Copper pre-plating method, copper plating method and copper plating device for superconducting strip

A technology of superconducting strip and pre-copper plating, which is applied in electrolysis process, electrolysis components, etc., can solve the problems that cannot solve the performance of the strip, and the bone structure of the strip affects the winding of the strip, so as to provide electroplating efficiency, power line Uniformity and non-concentration, the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] The invention provides a method for pre-plating copper on superconducting strips, which is not only suitable for electroplating of narrow strips, such as strips with a width of 1 mm to 3 mm, but also suitable for wide strips, such as processed ones with a width greater than 3 mm. Strip material 9, can reach the effect in the present invention by adopting pre-plating, superconducting strip material pre-copper plating method is to adopt the first electric current to carry out pre-copper-plating treatment to processed strip material 9, wherein, described pre-copper-plating treatment Pre-plating additives that allow working at the current density of the first current are added to the copper pre-plating solution used, and the current density used by the preset current is 6-20A / dm 2 , the weight composition of described pre-plating copper electroplating solution is:

[0075] 200-240 parts of copper sulfate;

[0076] 50-70 parts of sulfuric acid;

Embodiment 2

[0093] This embodiment is a preferred example of Embodiment 1.

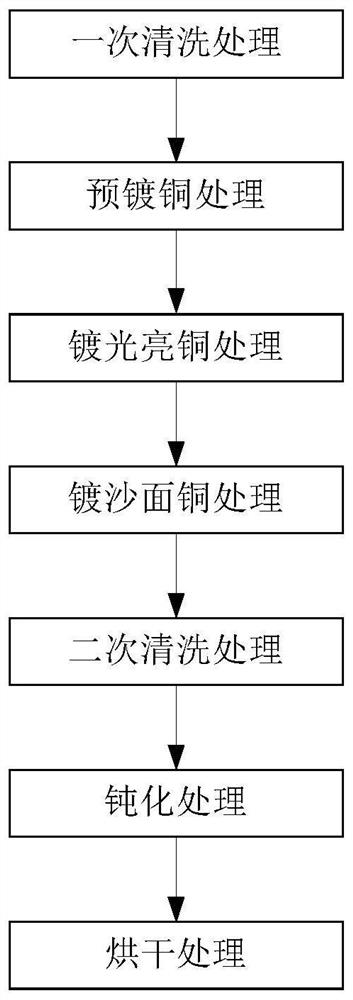

[0094] In this embodiment, the superconducting strip is first cleaned with pure water, and then the superconducting strip is subjected to the first current pre-copper plating treatment, the third current electroplating bright copper treatment, and the second current electroplating sand copper layer treatment, and then proceeds again. Cleaning with pure water, passivation treatment, drying, and drying to complete the copper plating operation of the superconducting strip.

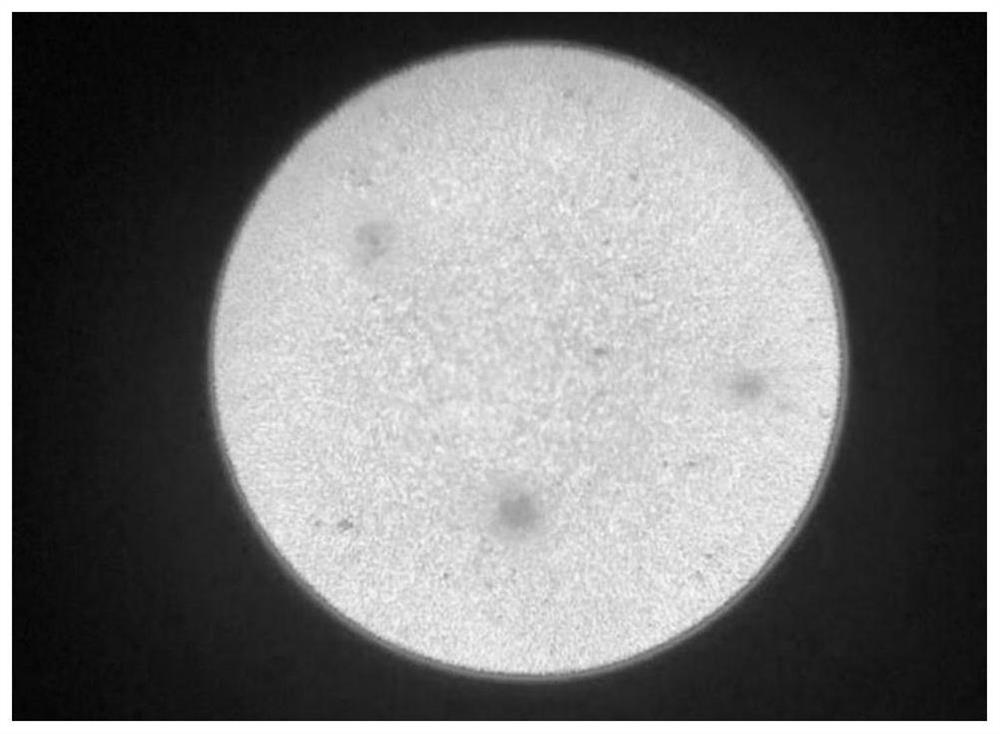

[0095] After the superconducting strip is cleaned with ultrasonic pure water, use a current density of 10A / dm 2 Rapid pre-plating copper layer with high current, so that copper can quickly cover the surface of double-sided silver-plated superconducting bare tape, and then use 2A / dm after pre-plating 2 The current density is used to electroplate the bright copper layer to make the thickness in the middle and the surface smooth, and then use 6A / d...

Embodiment 3

[0098] This embodiment is another preferred example of Embodiment 1.

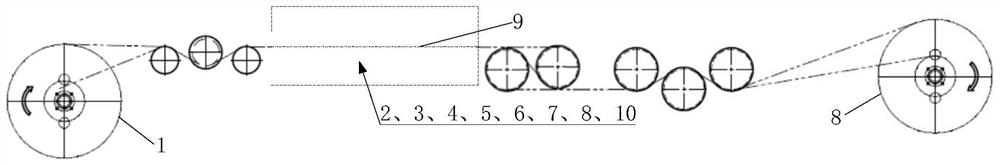

[0099] In this embodiment, the superconducting tape is carried out through a linear arrangement. After coming out of the discharge end of the discharge mechanism 1, it will first pass through a section of 60-180 cm adjustable ultrasonic pure water cleaning tank to clean the surface impurities. The belt will pass through 2~8 copper plating pre-plating tanks to quickly plate the copper cladding layer on the surface of the silver layer of the strip. The pre-plating copper plating solution used for the pre-plating is added to allow 6~20A / dm 2 The pre-plating acid copper additive for current density work will pass through 6 to 36 bright copper plating tanks to increase the thickness of the relatively uniform copper layer. Ability of bright copper copper additives, use 0.5 ~ 3.5A / dm 2 The current density can obtain the ideal intermediate copper layer, and the tape will pass through 2 to 8 sand surface copper gro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com