Press fitting mechanism for workpiece

A press-fitting and workpiece technology is applied in the field of press-fitting mechanism and workpiece press-fitting mechanism. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

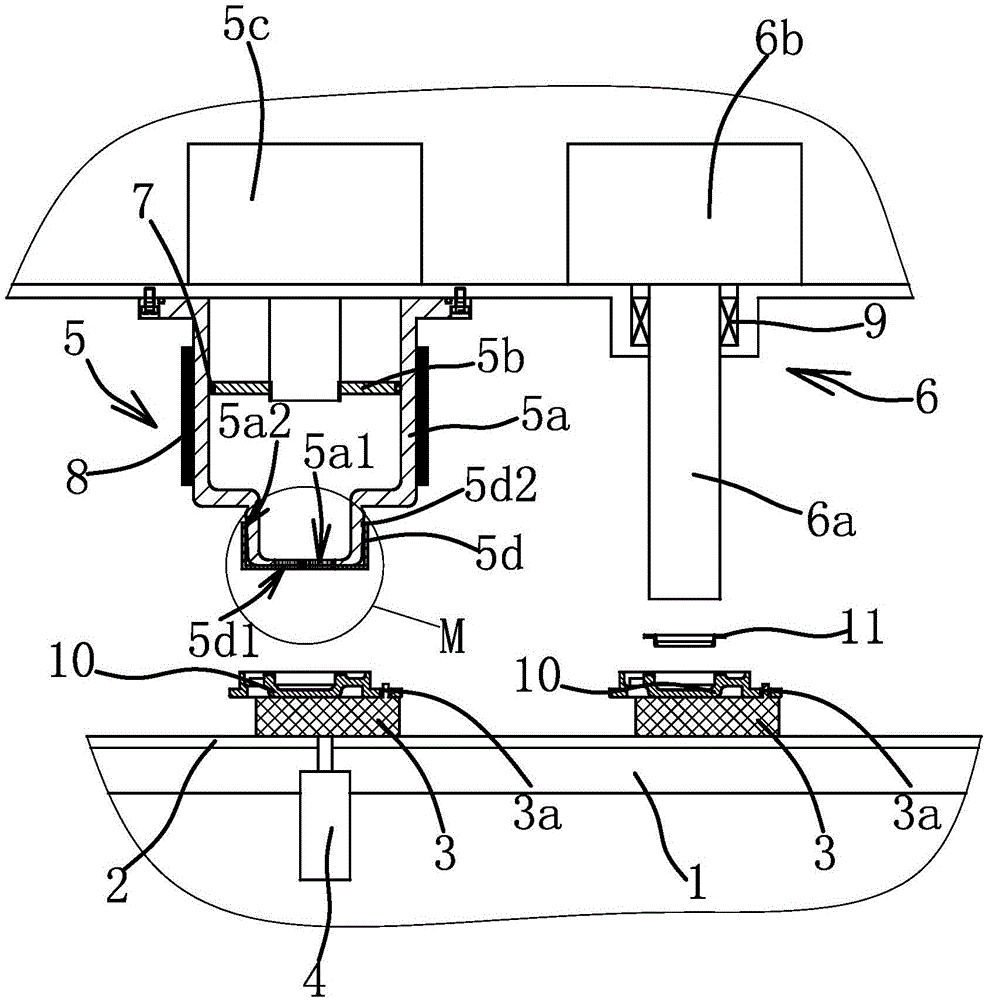

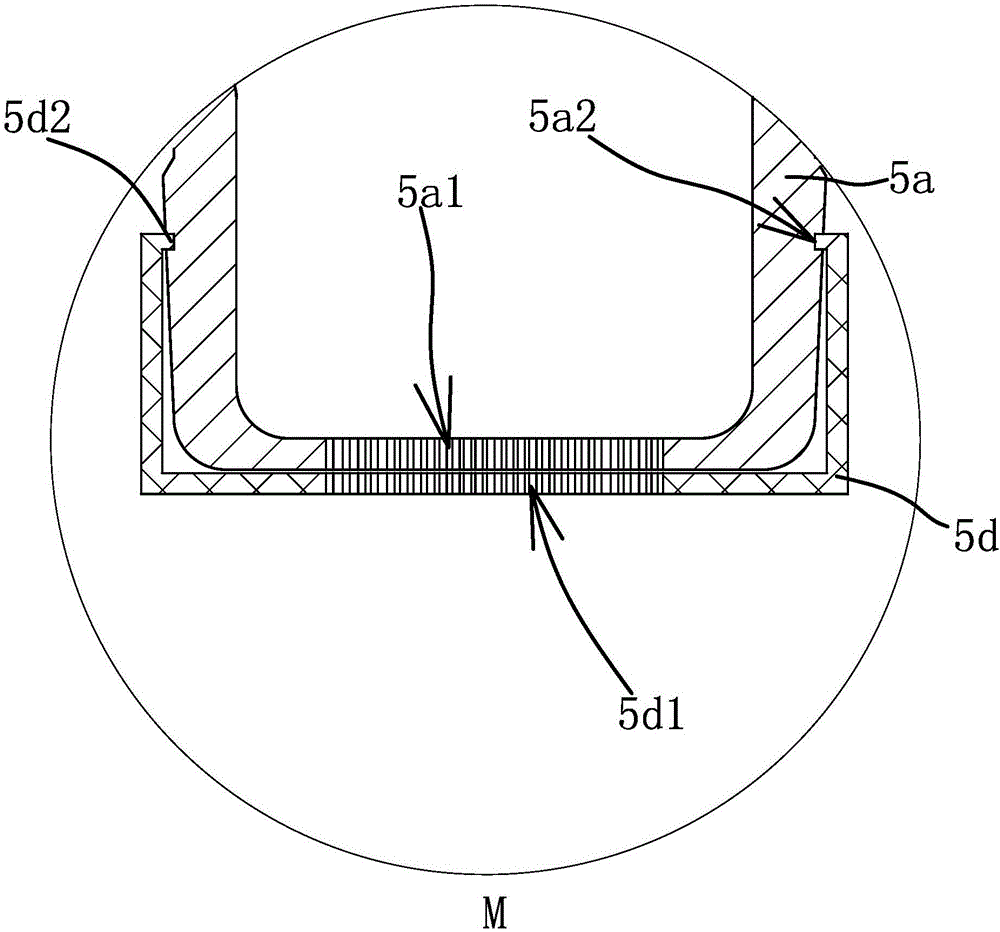

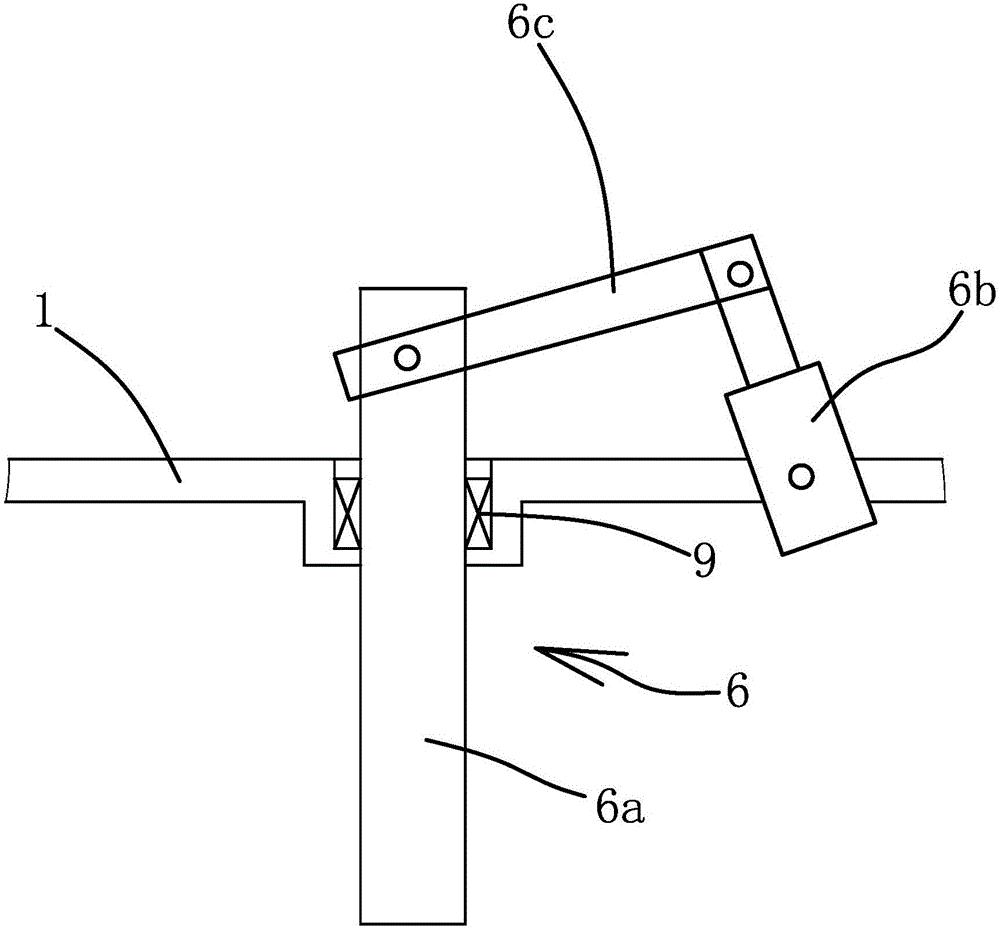

[0025] Such as figure 1 with 2 As shown, a workpiece press-fitting mechanism includes a frame 1 and a conveyor belt 2. The conveyor belt 2 is provided with a positioning tool 3 for positioning the pump cover 10. The positioning tool 3 is made of nylon material and the upper part of the positioning tool 3 is The side is provided with a positioning convex body 3a. The frame 1 is successively provided with a gluing device 5 and a pressing device 6 positioned on the upper side of the conveyor belt 2. The gluing device 5 includes a glue tank 5a fixed on the support. The outer wall of the glue tank 5a is provided with a heating pipe 8. The effect of setting the heating pipe 8 to heat the glue in the glue tank 5a has the advant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com