High-strength, high-elasticity modulus and low-stress gray cast iron and manufacturing method thereof

A manufacturing method and high-elasticity technology, which is applied in the field of gray cast iron, can solve the problems that it is difficult to achieve high strength and high elastic modulus at the same time, the heating and cooling speed, the holding time is not in accordance with the specification, and the residual stress changes greatly, so as to achieve good inoculation. effect, the effect of improving nucleation ability, and improving the uniformity of tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

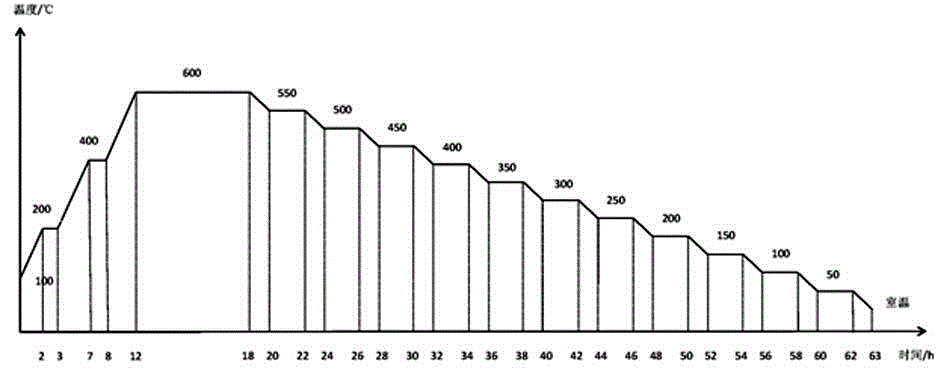

Method used

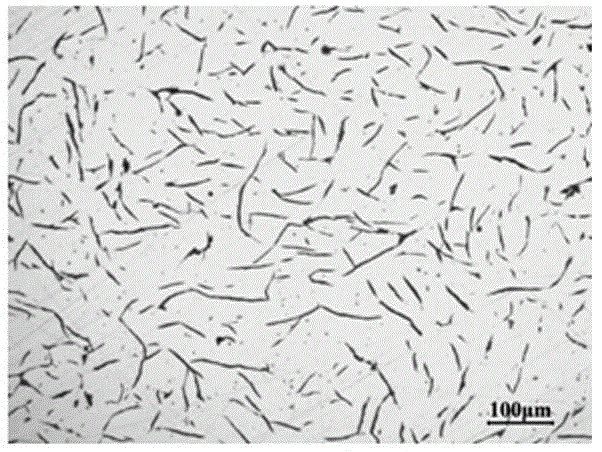

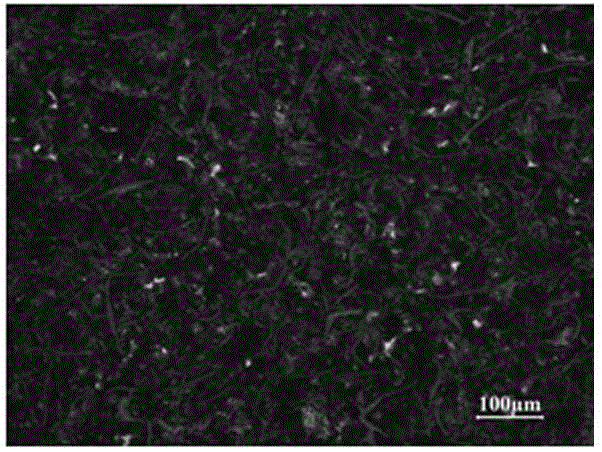

Image

Examples

Embodiment 1

[0034] The manufacturing composition is C: 3.15%; Si: 1.80%; CE: 3.75%; Mn: 0.80%; P≤0.07%; S: 0.06%; Cu: 0.50%; Cr: 0.20%; cast iron:

[0035]The first step, molding and core-making: use resin sand for molding and core-making, and paint alcohol-based graphite paint on the surface of the cavity. The important parts should be brushed twice. The surface of iron and cold iron is required to be flat and free of defects such as oil stains, pores, rust, and defects;

[0036] The second step, raw material preparation: Weigh raw materials according to the weight percentage of "carbon scrap: high-purity pig iron: return charge = 60%: 5%: 35%", wherein: the chemical composition of high-purity pig iron is: C: 4.61% ; Si: 0.62%; Mn: 0.08%; S: 0.026%; P: 0.011%; Ti: 0.030%, the balance is Fe; : 0.44%; S: 0.02%; P: 0.027%, the balance is Fe; the returned charge is the same material returned charge, the chemical composition is: C: 3.20%; Si: 1.90%; Mn: 0.80%; P: 0.03% ;S: 0.08%; Cu: 0.60%...

Embodiment 2

[0044] The manufacturing composition is C: 3.25%; Si: 1.90%; CE: 3.88%; Mn: 1.00%; P≤0.07%; S: 0.08%; Cu: 0.70%; Cr: 0.30%; cast iron:

[0045] The first step, molding and core-making: use resin sand for molding and core-making, and paint alcohol-based graphite paint on the surface of the cavity. The important parts should be brushed twice. The surface of iron and cold iron is required to be flat and free of defects such as oil stains, pores, rust, and defects;

[0046] The second step, raw material preparation: Weigh the raw materials according to the weight percentage of "carbon scrap: high-purity pig iron: return charge = 70%: 10%: 20%", wherein: the chemical composition of high-purity pig iron is: C: 4.61% ; Si: 0.62%; Mn: 0.08%; S: 0.026%; P: 0.011%; Ti: 0.030%; : 0.44%; S: 0.02%; P: 0.027%, the balance is Fe; the returned charge is the same material returned charge, the chemical composition is: C: 3.20%; Si: 1.90%; Mn: 0.80%; P: 0.03% ;S: 0.08%; Cu: 0.60%; Cr: 0.25%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com