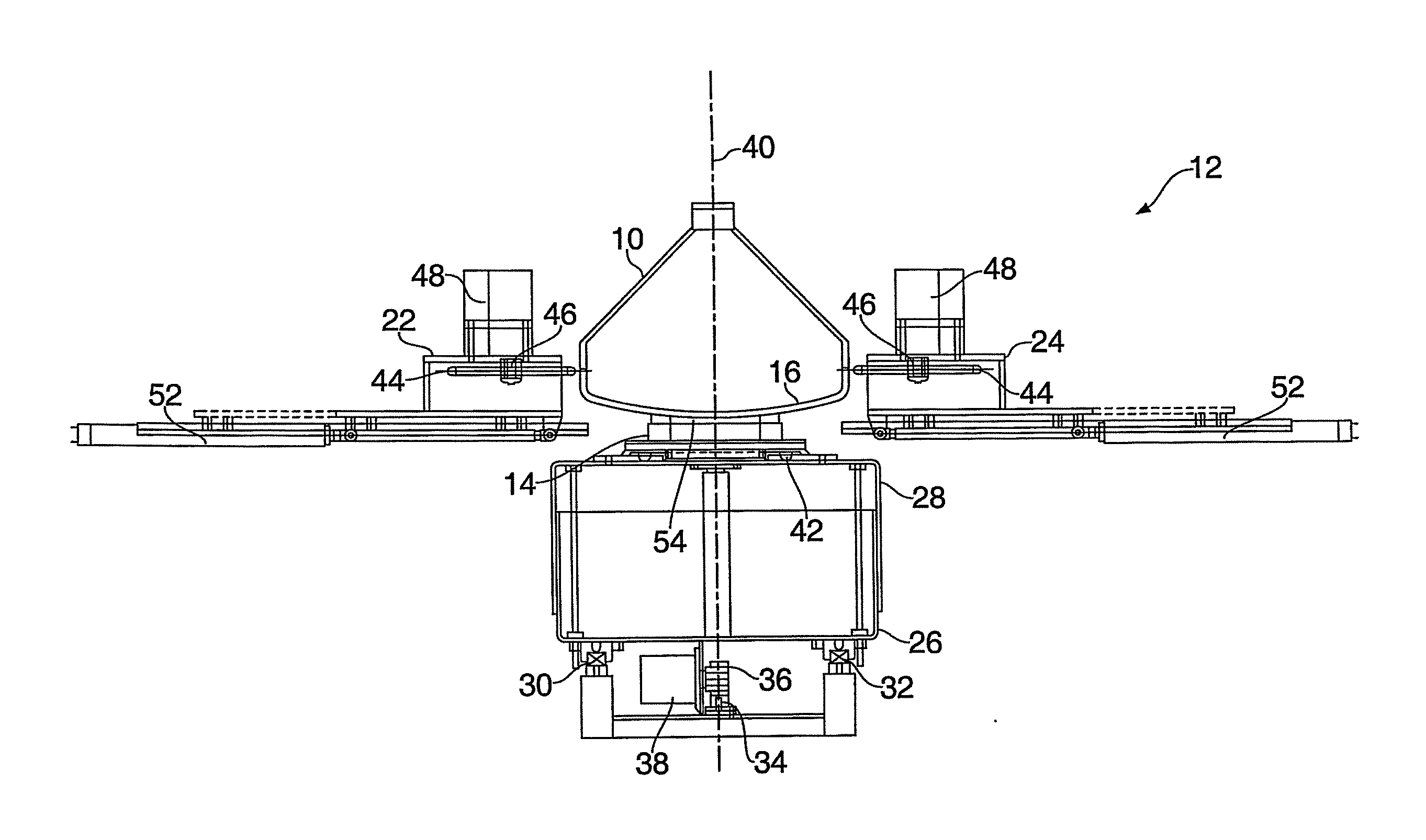

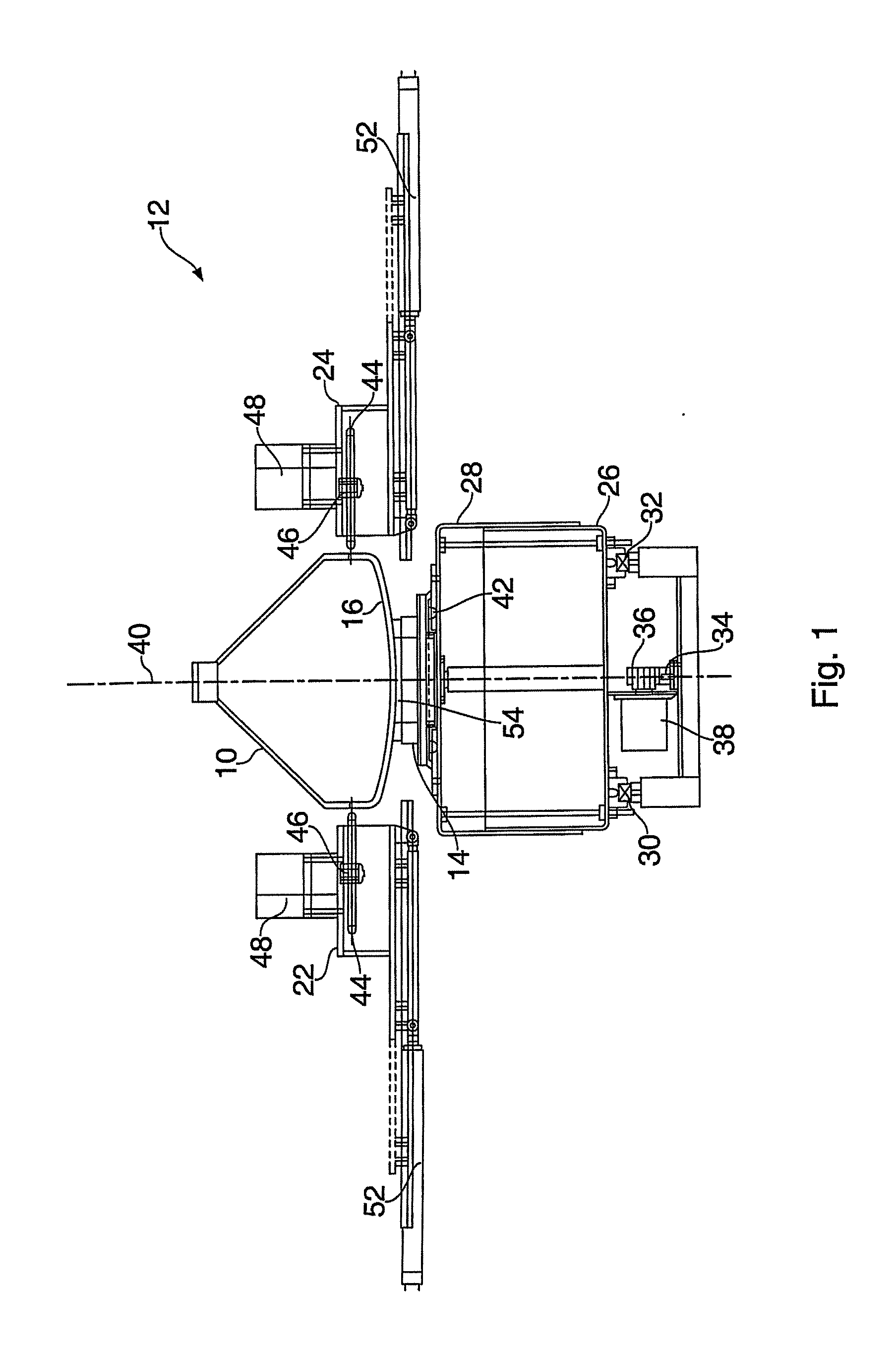

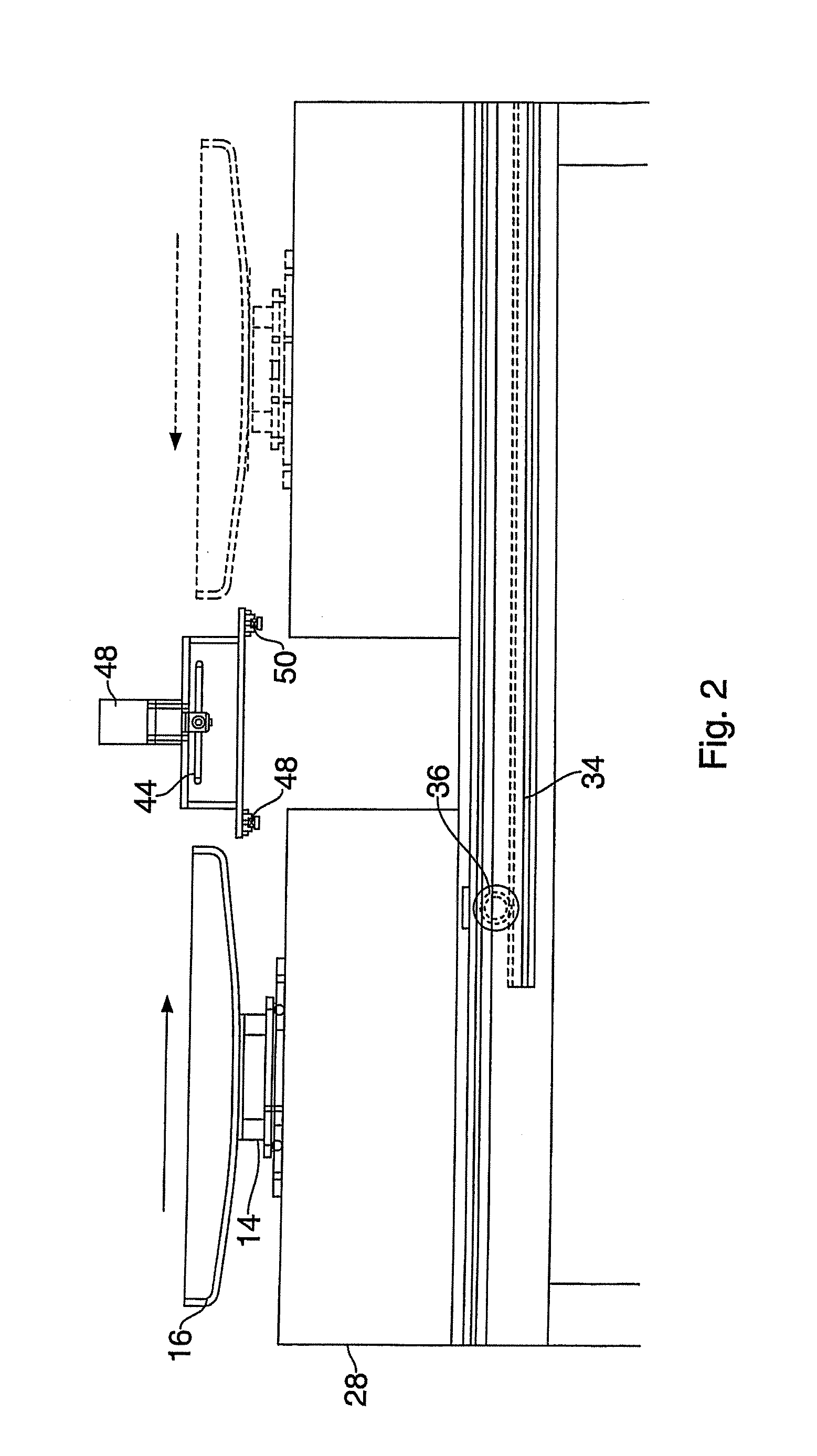

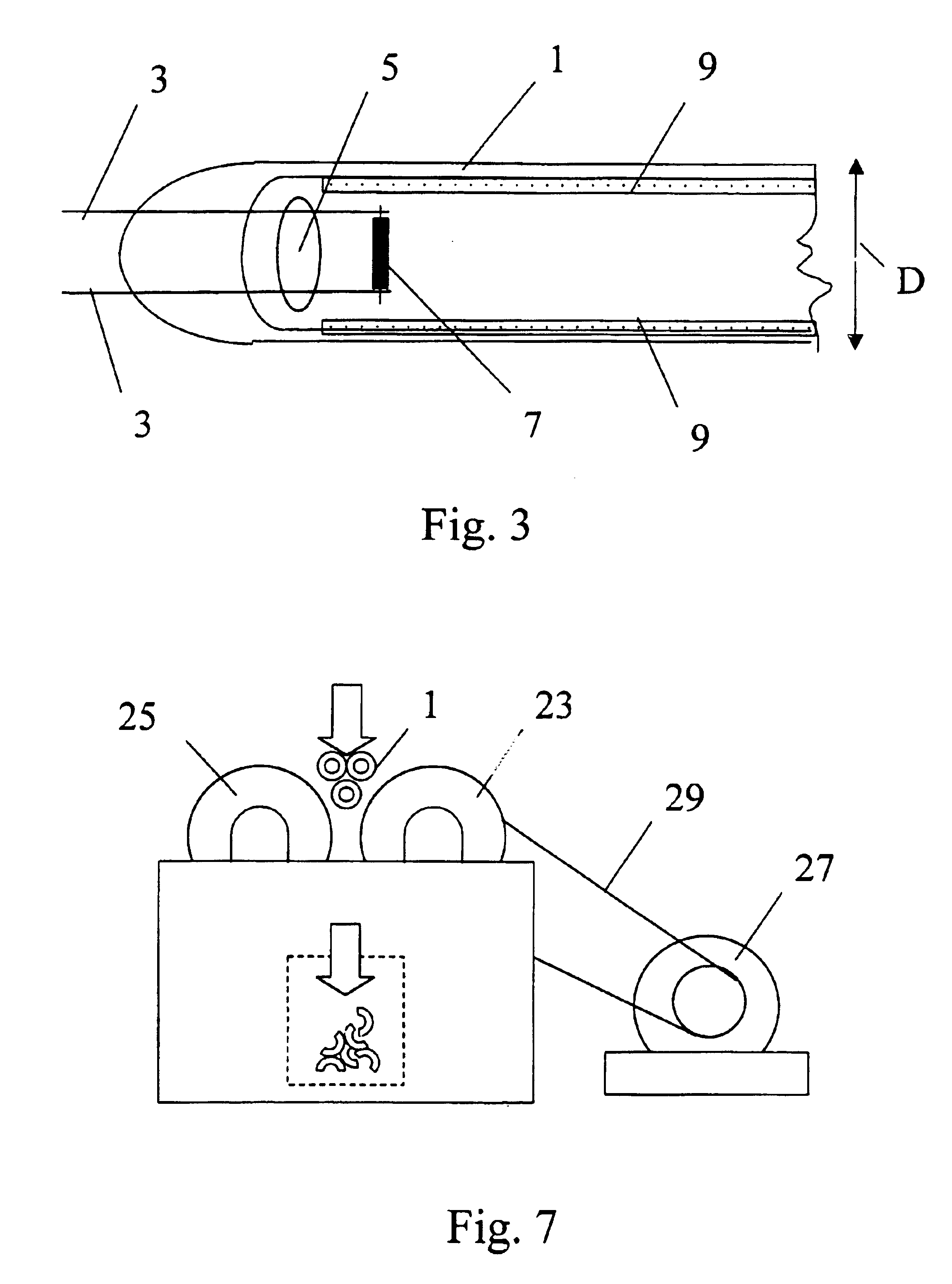

Apparatus and Method for Cutting a Cathode Ray Tube

An apparatus 12 for cutting a cathode ray tube 10 comprises a support means 14 for supporting the screen 16 of the cathode ray tube 10, first and second sensors 18,20 (shown in FIGS. 3 and 4) for determining the external dimensions of the screen 16, first and second spaced diamond cutting means 22,24, and displacement means 26 for moving the support means 14 relative to the diamond cutting means 22,24.

Owner:CRT HEAVEN

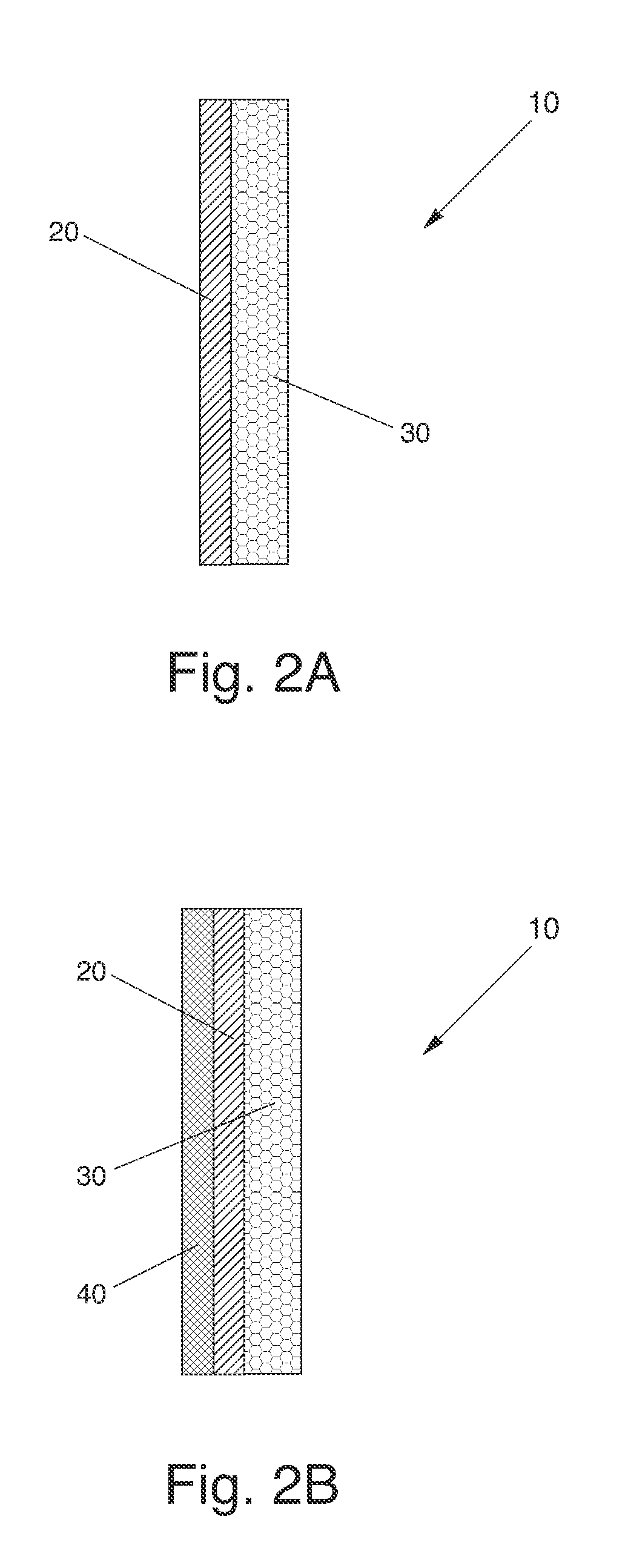

Control of mercury leaching

InactiveUS20090200941A1Safe disposalLow-pressure discharge lampsSolid cathode detailsManganeseCopper

A safely disposable, mercury-containing lamp includes a component comprising an effective amount of materials to allow the lamp to safely be disposed of, the materials forming a tri-partite component comprising a divalent manganese compound, a copper containing compound and a compound selected from the group consisting of metallic silver and silver containing compounds.

Owner:OSRAM SYLVANIA INC

Method for recovering fluorescent material from faulty glass bodies of discharge lamps

InactiveUS6869327B2Efficiently good resultEasy to separateDischarge tube luminescnet screensLamp detailsGlass particleCrusher

Owner:GENERAL ELECTRIC CO

Plasma display panel cutting method, plasma display panel recycling method and plasma display panel cutting apparatus

InactiveUS20090156081A1Efficient cuttingReduce facility costsTube/lamp screens manufactureAlternating current plasma display panelsEngineeringPlasma display

In a method of cutting a plasma display panel, a front glass substrate and a rear glass substrate are sealed so as to face each other. The front glass substrate and the rear glass substrate are sandwiched between pairs of rotating cutters, and the pairs of rotating cutters are pressed onto the front glass substrate and the rear glass substrate to be in contact therewith so that the rotating cutters are run thereon in order to cut the substrates.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com