Spinning process of covering yarn with high hollowness degree, prepared covering yarn and process for weaving towel by utilizing covering yarn

A technology of core-spun yarn and hollowness, which is applied in the field of spinning, which can solve the problems of incomplete hollow structure of yarn, low hollowness of yarn, and unreachability, and achieve the effect of improving thermal performance and strong water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

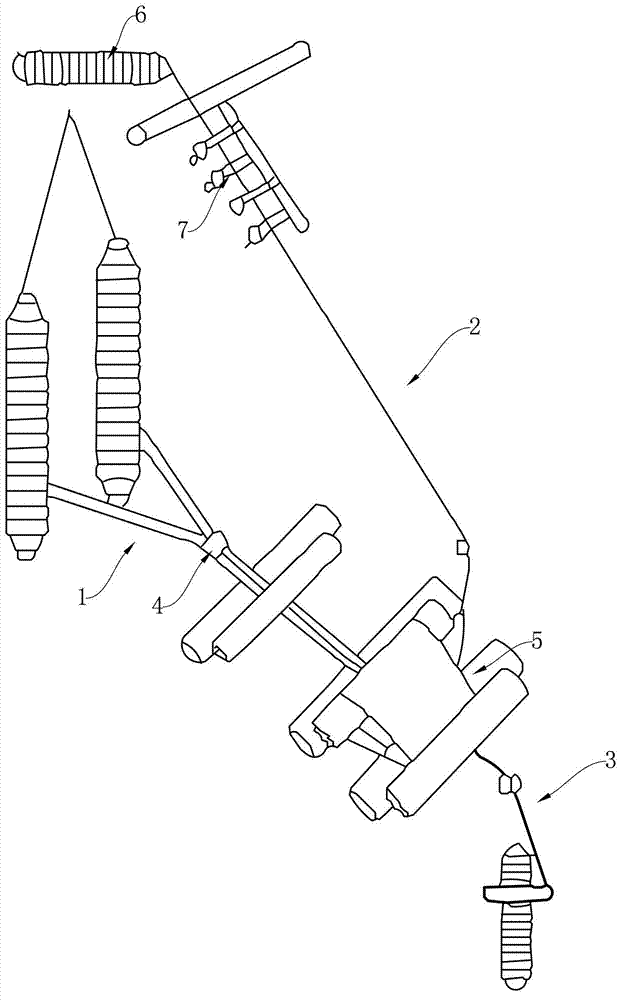

Image

Examples

Embodiment 1

[0049] According to the process method, 29.2tex color-spun pure cotton hollow core-spun composite yarn is spun, and the core yarn is 4.1tex imported water-soluble vinylon filament.

[0050] First prepare the lint fiber, the steps are as follows.

[0051] 1. Refining process: Refining the lint fiber with the cylinder dyeing machine of Dess, Germany, the liquor ratio is 1:6, adding 2ml of chelating dispersant G600, 3ml of stabilizer, 36°Be, caustic soda to each liter of bath liquid 5.0ml, 6ml of 27.5% hydrogen peroxide, heat up to 85°C, and treat for 40min;

[0052] 2. Pickling process: add citric acid, 0.1g of citric acid per liter of bath liquid, and treat at 35°C for 5 minutes;

[0053] 3. Deoxygenation process: add 0.15ml deoxygenase JN-500 to each liter of bath liquid, and treat at 35°C for 5 minutes.

[0054] The above steps can obtain the original white cotton fiber after refining.

[0055] Part of the original white cotton fiber is dyed, and the steps are as follows. ...

Embodiment 2

[0073] According to the above process method, 36.4t ex hollow core-spun composite yarn is spun, and the core yarn is 4.4t ex imported water-soluble vinylon filament.

[0074] Proceed as follows.

[0075] The FA002 disc bale grabbing machine is used to grab raw materials. The beaters of FA002 extend out the ribs by 3.5mm, and the beaters drop intermittently by 4mm. Then through the FA105A single-axis flow opener to remove impurities, the A035F automatic cotton mixer to mix, and the FA046 vibrating cotton box feeder to transport the cotton flow to the A076F single-hand roll machine to make cotton rolls, the weight is 440g / m; The rolls are fed to the FA231 carding machine for carding and impurity removal, and made into raw sliver with a gram weight of 20g / 5m. Adopt the principle of "small quantitative, medium distance, low speed", adjust the five-point distance between the cylinder and the cover plate to 0.22, 0.2, 0.18, 0.18, 0.2mm; reduce the cylinder speed to 360r / min to redu...

Embodiment 3

[0084] According to the process method, 32.4tex color spinning pure cotton hollow core-spun composite yarn is spun, and the core yarn is 7.3tex imported water-soluble vinylon filament.

[0085] First prepare the lint fiber, the steps are as follows.

[0086] 1. Refining process: Refining the lint fiber with the cylinder dyeing machine of Dess in Germany, the bath ratio is 1:8, adding 2.5ml of chelating dispersant G600 and 3.5ml of stabilizer to each liter of bath liquid, 36°Be, 5.5ml caustic soda, 7ml hydrogen peroxide with a concentration of 27.5%, heat up to 90°C, and treat for 50min;

[0087] 2. Pickling process: add citric acid, 0.13g of citric acid per liter of bath liquid, and treat at 40°C for 13min;

[0088] 3. Deoxygenation process: add 0.17ml deoxygenase JN-500 to each liter of bath liquid, and treat at 40°C for 13min.

[0089] The above steps can obtain the original white cotton fiber after refining.

[0090] The original white cotton fiber is dyed, and the steps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com