Press fit equipment for plywood

A lamination equipment and technology for plywood, applied in the direction of plywood press, veneer press, wood veneer joining, etc. The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

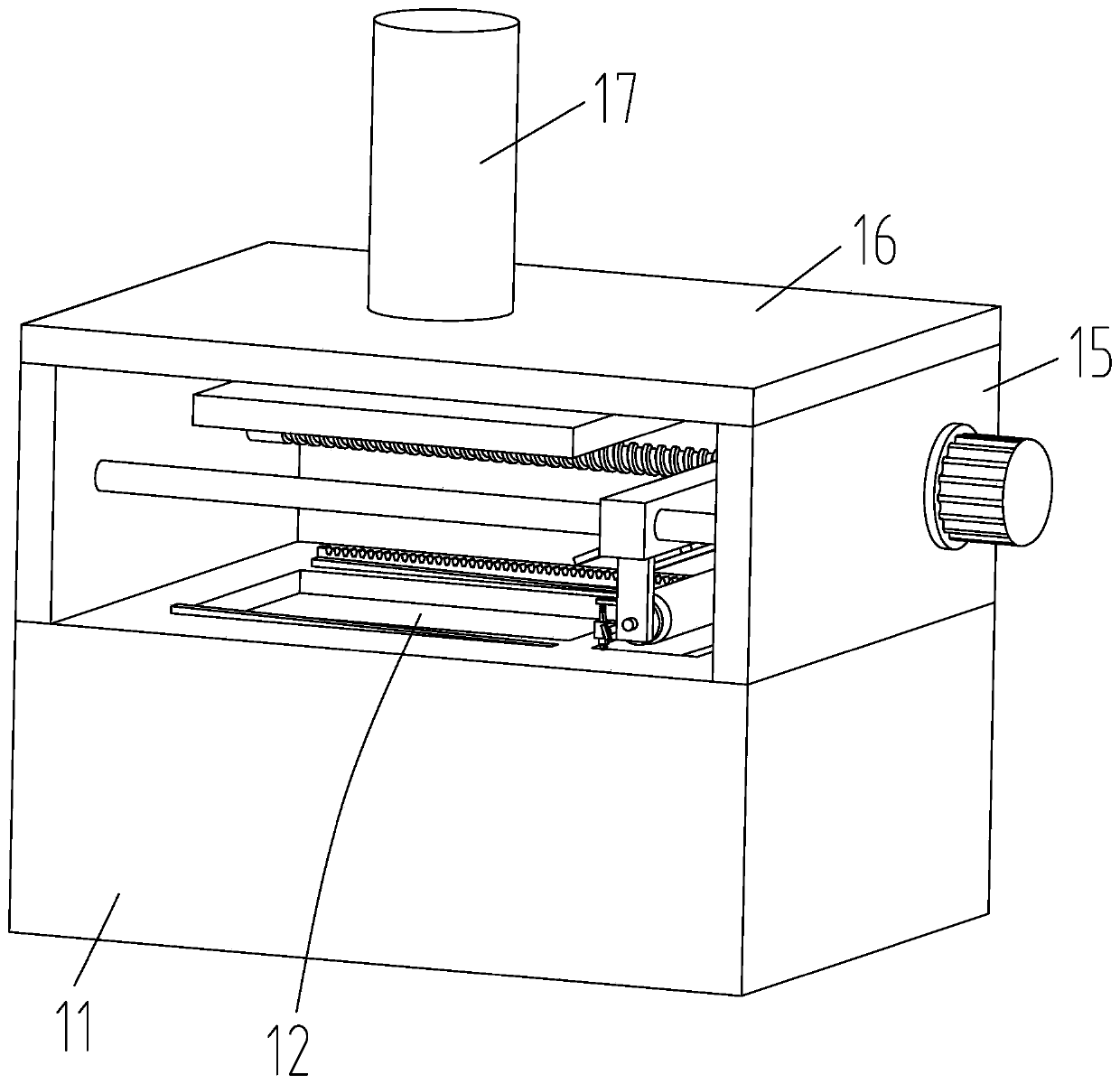

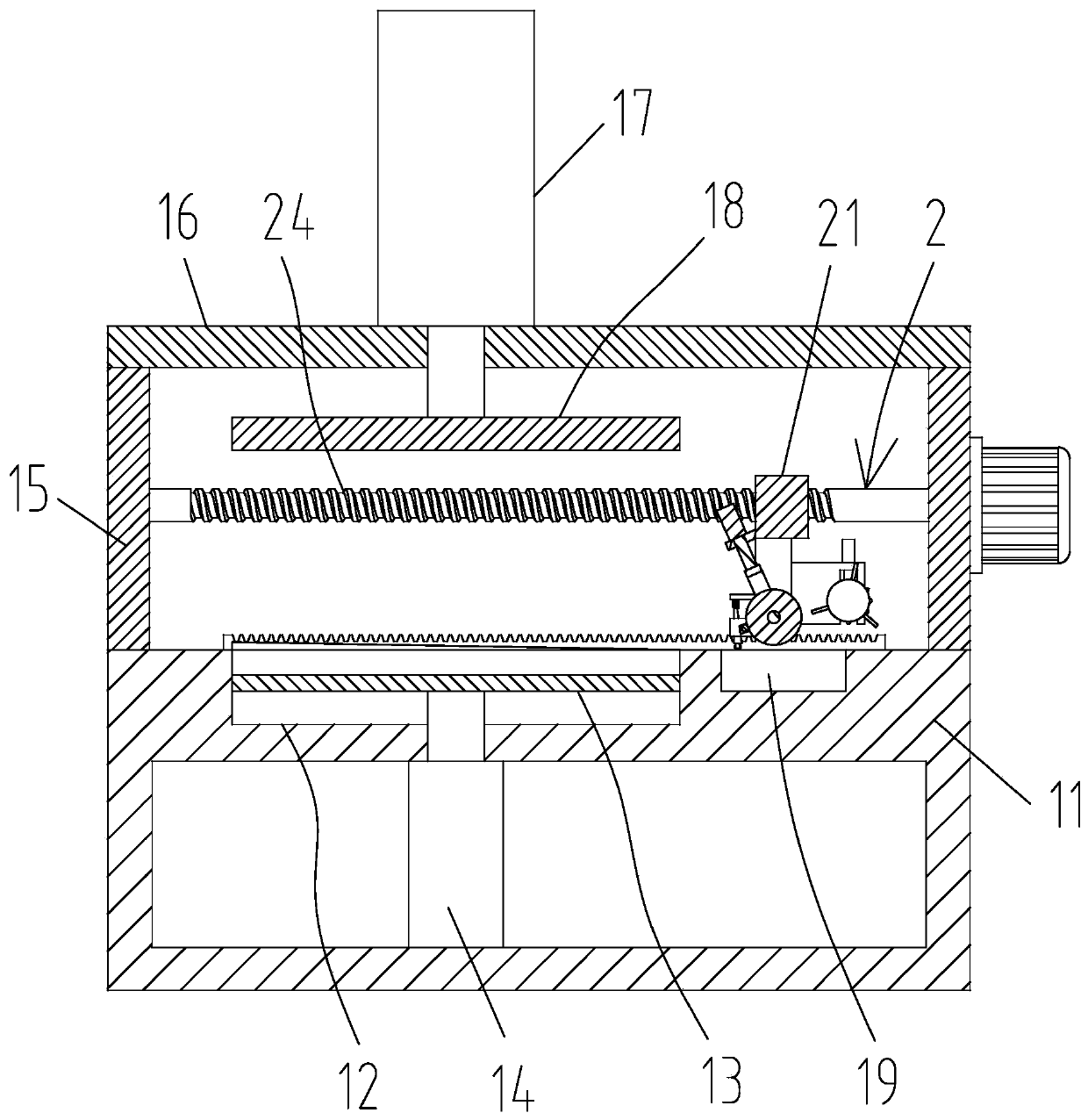

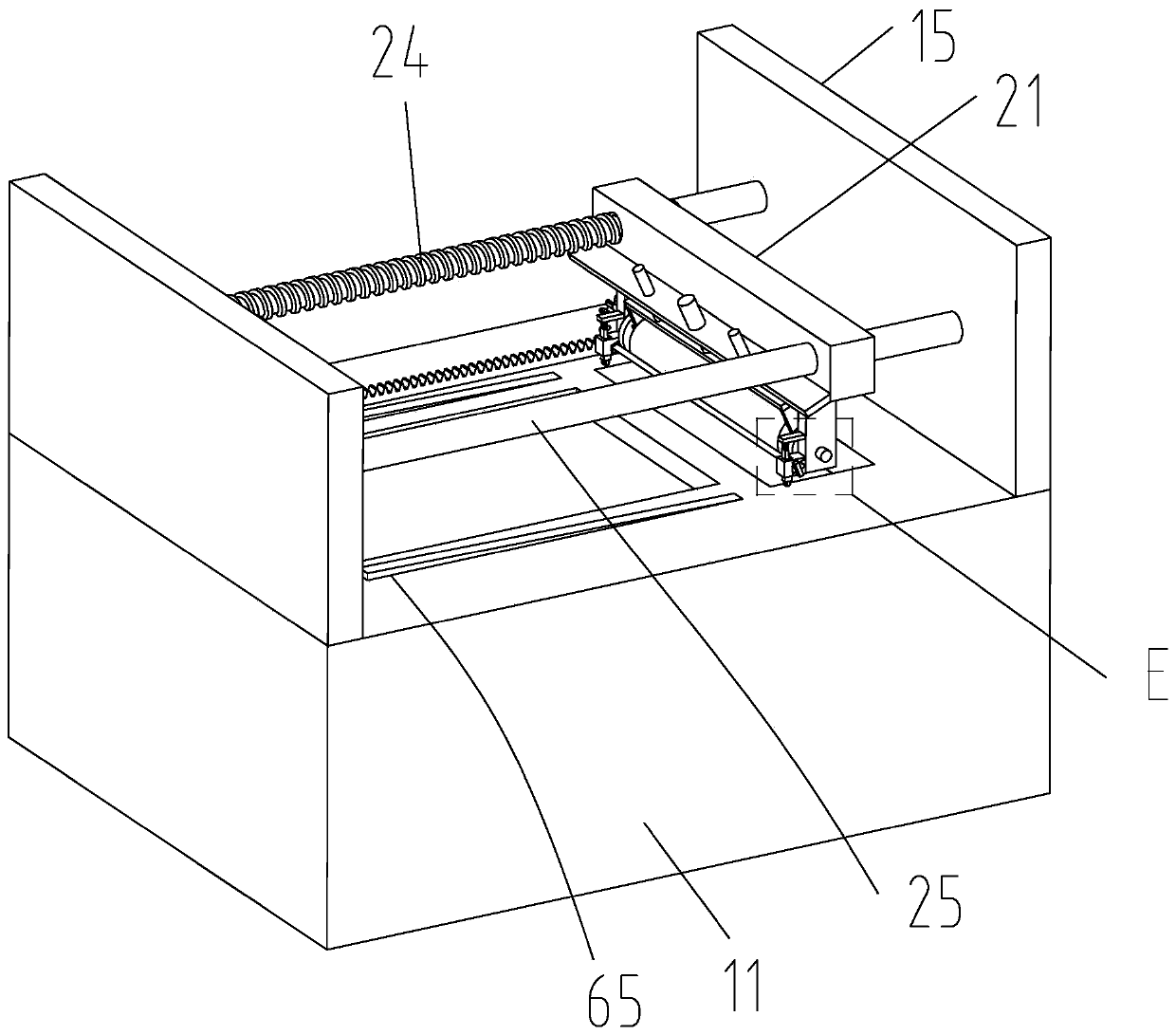

[0028] Such as Figure 1-Figure 9 As shown, a kind of plywood pressing equipment provided by the present invention includes a box body 11, and the upper side of the box body 11 is provided with a placement groove 12, and the plywood that needs to be laminated layer by layer is placed in the placement groove 12, and placed in the groove 12 The support plate 13 is slidably connected, and the inside of the box body 11 is fixedly connected to the support cylinder 14. The telescopic rod of the support cylinder 14 extends into the placement groove 12 and is fixedly connected with the bottom of the support plate 13. After the plywood is placed in one layer, it is glued and placed on the top. After a layer of plywood is pressed, after a single pressing is completed, the supporting plate 13 is lowered by a height of a veneer and then circulated. After the final pressing is completed, the supporting plate 13 pushes all the plywood out of the placement slot 12, and the upper side of the b...

Embodiment 2

[0033] Such as Figure 6-Figure 11 As shown, on the basis of Embodiment 1, in order to solve the problem that the glue on the edge of the slot 12 solidifies and is difficult to clean, a rubber scraping device 8 is provided on one side of the vertical plate 22. The rubber scraping device 8 includes a support block 81, and the support block 81 Fixedly connected to one side of the vertical plate 22, the middle part of the support block 81 is provided with a third chute 82, and the third chute 82 is slidably connected to the third slider 83, and the middle part of the third slider 83 is rotatably connected to the second rotating shaft 84, and the second One end of the rotating shaft 84 is fixedly connected to the scraping roller 85. The scraping roller 85 includes a roller 851. The outer ring of the roller 851 is provided with a group of elastic sheets 852. The elastic sheets 852 are stainless steel sheets. There are at least three elastic sheets 852, and the rollers The axis of 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com