Bismuth-based glass, manufacturing method of bismuth-based glass, and sealing material

A bismuth-based glass and sealing material technology, applied in the manufacturing method of bismuth-based glass and sealing materials, and in the field of bismuth-based glass, capable of solving problems such as thermal degradation of active components or organic light-emitting layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0066] Based on examples, the present invention will be described in detail. It should be noted that the following examples are merely examples. The present invention is not limited by the following examples.

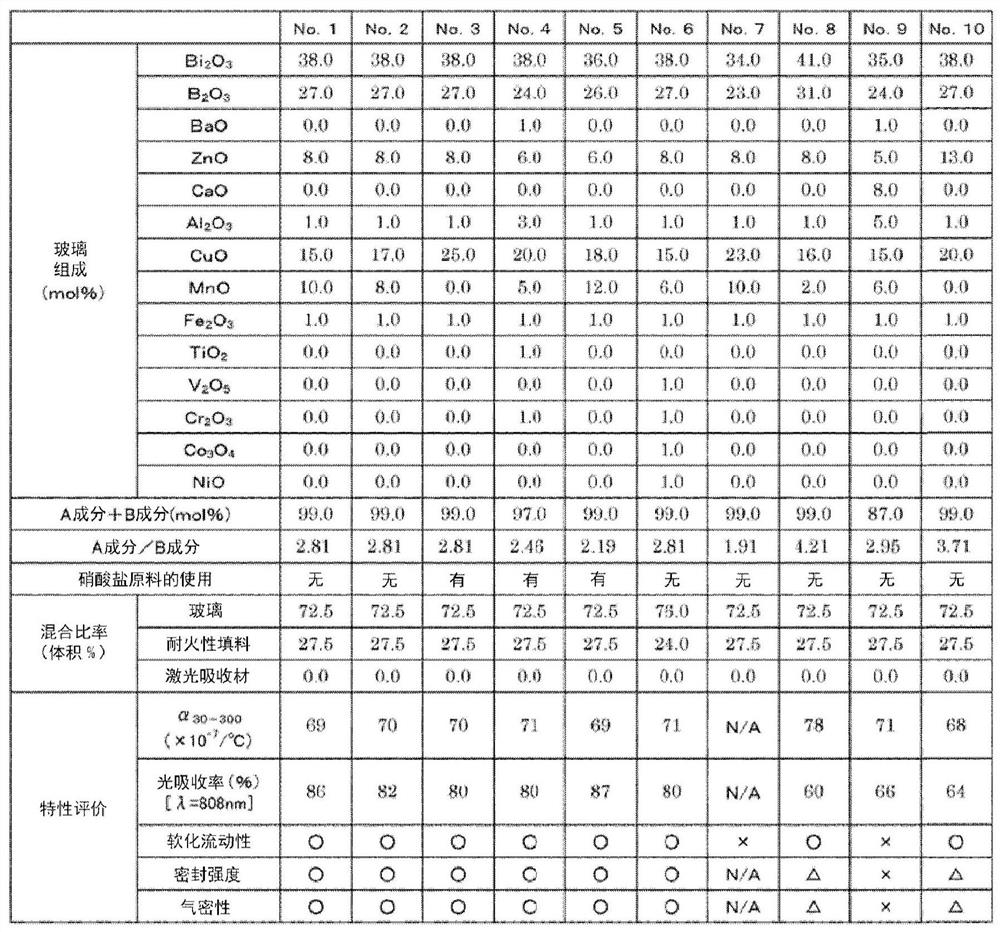

[0067] Tables 1 and 2 show examples (sample Nos. 1 to 6) and comparative examples (sample Nos. 7 to 10) of the present invention.

[0068] [Table 1]

[0069]

[0070] The glass powders described in the table were prepared as follows. First, glass batches containing various raw materials were prepared so as to have the glass compositions in the table, which were put into platinum crucibles and melted at 1000° C. for 1 hour. During melting, stirring was performed using a platinum rod to homogenize the molten glass. It should be noted that, for Sample Nos. 3 to 5, Bi was introduced from a nitrate raw material. 2 o 3 10% of the content. Next, part of the obtained molten glass was flowed between water-cooled twin rolls and formed into a film, and the remaining molt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com