Exhaust gas purifying device

An exhaust gas purification device and exhaust gas technology are applied in the direction of exhaust devices, noise reduction devices, exhaust treatment device diagnostic devices, etc., which can solve problems such as the cost of electrical wiring, the reduction of assembly workability, and the separation and movement of conduits. Achieve the effects of improving assembly efficiency, prolonging life, and facilitating maintenance operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

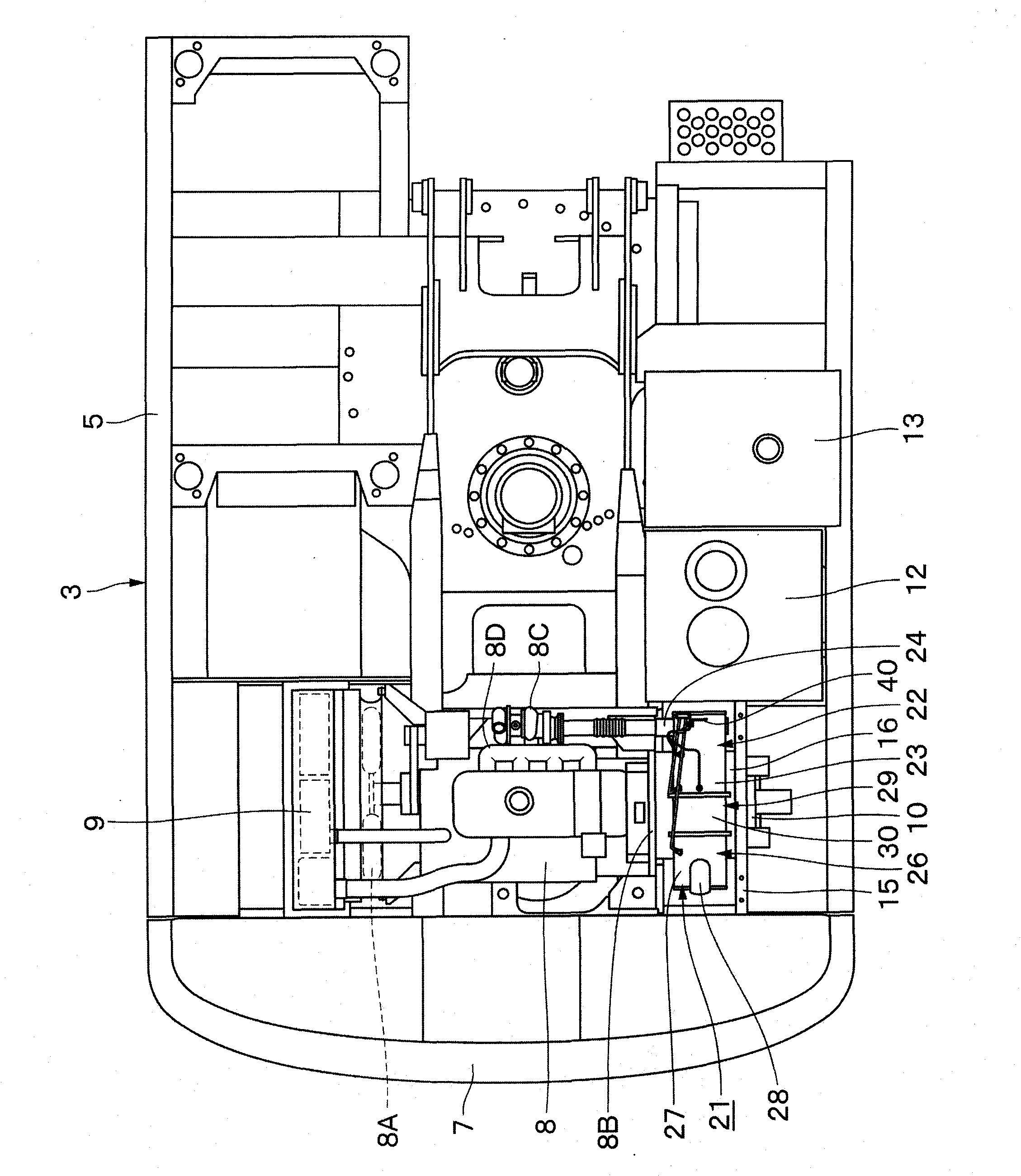

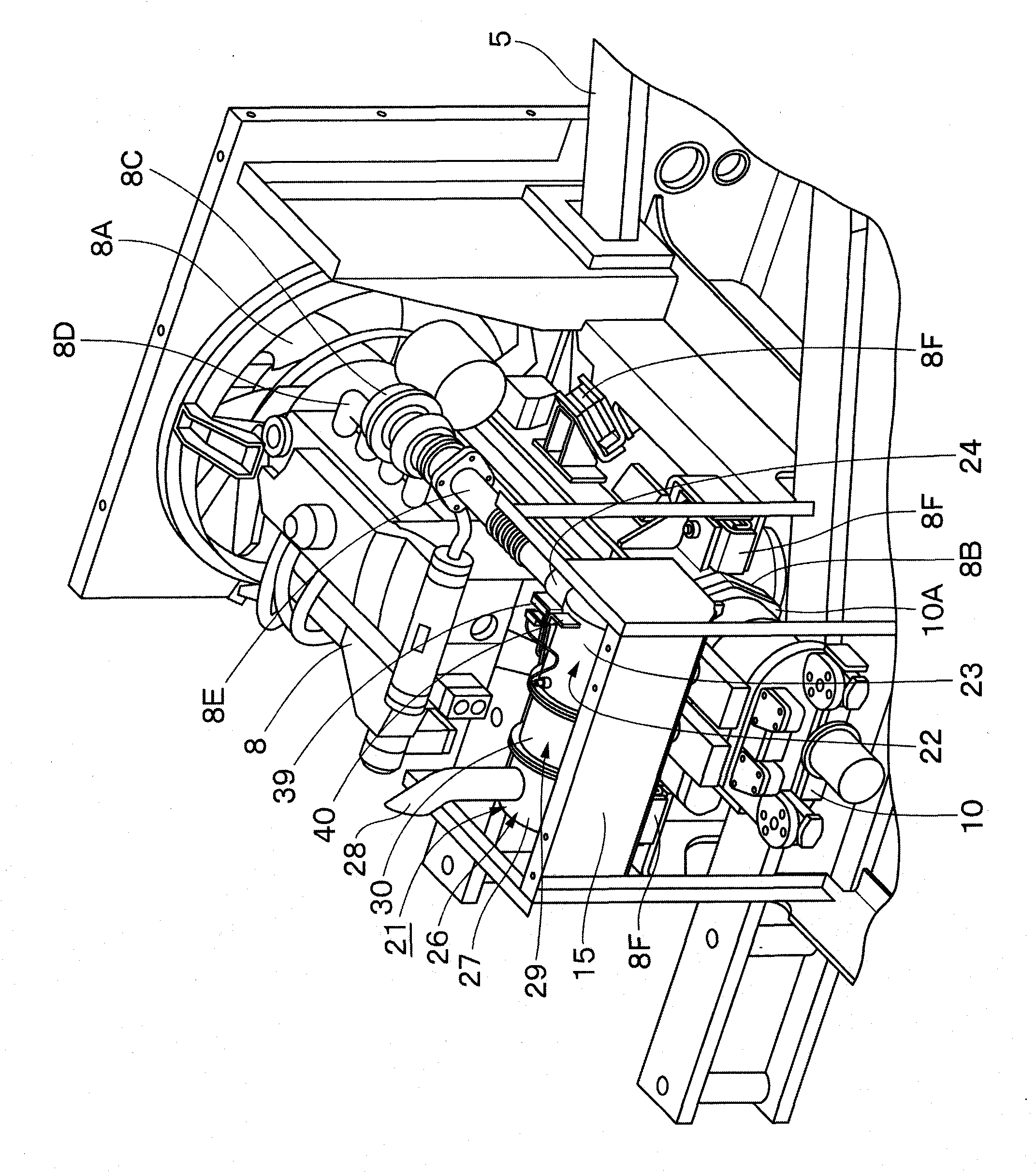

[0042] Hereinafter, a case in which the exhaust gas purification device according to the embodiment of the present invention is mounted on a hydraulic excavator will be described in detail with reference to the drawings.

[0043] first, Figure 1 to Figure 11 The first embodiment of the exhaust gas purification device of the present invention is shown.

[0044] figure 1 Among them, reference 1 is a crawler-type hydraulic excavator as a construction machine, and the hydraulic excavator 1 generally includes: a self-driving undercarriage body 2; rotatably mounted on the undercarriage body 2, and 2 together constitute the upper revolving body 3 of the vehicle body; and the working device 4 provided on the front side of the upper revolving body 3 and capable of pitching and digging operations such as earth and sand. In addition, the undercarriage 2 and the upper revolving structure 3 are specific examples of the vehicle body of the present invention.

[0045] Here, the upper rev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com