Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

103results about How to "Prevent axial slippage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

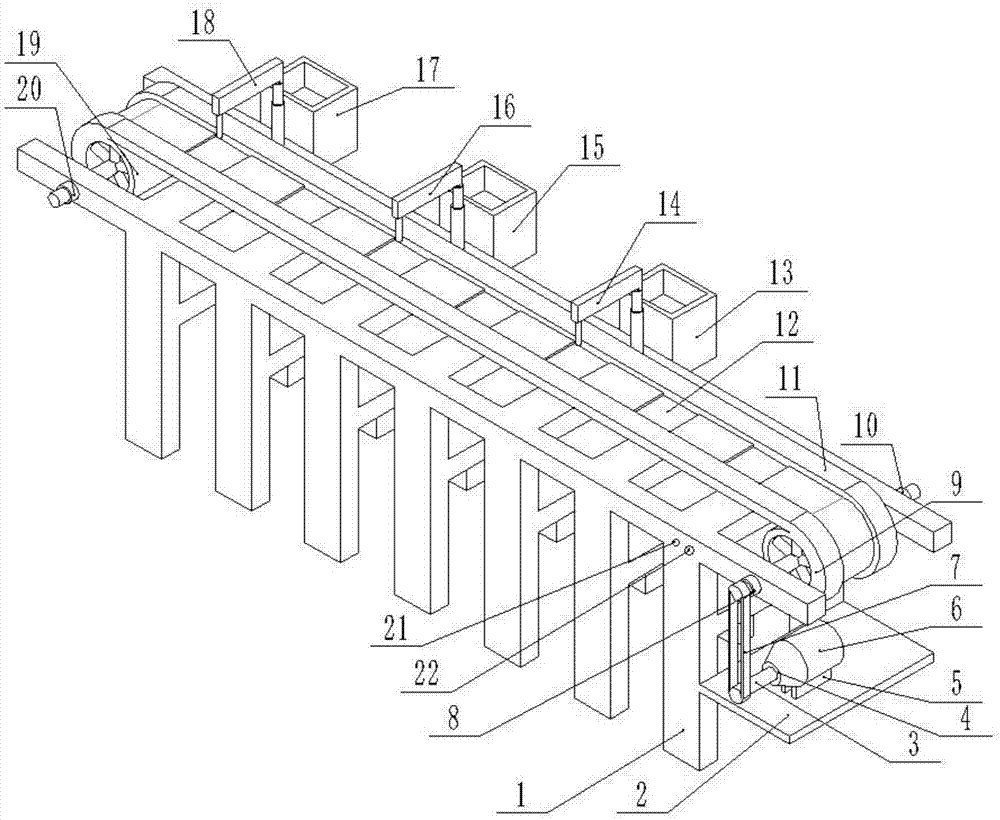

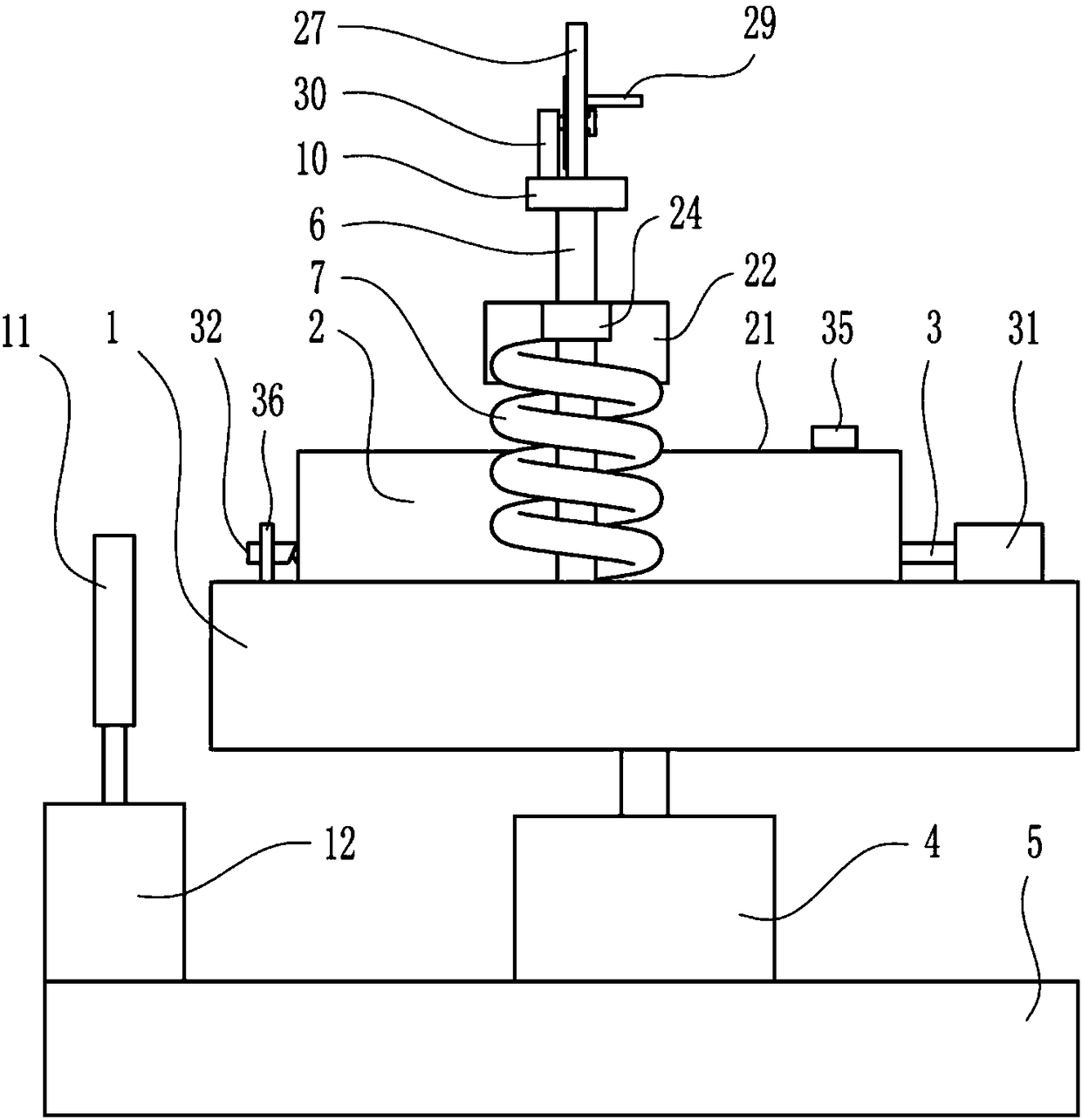

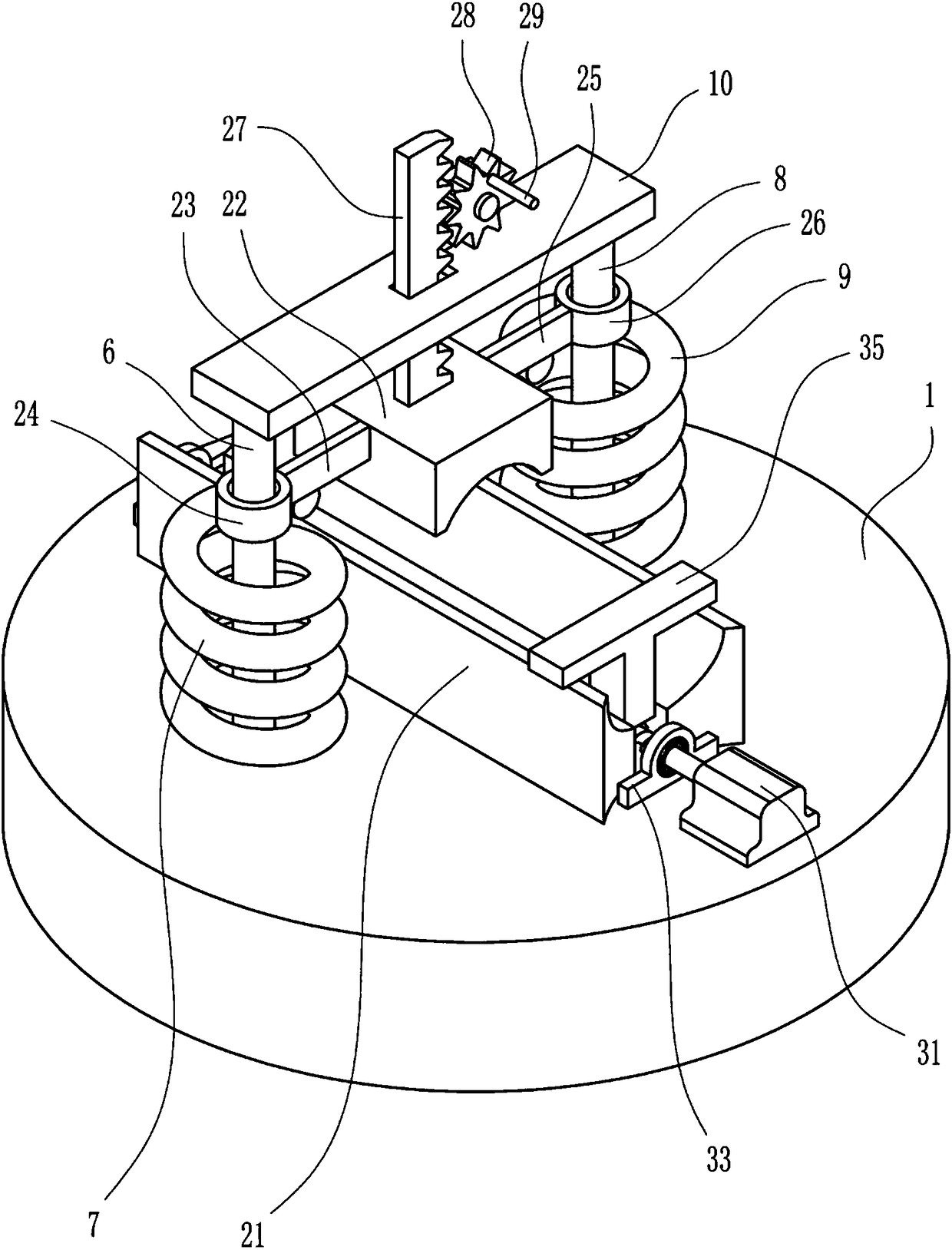

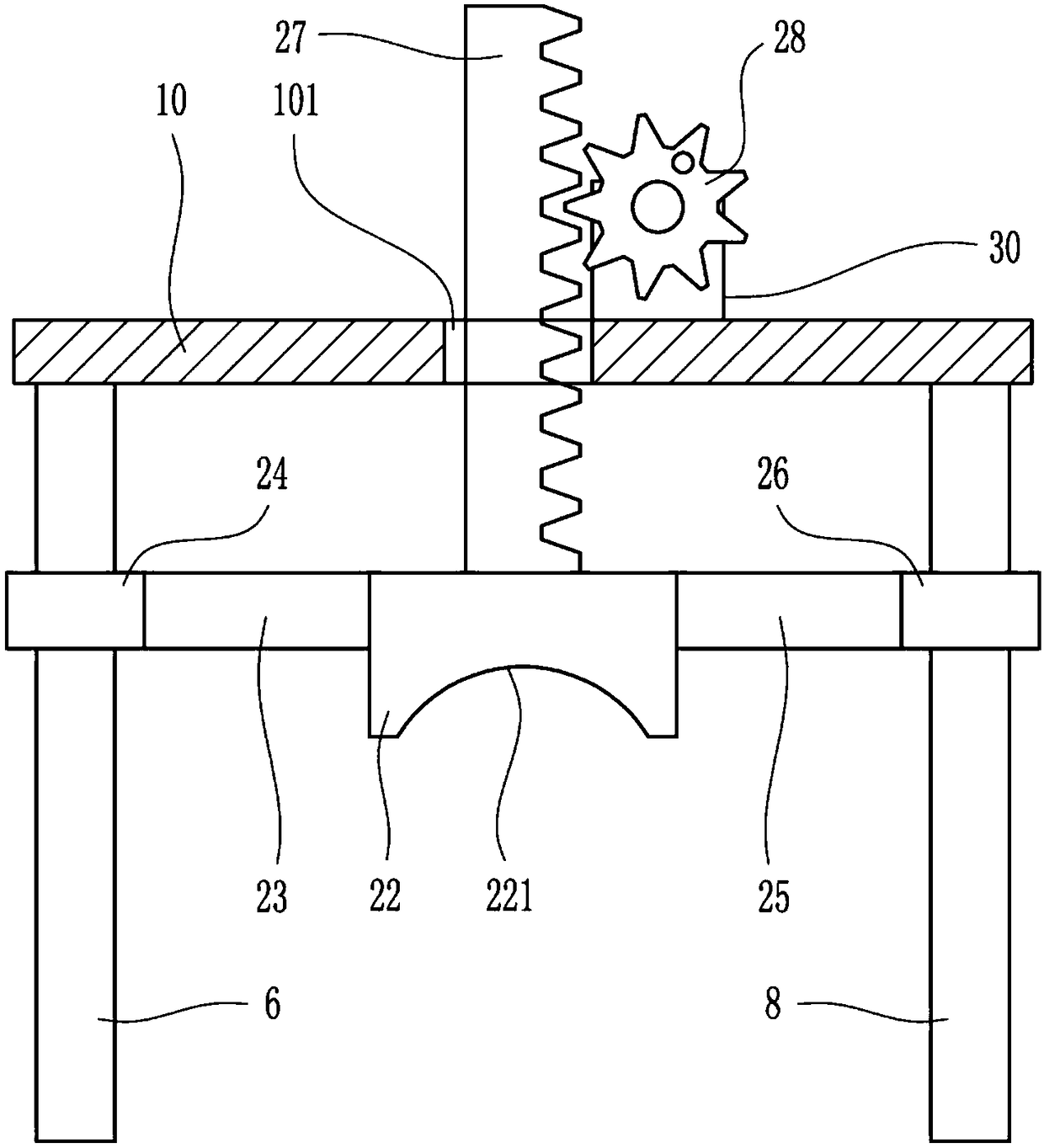

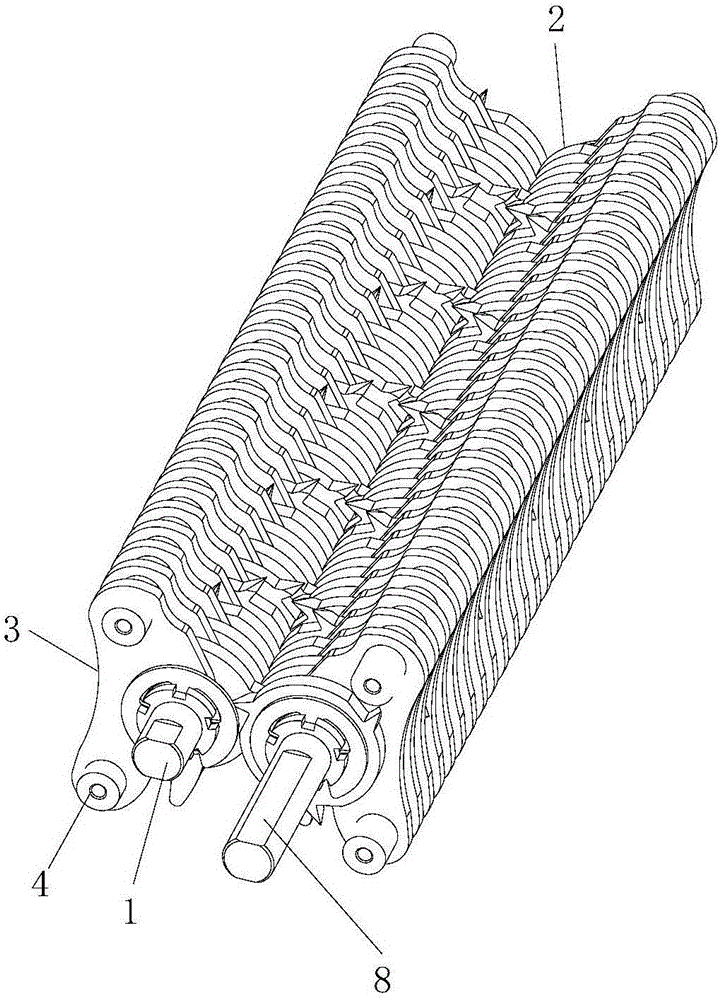

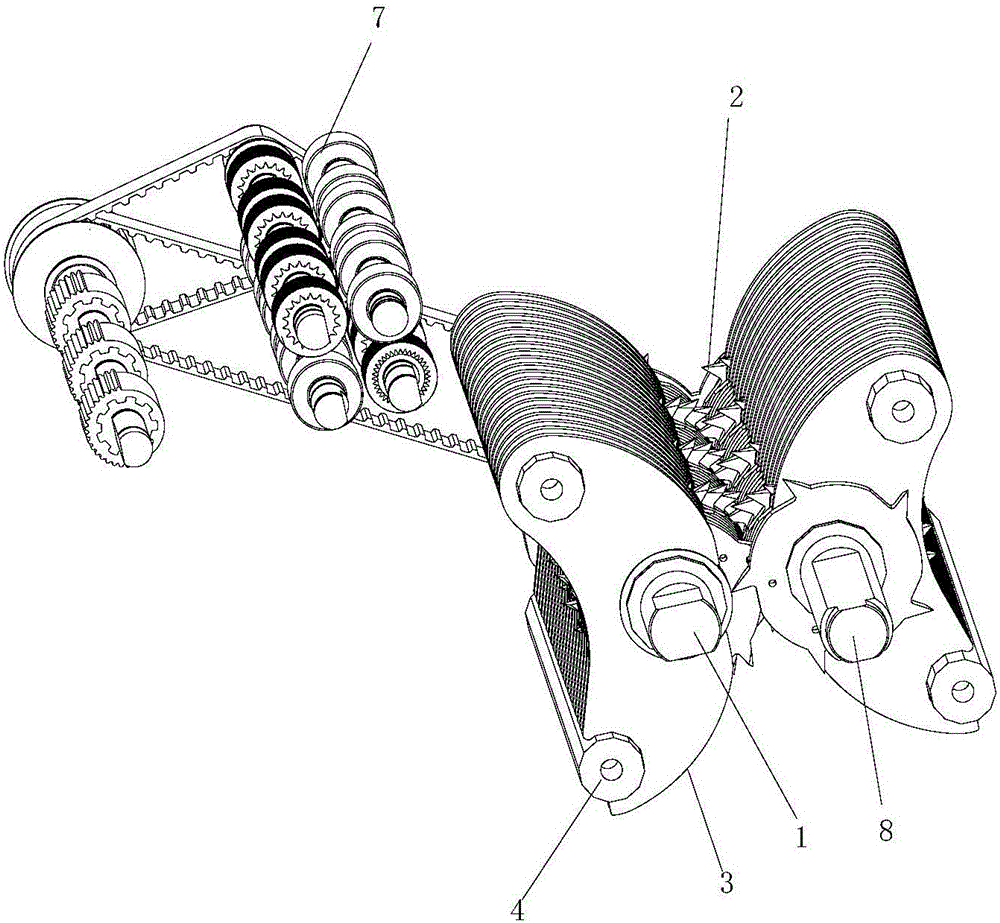

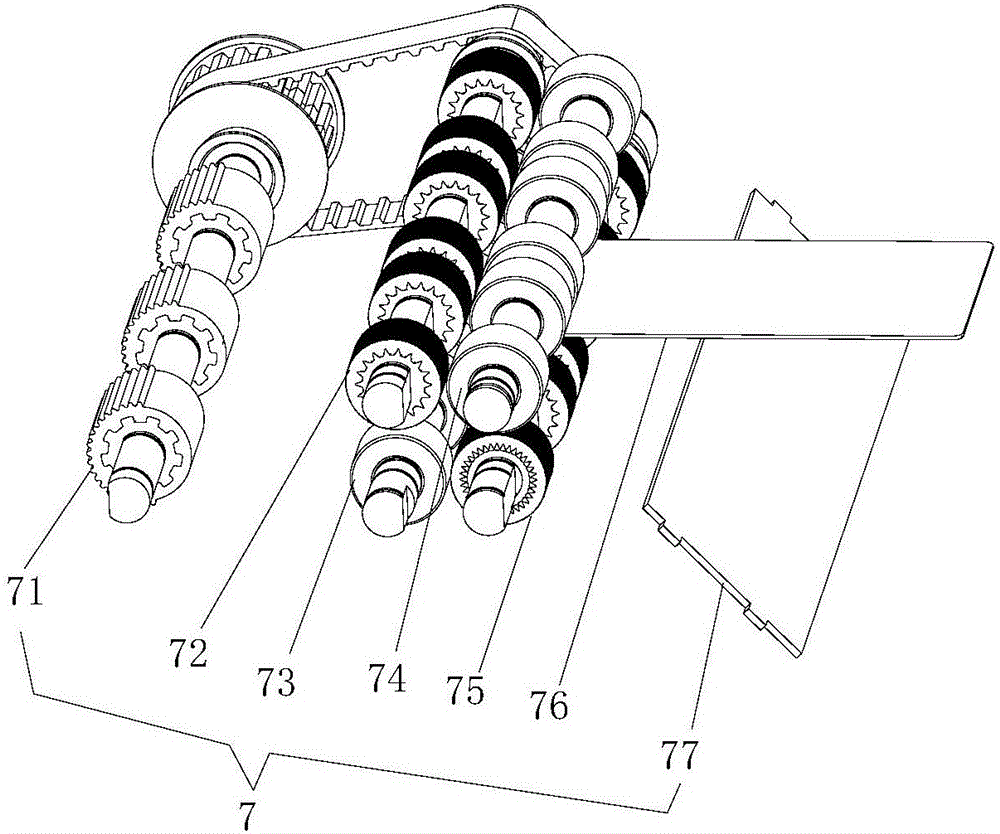

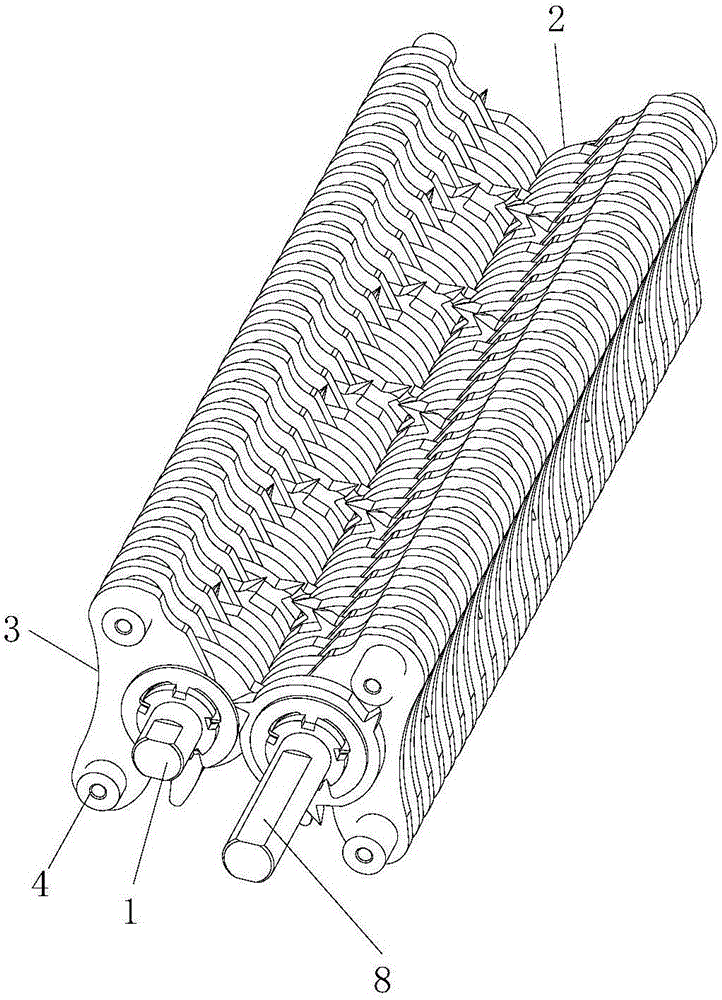

Spiral stirrup continuously and synchronously machining machine and machining method

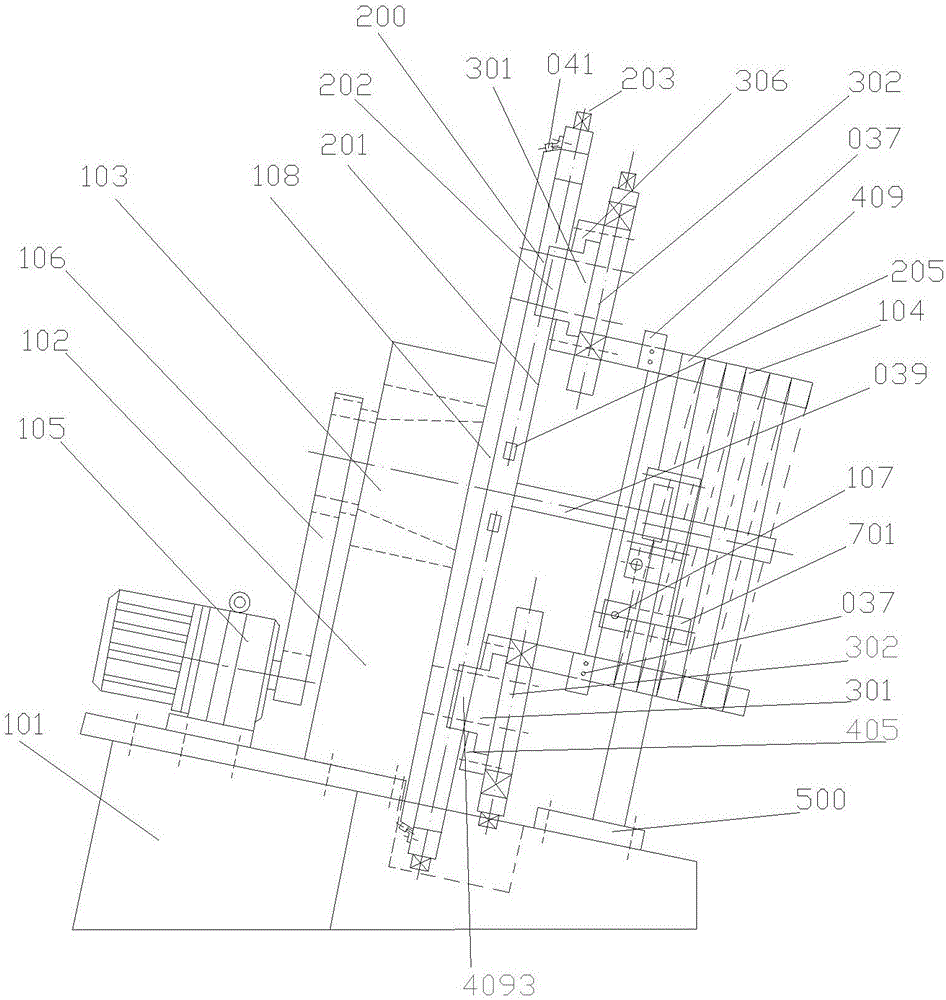

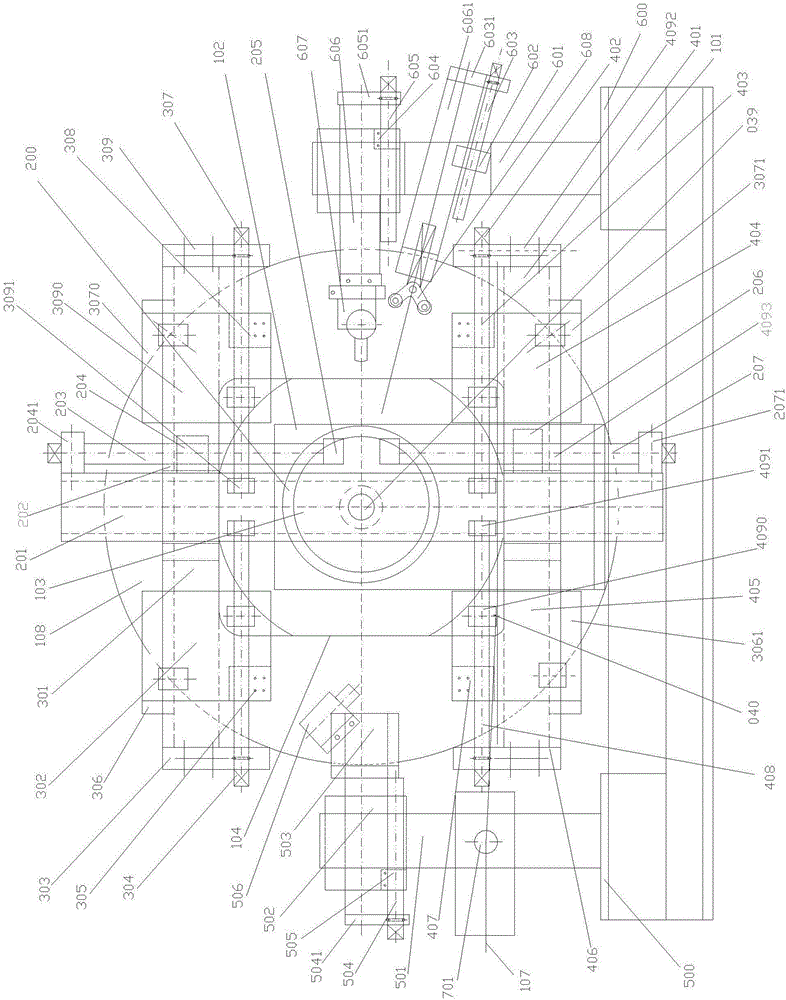

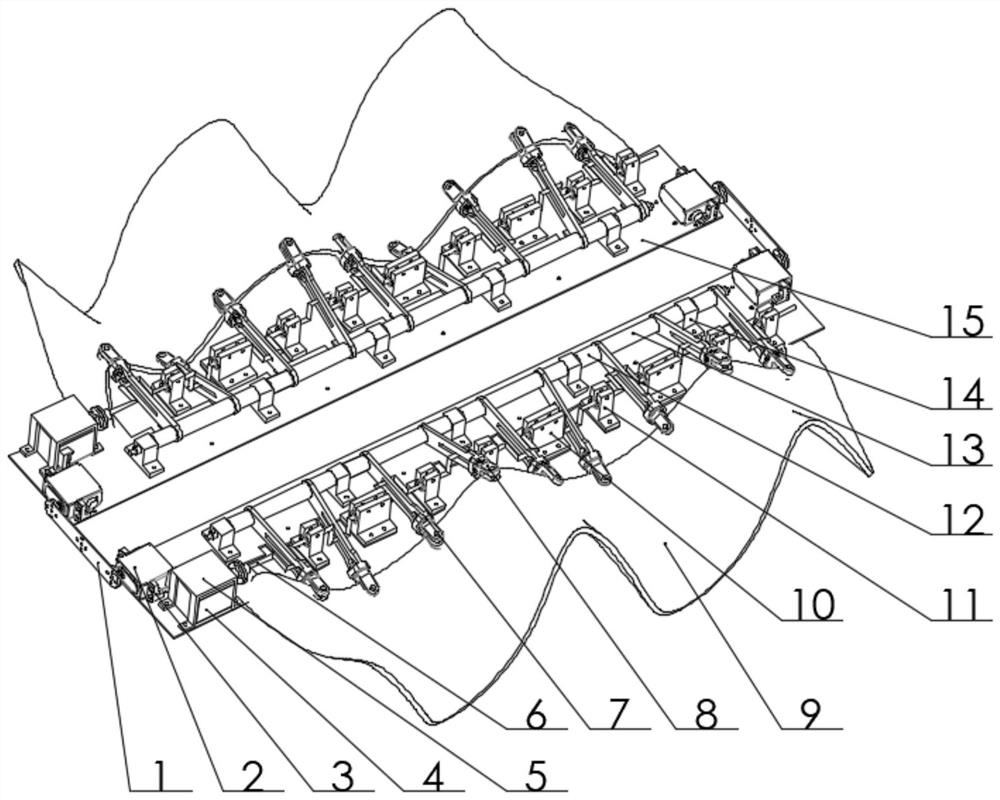

The invention discloses a spiral stirrup continuously and synchronously machining machine and a machining method. The machining machine comprises a machine body seat, a spiral stirrup machining device and a monitoring device. The spiral stirrup machining device comprises a rotary workbench, a stirrup winding mechanism, a feeding mechanism and a cutting mechanism. The stirrup winding mechanism comprises a stirrup twining frame, a rolling type bending mechanism and a screw pitch axial feed mechanism. The monitoring device comprises a control device, a counting unit and a rotating speed measuring unit. The machining method comprises the first step of determining the number of winding shafts and the installation position, the second step of adjusting the positions of the winding shafts, the third step of feeding and positioning stirrup material, the fourth step of forming spiral stirrups and the fifth step of cutting spiral stirrups. The machining machine is simple in structure, continuous machining of spiral stirrups is achieved, and the production efficiency is high; meanwhile, the concrete constraining force of beam columns of buildings can be improved through the produced spiral stirrups, and therefore the seismic capacity of the buildings is improved. Practicality is high, and the machining machine and the machining method are low in carbon, environmentally friendly and efficient and save energy.

Owner:刘国政 +1

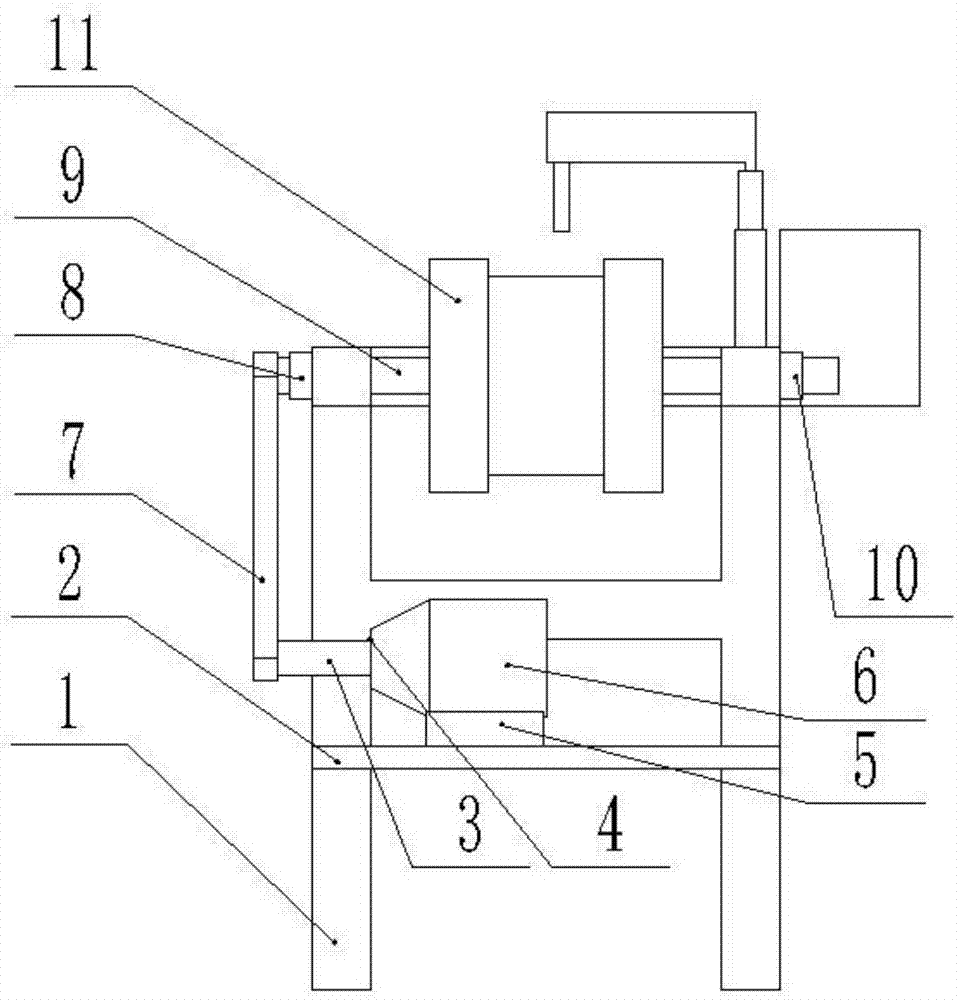

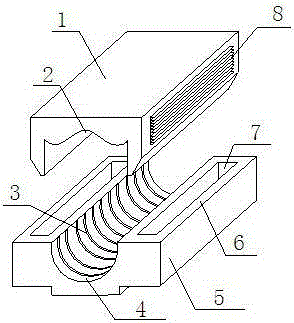

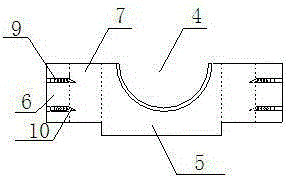

Centering clamping apparatus of ellipsoidal workpiece

PendingCN106826294APrevent axial slippageAchieve peace of mindPositioning apparatusMetal-working holdersLever pressingScrew thread

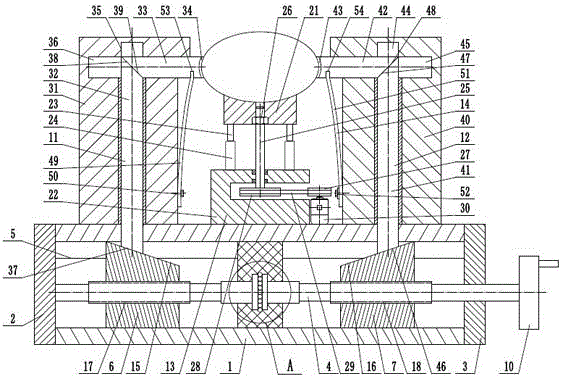

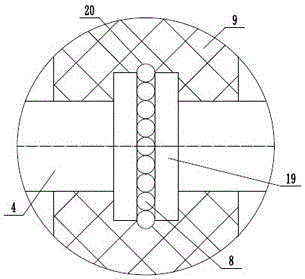

The invention provides a centering clamping apparatus of an ellipsoidal workpiece, which belongs to the technical field of a clamping device. The centering clamping apparatus comprises a screw, a left slide block, a right slide block, a left centering clamping assembly, a right centering clamping assembly, a height adjusting assembly and a return assembly, wherein both the left slide block and the right slide block can be arranged on a guiding seat in a sliding manner, a left threaded section of the screw is connected with the left slide block in a threading manner, a right threaded section of the screw is connected with the right slide block in a threading manner, a carrier frame of the height adjusting assembly is arranged on a fixed seat in an up-down sliding manner by virtue of a guide rod and a guide column, a left centering clamping assembly and a right centering clamping assembly are symmetrically arranged at the left side and the right side of the height adjusting assembly, the lower end of a left leaf spring of the return assembly is installed on a left supporting frame by virtue of a left nail, and the upper end of a right leaf spring is inserted into a right clamping groove of a right centering pressure rod. The centering clamping apparatus not only rapidly centers and clamps the ellipsoidal workpiece and is reasonable in structure, but also can be suitable for various models of ellipsoidal workpieces, and is high in universality.

Owner:全彬强

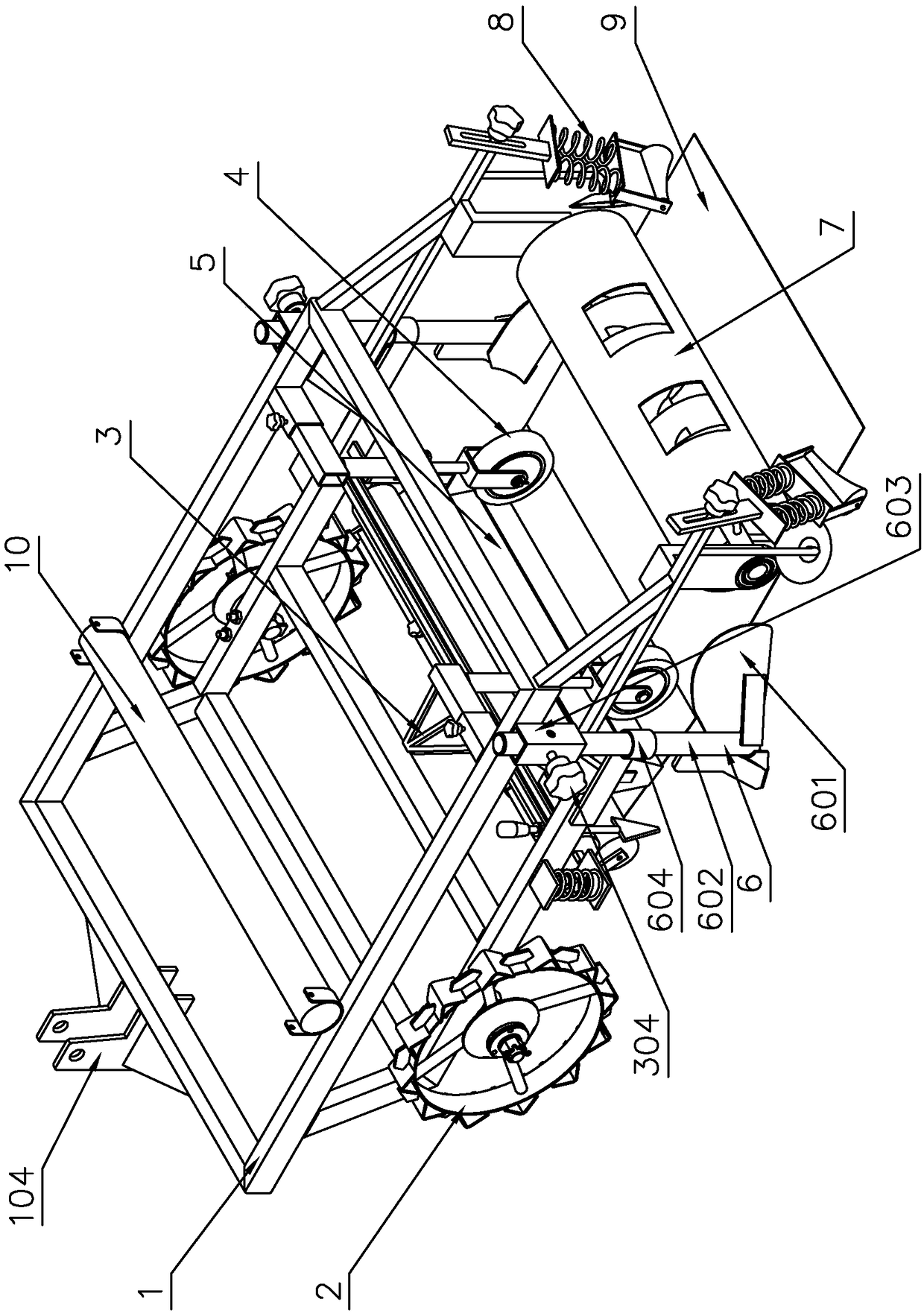

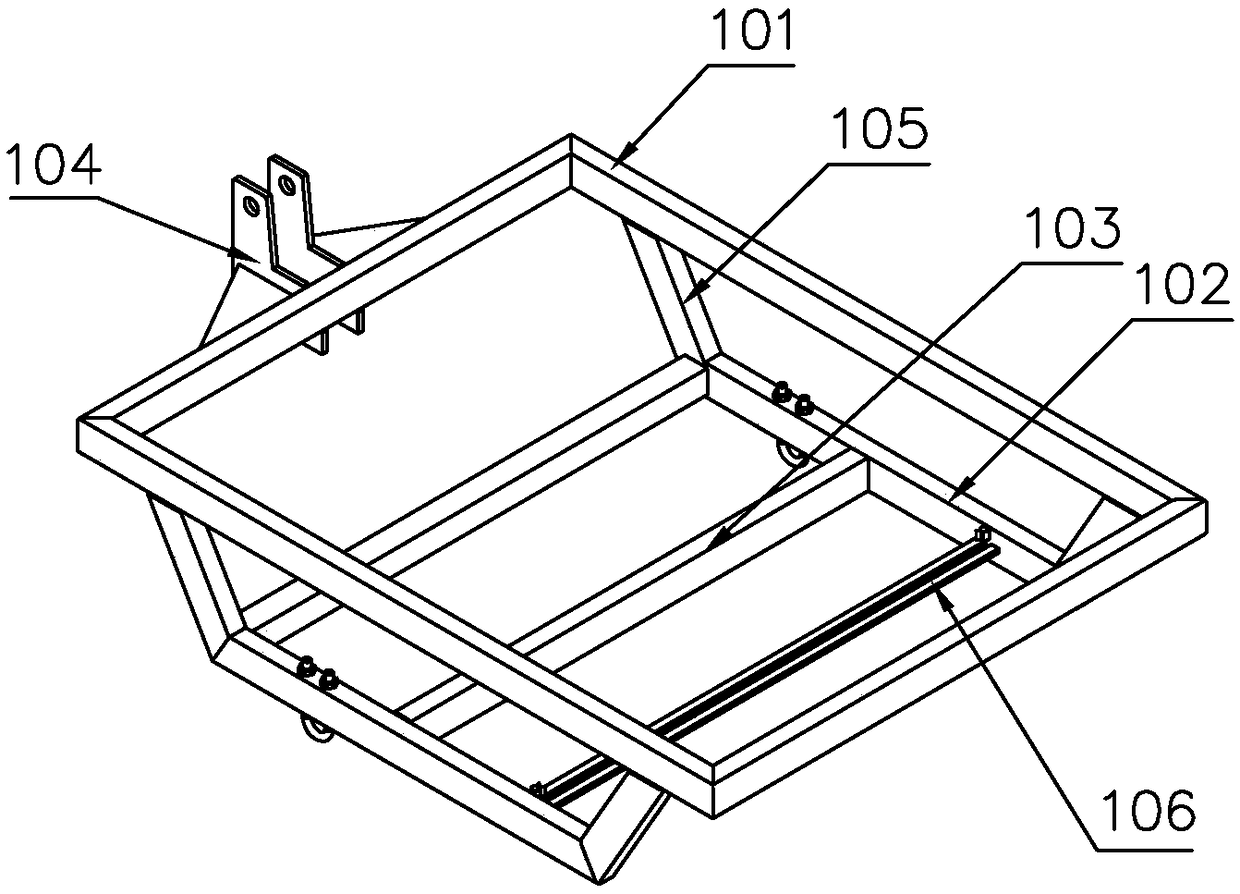

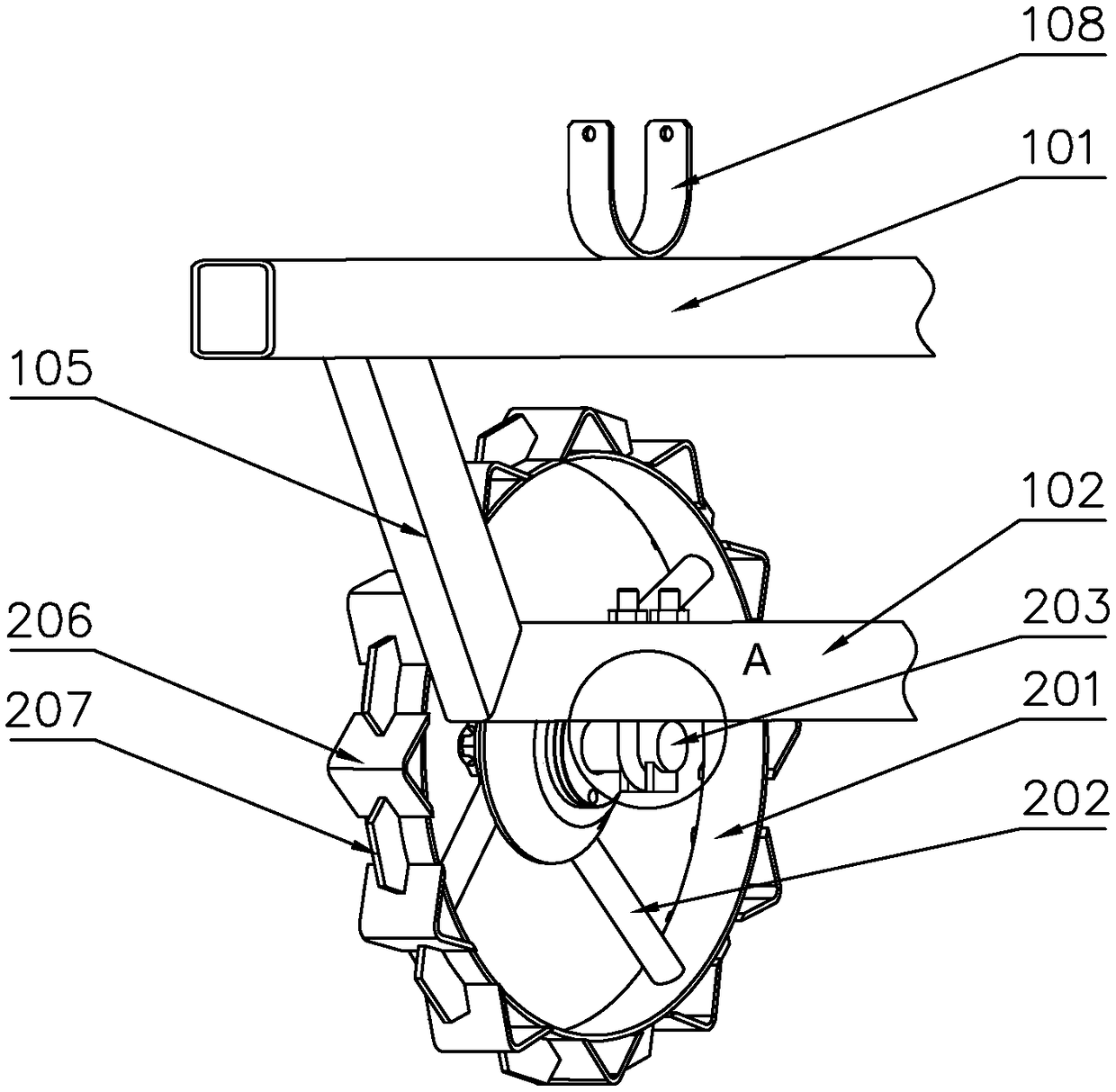

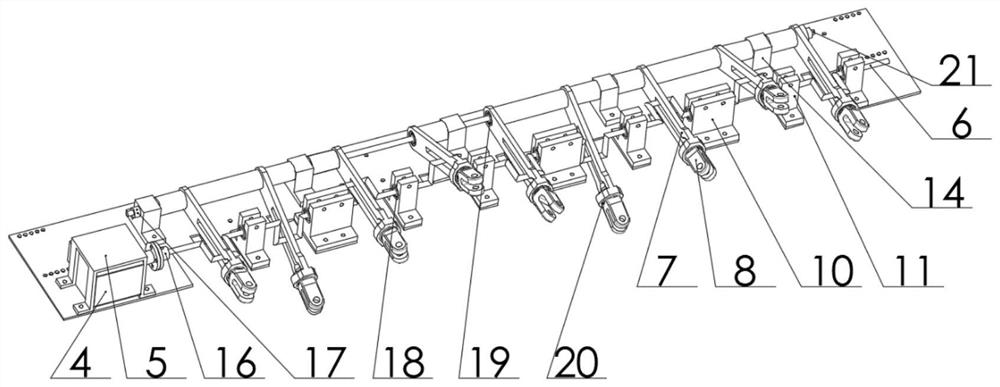

Furrow ridge film mulching device for agricultural use

ActiveCN109220426AImprove work efficiencyGuaranteed effectPlant protective coveringsVehicle frameAgricultural engineering

The invention discloses a furrow ridge film mulching device for agricultural use. The device comprises a vehicle frame, rolling wheels, a film placing mechanism, film pressing mechanisms, a soil storage box, soil covering mechanisms and soil pressing mechanisms; the rolling wheels are arranged on both sides of a lower frame, the film placing mechanism is arranged on one side of the lower frame, the soil storage box is arranged on one side of the film placing mechanism, the film pressing mechanisms are symmetrically arranged on one side of the soil storage box, the soil covering mechanisms aresymmetrically arranged on one sides of the film pressing mechanisms, and each soil pressing mechanism is arranged on one side of the corresponding soil covering mechanism. The soil storage box is arranged on the lower frame; when film mulching of one furrow ridge is completed, a film is cut by a cutter, and soil in the soil storage box drops down under the action of gravity to press the tail end of the film, so that manual soil pressing is avoided, and the work efficiency of film mulching is improved; meanwhile, the soil pressing mechanisms are arranged at the tail part of the vehicle frame tocompact the soil on both sides of the film, so that the film mulching effect is ensured, and the situation that wind enters from the sides of the film and blows the film upward is avoided.

Owner:众智机械(临沂)有限公司

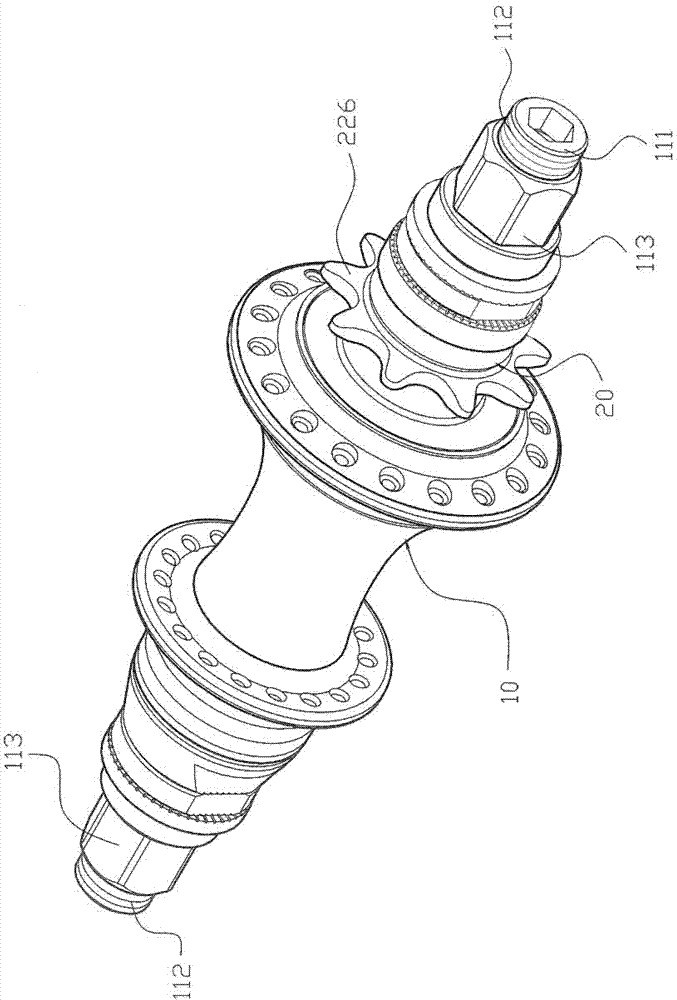

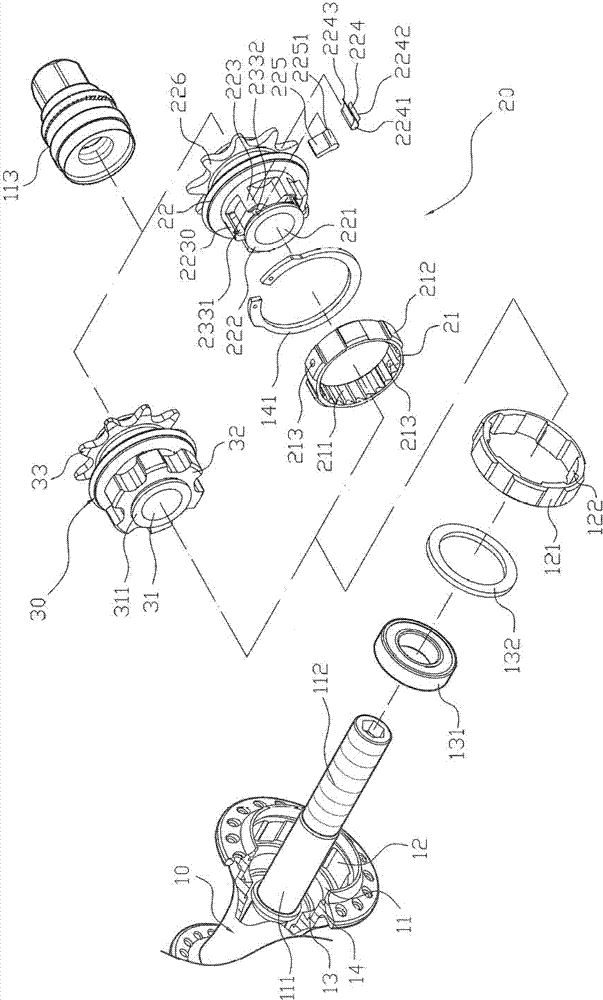

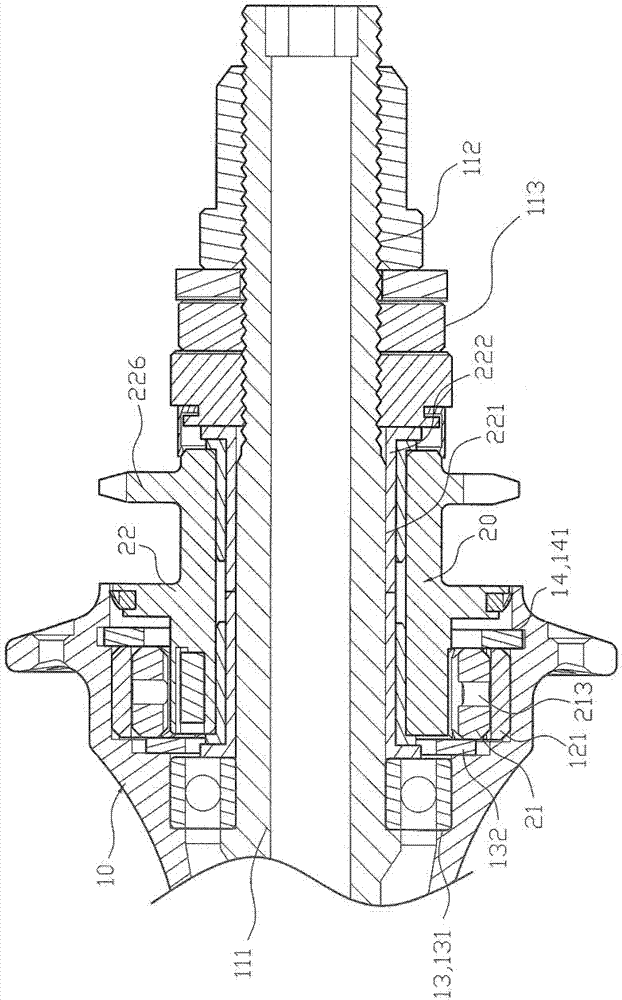

Driving device for rear hub of bicycle

The invention relates to a driving device for a rear hub of a bicycle. The driving device comprises a hub shell, a unidirectional driving component and a bidirectional driving seat, wherein the unidirectional driving component comprises a ratchet ring and a ratchet wheel seat. A plurality of unidirectionally diagonal bevel gear sides are arranged on the inner peripheral ring of the ratchet ring, a plurality of embedded ribs are arranged on the outer peripheral ring of the ratchet ring and are embedded in fastening ribs of a fixed ring of the hub shell. A plurality of groups of combining portions oppositely arranged are arranged on the outer peripheral ring of one end of the ratchet seat, and an elastic part and a pawl abutted to the bevel gear sides are assembled on the each combining portion. The bidirectional driving seat is provided with a plurality of nested ribs arranged on an end ring, and the nested ribs of the bidirectional driving seat are nested with the fastening ribs of the fixed ring of the hub shell. The driving device in the above structure can meet requirements of riders and can be switched in unidirectional driving or bidirectional driving mode, applicability of the hub is improved, required product types of enterprises are simplified, product stock is reduced and production cost is reduced.

Owner:CHOSEN

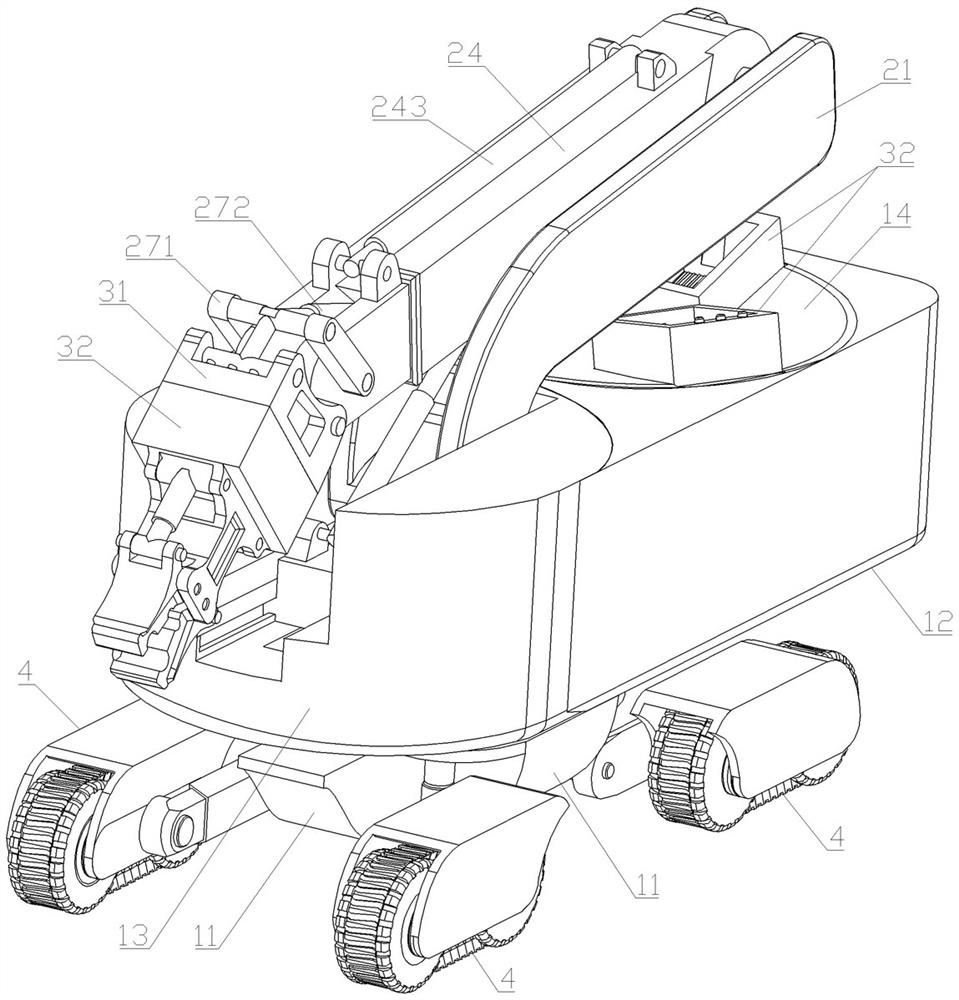

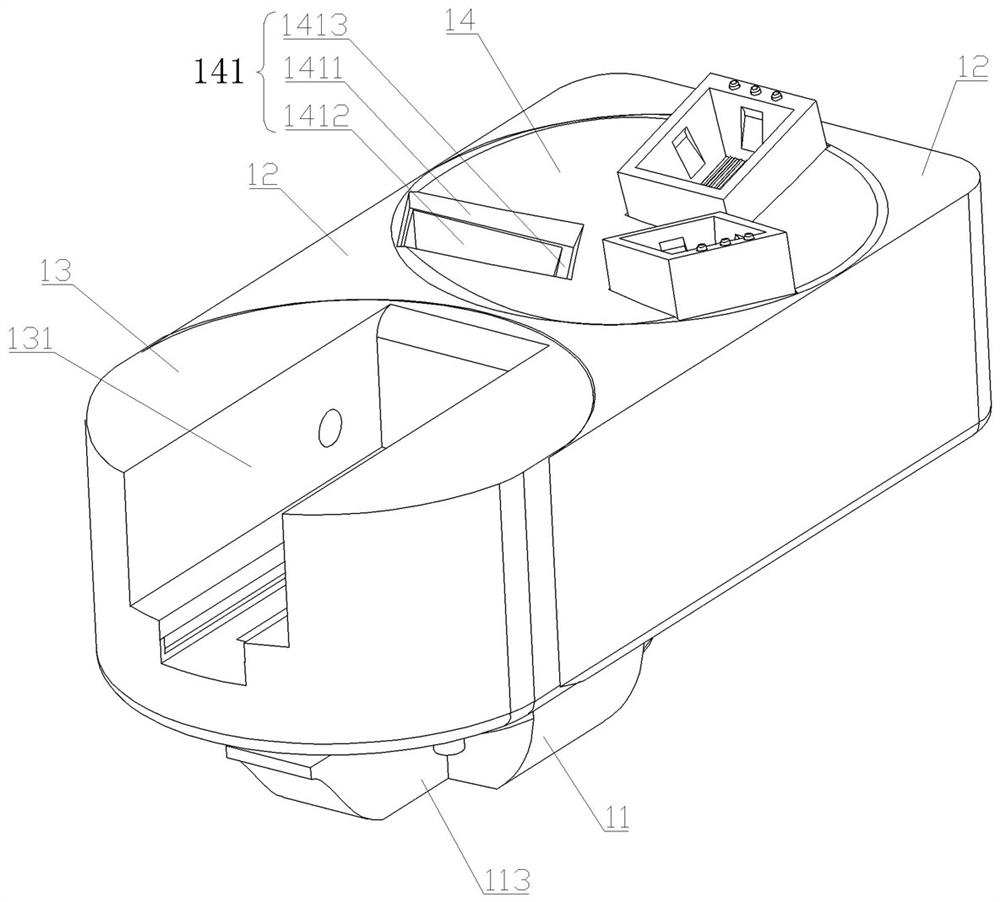

Nuclear emergency multi-functional operation robot

ActiveCN112091926AEasy maintenanceFor quick maintenanceProgramme-controlled manipulatorGripping headsPhysical medicine and rehabilitationPhysical therapy

A nuclear emergency multi-functional operation robot comprises a base, a mechanical arm, a tool replacing and connecting device and motion supporting devices, wherein the base comprises a base, a mounting seat A, a mounting seat B, a mounting seat C, a rotary driving mechanism A and a rotary driving mechanism B; the front end of the mechanical arm is connected to the mounting seat B; the tool replacing and connecting device comprises a male connector and a female connector which can be in butt joint or separated from each other; and the motion supporting devices are used for driving the motionof the nuclear emergency multi-functional operation robot. The operation robot has the advantages that various tail end tools can be integrated on the base, so that the operation robot can conveniently switch the tools to perform all kinds of operation according to operation requirements; the mechanical arm has excellent folding performance, so that the operation robot can conveniently pass through a narrow section in an operation environment; and the male connector and the female connector of the tool replacing and connecting device can realize quick butt-joint or separation, so that the operation robot can quickly switch the tools to perform all kinds of operation.

Owner:NANHUA UNIV

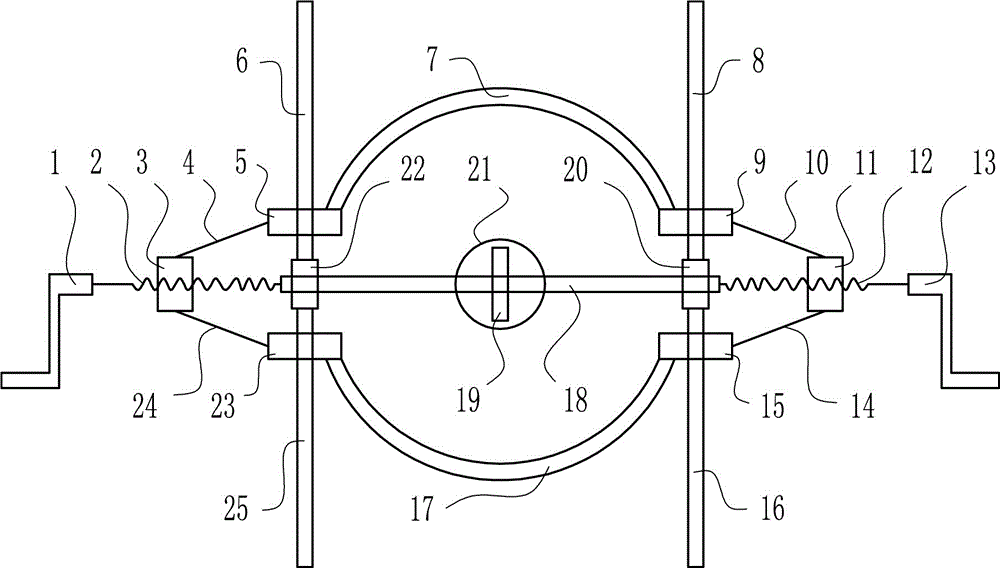

Lathe chuck capable of preventing axial sliding of workpiece

The invention relates to a chuck, in particular to a lathe chuck capable of preventing axial sliding of a workpiece. According to the technical aim, the lathe chuck capable of preventing axial sliding of the workpiece comprises a left rocking handle, a left lead screw, a left nut, a connecting rod III, a sliding block III, a sliding rod III, an upper arc fixed plate, a sliding rod II, a sliding block II, a connecting rod II, a right nut, a right lead screw, a right rocking handle, a connecting rod I, a sliding block I, a sliding rod I, a lower arc fixed plate, a cross rod, a fixed block, a right bearing, a connecting shaft, a left bearing, a sliding block IV, a connecting rod IV and a sliding rod IV. The right lead screw is arranged on the left side of the right rocking handle. According to the lathe chuck capable of preventing axial sliding of the workpiece, by means of the structure of the vertically symmetric arc fixed plates and cooperation of the nuts and the lead screws, the center of the workpiece can be located conveniently.

Owner:西安朋邦工贸有限公司

Pipeline repair device

ActiveCN106439374AAvoid accelerated agingPrevents axial seal grooves or blowoutsPipe elementsEngineeringButt joint

The invention discloses a pipeline repair device which comprises an upper shell body, a lower shell body and sealing gaskets arranged on the upper shell body and the lower shell body correspondingly. Flange and bolt connecting pieces used for joining the upper shell body and the lower shell body into a whole shell in a butt joint mode are arranged on the two sides of the upper shell body and the lower shell body correspondingly. Each sealing gasket comprises radial sealing bodies and axial sealing bodies. The upper shell body and the lower shell body are each provided with radial sealing grooves and axial sealing grooves used for installing the radial sealing bodies and the axial sealing bodies correspondingly. The upper shell body or the lower shell body is provided with protruding protective walls arranged on the outer sides of the axial sealing grooves. When the upper shell body and the lower shell body are in a relatively butt joint state, the protective walls closes gaps between correspondingly flanges from the outsides. By adoption of the pipeline repair device, the situation that accelerated aging of the sealing gaskets are caused by exposure out of the shell can be effectively prevented; and meanwhile, the defect that the portions, located in the axial grooves, of the sealing gaskets are squeezed out of the sealing grooves or burst due to overlarge pressure can be overcome, the anti-pressure ability and the reliability are greatly improved, and the sealability and reliability are higher.

Owner:安徽欧泰祺智慧水务科技有限公司

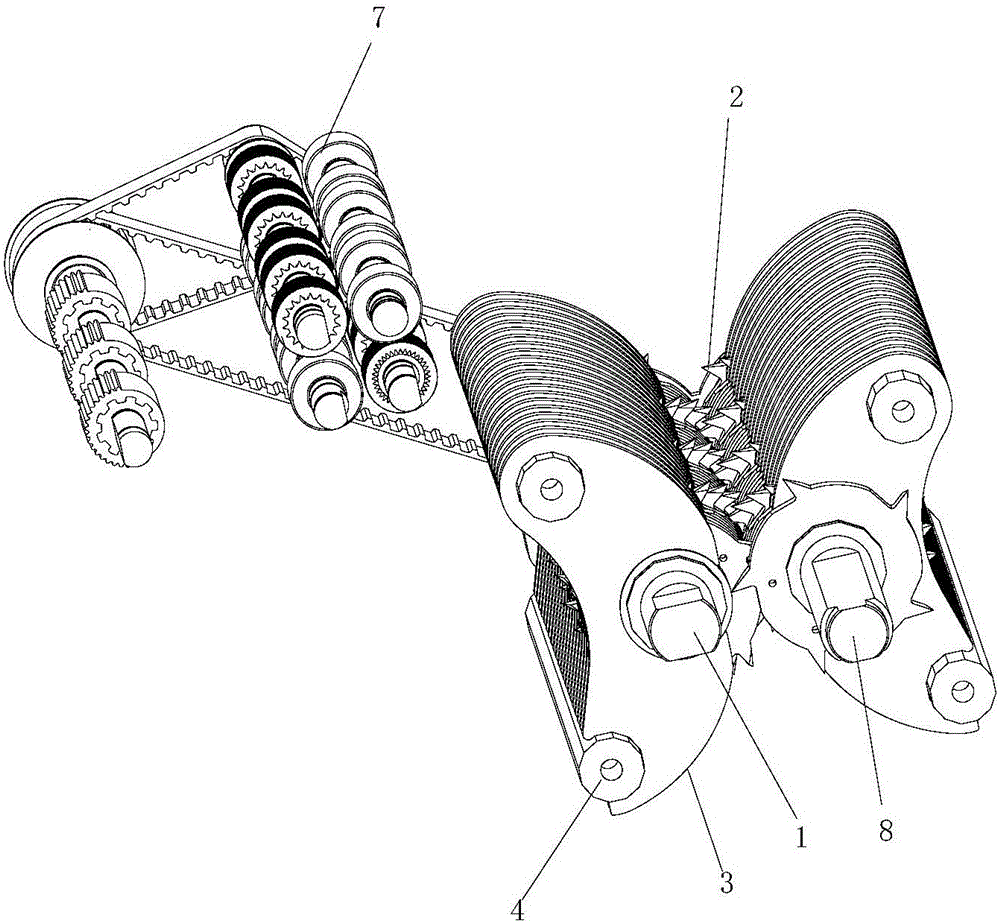

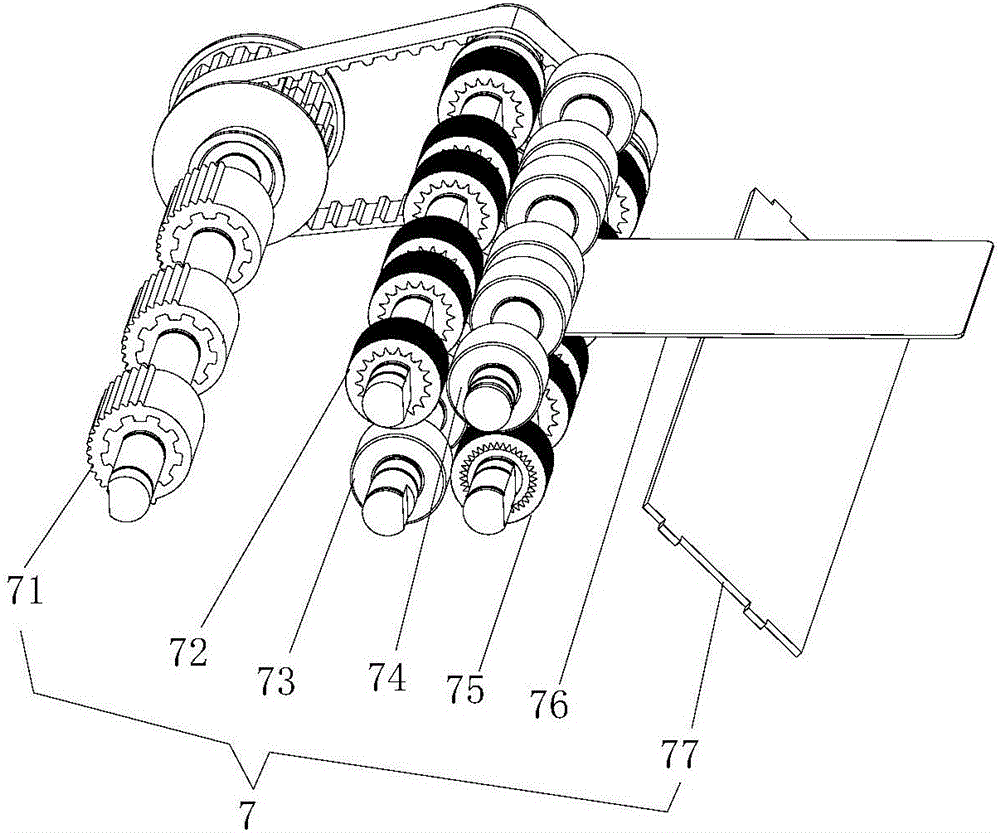

Fin ray-free amphibious propelling device with bionic undulating fins

PendingCN113696685AImprove flexibilityEnough supportAmphibious vehiclesPropulsive elements of non-rotary typeMarine engineeringCam

The invention discloses a fin ray-free amphibious propelling device with bionic undulating fins, which is characterized in that two end fixed type crankshaft swing rod transmission modules are arranged on corresponding bottom plates correspondingly, and the front ends and the rear ends of the two bottom plates are connected with a front waterproof steering engine amphibious mode switching module and a rear waterproof steering engine amphibious mode switching module correspondingly; the front and back waterproof steering engine land and water mode switching module is used for maintaining the state of the bottom plate; each end fixed type crankshaft swing rod transmission module is connected with one flexible fin-ray-free flexible fin through the corresponding drive swing rod mechanism, and the joint of each drive swing rod mechanism and the corresponding flexible fin-ray-free flexible fin is provided with a rotational degree of freedom to drive the fin surface of the corresponding flexible fin-ray-free flexible fin to achieve fluctuating motion. The problems that an existing amphibious robot is complex in transmission mechanism, complex in amphibious mode switching, large in wheel paddle driving noise, low in flexibility and large in environment disturbance, the movement speed of fluctuation fins driven by a conventional steering engine is low, and a traditional cam and crankshaft connecting rod mechanism is low in bearing capacity and cannot conduct amphibious movement are solved.

Owner:XI AN JIAOTONG UNIV

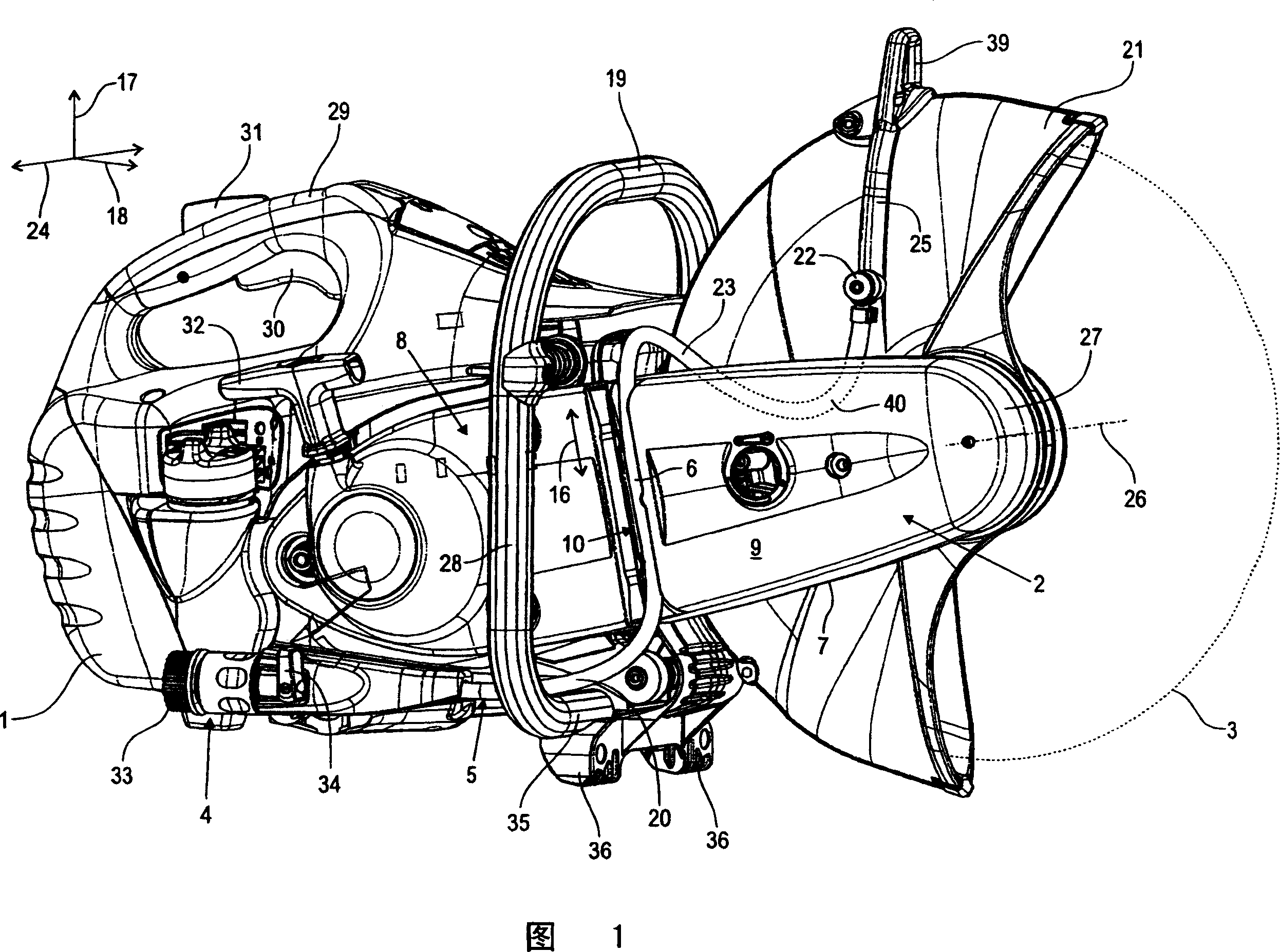

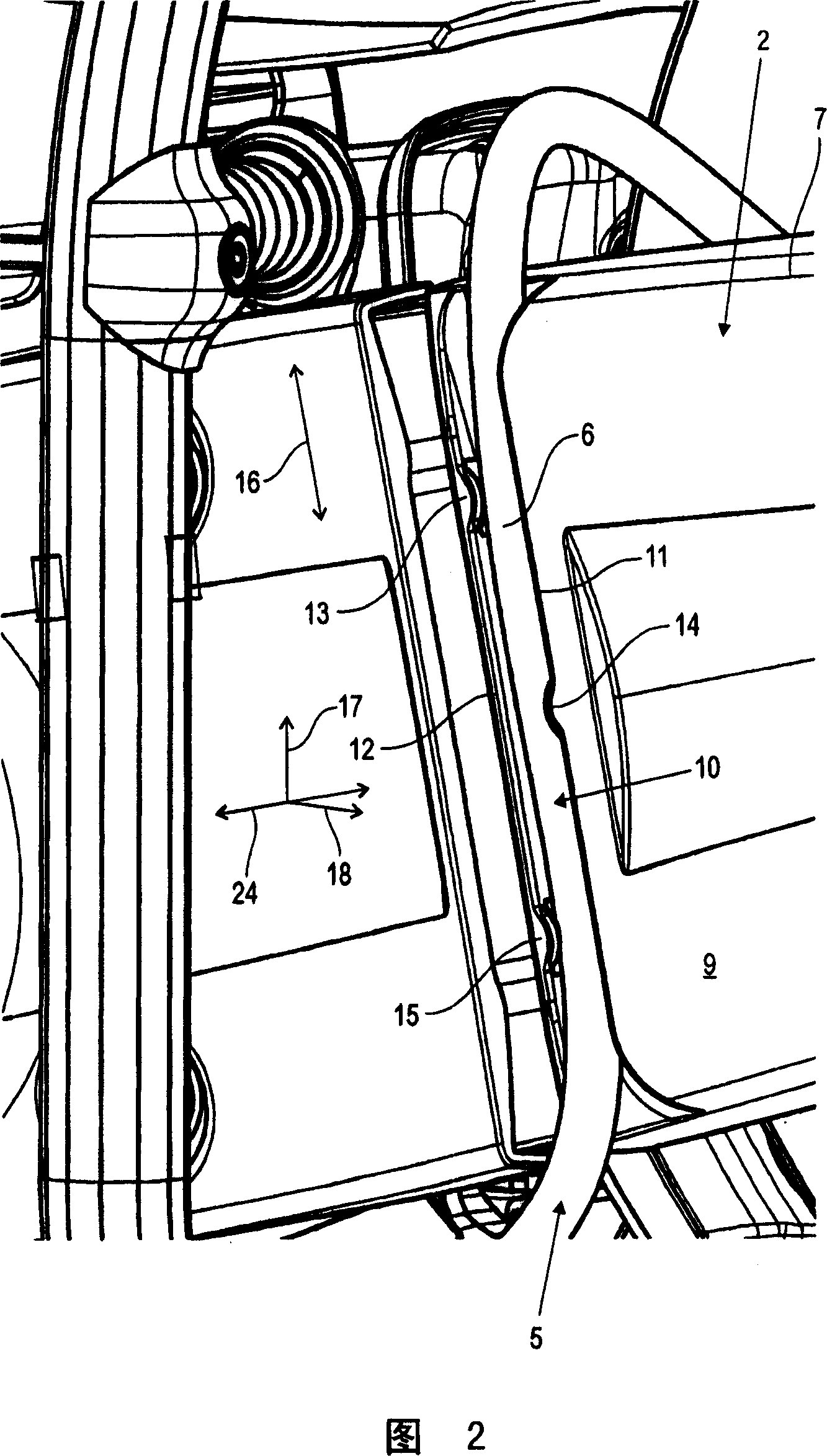

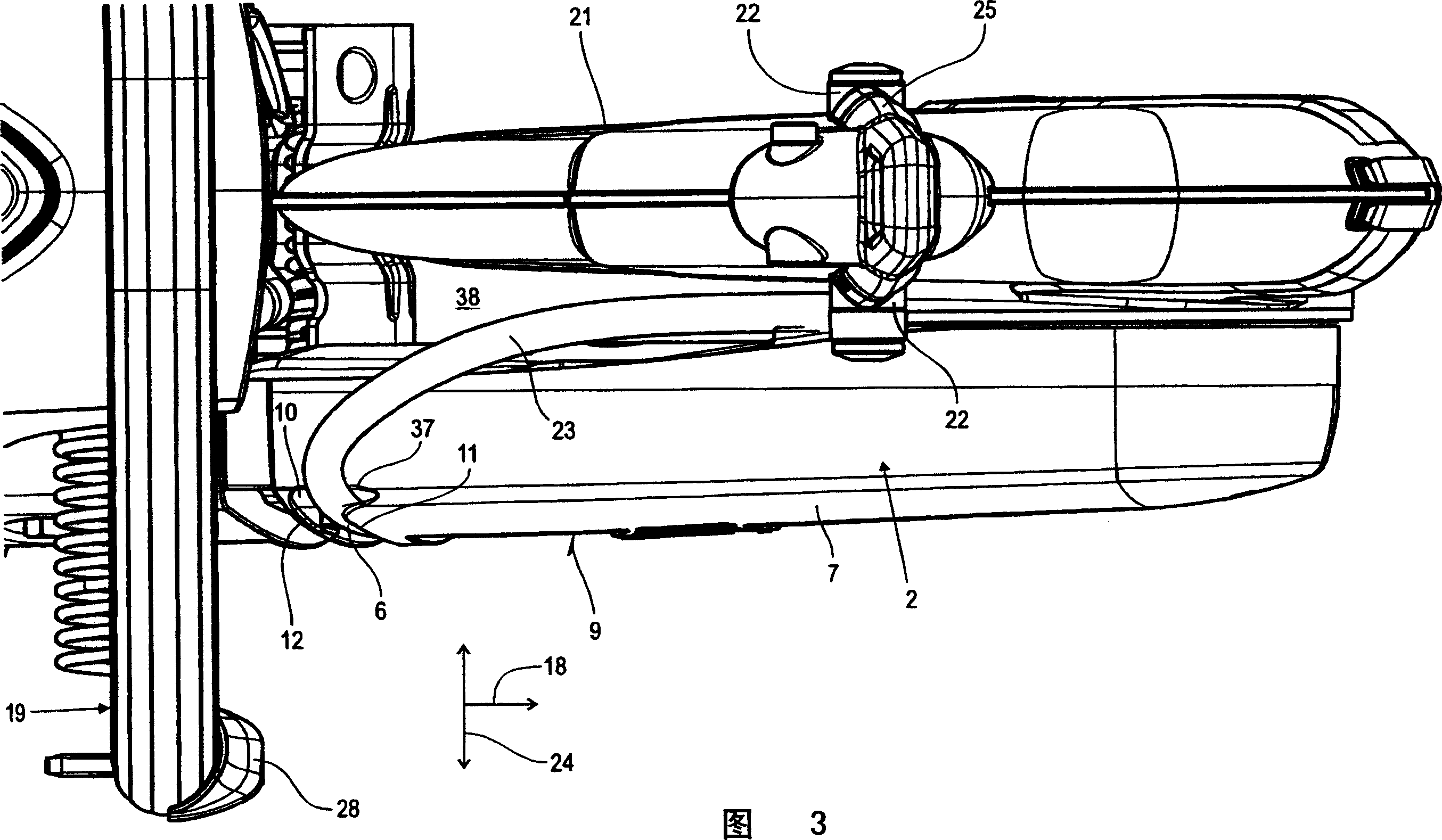

Hand-held cut-off machine

ActiveCN1951633AAvoid damageReduce riskMetal sawing accessoriesWorking accessoriesHand heldDrive motor

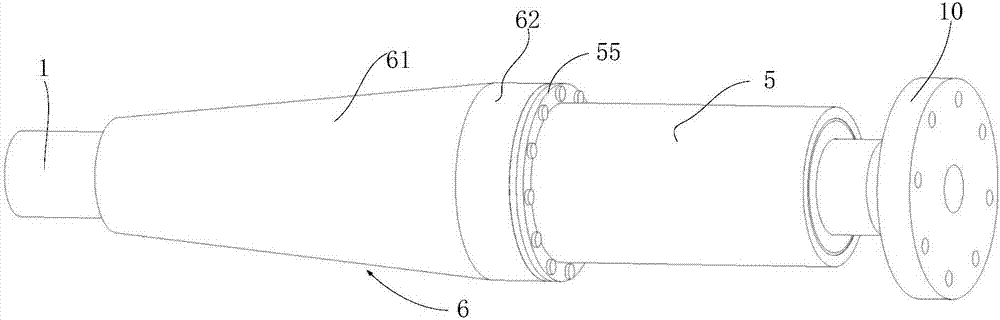

The invention relates to a portable grinding wheel cutting machine, which has a motor casing (1) installed with a driving motor, a saw blade grinding wheel (3) driven by the driving motor and supported on a cantilever (2) and a secondary water pipe The joint (4) leads to the water delivery pipe (5) of the saw blade grinding wheel. A section (6) of the pipeline (5) is built into the cantilever (2).

Owner:ANDREAS STIHL AG & CO KG

Assembling device for medical glass slide

InactiveCN107052747ARealize self-assemblyEasy to operateMetal working apparatusDrive wheelDrive motor

The invention discloses an assembling device for a medical glass slide. The assembling device comprises a machine frame and a supporting plate which are used for playing a supporting role. The machine frame is provided with a driving wheel and a driven wheel. The front side of the machine frame is provided with a start key and a stop key. The driving wheel and the driven wheel are connected together through a material conveying belt. Two support plates are fixed to the supporting plate. A driving motor is installed on the support plates and stretches out of a motor shaft. The motor shaft and the driving motor are connected through a motor buffer plug. The motor shaft and the driving wheel are connected together through a deceleration conveying belt. The assembling device has the advantages that the medical glass slice can be automatically assembled, operation is easy, and the automation degree is high.

Owner:鲁曦

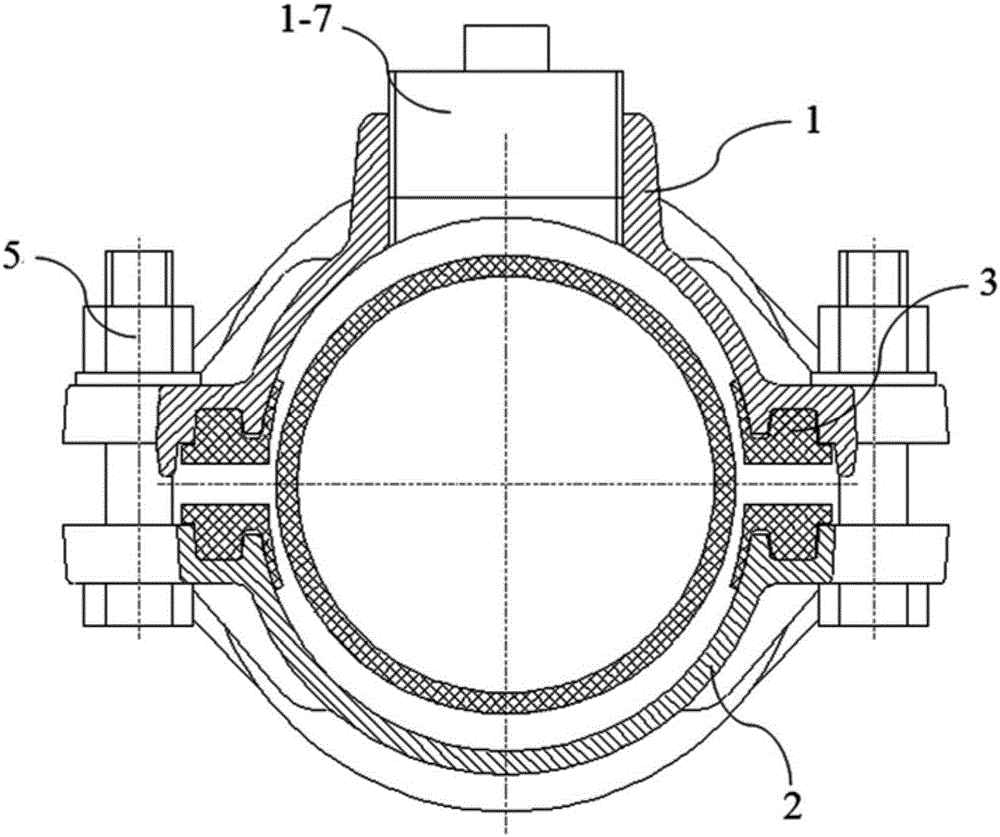

Slippage-preventing flexible pipe joint

ActiveCN106247053AImprove skid resistancePrevent axial slippageCorrosion preventionPipe protection against corrosion/incrustationPipe fittingBiomedical engineering

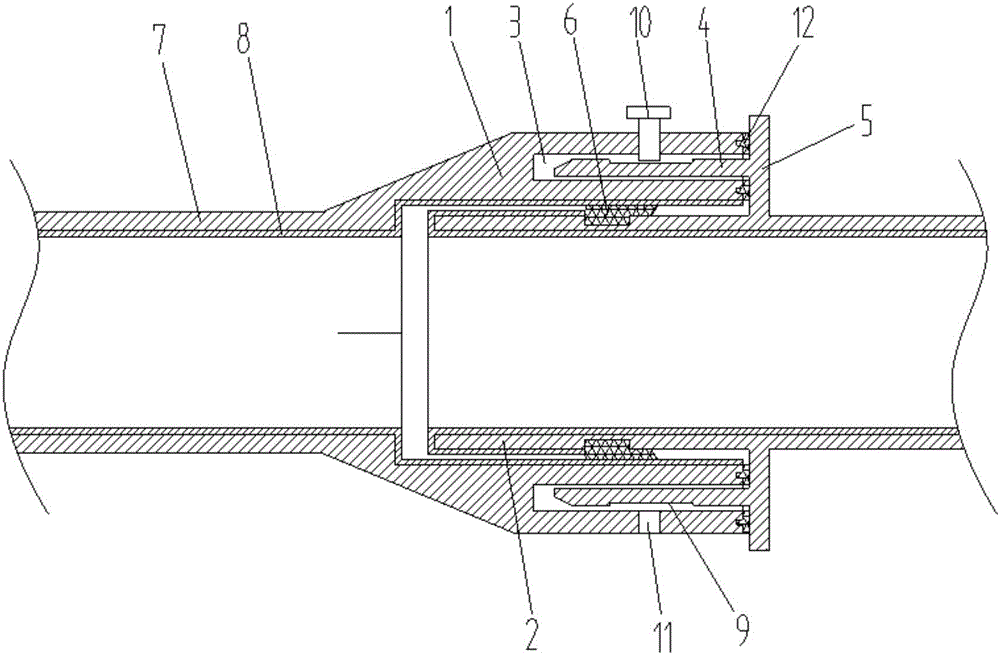

The invention discloses a slippage-preventing flexible pipe joint, which comprises a socket and a spigot which are matched in manner of insertion on a pipe fitting; a seal ring is arranged between the socket and the spigot; a circular ring-shaped seizing groove coaxial with the center hole of the socket is formed in the end face of the socket; correspondingly, a cutting sleeve which is coaxial with the spigot and can be inserted into the seizing groove also sheathes the outer wall of the spigot; limiting grooves are circumferentially formed in the outer wall of the cutting sleeve in manner of surrounding the spigot; a plurality of through holes communicating with the seizing groove are formed along a radial direction in the outer wall of the socket; each through hole is matched with a limiting pin; after the socket and the spigot are matched in manner of insertion, the cutting sleeve correspondingly extends into the seizing groove, and position of each limiting groove is matched with that of the corresponding through hole. According to the slippage-preventing flexible pipe joint, after the socket and the spigot are matched in manner of insertion, the cutting sleeve also correspondingly extends into the seizing groove, and each limiting pin is seized into the corresponding limiting groove from the through hole, and therefore, the goal of preventing the socket and the spigot from axially slipping is achieved.

Owner:QINHUANGDAO TAIDY FLEX TECH

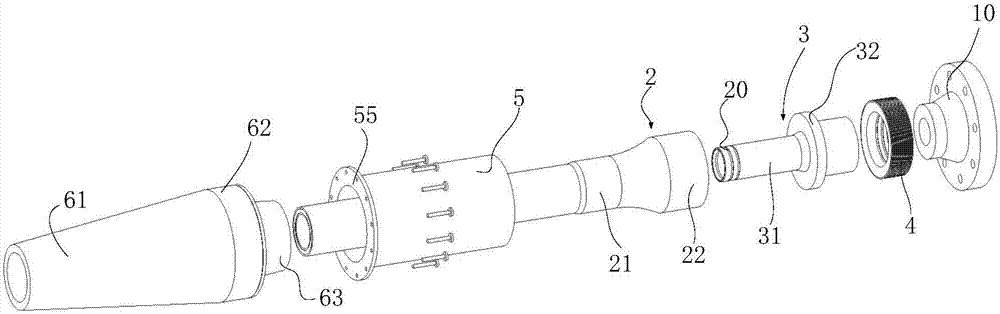

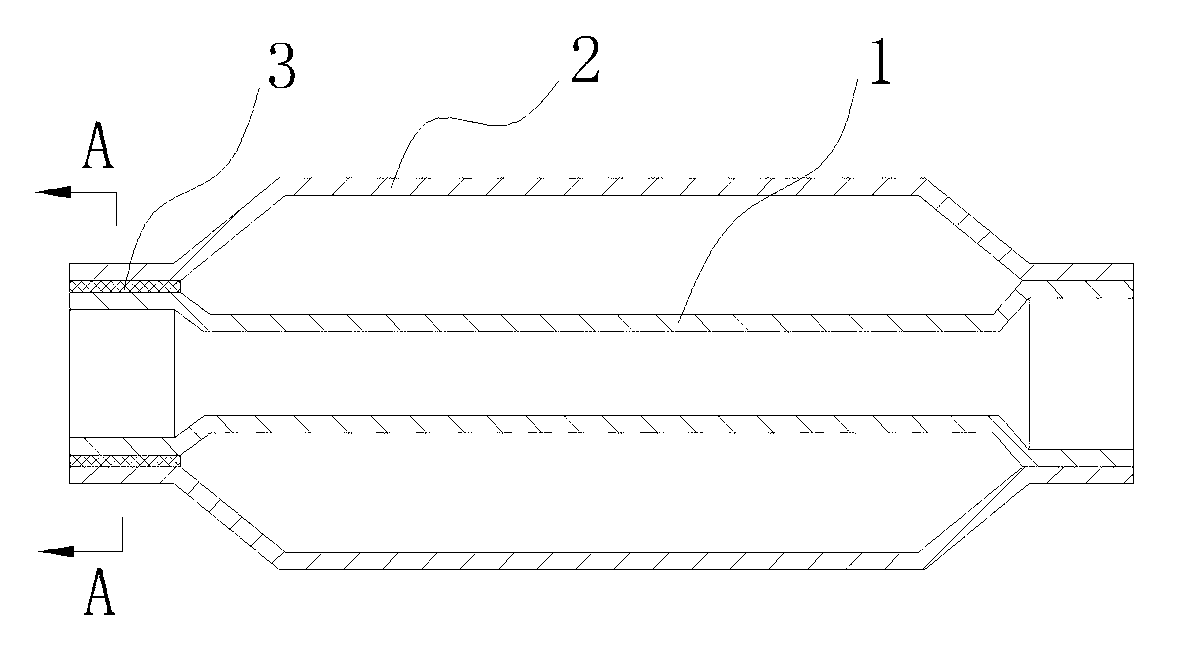

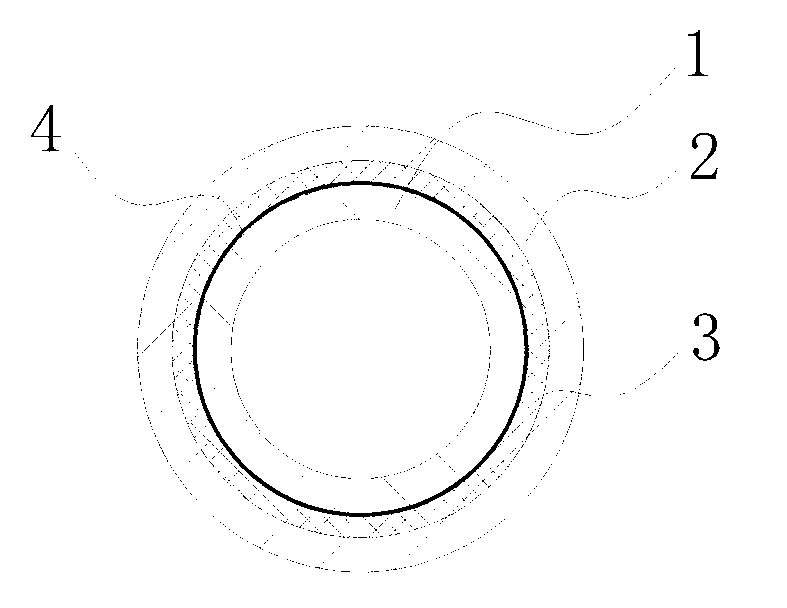

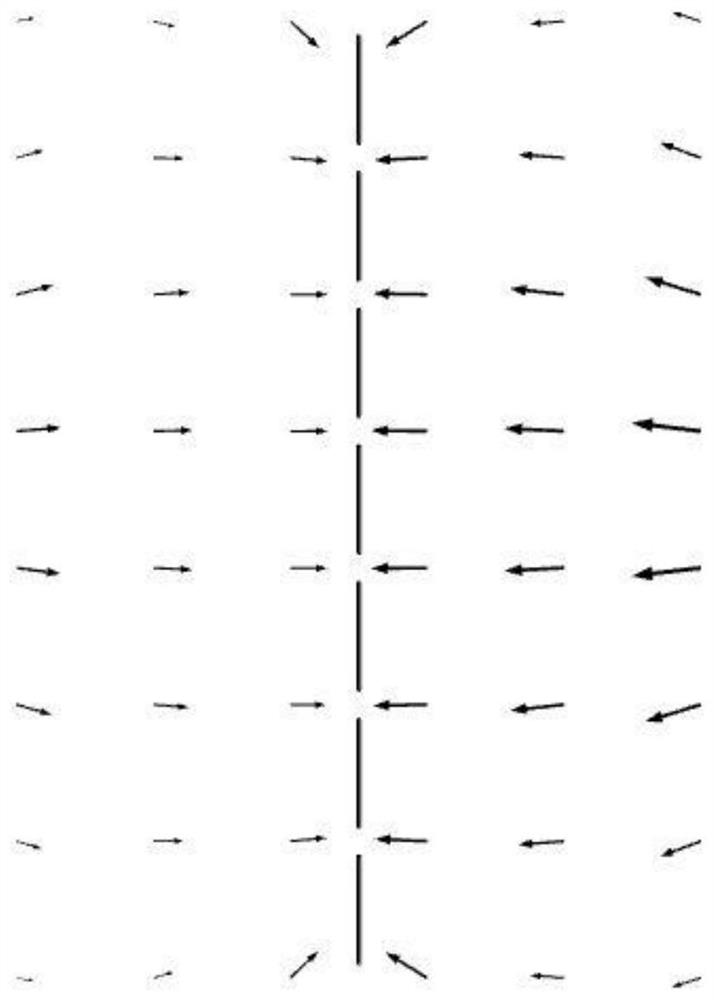

Double-limitation connecting system for marine fiber reinforced composite pipe

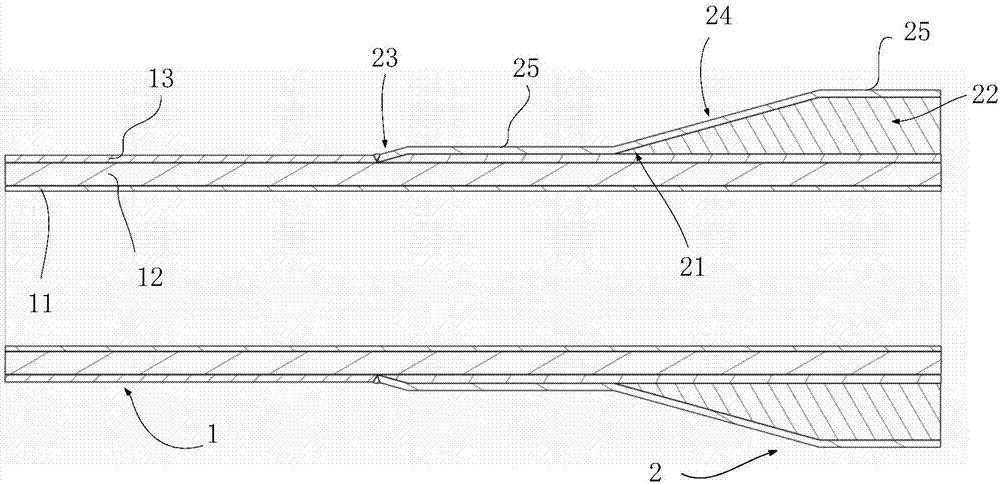

ActiveCN107477281AImprove tensile propertiesImprove stress resistanceSleeve/socket jointsFlanged jointsEngineeringFiber-reinforced composite

The invention discloses a double-limitation connecting system for a marine fiber reinforced composite pipe. The double-limitation connecting system comprises a thickened pipe portion and a connecting portion; the thickened pipe portion is bonded with the composite pipe and comprises a first thickened layer and a second thickened layer arranged on the outer side of the back half section of the first thickened layer, and the composite pipe, the first thickened layer and the second thickened layer are in transition connection with one another through conical surfaces; the connecting portion comprises a clamping part, an inner spindle and a locking ring, the clamping part is arranged on the outer side of the thickened pipe portion, and a front-end plug of the inner spindle is inserted into the composite pipe and generates initial interference; the conical surface of the second thickened layer is matched with the conical surface of the corresponding portion of the clamping part, the thickened pipe portion is subjected to the axial geometric limitation and the friction force action generated on the contact surface under the action of external force, and then double limitation of clamping locking and mechanical clamping of the connecting portion on a pipeline and the thickened pipe portion is achieved; meanwhile, the two thickened layers effectively share the pipe body stress, and therefore the bearing capacity of the connecting system is significantly improved. The connecting system is high in structural strength and good in bearing performance and can be applied to deep-sea, high-temperature and complex using environments.

Owner:OCEAN UNIV OF CHINA

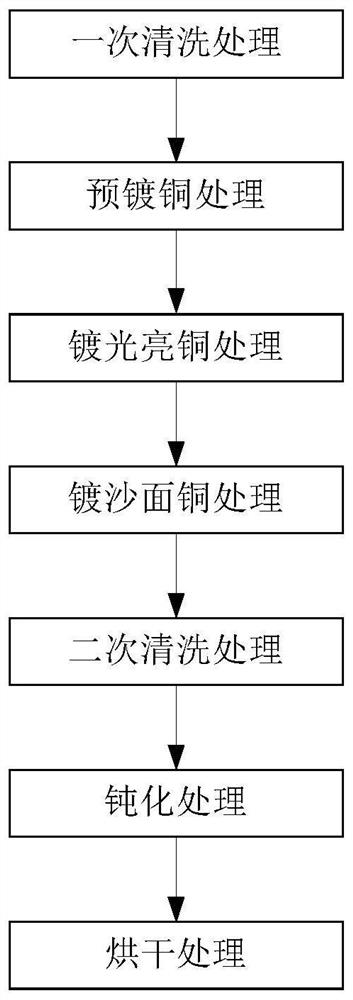

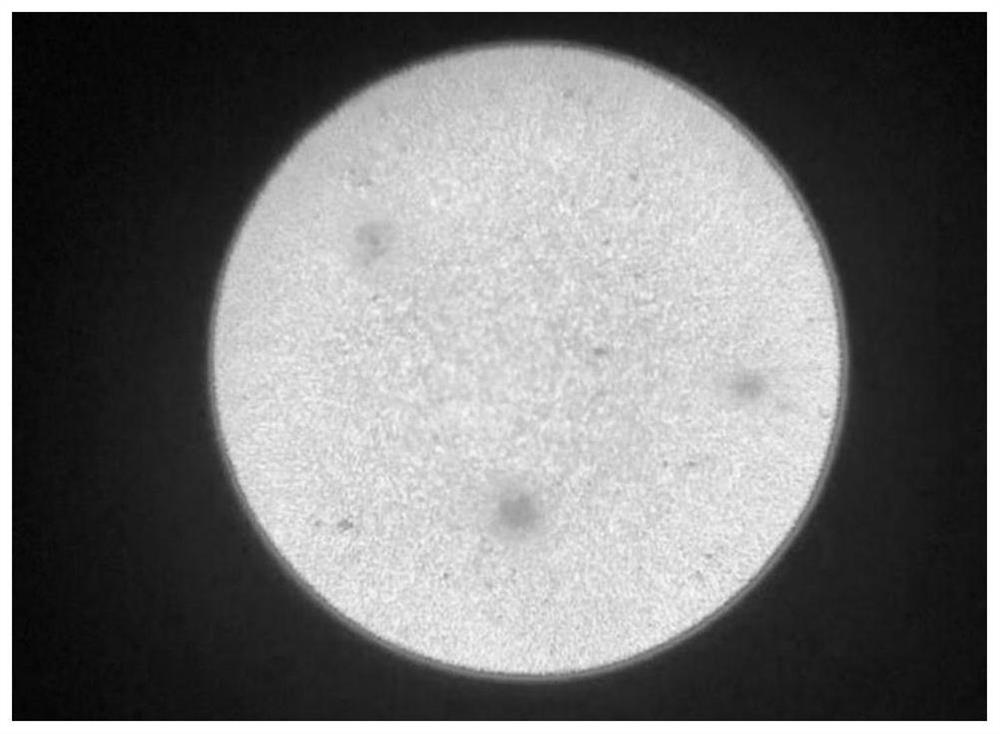

Copper pre-plating method, copper plating method and copper plating device for superconducting strip

PendingCN113089038AQuality improvementProvides plating efficiencyElectrolysis componentsCopper platingElectroplating

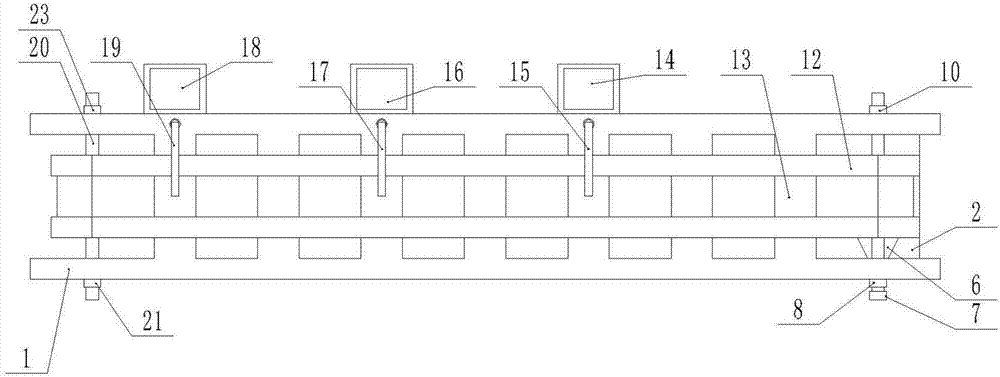

The invention provides a copper pre-plating method, a copper plating method and a copper plating device for a superconducting strip. The copper plating device for the superconducting strip comprises a discharging mechanism, a first cleaning mechanism, a copper pre-plating mechanism, a bright copper plating mechanism, a sand surface copper plating mechanism, a second cleaning mechanism, a passivation mechanism, a drying mechanism and a collecting mechanism. The discharging mechanism is used for unwinding the machined strip, the machined strip sequentially passes through the first cleaning mechanism, the copper pre-plating mechanism, the bright copper plating mechanism, the sand surface copper plating mechanism, the second cleaning mechanism, the passivation mechanism and the drying mechanism during machined and is wound on the collecting mechanism, the copper pre-plating mechanism adopts first current electroplating treatment, the bright copper plating mechanism adopts third current electroplating treatment, and the sand surface copper plating mechanism adopts second current electroplating treatment. By adopting the design of copper pre-plating, copper plating and the like, the problem that a superconducting layer is corroded by liquid is solved, and meanwhile, the electroplated superconducting strip is good in quality and high in electroplating efficiency.

Owner:SHANGHAI SUPERCONDUCTOR TECH CO LTD

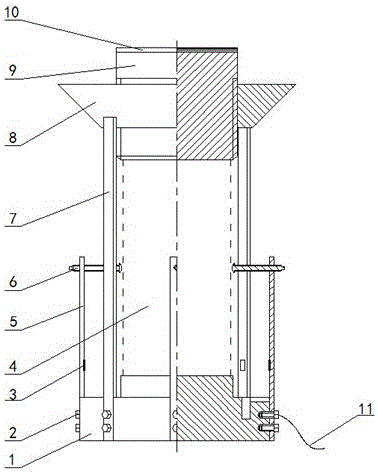

Static deformation experiment device for testing low-strength test piece

InactiveCN106525590APrevent axial slippageEasy to install and debugMaterial strength using tensile/compressive forcesObservational errorEngineering

The invention relates to a static deformation experiment device for testing a low-strength test piece. The technical scheme is that the static deformation experiment device comprises a testing device and a pressure transmitting device, wherein the testing device, the test piece (4) and the pressure transmitting device constitute a test piece testing body. Eight axial grooves (14) are uniformly formed along a generatrix of a large cylinder of a base (1), lower ends of radial strain measuring rods (5) and axial strain measuring rods (7) are fixed in the corresponding axial grooves (14) through screws (2) respectively, and the radial strain measuring rods (5) and the axial strain measuring rods (7) are in alternative distribution; big-head screws (6) are connected with upper ends of the radial strain measuring rods (5) through threads, electric resistance strain gauges (3) are attached to the radial strain measuring rods (5) and the axial strain measuring rods (7) respectively, and each electric resistance strain gauge (3) is externally connected with a strain indicator or a computer through a corresponding signal line (11); a gland (8) and a pressure head (9) are in threaded connection, and a rubber pad (10) adheres to the upper plane of the pressure head (9). The static deformation experiment device has the characteristics of convenience in mounting and debugging and small measurement errors.

Owner:WUHAN UNIV OF SCI & TECH

Wire connection fitting

InactiveCN105226585APrevent radial looseningEasy to loosenOverhead installationEngineeringMechanical engineering

The invention discloses a wire connection fitting, which belongs to the field of power tools. The wire connection fitting comprises a base and a wire pressing plate, wherein the wire pressing plate comprises a crossbeam part and two vertical insertion plates fixedly connected with two sides of the crossbeam part respectively; the crossbeam part is provided with a first wire groove; the inner wall of the first wire groove is provided with a plurality of anti-slip stripes vertical with the central axis of a to-be-connected wire; the bottom part of each vertical insertion plate is slope-shaped, and the outer side surface of the vertical insertion plate is provided with a plurality of clamping teeth; the base is provided with a second wire groove; the inner wall of the second wire groove is provided with a plurality of anti-slip stripes vertical with the central axis of the to-be-connected wire; two side walls of the second wire groove are respectively provided with a locking groove; the wall of the locking groove is provided with a plurality of elastic part mounting holes from top to bottom; an elastic part is horizontally arranged inside the elastic part mounting hole; and the tail end of the elastic part is fixedly connected with a locking tongue engaged with the clamping tooth. The wire connection fitting has the advantages that the structure is simple, the operation is convenient, manpower is saved, and the wire can be connected high efficiently and firmly.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

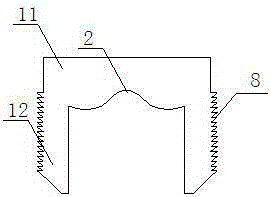

Winding machine capable of adjusting chemical fiber yarn winding paper tube

PendingCN107473008AReduce manufacturing costPrevent axial slippageFilament handlingWinding machineYarn

The invention relates to the technical field of winding machines, in particular to a winding machine capable of adjusting a chemical fiber yarn winding paper tube. The winding machine comprises two rotary tables, supports, a drive device, a plurality of supporting rods, bearing pedestals, an output shaft and a first connection shaft. Fixing holes are formed in the centers of the rotary tables, each rotary table is provided with a plurality of connection hole sets with the corresponding fixing hole as a circle center, each connection hole set comprises a plurality of connection holes, and the connection holes of each connection hole set are located in the same circumference. The supports are symmetrically connected with the two bearing pedestals correspondingly. The drive device is rotationally connected with one bearing pedestal through the output shaft, and one end of the output shaft is fixedly connected with one rotary table. The first connection shaft is rotationally connected to the other bearing pedestal, and one end of the first connection shaft is fixedly connected with the other rotary table. By arranging the rotary tables and the supporting rods, the positions of the supporting rods on the rotary tables are adjusted according to the diameter of an inner hole of the paper tube so that the paper tube can be supported and fixed, the paper tube can be fixed without a fixing shaft, and therefore the production cost is greatly reduced.

Owner:江苏垶恒复合材料有限公司

Exhaust pipe structure capable of eliminating welding stress

InactiveCN103291432AGuaranteed validityPrevent axial slippageExhaust apparatusSilencing apparatusStructural engineeringMechanical engineering

The invention discloses an automobile exhaust pipe structure, and provides an exhaust pipe structure which is simple in structure and ingenious in conception, can eliminate welding stress and avoid breakage of welding ports of an inner pipe and an outer pipe of the exhaust pipe due to high temperature and low temperature alternation, and solves the technical problems that when an automobile runs in a cold area, the welding ports at the two ends of the exhaust pipe are easy to break due to the high temperature and low temperature alternation, the abnormal sound of the exhaust pipe is caused, and even seriously, the failure of the exhaust pipe is caused in the prior art. The exhaust pipe structure comprises an inner barrel and an outer barrel, wherein the inner barrel is coaxially sleeved and covered with the outer barrel; one end of the outer barrel is welded and fixed on the corresponding inner barrel; an elastic piece is sandwiched between an internal wall surface at the other end of the outer barrel and a corresponding external wall surface of the inner barrel; and the inner barrel is supported in the outer barrel by the elastic piece elastically.

Owner:HUNAN GEELY AUTOMOBILE COMPONENTS +1

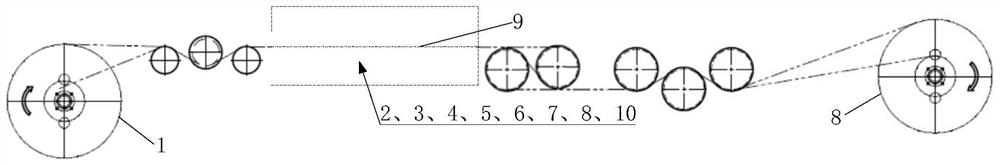

Roll-to-roll superconducting strip copper plating device and method

ActiveCN113089060AAvoid bony structuresGood qualityElectrolysis componentsCopper platingElectroplating

The invention provides a roll-to-roll superconducting strip copper plating device and method. The roll-to-roll superconducting strip copper plating device comprises a discharging mechanism, a first cleaning mechanism, a copper pre-plating mechanism, a copper plating mechanism, a second cleaning mechanism, a passivation mechanism, a drying mechanism and a collecting mechanism. The discharging mechanism is used for unwinding a machined strip, the machined strip is machined by the first cleaning mechanism, the copper pre-plating mechanism, the copper plating mechanism, the second cleaning mechanism, the passivation mechanism and the drying mechanism in sequence during machining and then is wound on the collecting mechanism, the copper pre-plating mechanism adopts high-current electroplating treatment, and the copper plating mechanism adopts low-current electroplating treatment. According to the device and method, a certain sand surface is met, axial sliding deviation of a wound coil cake body is prevented, a bone-shaped structure is avoided, the problem that a superconducting layer is corroded by liquid is solved, and the electroplated superconducting strip is good in quality and high in electroplating efficiency.

Owner:SHANGHAI SUPERCONDUCTOR TECH CO LTD

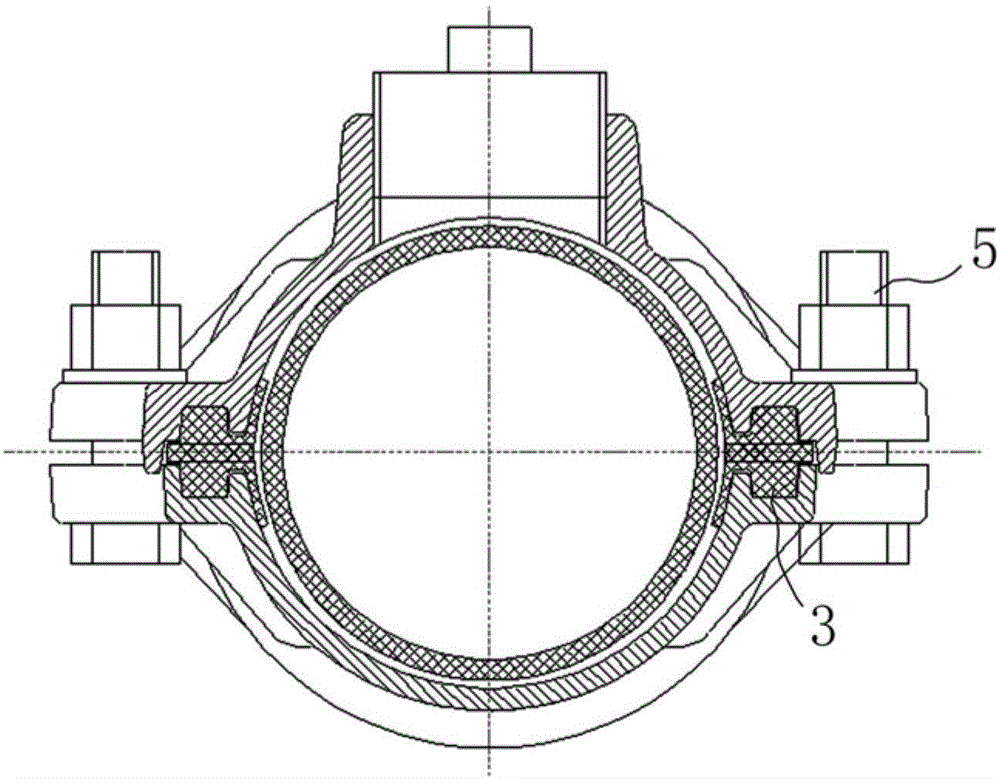

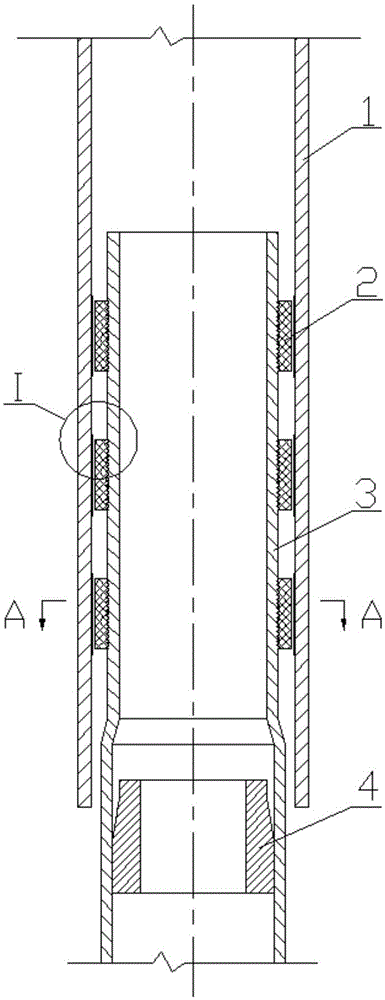

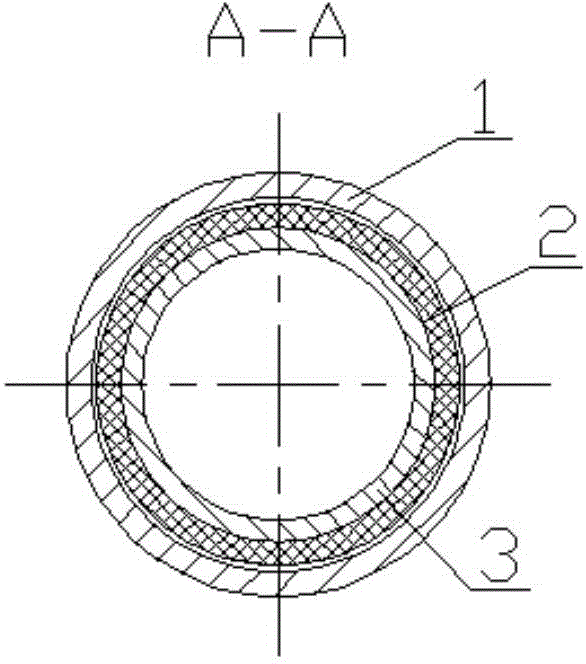

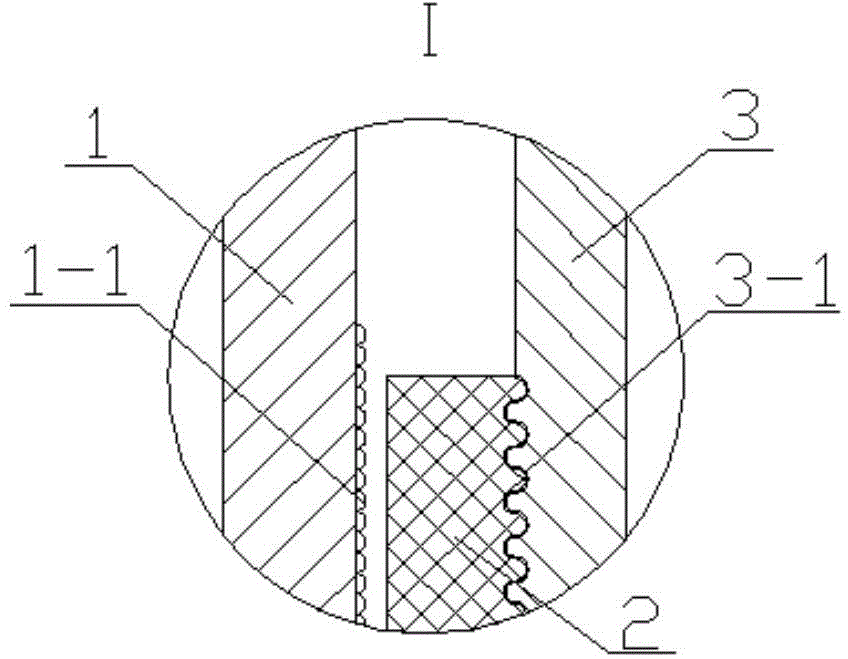

Metal rubber bearing and sealing-based expandable liner hanger joint

InactiveCN104563900AIncrease the initial preloadIncrease contact areaDrilling rodsSealing/packingAging propertyStructural stability

The invention relates to the field of petroleum drilling, well completion and cementing equipment, in particular to a metal rubber bearing and sealing-based expandable liner hanger joint. The joint comprises a bushing, a variable diameter liner, sealing elements and an expansion cone, wherein the sealing elements sleeve the outer wall of the upper section of the variable diameter liner in an equal spacing manner; the part, which is provided with the sealing elements, of the variable diameter liner sleeves in the bushing; the expansion cone is arranged on the variable diameter liner; the basic conception of the joint is that metal rubber cylinders are adopted as the sealing elements, the metal rubber cylinders closely sleeve the outer wall of the variable diameter liner, rough surfaces which are subjected to roughness machining are adopted as the outer wall surface of the variable diameter liner of a matching section for the metal rubber cylinders to sleeve and the inner wall of the bushing on the matching sections of the metal rubber cylinders. The metal rubber cylinders are adopted as the sealing elements; the mounting surfaces of matching parts are roughened to realize structural stability, high sealing property, extremely high oil resistance and acid resistance and anti-aging property, prolong the service life of the expandable liner hanger joint, improve the working efficiency and reduce the operation cost.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

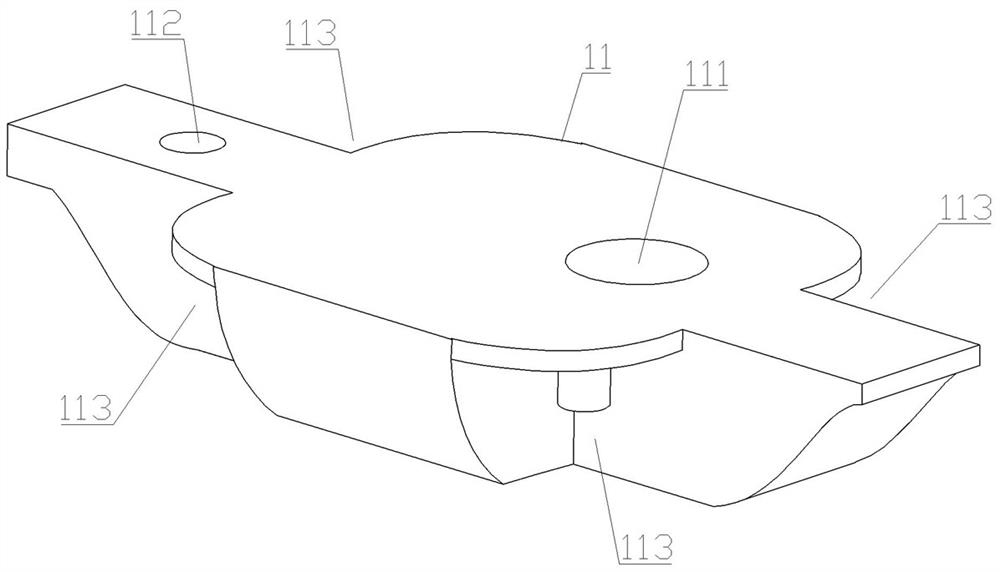

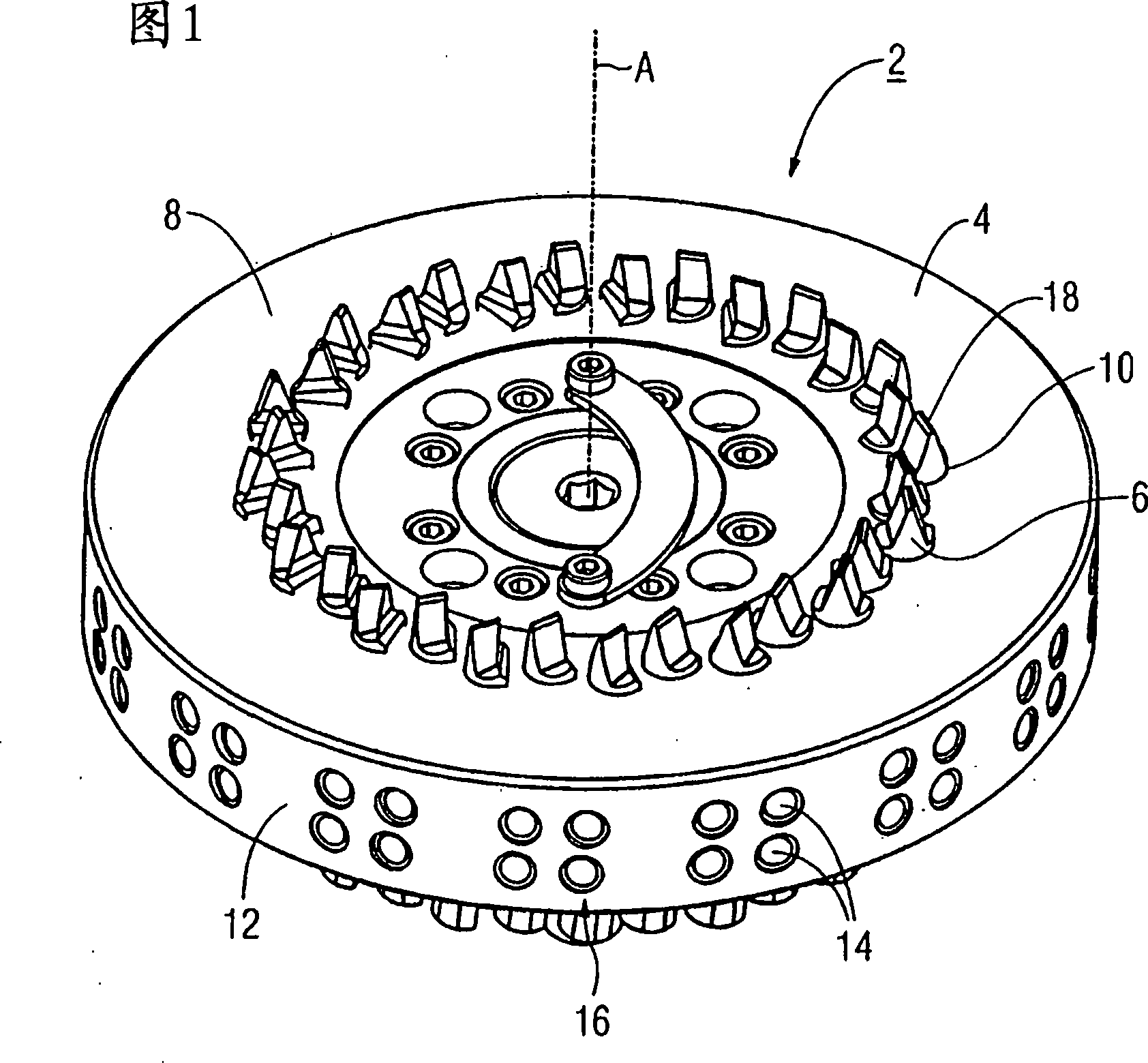

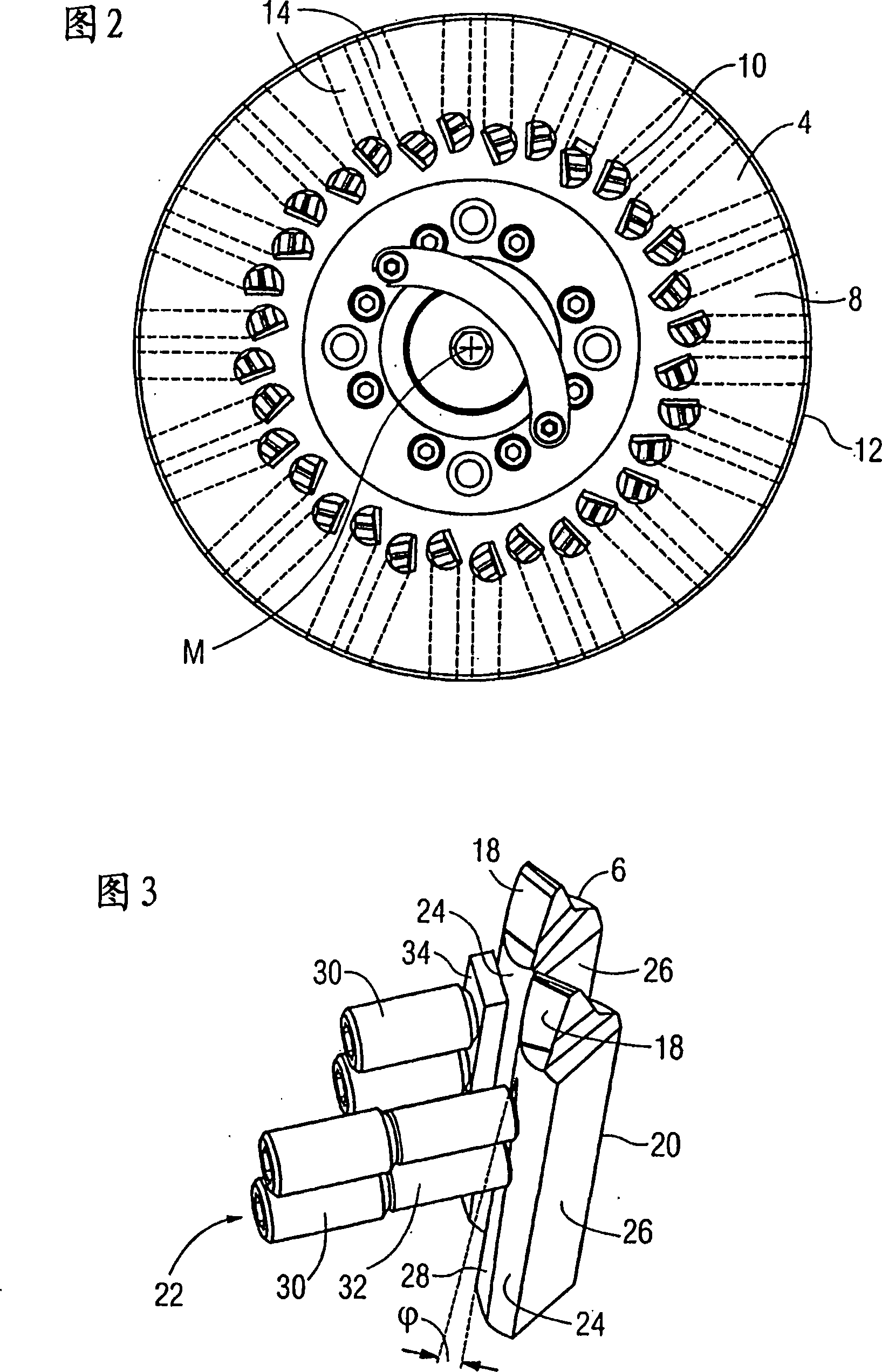

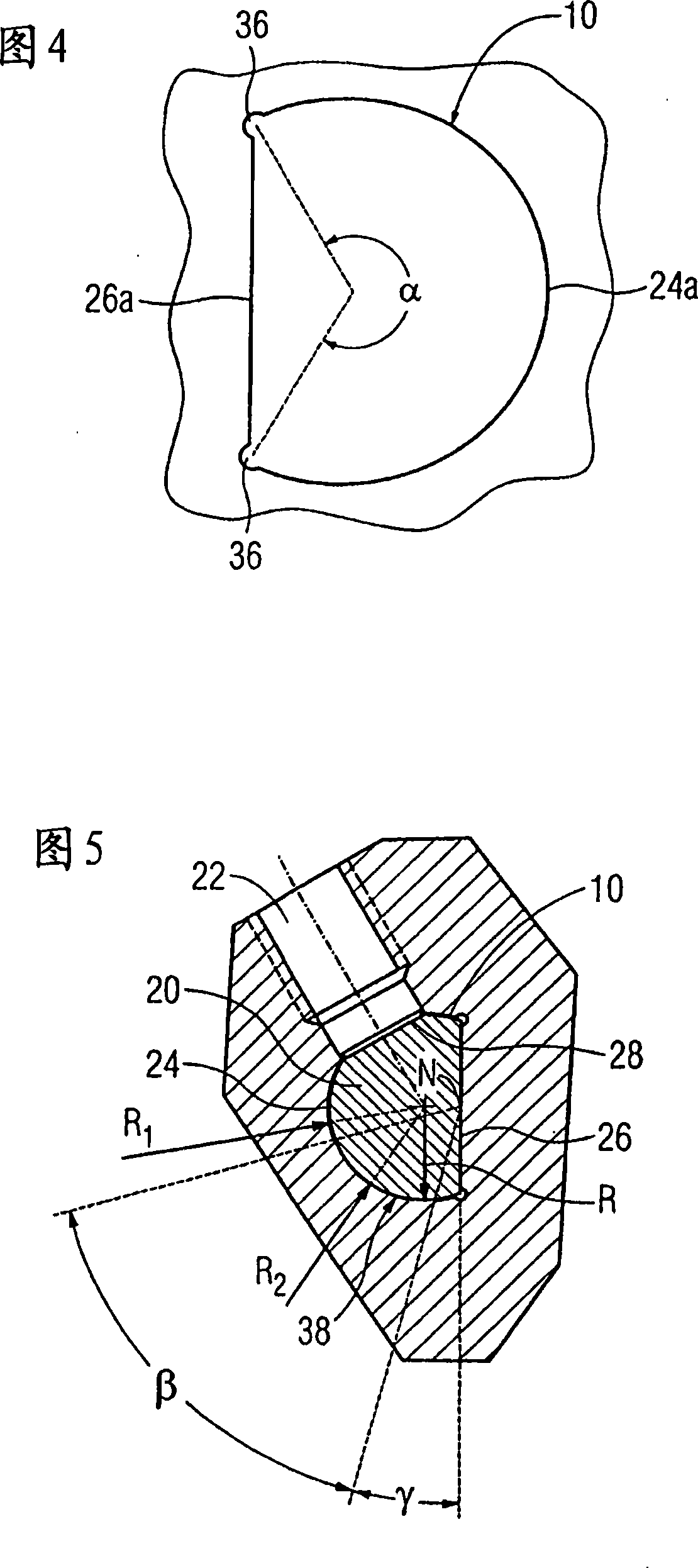

Blade head

InactiveCN101218059AAchieving Complementary StructuresEasy to replaceMilling cuttersGear teeth manufacturing toolsEngineeringCircular segment

The cutter head (2) includes a disc-shaped cutter holder (4) and a plurality of rod-shaped cutters (6) with handles (20). The disk-shaped tool holder (4) has a plurality of tool seats (10), into which tool holders (20) of rod-shaped tools (6) are inserted. The handle (20) has an arcuate cross-section. In order to achieve a simple and reliable fixing of the rod-shaped tool (6) in the tool seat (10), the tool seat (10) complementary to the rod-shaped tool (6) has an arcuate cross-section, so that the rod-shaped tool (6) Insert into the knife seat (10) with its knife handle (20) respectively precisely. The non-positive fastening is only achieved by pressing the clamping screw (22) of the rod-shaped tool (6).

Owner:KENNAMETAL INC

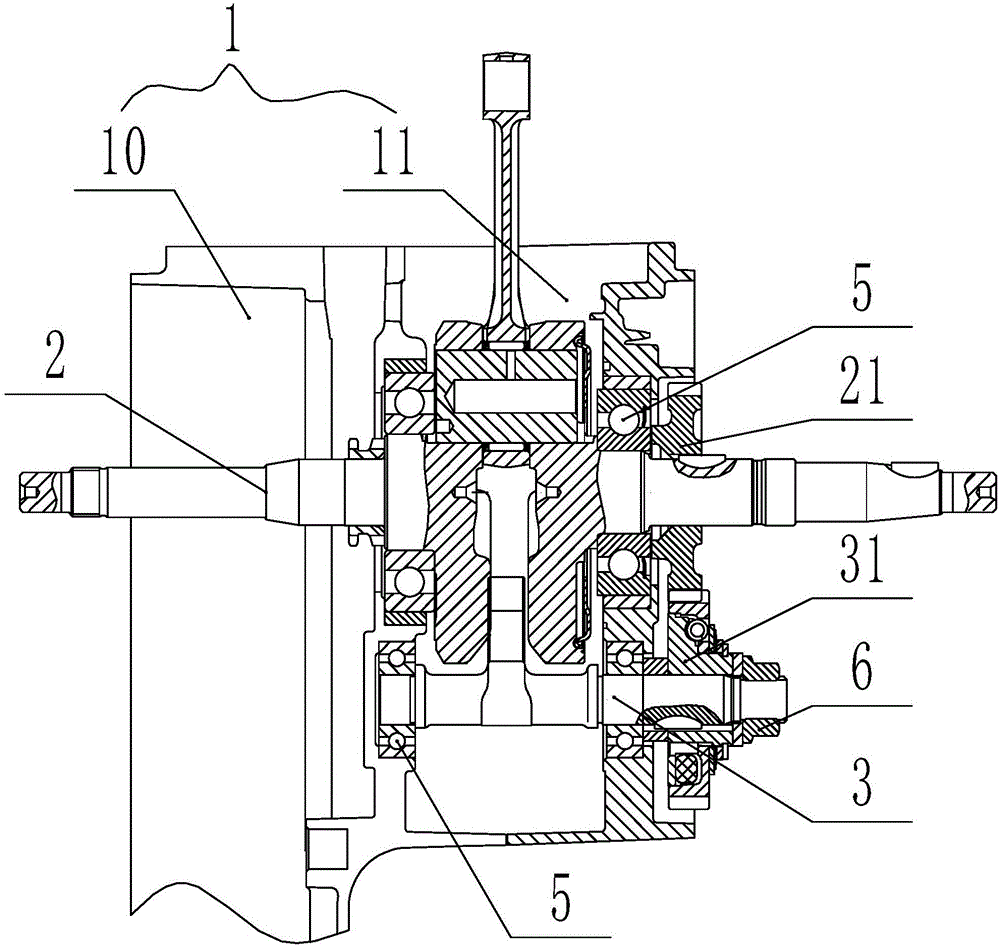

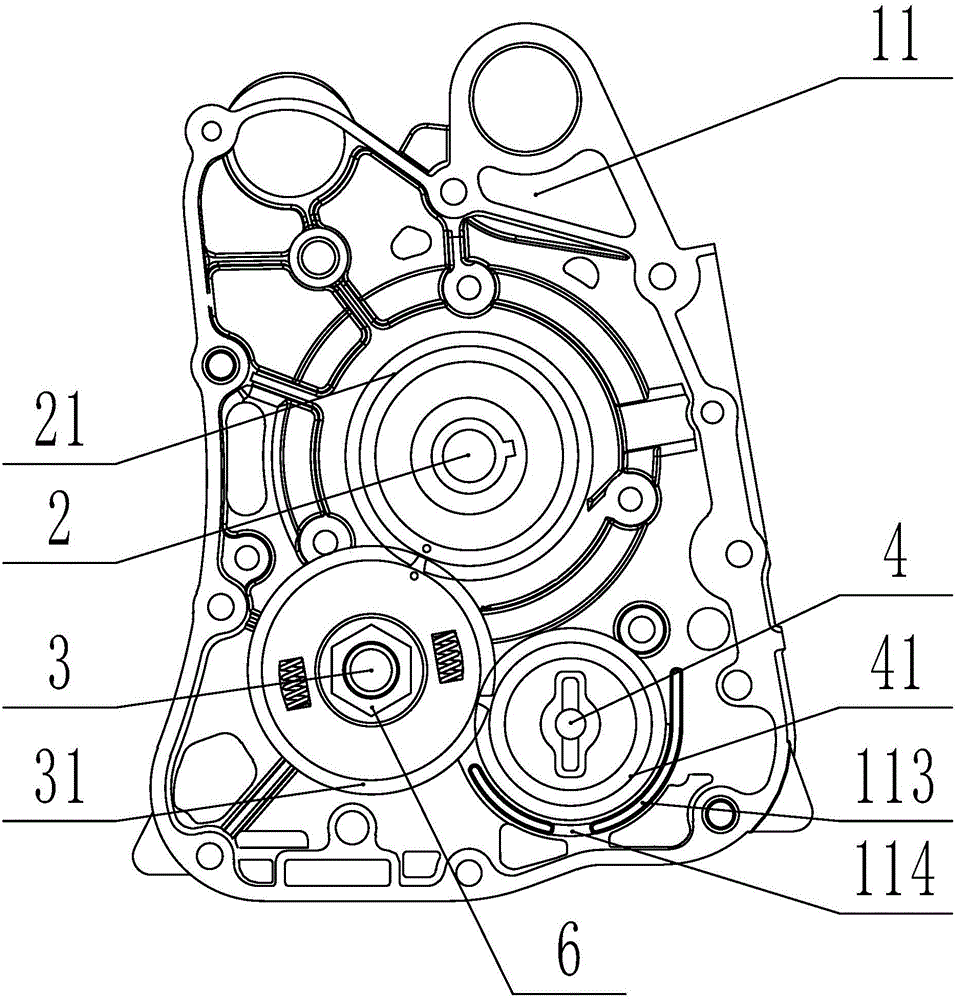

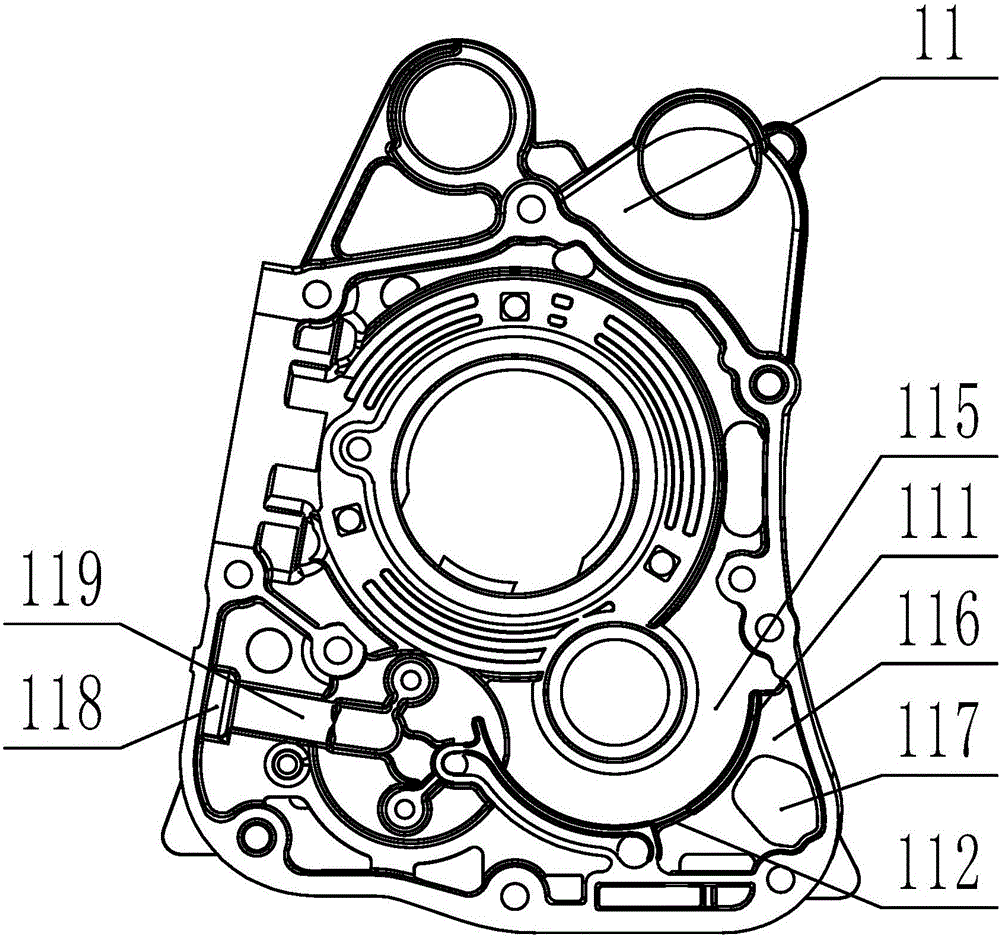

Scooter engine with balance shaft

InactiveCN105781782ANovel structureReduce vibration and noiseCasingsMachines/enginesGear transmissionBalance shaft

The invention discloses a scooter engine with a balance shaft. The scooter engine comprises a crankcase defined by a left crankcase body and a right crankcase body. An engine oil pump, a rotary crankshaft and the rotary balance shaft are mounted in the crankcase. The crankshaft is sleeved with a balance shaft driving gear. The balance shaft is sleeved with a balance shaft driven gear. The engine oil pump is sleeved with an engine oil pump driven gear. The balance shaft driving gear is engaged with the balance shaft driven gear. The balance shaft driven gear is engaged with the engine oil pump driven gear. A first arc baffle is arranged on the inner surface of the left crankcase body. A second arc baffle corresponding to the first arc baffle is arranged on the inner surface of the right crankcase body and provided with a first oil drainage port. A third arc baffle is arranged on the outer surface of the right crankcase body and provided with a second oil drainage port. By the adoption of the structure, the volume of the crankcase does not need to be increased, and vibration and noise of the scooter engine are reduced effectively; and gear transmission is adopted in the crank shaft, the balance shaft and the engine oil pump, reliability is improved, and the service life is prolonged.

Owner:力帆科技(集团)股份有限公司

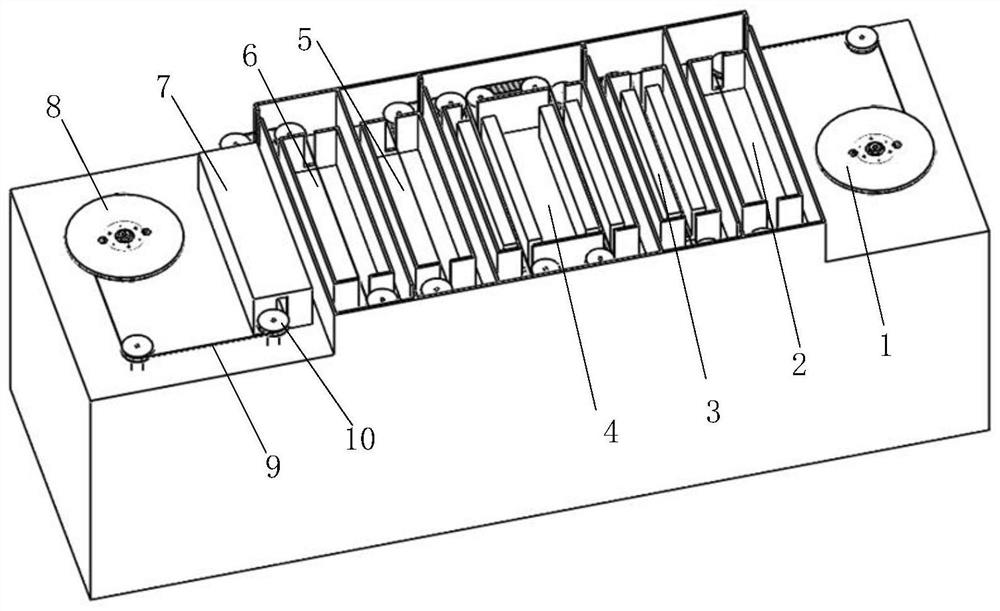

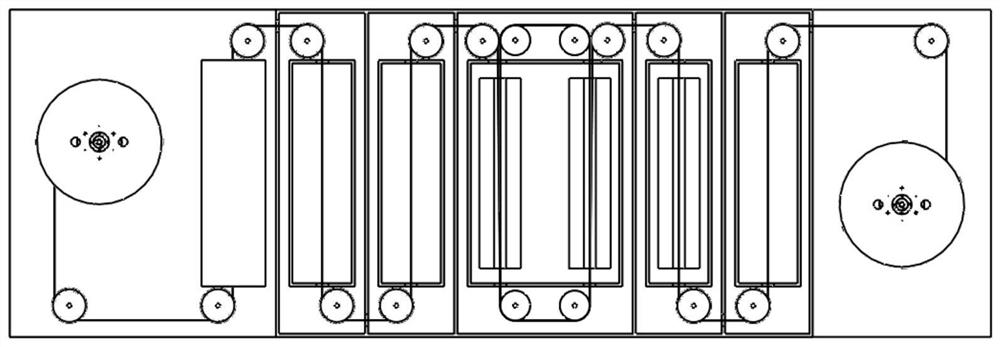

Cutting device for heat exchange pipe of chemical heat exchanger

InactiveCN108161128APrevent axial slippageIncrease production capacityPositioning apparatusMetal working apparatusEngineeringBolt connection

The invention relates to a cutting device, particularly to a cutting device for a heat exchange pipe of a chemical heat exchanger, and provides the cutting device for the heat exchange pipe of the chemical heat exchanger. The cutting device for the heat exchange pipe of the chemical heat exchanger provided to solve the technical problem comprises a workbench, a clamping device, a pushing device, afirst rotating motor, a base, a first guide rod, a first spring, a top plate, and the like, wherein the bottom of the first rotating motor is in bolted connection with the top of the base; the firstguide rod and a second guide rod are arranged on the two sides of the pushing device in front-back symmetry; and the first guide rod and the second guide rod are positioned on the workbench. The cutting device for the heat exchange pipe of the chemical heat exchanger provided by the invention is provided with the clamping device and the pushing device, the heat exchange pipe can be tightly clampedthrough the clamping device, fixation is firm, and the heat exchange pipe can be accurately cut.

Owner:钟清

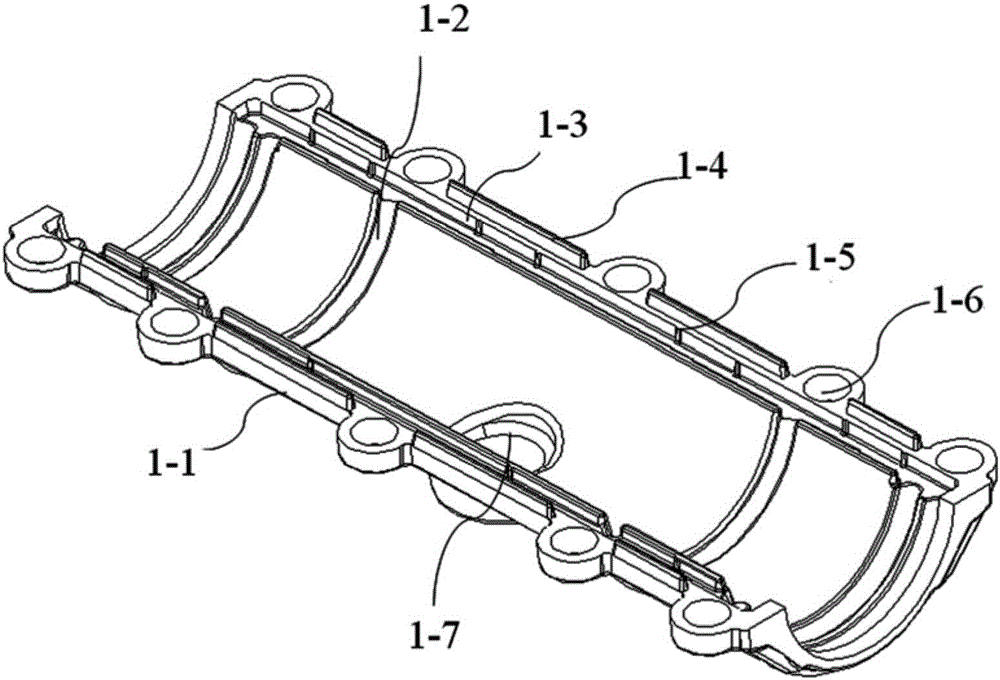

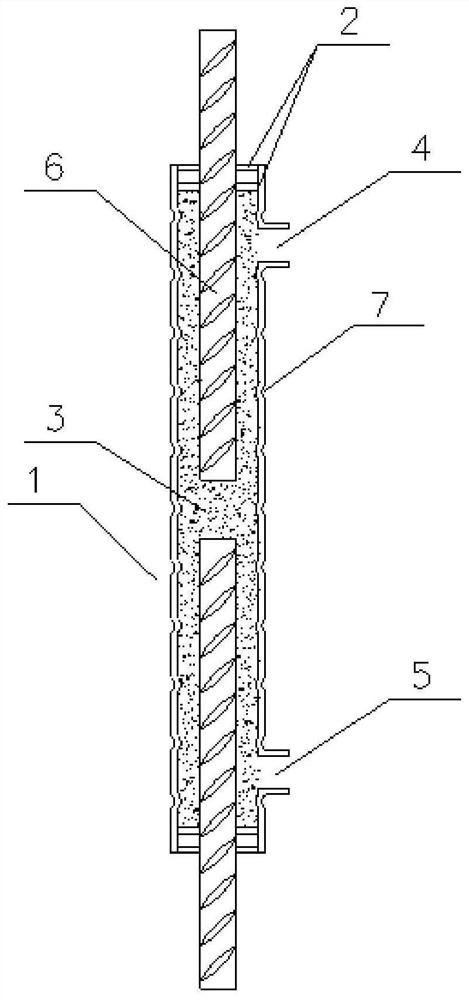

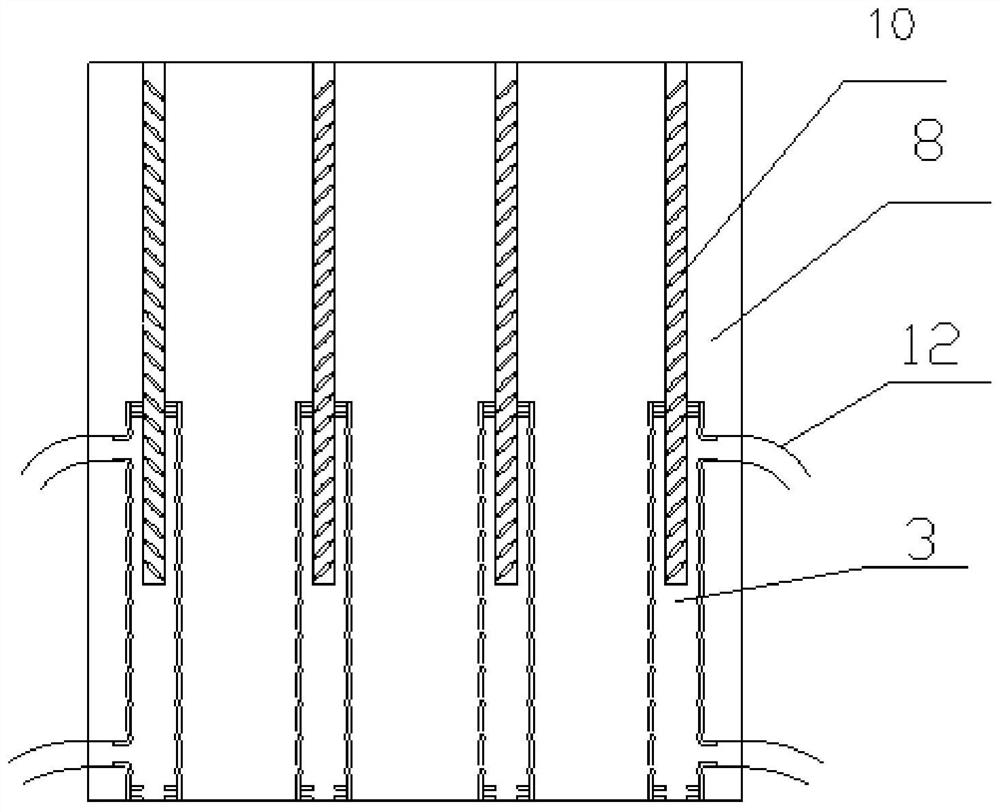

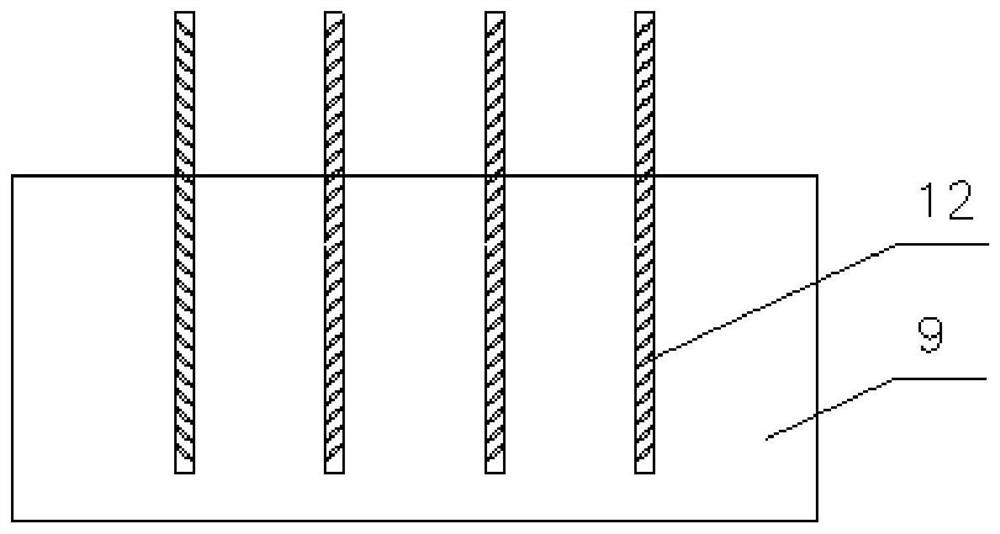

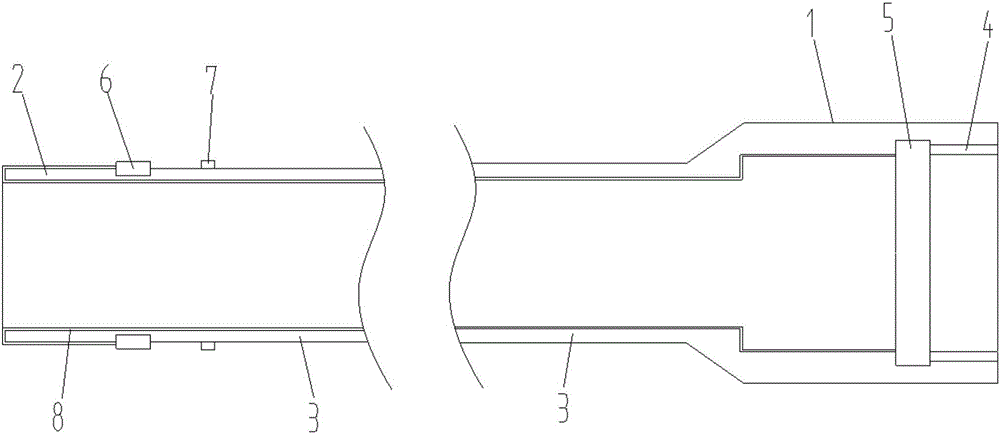

Grouting sleeve, fabricated bridge pier connected by grouting sleeve and construction method of fabricated bridge pier

PendingCN112853946AImprove connection strengthImprove adhesionBridge structural detailsBridge erection/assemblyRebarGrout

The invention discloses a grouting sleeve, a fabricated bridge pier connected with the grouting sleeve and a construction method of the fabricated bridge pier. The fabricated bridge pier comprises a cylinder body internally provided with a grouting cavity, gaskets arranged at the two ends of the cylinder body correspondingly and a grouting material layer arranged in the grouting cavity of the cylinder body in a filling mode. A grout outlet communicated with the grouting cavity is formed in the upper portion of the cylinder body, a grout inlet communicated with the grouting cavity is formed in the lower portion of the cylinder body, a connecting steel bar is anchored in the grouting material layer, and the end of the connecting steel bar penetrates through the gasket and extends out of the cylinder body. According to the invention, the structure is reliable, construction is convenient and fast, grouting materials are effectively prevented from sliding out of the sleeve, and the bonding force between the grouting materials and the inner wall of the sleeve is enhanced.

Owner:CHANGAN UNIV

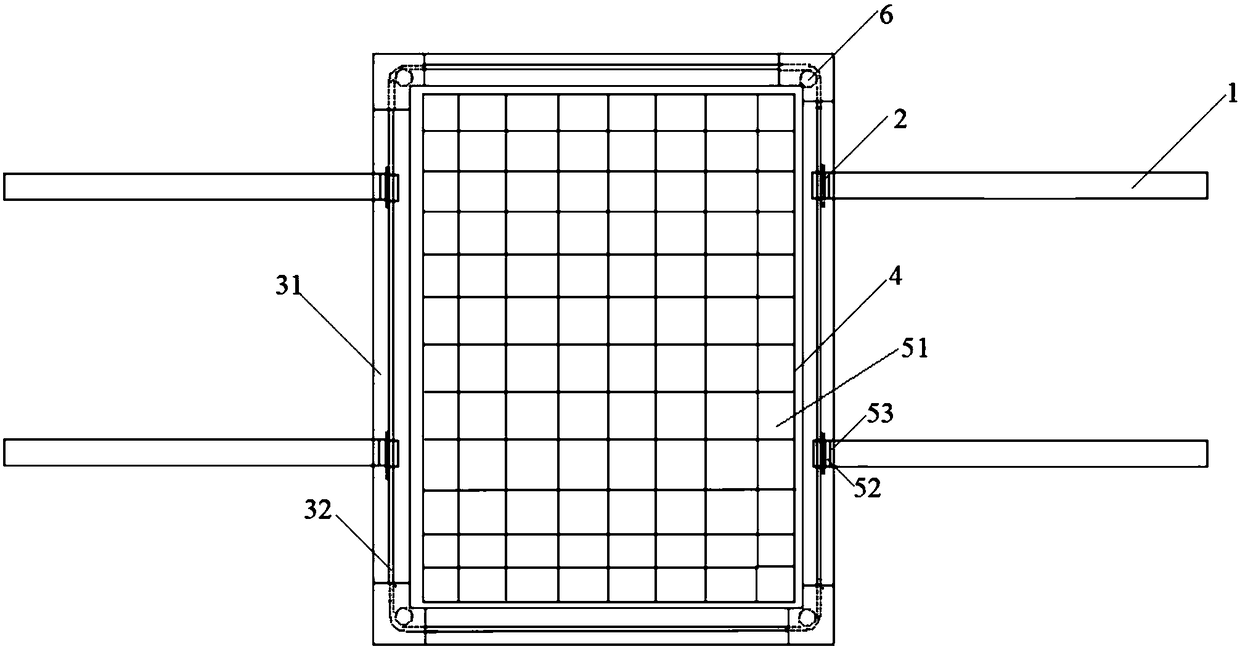

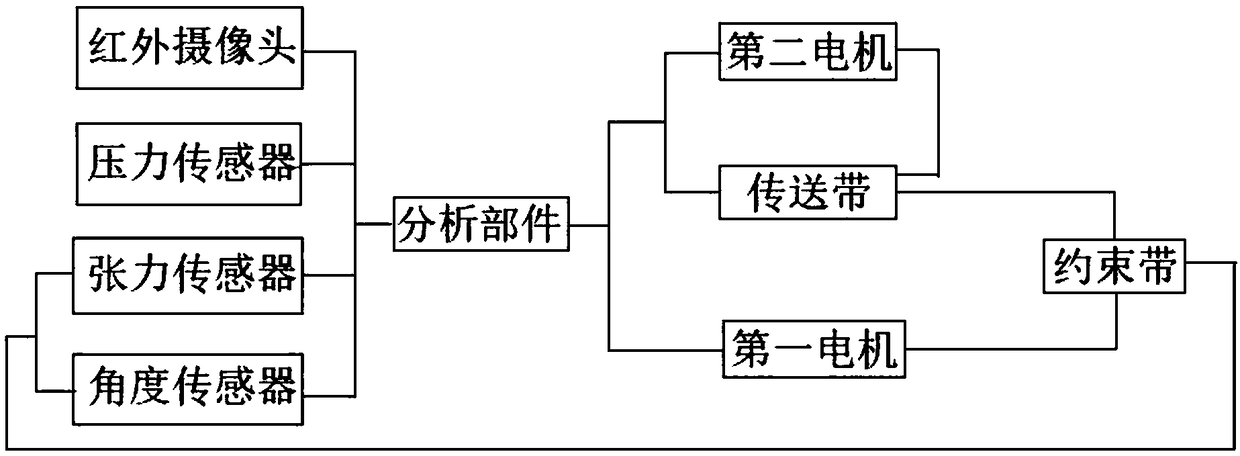

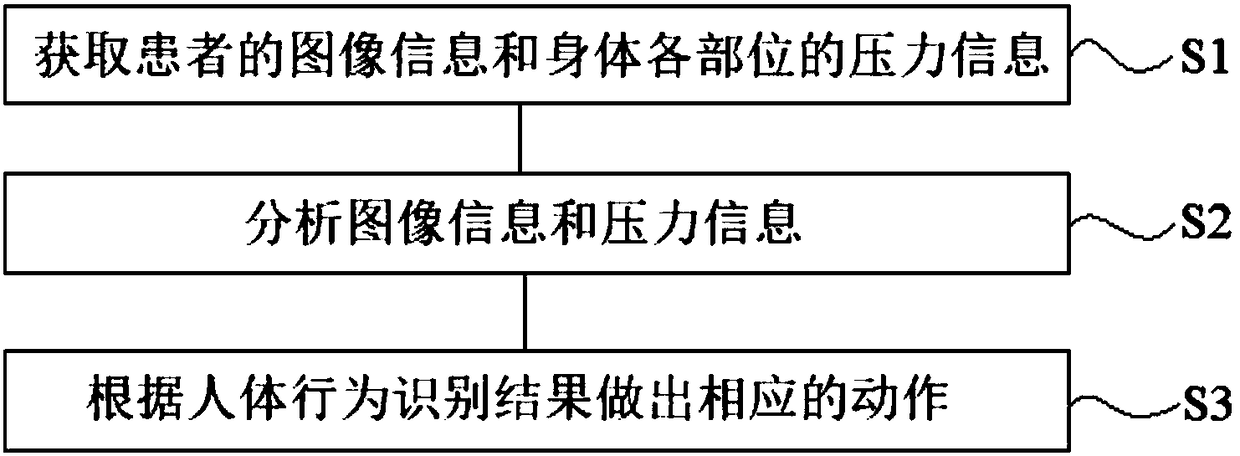

Constraining device and constraining method for same

ActiveCN108433859AAvoid physical problemsAvoid fixationRestraining devicesCharacter and pattern recognitionComputer sciencePsychological injury

Owner:ZHONGSHAN HOSPITAL FUDAN UNIV

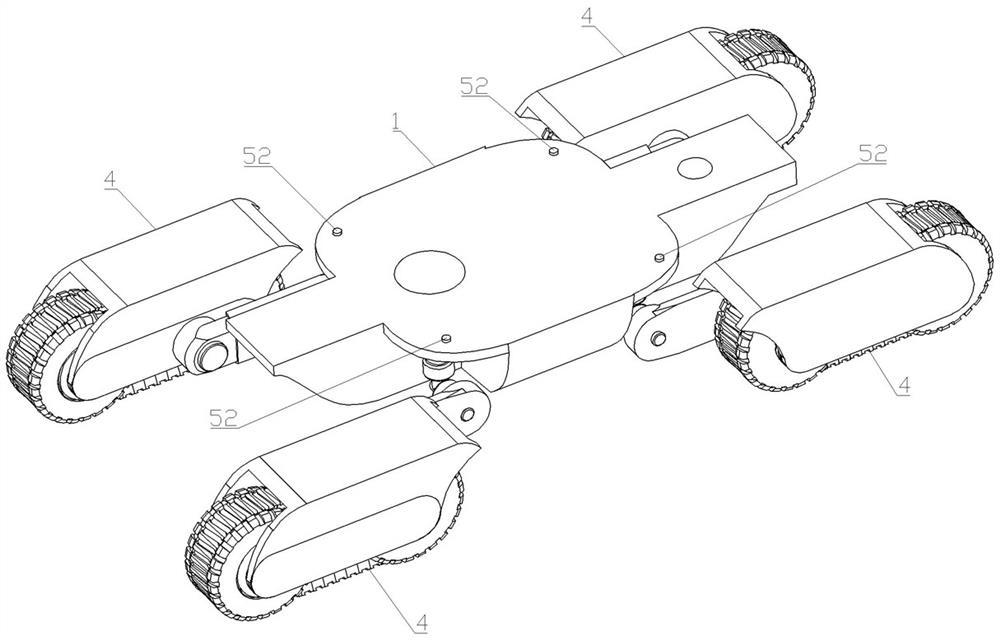

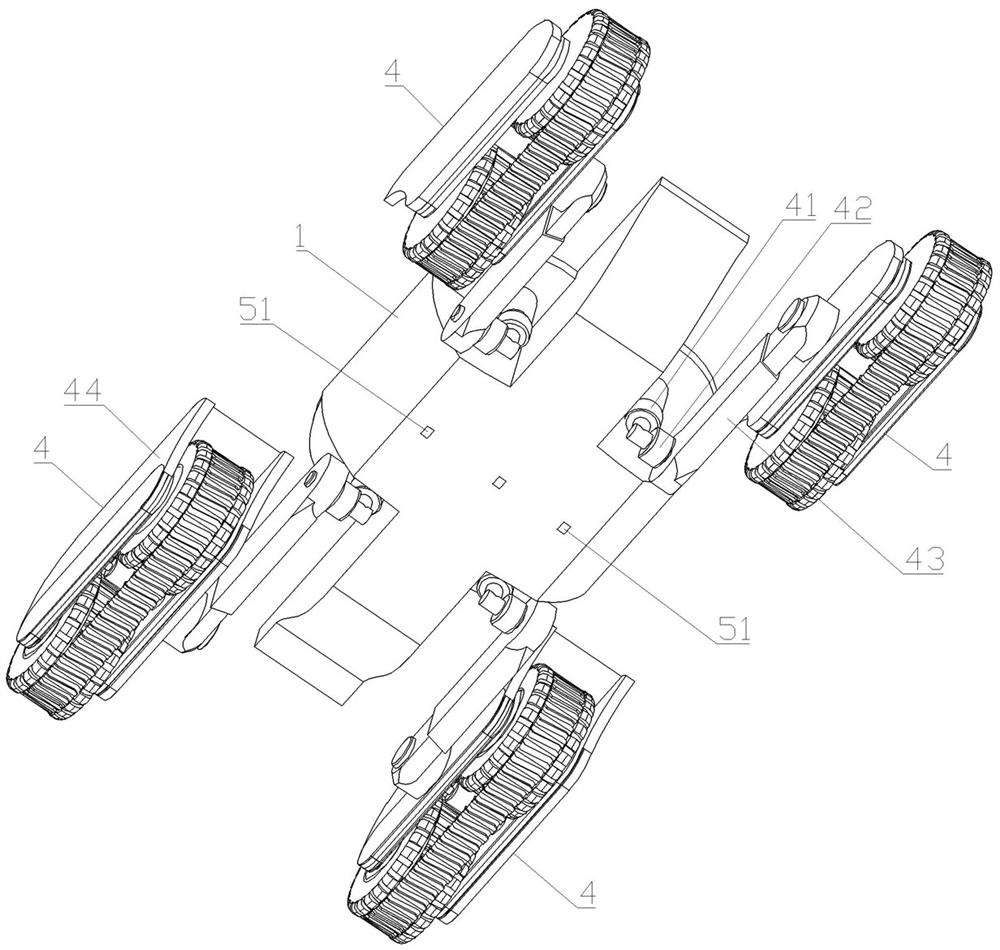

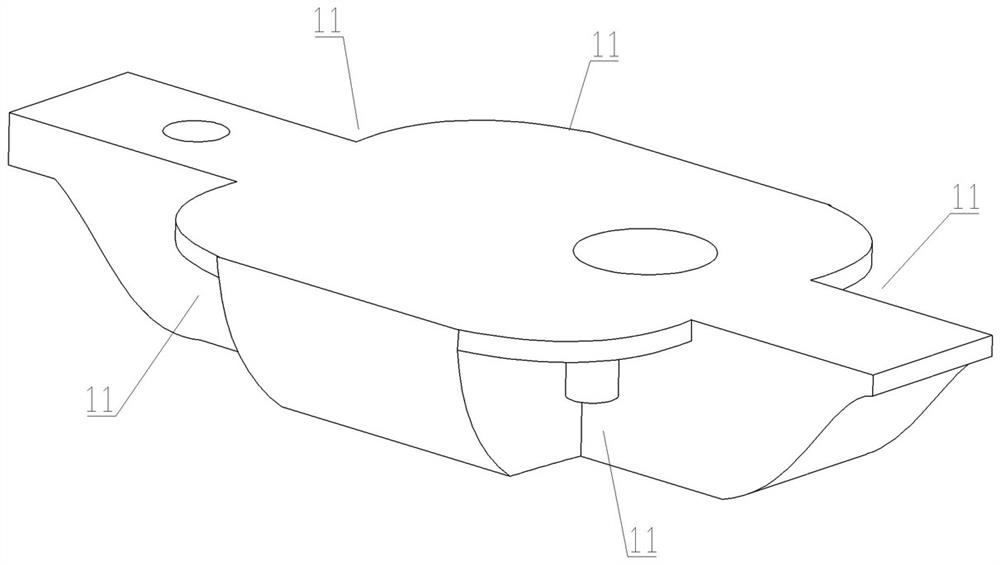

Nuclear emergency robot deformable composite chassis and application method thereof

ActiveCN112078678AIncrease the scope of applicationImprove job stabilityEndless track vehiclesRolling chassisRoboty

The invention discloses a nuclear emergency robot deformable composite chassis and an application method thereof, and relates to the technical field of nuclear emergency equipment. The nuclear emergency robot deformable composite chassis comprises a base and motion supporting devices. Mounting notches used for mounting the motion supporting devices are formed at the two sides of the front end andthe two sides of the rear end of the base correspondingly. The motion supporting devices are installed at the two sides of the front end and the two sides of the rear end of the base. Each motion supporting device comprises a hydraulic motor A, a hydraulic motor B, a telescopic sleeve, a supporting shell, a wheel belt assembly and a driving assembly. The application method of the chassis is basedon the nuclear emergency robot deformable composite chassis, and comprises a method for improving the operation stability of a nuclear emergency robot, a method for crossing obstacles on the ground and a method for improving the operation range of the nuclear emergency robot. When the method is applied to the nuclear emergency robot, the application range of the nuclear emergency robot can be greatly expanded.

Owner:NANHUA UNIV

Card smashing machine

The invention relates to a card smashing machine. The card smashing machine comprises a transmission assembly and a cutter shaft assembly; the cutter shaft assembly comprises two cutter shafts which are arranged in a spaced manner in parallel, and each cutter shaft is provided with a plurality of annular space rings and a plurality of annular blades with cutter noses; the position, between every two adjacent annular blades, on each cutter shaft is provided with one annular space ring, so that gaps are reserved between the adjacent annular blades; a groove is formed in the outer annular wall of each annular space ring in the circumferential direction of the annular space ring, the cutter noses of the annular blades on one cutter shaft extend to the corresponding grooves of the annular space rings on the other cutter shaft, and the cutter noses and the grooves are distributed in an adjoining manner; a discharging opening of the transmission assembly is formed above the gap between the opposite inner sides of the two cutter shafts; and when the card smashing machine is used, the two cutter shafts reversely rotate to the opposite inner sides, and the annular blades are driven to conduct cutting smashing on cards entering the position between the two cutter shafts. A groove is formed between every two adjacent annular blades, the top ends of the cutter noses are closely arranged along the grooves, the distances between the cutter noses and the corresponding cutter shafts can be reduced, and the diameter of the cutter shafts can be increased under the same conditions.

Owner:常州川刃办公设备有限公司

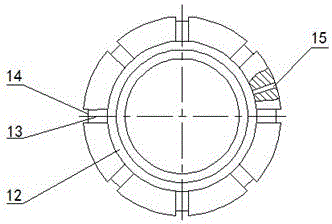

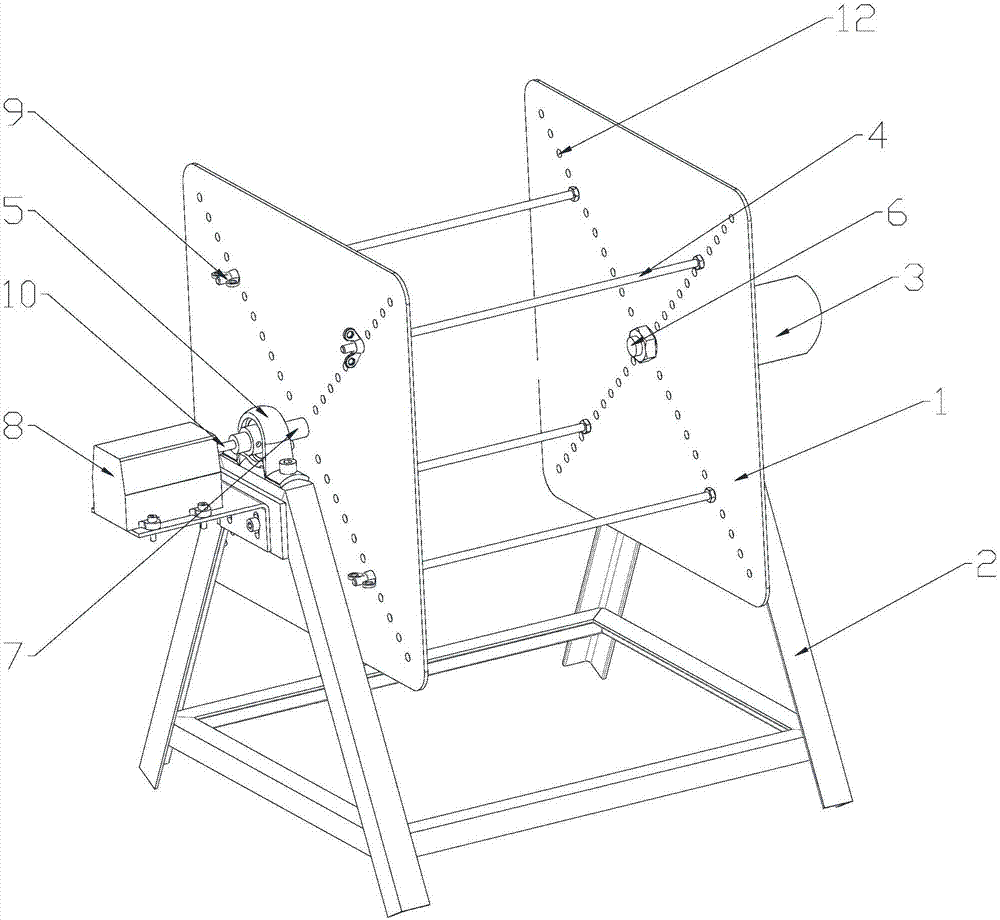

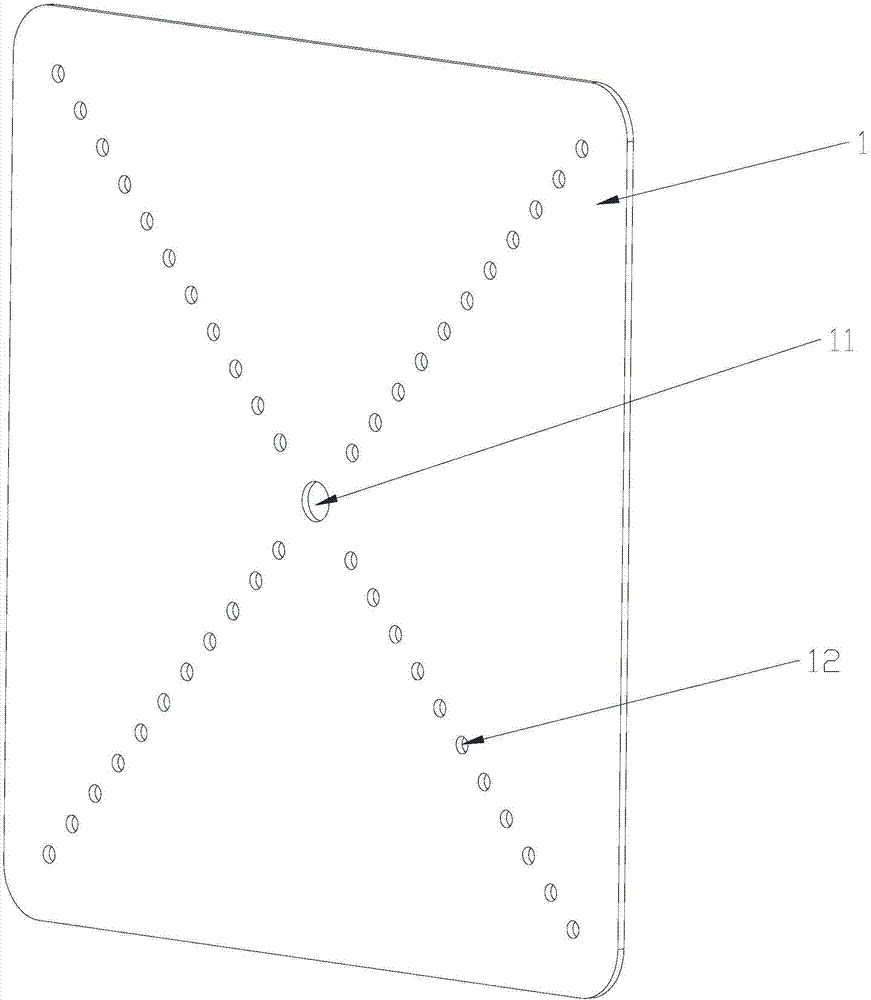

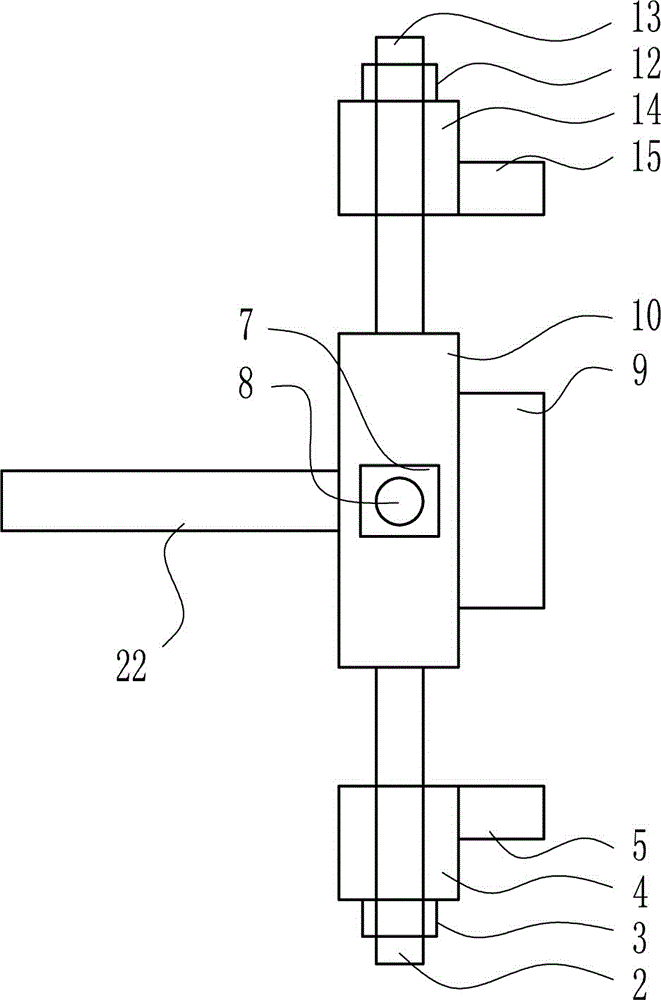

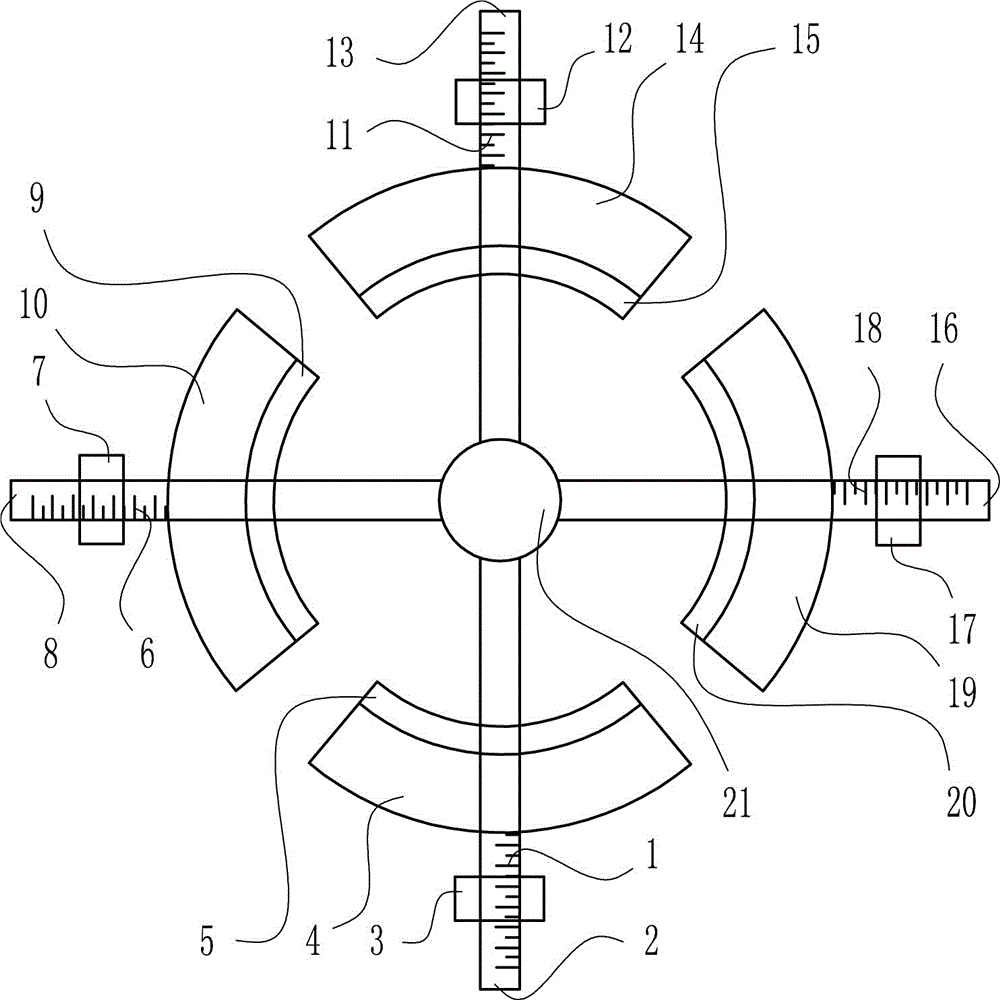

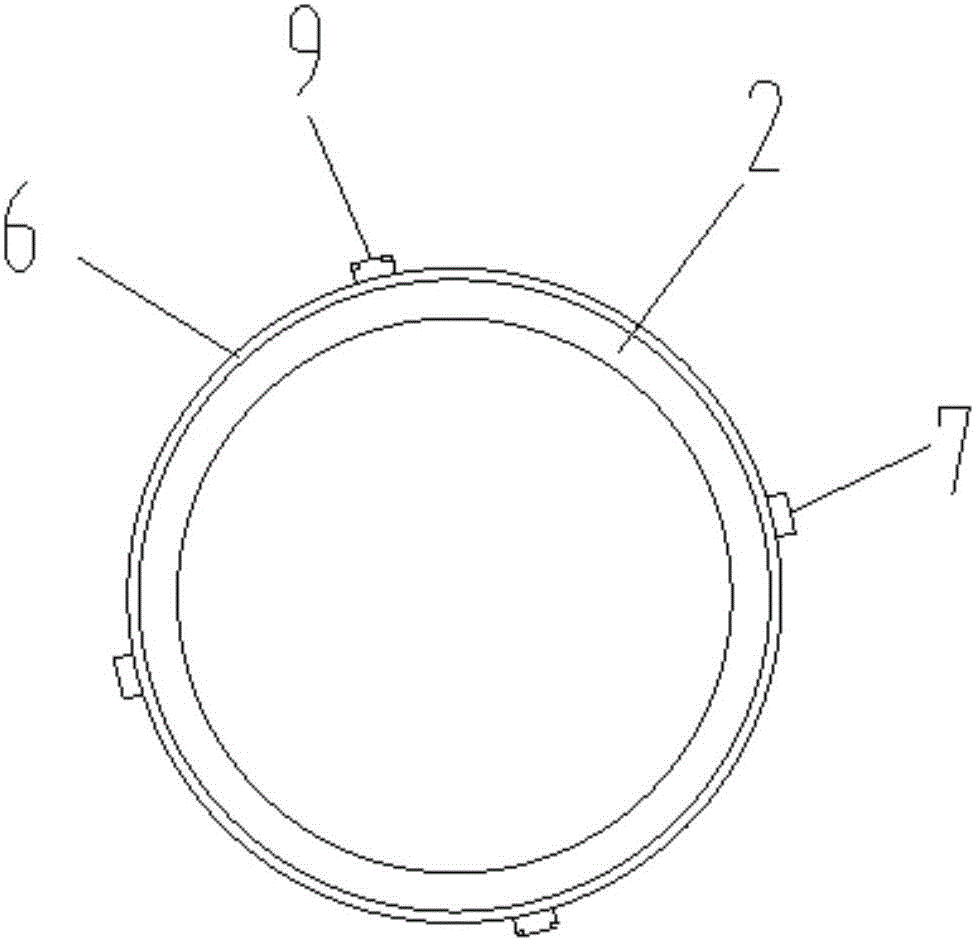

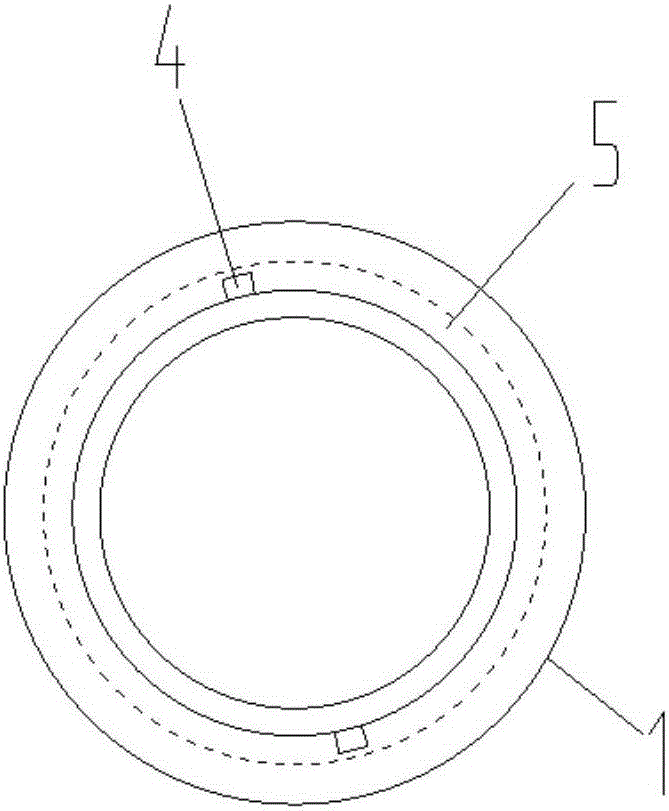

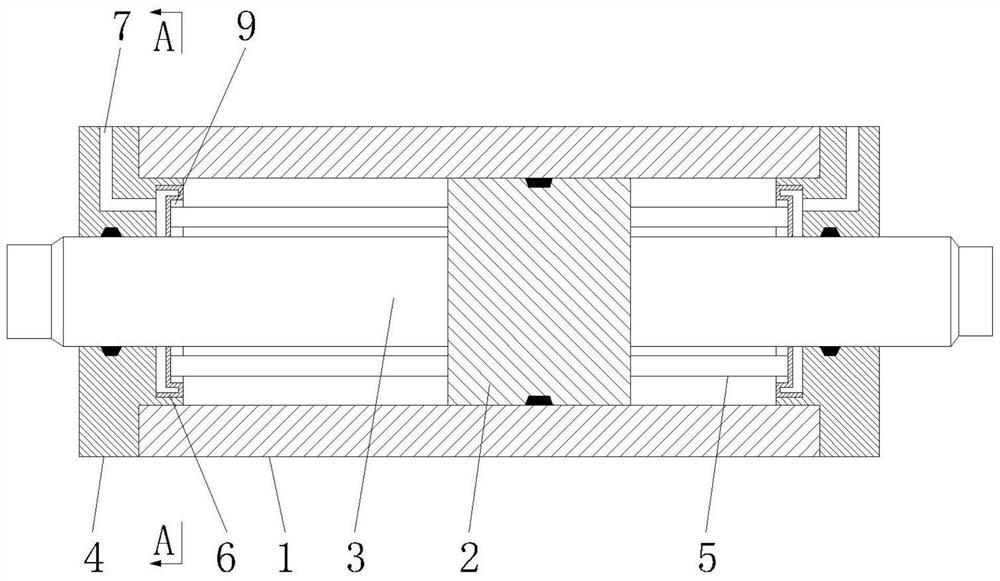

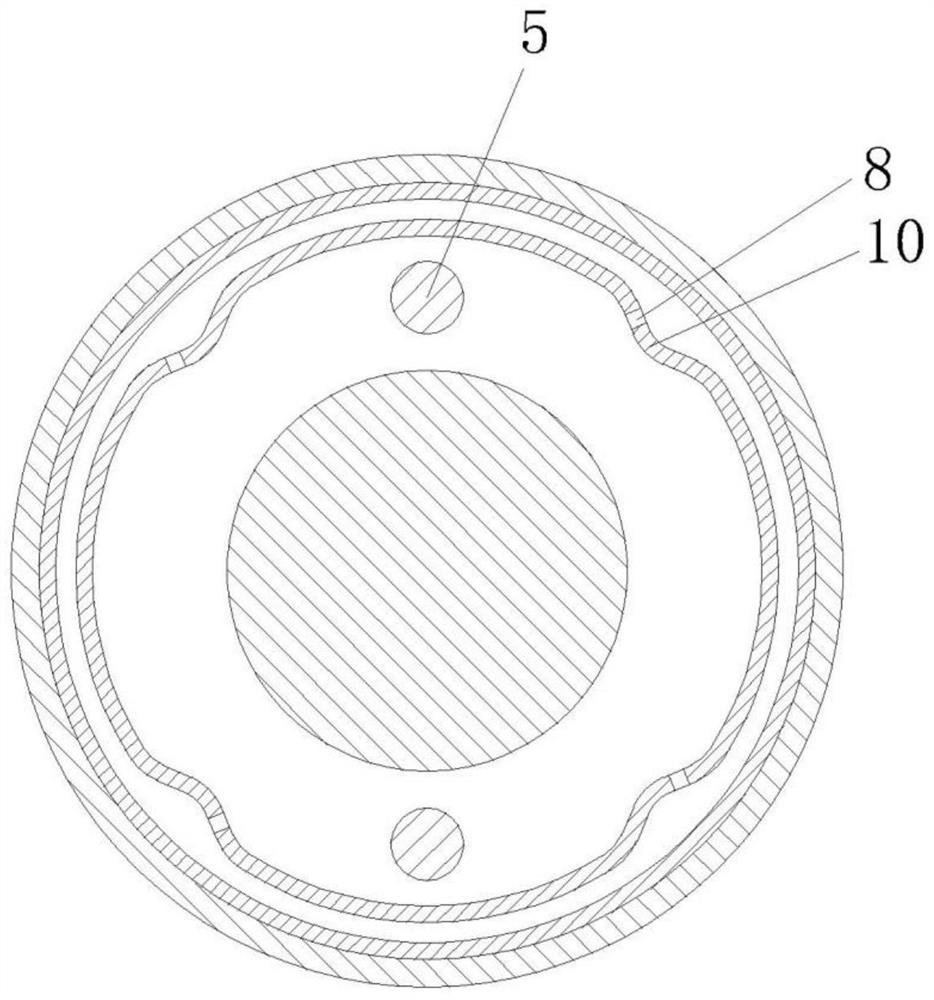

Lathe chuck for preventing workpiece from axially sliding

ActiveCN106001658APrevent axial slippageEasy to fixChucksPositioning apparatusCircular discClassical mechanics

The invention relates to a chuck, in particular to a lathe chuck for preventing a workpiece from axially sliding. The technical purpose of the invention is to provide the lathe chuck for preventing a workpiece from axially sliding. In order to realize the technical purpose, the lathe chuck for preventing a workpiece from axially sliding is provided and comprises a guide rod IV, a nut IV, a fan-shaped fixing plate IV, a fan-shaped fixing block IV, a nut III, a guide rod III, a fan-shaped fixing block III, a fan-shaped fixing plate III, a nut II, a guide rod II, a fan-shaped fixing plate II, a fan-shaped fixing block II, a guide rod I, a nut I, a fan-shaped fixing plate I, a fan-shaped fixing block I, a disc-shaped electromagnet and a connecting shaft. The guide rod I is arranged on the right side of the disc-shaped electromagnet. The lathe chuck, provided by the invention, for preventing a workpiece from axially sliding is simple and novel in structure, reasonable in design, good in workpiece fixing effect, high in workpiece machining precision and capable of preventing a workpiece from axially sliding during workpiece machining.

Owner:CHONGQING SHUAIBANG MACHINERY CO LTD

Socket type pipe fitting structure

Owner:浙江大业法兰有限公司

Telescopic rotary hydraulic cylinder

ActiveCN112727850ASmooth axial slidingPrevent axial slippageFluid-pressure actuatorsHydraulic cylinderEngineering

The invention discloses a telescopic rotary hydraulic cylinder. The telescopic rotary hydraulic cylinder comprises a cylinder body, a piston, a piston rod and end covers covering the two ends of the cylinder body, the piston rod and the end covers are matched in the mode that the piston rod and the end covers can axially slide in a sealed mode and can rotate in a sealed mode, the inner sides of the end covers are connected with rotating assemblies used for being driven by hydraulic oil injected into or flowing out of the cylinder body to rotate, a guide rod axially penetrating through the piston in a sliding mode is arranged in the cylinder body, and the two ends of the guide rod are connected to the rotating assemblies and synchronously rotate along with the rotating assemblies. Hydraulic oil injected into or flowing out is used as power, the piston can be driven to axially slide and rotate, other external power equipment additionally arranged for driving the piston rod to rotate is not needed, circumferential acting force can be applied to the piston through the cooperation of the piston and the guide rod, axial resistance to the piston can be reduced, and the local stress concentration phenomenon of the piston is improved, so that the piston slides smoothly in the axial direction, and the operation stability and reliability of the whole hydraulic cylinder are improved.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

a chip breaker

The invention relates to a card smashing machine. The card smashing machine comprises a transmission assembly and a cutter shaft assembly; the cutter shaft assembly comprises two cutter shafts which are arranged in a spaced manner in parallel, and each cutter shaft is provided with a plurality of annular space rings and a plurality of annular blades with cutter noses; the position, between every two adjacent annular blades, on each cutter shaft is provided with one annular space ring, so that gaps are reserved between the adjacent annular blades; a groove is formed in the outer annular wall of each annular space ring in the circumferential direction of the annular space ring, the cutter noses of the annular blades on one cutter shaft extend to the corresponding grooves of the annular space rings on the other cutter shaft, and the cutter noses and the grooves are distributed in an adjoining manner; a discharging opening of the transmission assembly is formed above the gap between the opposite inner sides of the two cutter shafts; and when the card smashing machine is used, the two cutter shafts reversely rotate to the opposite inner sides, and the annular blades are driven to conduct cutting smashing on cards entering the position between the two cutter shafts. A groove is formed between every two adjacent annular blades, the top ends of the cutter noses are closely arranged along the grooves, the distances between the cutter noses and the corresponding cutter shafts can be reduced, and the diameter of the cutter shafts can be increased under the same conditions.

Owner:常州川刃办公设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com