Card smashing machine

A card shredding and knife shaft technology, applied in the field of card shredders, can solve the problems of card shredding, environmental pollution, large thickness, etc., and achieve better cutting effect, avoid insufficient strength, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

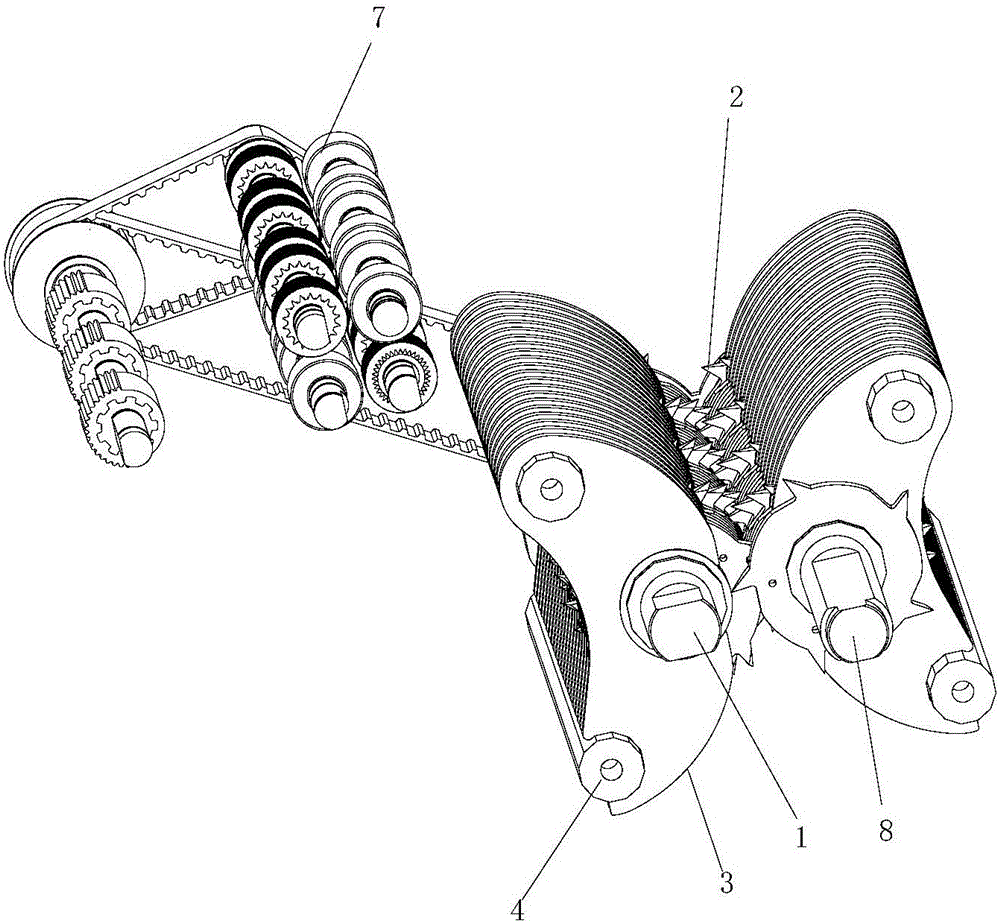

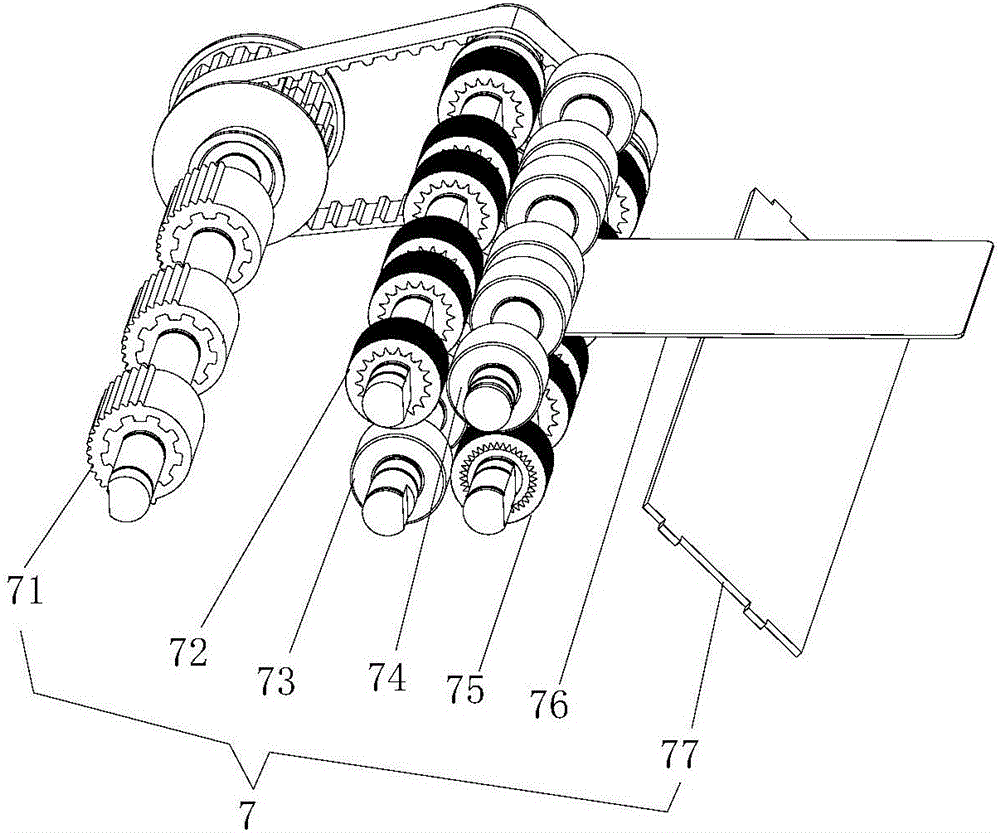

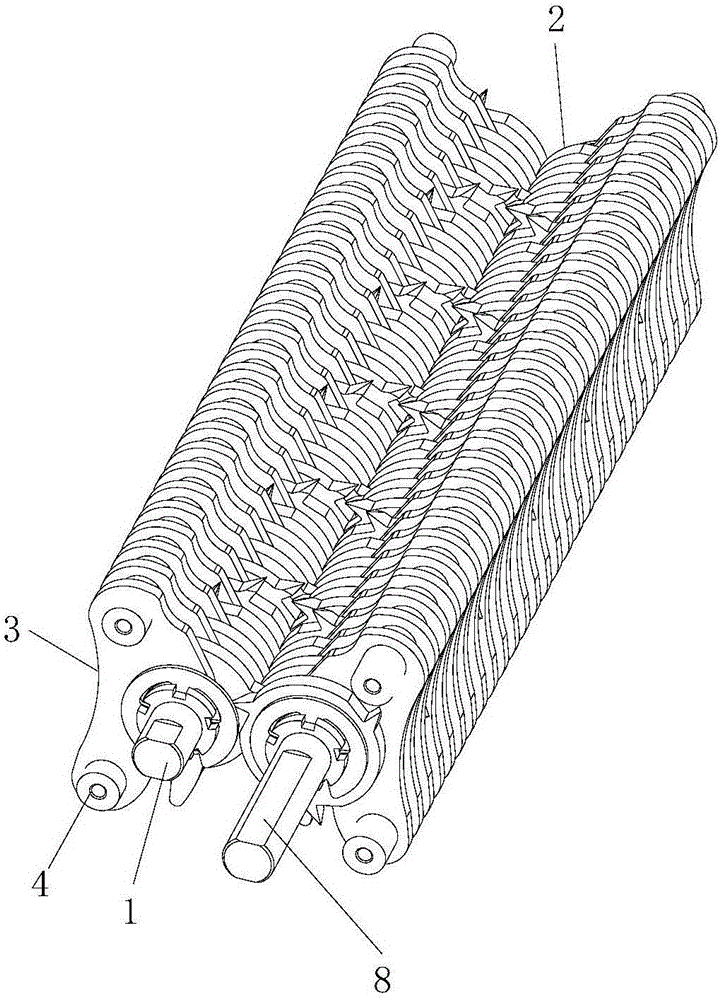

[0044] Such as Figure 1 to Figure 2 As shown, the card shredder of this embodiment includes a transmission assembly 7 and a cutter shaft assembly; the transmission assembly 7 includes a friction separation wheel 71 arranged below the stacked cards, and behind the friction separation wheel 71 is provided a vertical parallel arrangement. The first driving wheel 72 and the first driven wheel 73, between the first driving wheel 72 and the first driven wheel 73, be provided with the gap that is suitable for the card to be cut to pass through; The second driving wheel 74 and the second driven wheel 75 that are arranged in parallel up and down are arranged, be provided with the gap that is suitable for the card to be cut to pass between the second driving wheel 74 and the second driven wheel 75; The second driving wheel 74 and the second The rear of the driven wheel 75 is provided with an upper baffle plate 76 and a lower baffle plate 77, the upper baffle plate 76 is arranged horizo...

Embodiment 2

[0051] On the basis of Embodiment 1, the card shredder of this embodiment has the following deformations:

[0052] Such as Figure 12 As shown, the ring-shaped blade 2 of the present embodiment is made up of the left ring-shaped blade and the right ring-shaped blade that are all identical in structure and shape, and when the two ring-shaped blades are close together, the tip of the knife is also put together, The cross-section at the top of the knife point 22 formed is A-type; as Figure 13 As shown, the outer ring wall of the annular spacer 6 is provided with a V-shaped groove 62 along the circumference, as shown in the assembly. Figure 14 The A-shaped top of the shown knife point 22 is in close contact with the bottom of the V-shaped groove 62 .

Embodiment 3

[0054] On the basis of Embodiment 1, the card shredder of this embodiment has the following deformations:

[0055] Such as Figure 15 As shown, the ring-shaped blade 2 of the present embodiment is made up of the left ring-shaped blade and the right ring-shaped blade that are all identical in structure and shape, and when the two ring-shaped blades are close together, the tip of the knife is also put together, The section at the top of the formed knife point 22 is V-shaped; as Figure 16 As shown, the cross-section of the outer ring wall of the annular spacer 6 is set in an inverted V shape, so that a W-shaped recess is formed in the circumferential direction between the outer ring wall of the annular spacer 6 and the annular blades 2 on adjacent sides. Slot 62, assembled as Figure 17 The A-shaped top of the knife point 22 shown is adjacent to the bottom of the inverted V-shaped groove 62 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com