Wind water mixed atomizing method for down-hole coal cutter fully-mechanized coal winning machine

The technology of coal shearer and fully mechanized excavator, which is applied in the field of feng shui mixed spraying, can solve the problems that gas cannot be dissipated in time, threaten production safety, easily affect coal quality, etc., so as to reduce gas ignition accidents, ensure safe production, and reduce dust effects. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

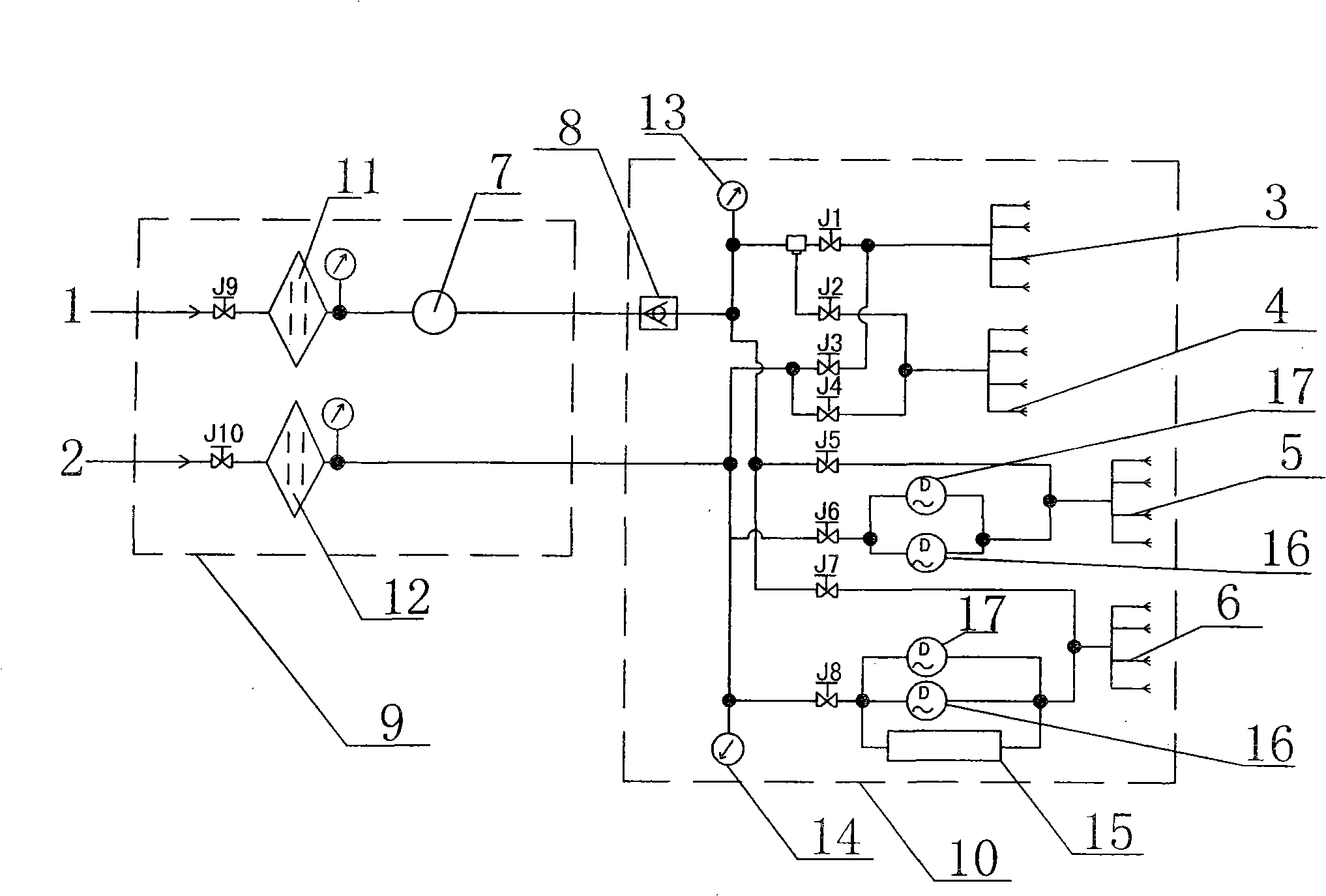

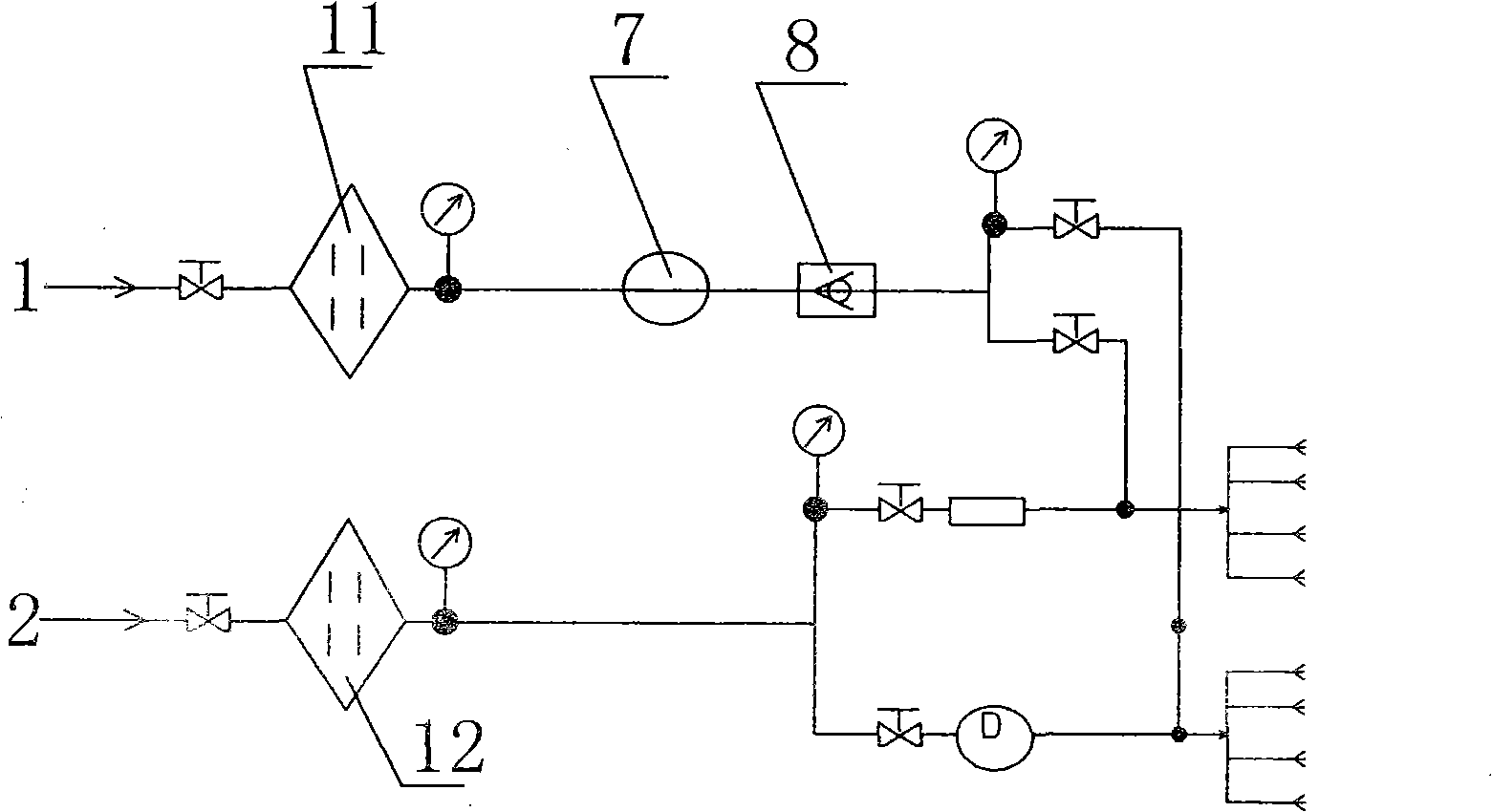

[0020] Below in conjunction with accompanying drawing, the present invention is described further:

[0021] In order to better reduce the probability of coal dust and gas accidents, improve coal quality, promote safe production, and ensure the physical and mental health of employees, the present invention has been practiced and explored repeatedly in Daxing Coal Mine N 2 705、S 5 711 and fully mechanized excavation working face tests successfully completed the Fengshui mixed spray system.

[0022] The system forms a strong wind-water mixed airflow, which can blow away the local gas generated when cutting coal bodies and capture coal dust more effectively.

[0023] The method of the present invention uses and comprises the water source 2 of the air source 1,3~5Mpa of the 0.5~2Mpa wind source 1,3~5Mpa of the excavation working face through pipeline and shut-off valve J9, J10 that the ground pressure fan is used, as figure 1 As shown, the dotted line part on the left side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com