Double-limitation connecting system for marine fiber reinforced composite pipe

A fiber-reinforced composite and connection system technology, which is applied in the field of double-limited connection systems for marine fiber-reinforced composite pipes, can solve problems such as low reliability and pipeline connection failure, and achieves improved reliability, reduced pre-pressure loss, and good application effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

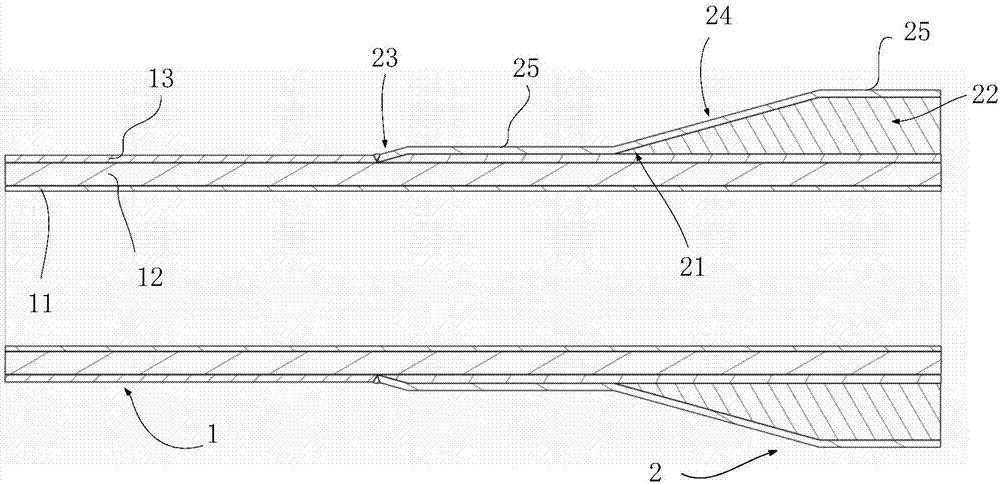

[0033] Example 1, this scheme is mainly aimed at fiber-reinforced thermoplastic composite pipes, refer to figure 1 , the main body of the composite pipe includes a fiber-wound reinforcement layer 12 in the middle of the pipe, a matrix outer protective layer 13 adhered to the outside of the reinforcement layer, and a matrix inner liner 11 adhered to the inside of the reinforcement layer; the material of the reinforcement layer 12 is capable of secondary processing The reinforcing fiber tape (glass fiber or carbon fiber) and thermoplastic matrix material (HDPE, PEEK, PEAK), the winding fiber of the reinforcing layer is wound symmetrically at the same positive and negative angles with the fiber reinforced tape prepreg tape (the angle is the winding direction of the fiber tape and the pipe Angle in the axial direction).

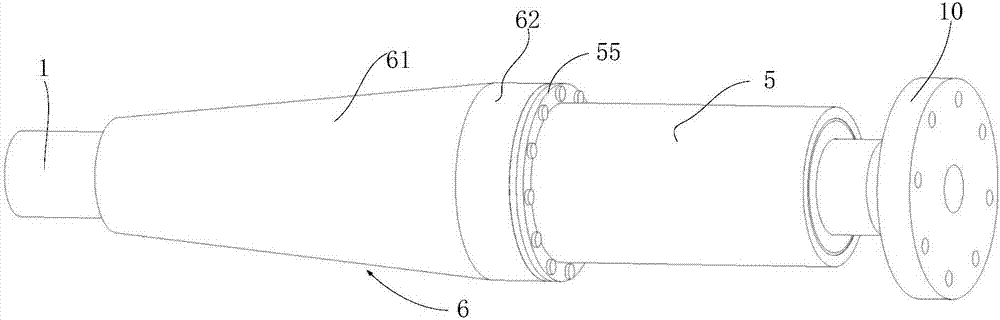

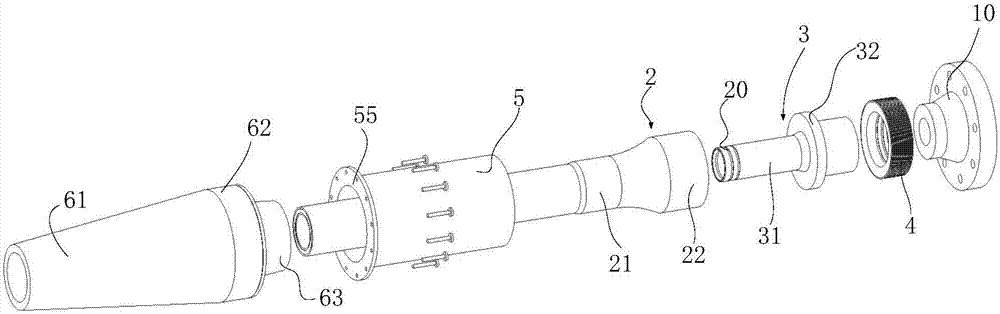

[0034] A new connection system for marine fiber-reinforced composite pipes, reference figure 1 , figure 2 , including the thickened pipe part 2 and the connec...

Embodiment 2

[0048] The difference between embodiment 2 and embodiment 1 is that the snap ring is only designed in the form of the second outer ring 7, and the anti-bending device is omitted. Refer to Figure 5-Figure 7 , the outer surface profile of the second outer ring 7 includes a front tapered portion 71 and a rear cylindrical portion 72, such as Figure 7 As shown, its inner surface profile is a three-section type, including a front section 73, a middle section 74, and a rear section 75. The inner diameters of the front section 73 and the rear section 75 remain unchanged, and are respectively in line with the first thickened layer 21 and the second thickened layer 22. The pipe sections match, the middle section 74 matches the outer contour of the second tapered transition section 24 so as to be closely connected, and the inner wall of the rear section 75 is provided with an ANSI standard internal thread that cooperates with the locking ring 4; the second outer sleeve The inner diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com