Preparation method of hyperin and hypericin of Hypericum perforatum

A technology of hypericin and hypericin is applied in chemical instruments and methods, preparation of sugar derivatives, medical preparations containing active ingredients, etc. issues such as

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

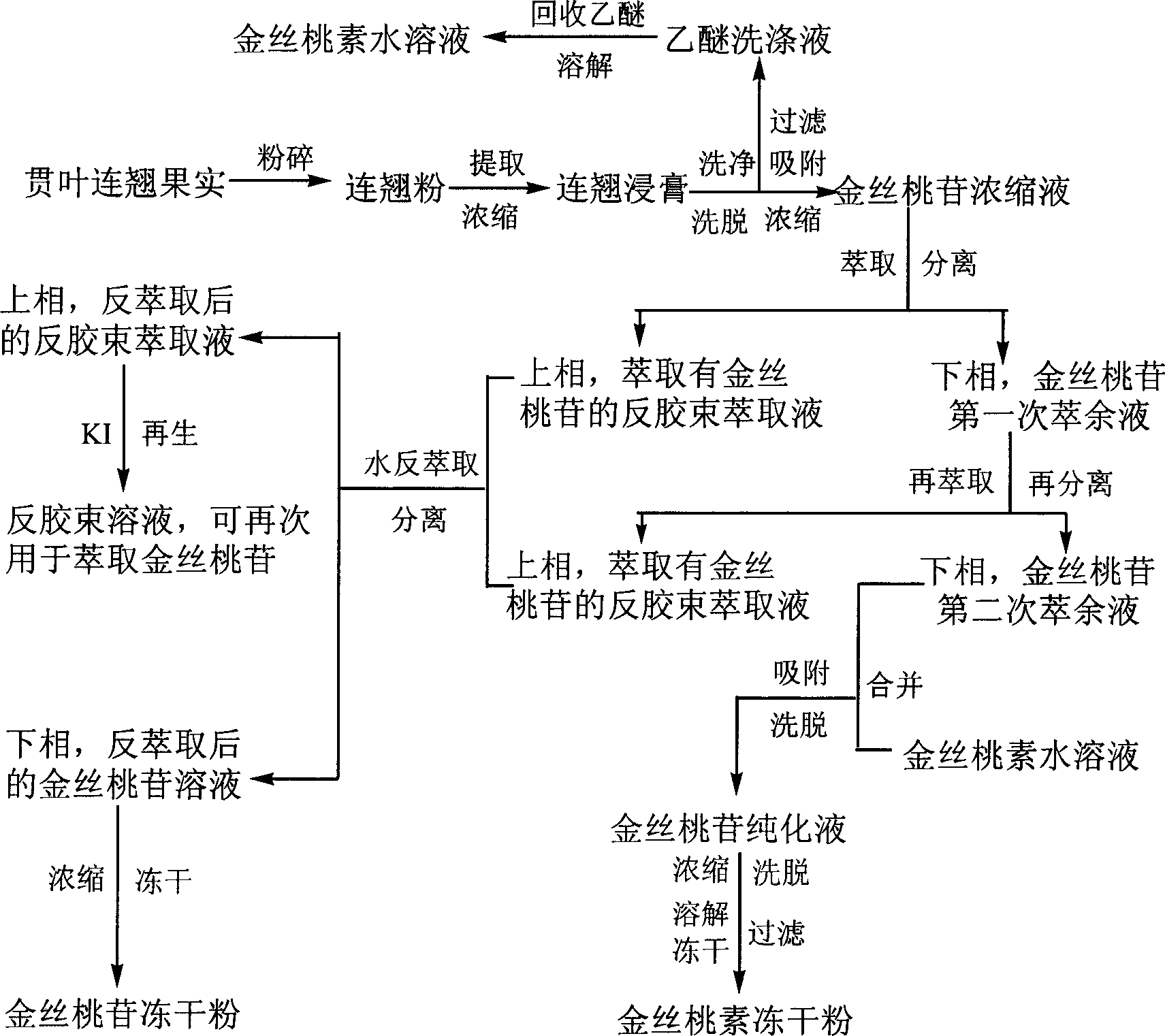

Method used

Image

Examples

Embodiment 1

[0055] A preparation method of hypericin and hypericin in Hypericum perforatum, the concrete method steps are as follows:

[0056] (1) Preparation of Forsythia extract

[0057] After the fruit of Hypericum perforatum is crushed into forsythia powder, the ratio of the weight of the forsythia powder to the volume of 85% ethanol is 1:10, adding 85% ethanol to the forsythia powder, and refluxing extraction at a temperature of 70 ° C. After 4 hours, it was filtered again and the filtrate was collected. For the filter residue, the ratio of the weight of the filter residue to the volume of 70% ethanol is 1:5, and then reflux extraction with 70% ethanol for 2 hours, then filter and collect the filtrate, discard the filter residue, and then use 70% ethanol. The filtrate was placed in an evaporator, and concentrated under -0.08MPa vacuum to form Hypericum perforatum extract and recovered ethanol. The ethanol concentration in the recovered and distilled ethanol is measured with an alco...

Embodiment 2

[0091] A preparation method of hyperin and hypericin in Hypericum perforatum, the specific method steps are as follows:

[0092] (1) Preparation of forsythia extract

[0093] After the Hypericum perforatum fruit is crushed into Forsythia powder, add 95% ethanol to the Forsythia powder at a ratio of 1:20 by the weight of the Forsythia powder and the volume of 95% ethanol, and extract under reflux at a temperature of 85°C After 6 hours, filter again and collect the filtrate. For the filter residue, the ratio of the weight of the filter residue to the volume of 80% ethanol is 1:10, and then reflux extraction with 80% ethanol for 3 hours, then filter and collect the filtrate, and discard the filter residue. Then, the filtrate collected twice was placed in an evaporator, concentrated into Hypericum perforatum extract and recovered ethanol under a vacuum of -0.05MPa. Measure the concentration of ethanol in the recovered and distilled ethanol with an alcohol meter, then adjust it t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com