Power maintenance climbing box

A technology for power maintenance and box body, applied in the direction of overhead line/cable equipment, etc., can solve the problems of inconvenience of maintenance equipment, increase maintenance cost, and high maintenance cost, and achieve the effect of convenient transportation of tools, saving maintenance cost, and good safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

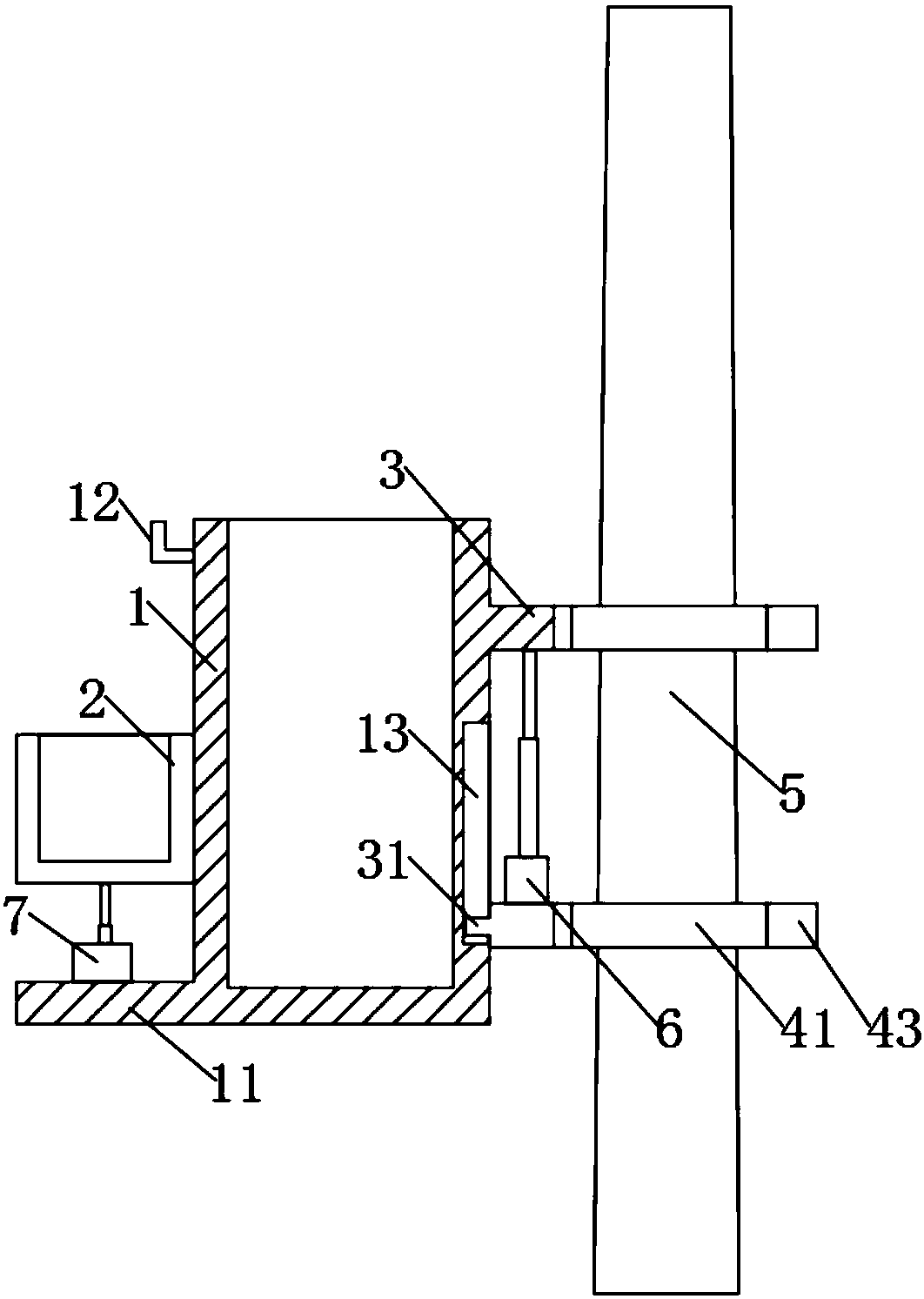

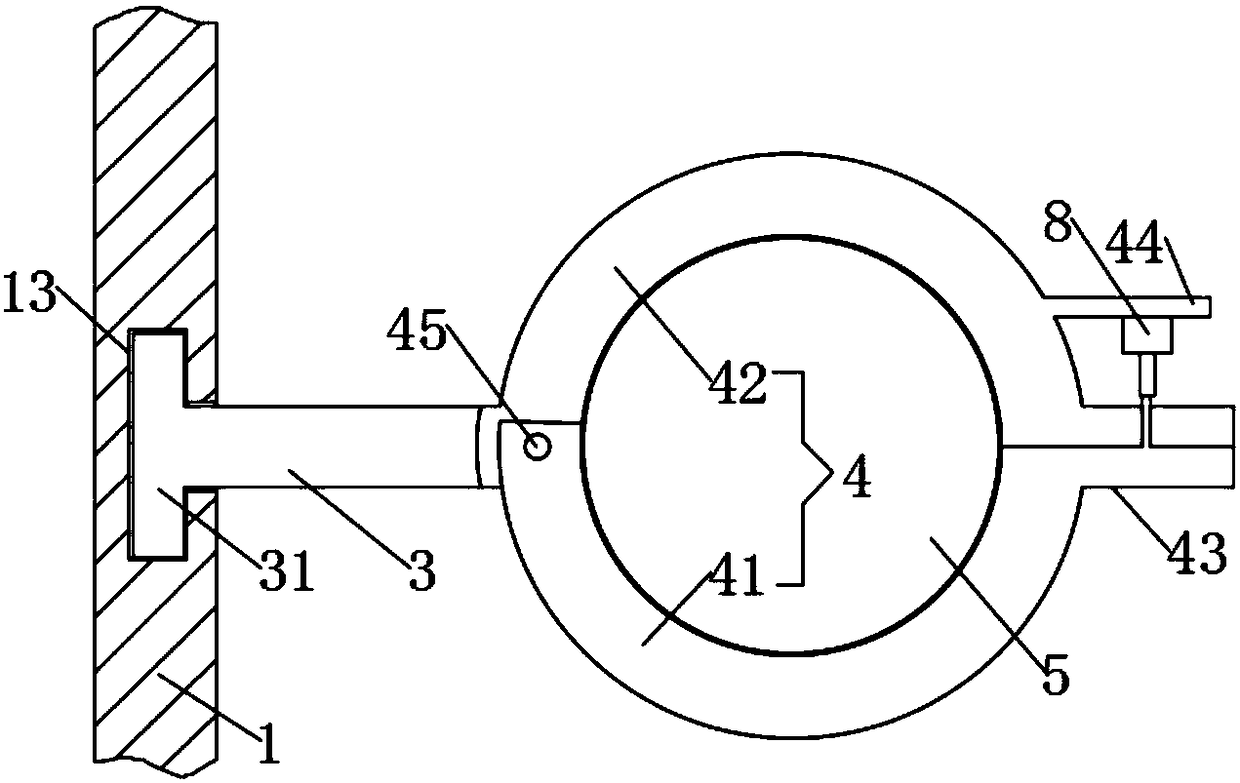

[0025] Such as figure 1 with 2 As shown, a climbing box for electric power maintenance includes a climbing box body 1, a tool box 2, a fixing rod 3 and a fixing ring 4, the climbing box body 1 and the tool box 2 are in a rectangular box structure, The tool box 2 is slidably attached to the side of the climbing box body 1, and some equipment for power maintenance can be placed in the tool box 2, and it is not easy to drop; the lower end of the climbing box body 1 is fixed with a The fixed plate 11 of rectangular structure, the cylinder two 7 that drives described tool box 2 lifting is arranged on described fixed plate 11, and the telescoping link upper end of described cylinder two 7 is fixedly connected with described tool box 2, passes through described cylinder two The expansion and contraction of 7 realizes the lifting of the tool box 2, which is convenient for carrying and taking power maintenance tools; the fixing ring 4 includes at least two upper fixing rings and lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com