Sterilizing method and sterilizing apparatus for retorted product

A sterilizing device and product technology, which is applied in food preservation, heating, food science, etc., can solve the problems of complex shaft sealing mechanism and restrictions on the configuration of distilled food production lines, so as to shorten the sterilization time, reduce vibration and noise, and reduce the installation space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

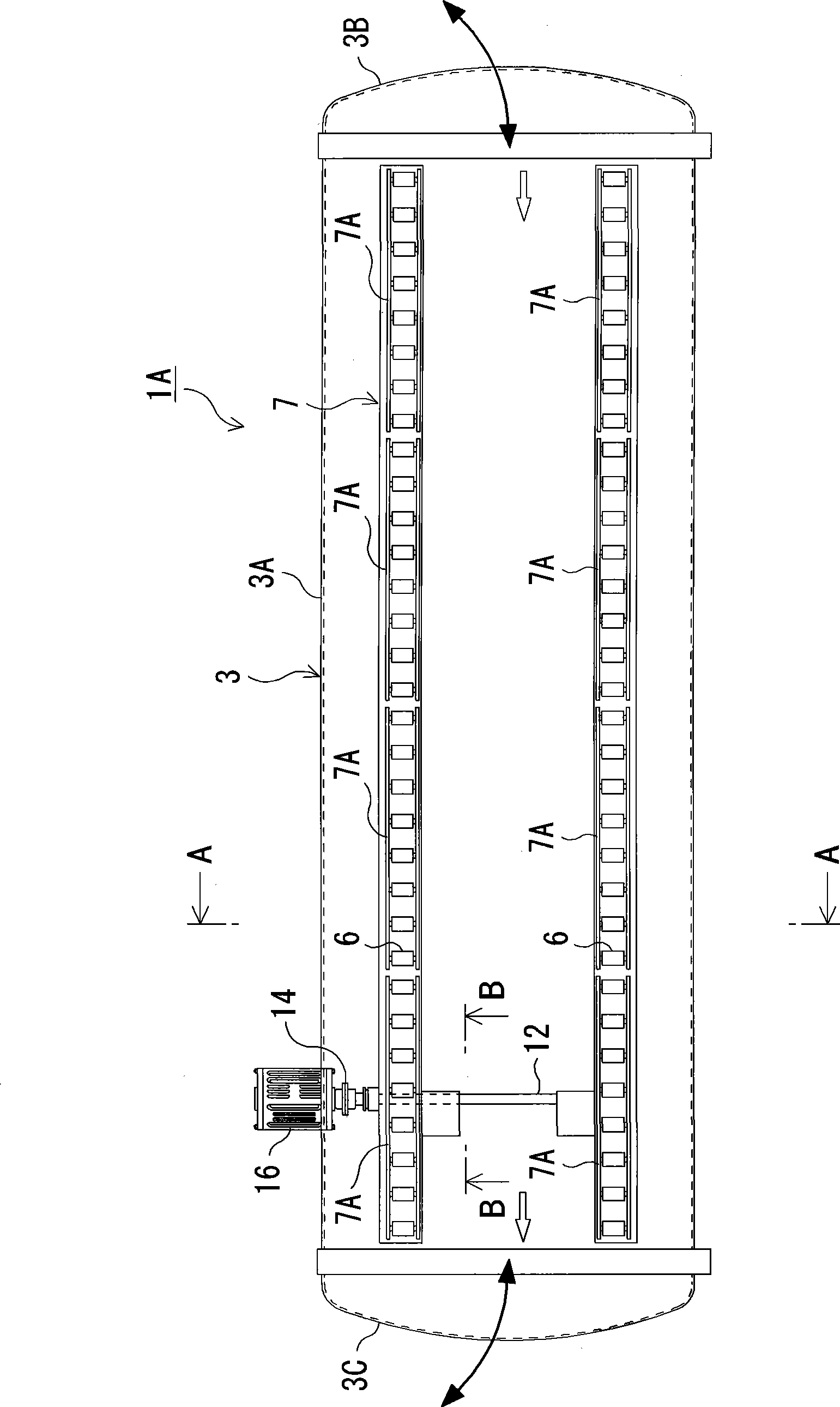

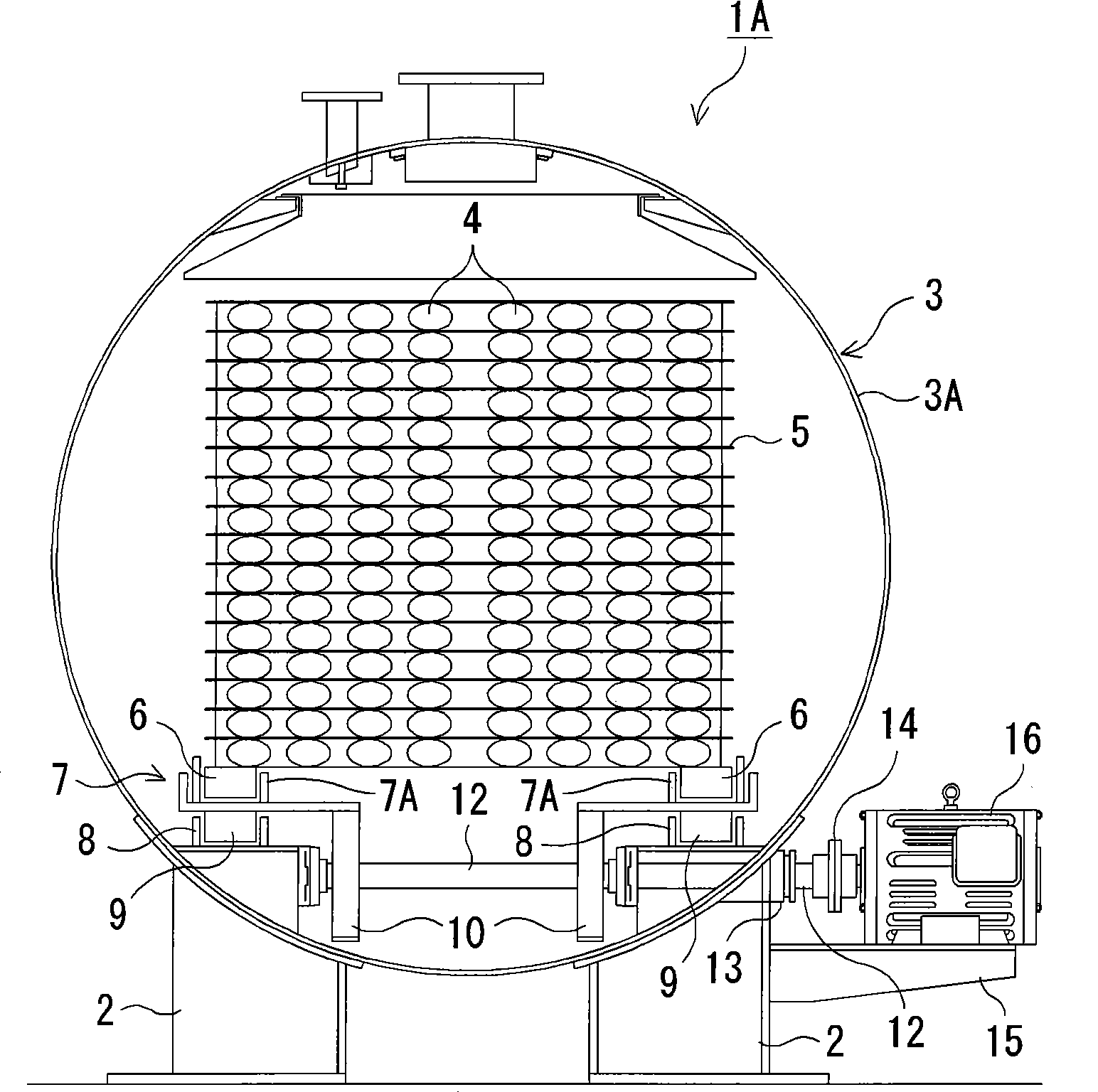

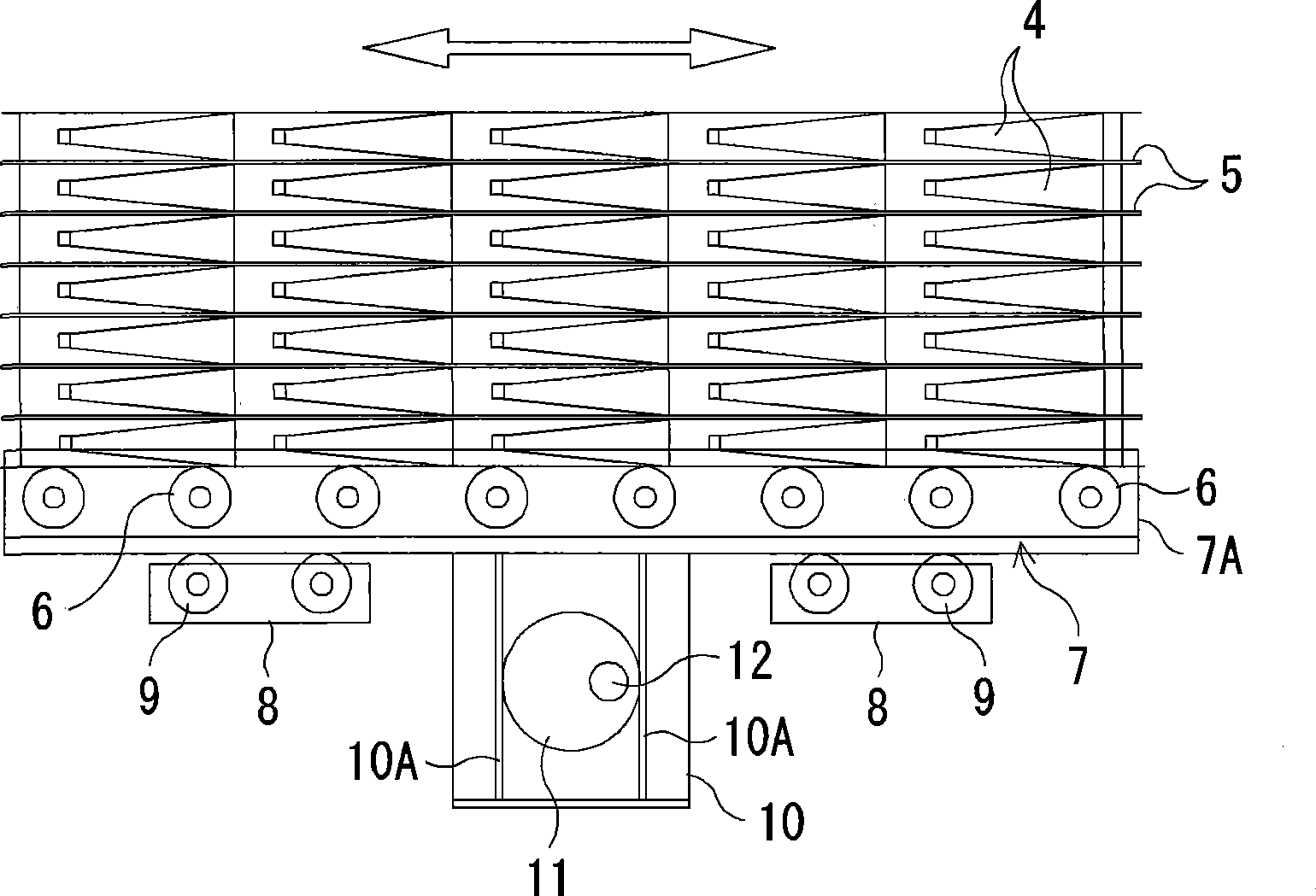

[0079] In order to confirm the effect of the retort sterilization method using the device of the present invention, a sterilization treatment test was performed by sliding retort products at various vibration numbers. Figure 7 to Figure 10 Indicates its result. Figure 7 to Figure 10 It is a calculation table showing the measurement results when the retort product is slid by various vibration numbers and the sterilization treatment test is carried out. The retort product used for the measurement is 1 kg of curry soup, the sterilization temperature in the retort container is 120°C, and it takes 12 minutes to complete. Step by step with the bactericidal value, namely Fo value = 5, and the sliding stroke of the distilled product is 75mm.

[0080] "Come up" here refers to the time when the temperature of the atmosphere in the distillation vessel reaches the sterilization temperature, and 12 minutes of completion means that it is 12 minutes from the moment the treatment starts to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com