Pedicle screw and bar pressing device

A technology of pedicle screw and pressing rod, which is used in medical science, surgery, fixator and other directions, can solve the problem that it is easy to get stuck in the groove of the side wall of the screw seat, and it needs to be repeatedly shaken from side to side to take it out, with high cost and low efficiency. and other problems, to achieve the effect of convenient direction and jacking degree, precise position control, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

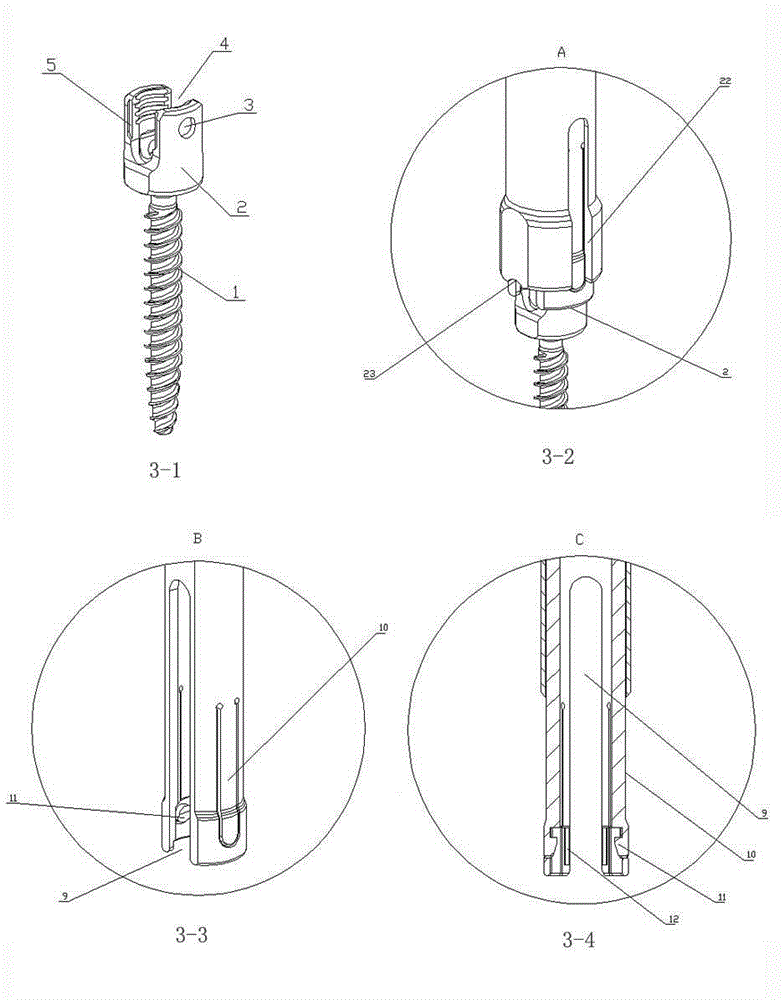

[0021] Such as image 3 The pedicle screw shown in Figure 3-1 includes a screw body 1 and a screw seat 2. The screw seat 2 is provided with a U-shaped rod placement groove 3, and the U-shaped rod placement groove 3 divides the screw seat into mutually symmetrical cross sections. Arc-shaped left plate body and right plate body, positioning grooves 4 are respectively provided on the left side of the left plate body and the right side of the right plate body, and the front side and the rear side of the upper end of the left plate body and the right plate body are respectively longitudinally provided with There is a positioning chute 5 with an open upper end. It can be seen from the figure that the front and rear sides of the screw seat are processed into flat surfaces, and the positioning chute 5 is arranged on the flat surfaces of the upper ends of the left plate body and the right plate body.

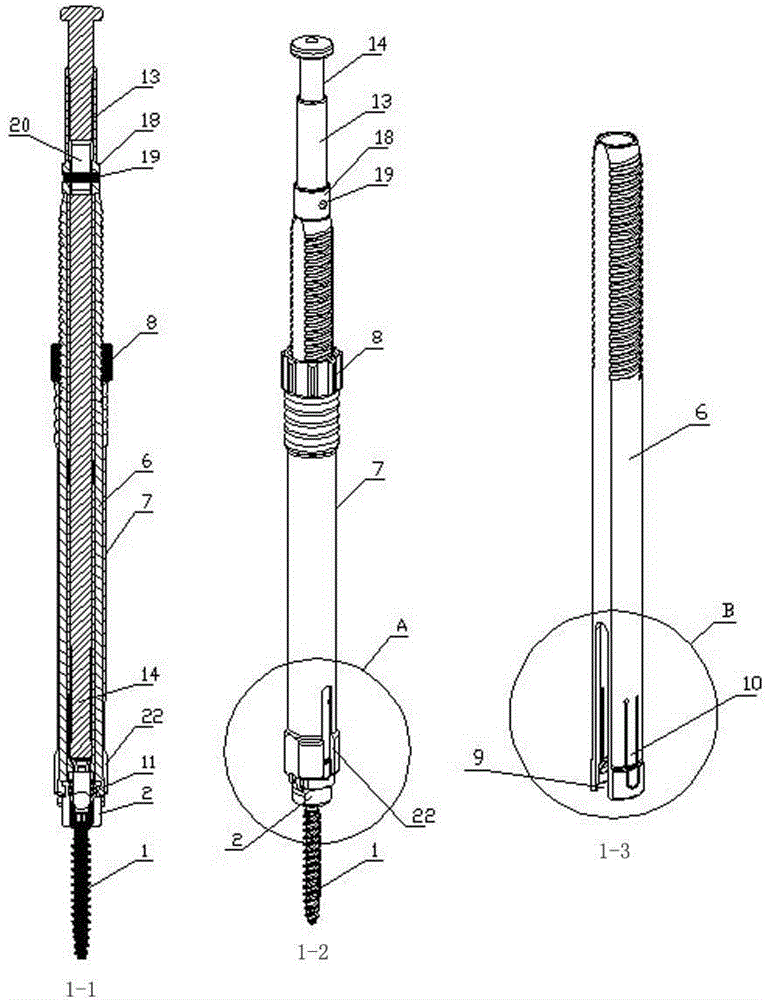

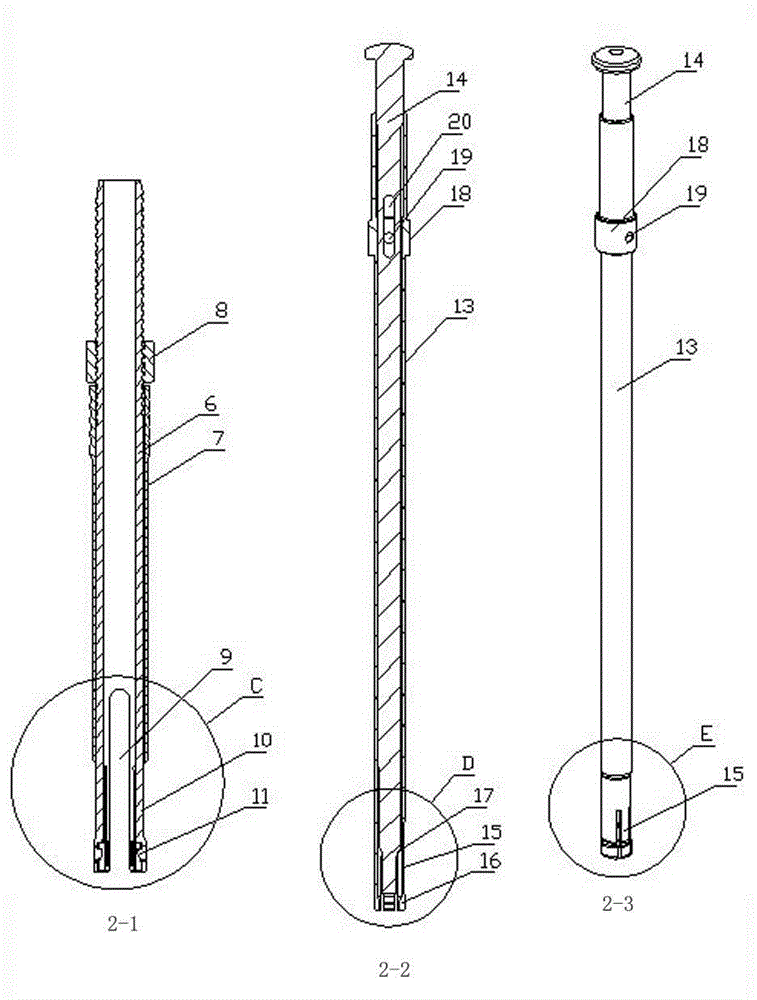

[0022] Such as figure 1 , figure 2 , image 3 Middle 3-2, 3-3, 3-4, Figure 4T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com