Mold-pressing device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

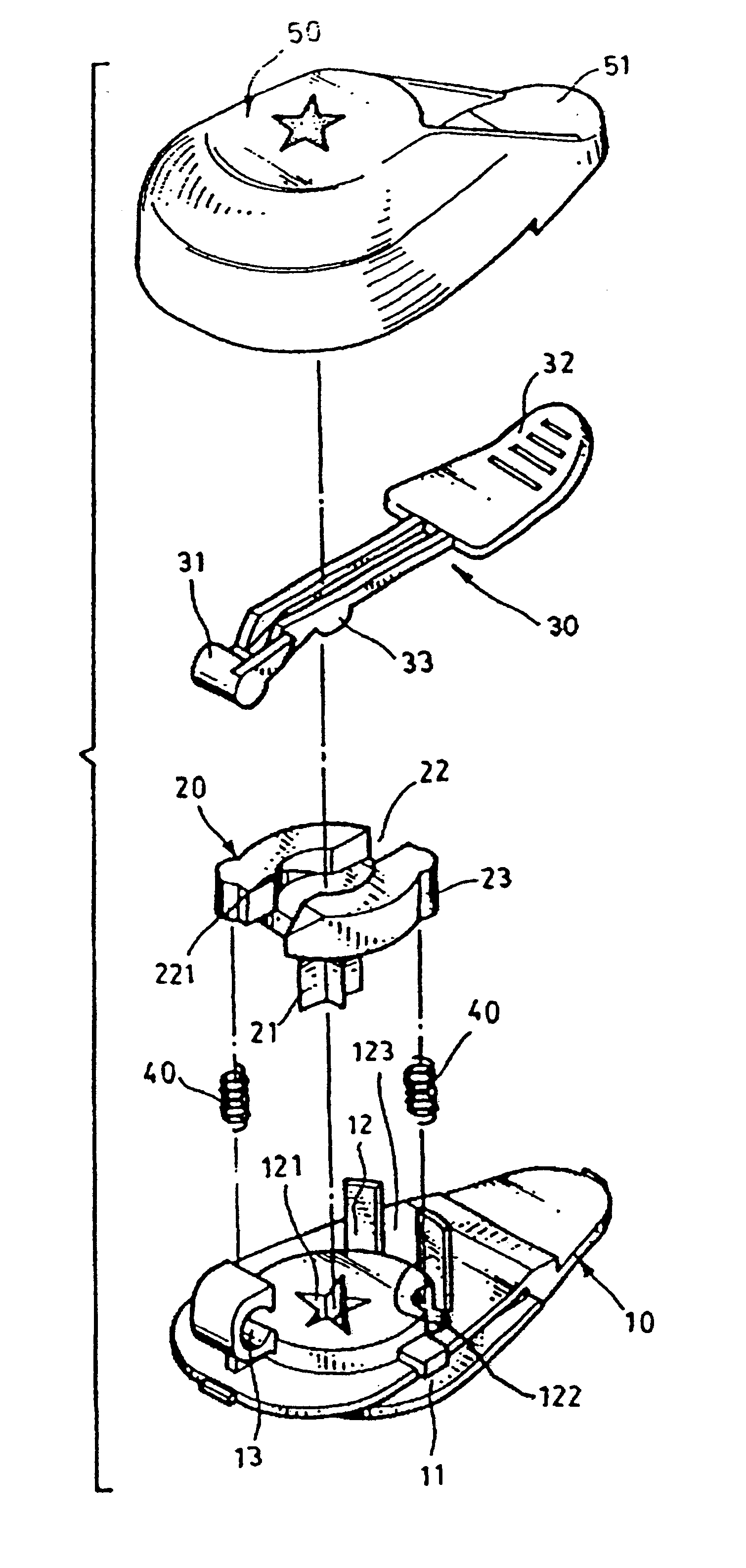

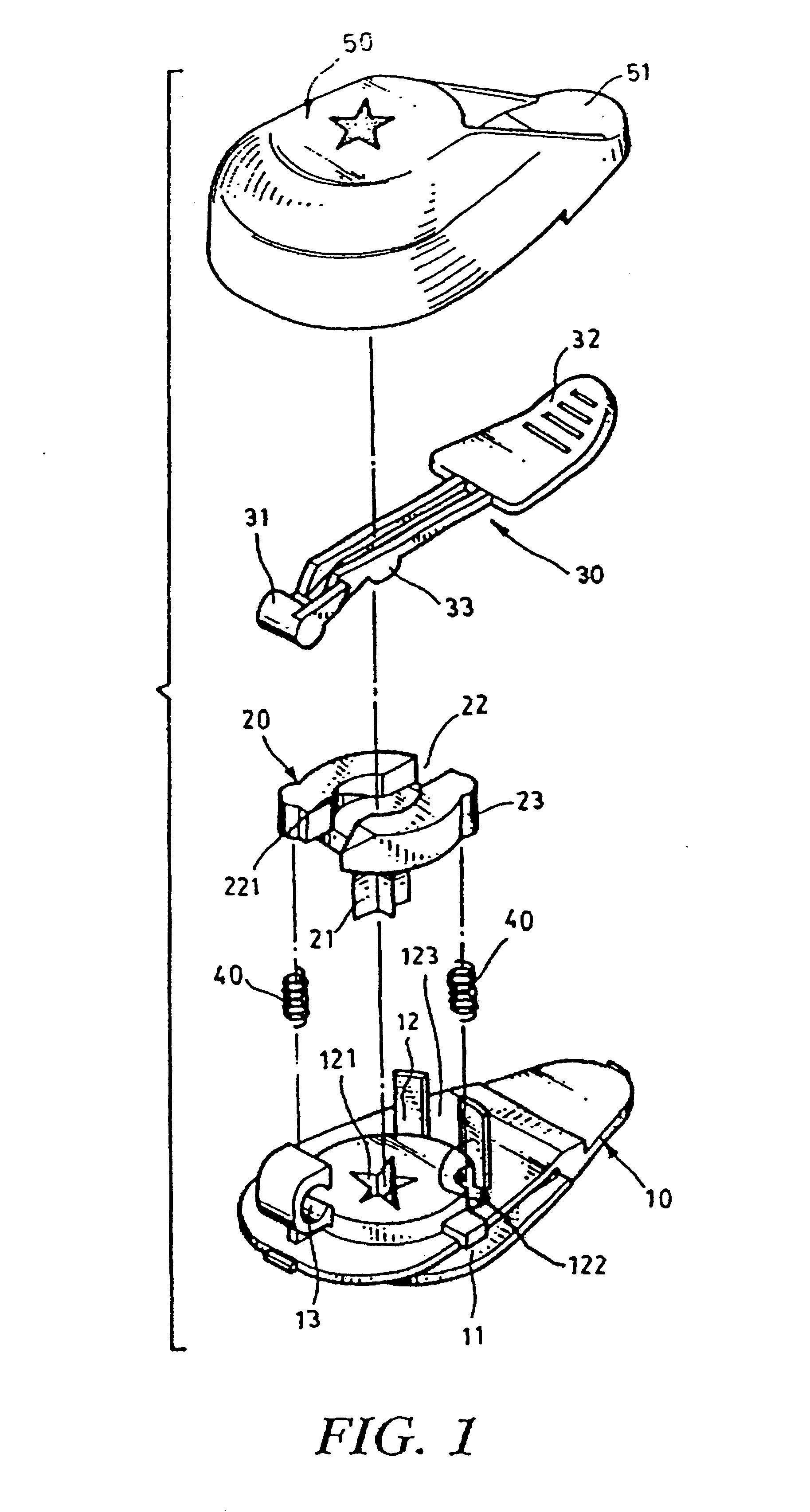

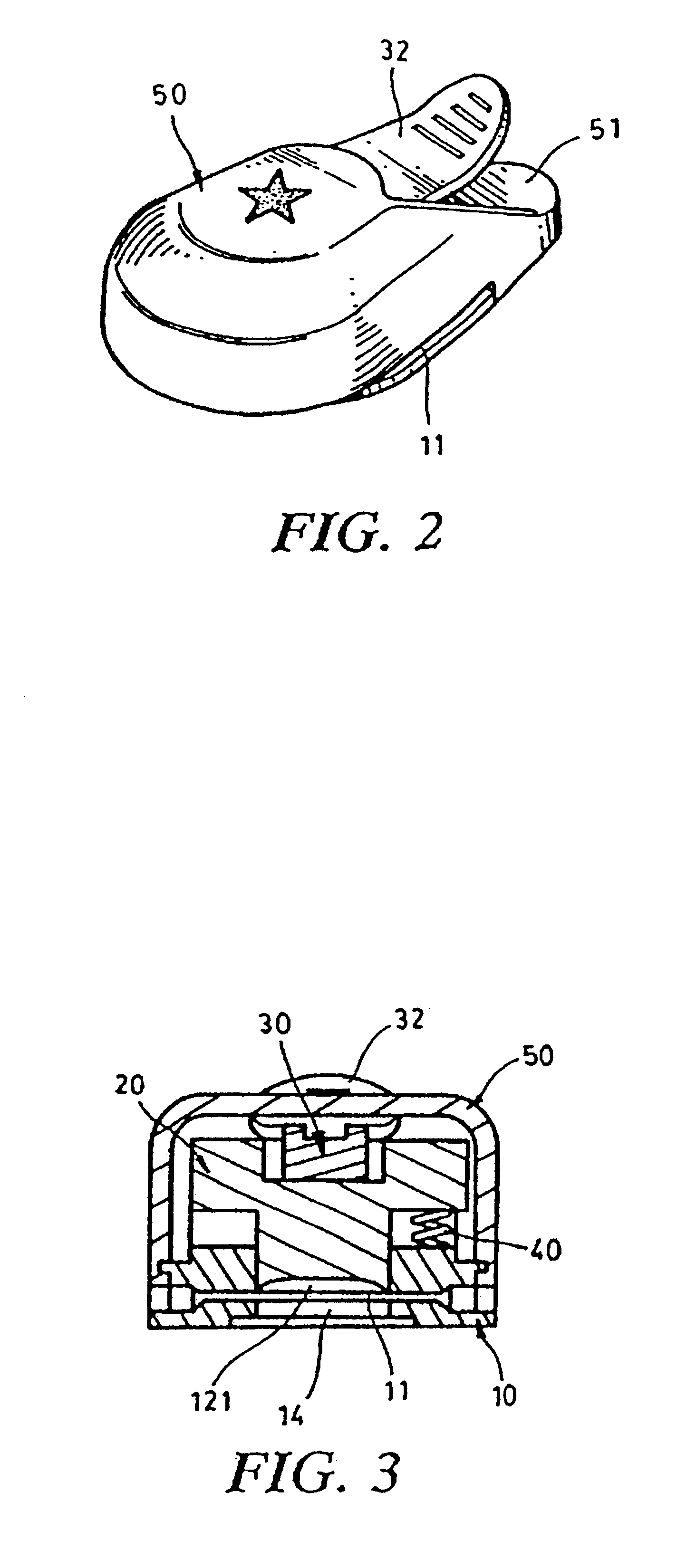

Please refer to FIGS. 1 to 5. The mold-pressing device of the present invention includes a seat body 10 formed with a horizontal fissure 11 at one end and a vertical chamber 12. The bottom of the chamber 12 is formed with an opening 121 communicated with the fissure 11. An upward extension 122 is disposed on rear side of the chamber 12. A pair of opposite notches 123 are formed on the periphery of the chamber 12. An insertion cavity 13 is disposed in one notch 123 opposite to the other notch 123. The bottom of the seat body 10 is formed with a through hole 14 communicated with the fissure 11 opposite to the opening 121.

A mold block 20 is disposed on the seat body 20. One face of the mold block 20 facing the fissure 11 is disposed with a solid die 21 such as an animal or a cartoon picture. The other face of the mold block 20 is disposed with a channel 22 passing through the mold block 20. Two opposite recesses 221 are formed on two sides of the channel 22. The mold block 20 is dispos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shape | aaaaa | aaaaa |

| Resilience | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com