Method for improving optional performances of large H13 steel hot-extrusion mould

A hot extrusion die and performance technology, which is applied in the field of improving the performance of large H13 steel hot extrusion dies, can solve the problems of short service life of the die, uneven internal structure, and insufficient density, etc., to improve the structure of the crystal phase, eliminate Network carbide, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be further described below in conjunction with the drawings:

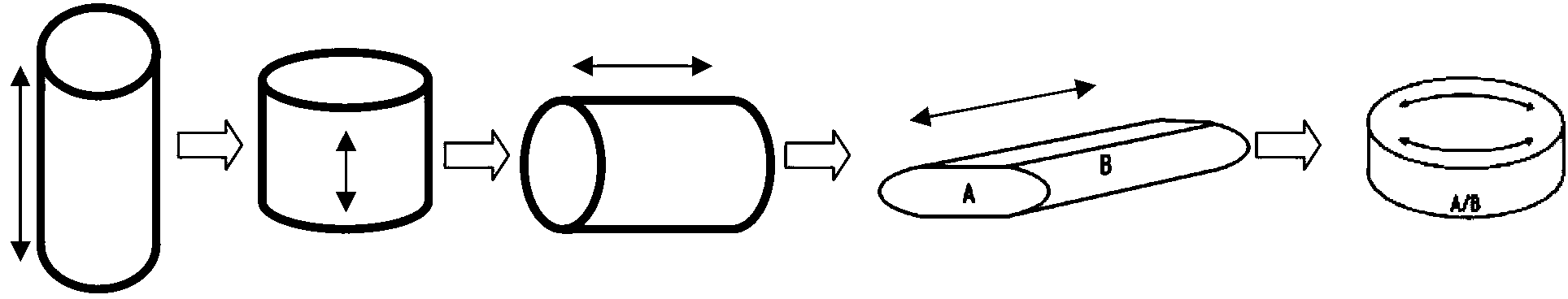

[0015] The method of the present invention for improving the performance of a large H13 steel hot extrusion die includes the transverse fiber flow direction forging used in the forging process, post-forging normalizing and spheroidizing annealing, which specifically includes the following steps:

[0016] 1) When the blank is loaded into the furnace, the temperature in the furnace is 400-450°C, after the furnace is loaded, the temperature is increased to 850-900°C at a rate of 55-60°C / h, and after holding for 2 hours, the temperature is increased at a rate of 100-110°C / h To 1180~1200℃, keep for 3h;

[0017] 2) Carry out axial forging of the blank, upsetting and drawing out operations no less than 4 times, forging ratio ≥4, continue to carry out radial forging of the blank, in the order of upsetting, rounding, and leveling, no less than 4 operations to make The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com