Roll-to-roll superconducting strip copper plating device and method

A superconducting tape, roll-to-roll technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems that cannot solve the performance of the strip, and the bone-shaped structure of the strip affects the winding of the strip, so as to avoid the bone-shaped structure, High electroplating efficiency, saving equipment space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

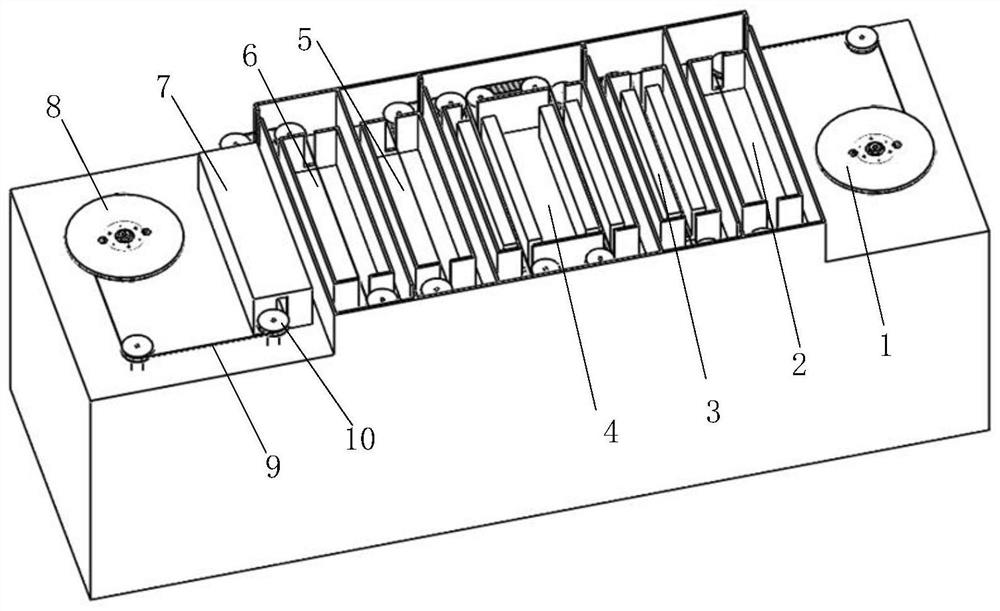

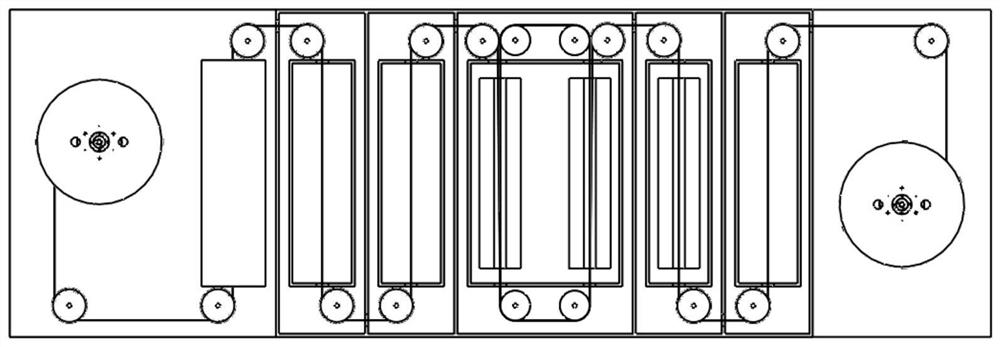

Embodiment 1

[0053] The invention provides a roll-to-roll superconducting strip copper plating device, which is especially suitable for superconducting strips with a width of 1mm-3mm. In the prior art, superconducting strips of 1-2mm The strip is easy to break, and the roll-to-roll superconducting strip copper plating device with roll-to-roll structural design can take in and unwind the superconducting strip as a whole, which solves the defect that the strip is easy to break in the prior art . Such as figure 1 As shown, the roll-to-roll superconducting strip copper plating device includes a discharge mechanism 1, a first cleaning mechanism 2, a pre-copper plating mechanism 3, a copper plating mechanism 4, a second cleaning mechanism 5, a passivation mechanism 6, and a drying mechanism 7 and a receiving mechanism 8, the unwinding mechanism 1 is used for the unwinding operation of the processed strip 9, the processed strip 9 is a superconducting strip, and the processed strip 9 passes thro...

Embodiment 2

[0062] This embodiment is a preferred example of Embodiment 1.

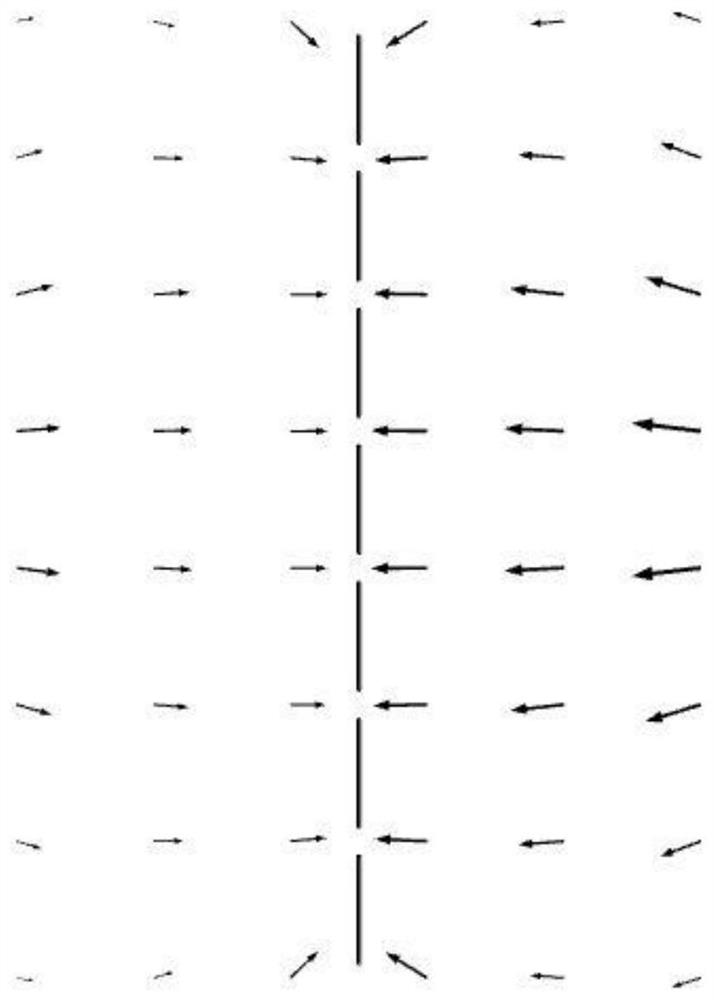

[0063] In this embodiment, the superconducting strip is limited and guided by the guide wheel 10, passes through the 60-100 cm long adjustable ultrasonic first cleaning tank through the discharging mechanism 1, and then passes through the U-shaped pre-plating Copper tank, multi-channel reciprocating copper plating tank, the second cleaning tank of overflow renewal pure water, heating passivation tank, adjustable carbon fiber far-infrared tube heater and then enter the material receiving mechanism 8, wherein, the U-shaped pre-plating copper tank can be at 10A / dm 2 Working under the environment, the multi-channel reciprocating copper plating tank can be used at 3A / dm 2 down to work.

[0064] In this embodiment, after the superconducting strip passes through the feeding mechanism 1, it first passes through a 60-100 cm long adjustable ultrasonic first cleaning tank. Provide pure water for cleaning, and then pass t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com