Dissimilar metal material brazing method

A technology of dissimilar metals and brazing methods, applied in the direction of welding/cutting media/materials, metal processing equipment, welding equipment, etc., can solve problems affecting welding quality, etc., to avoid electrochemical corrosion, increase reliability, and avoid environmental problems the effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

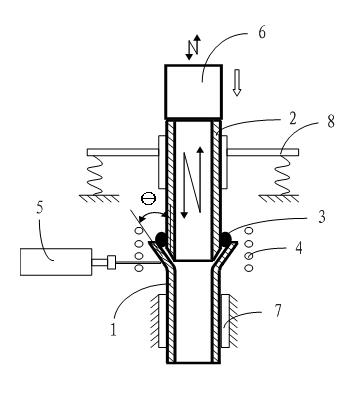

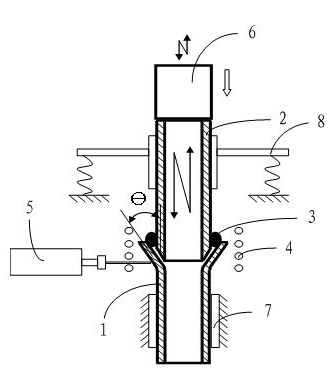

[0037] see figure 1 , select 6061 aluminum tube 1 and T2 copper tube 2, both of which have an outer diameter of 8mm and a wall thickness of 1mm. The solder used is Zn-4.7Al-0.5Cu (wt.%) flux-free solder paste 3, the solder has a solidus temperature of 380°C and a liquidus temperature of 397°C. Use a reamer to expand the mouth of one end of the aluminum tube 1 into a V shape. The angle between the flared slope and the center line of the tube is 30°, and the length of the slope is 5mm. Chamfering, flared slope, chamfered slope, and the straight pipe surface above the chamfered slope and opposite to the flared slope during welding are divided into welding surfaces.

[0038] see figure 1 , put the flared end of the aluminum tube 1 upright on the fixed fixture 7, and the chamfered end of the copper tube 2 faces down and align the flared end of the aluminum tube 1 vertically on the retractable fixture 8 , evenly fill the solder paste 3 in the V-shaped groove at the joint between ...

Embodiment 2

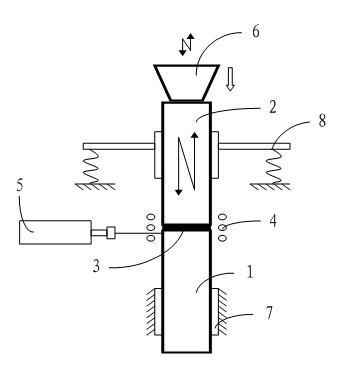

[0040] see figure 2 , select T2 copper rod 1 and 6061 aluminum alloy rod 2 as the base material, the diameter of the base material is 6mm, and the length is 40mm. A disc solder 3 with a composition of Zn-4.7Al-0.5Cu (wt.%), a diameter of 6 mm, and a thickness of 400 μm is selected. The solidus temperature of the solder is 380 °C and the liquidus temperature is 397 °C. Use No. 400 water abrasive paper to grind one end surface of the base metal as a welding surface, and use ethanol to ultrasonically clean the base metal and the brazing filler metal 3 .

[0041] see figure 2 , the copper rod 1 is vertically mounted on the fixed fixture 7 with its ground end facing upward, the aluminum alloy rod 2 is ground downward and the ground end of the copper rod 1 is vertically mounted on the retractable fixture 8 , the disc brazing filler metal 3 is preset between the copper and aluminum rod ground flat end faces. The other end of the aluminum alloy rod 2 is subjected to a pre-pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com