Tungsten alloy and preparation method thereof

A technology of tungsten alloy and alloy elements, which is applied in the field of tungsten alloy and its preparation, can solve the problems of insufficient solid solution strengthening, incomplete solid solution of alloy elements, low plasticity and toughness, etc., to achieve increased strength and hardness, improved plasticity and Toughness, the effect of improving the plasticity and toughness of alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

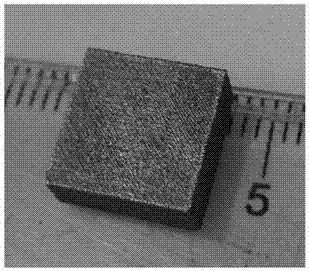

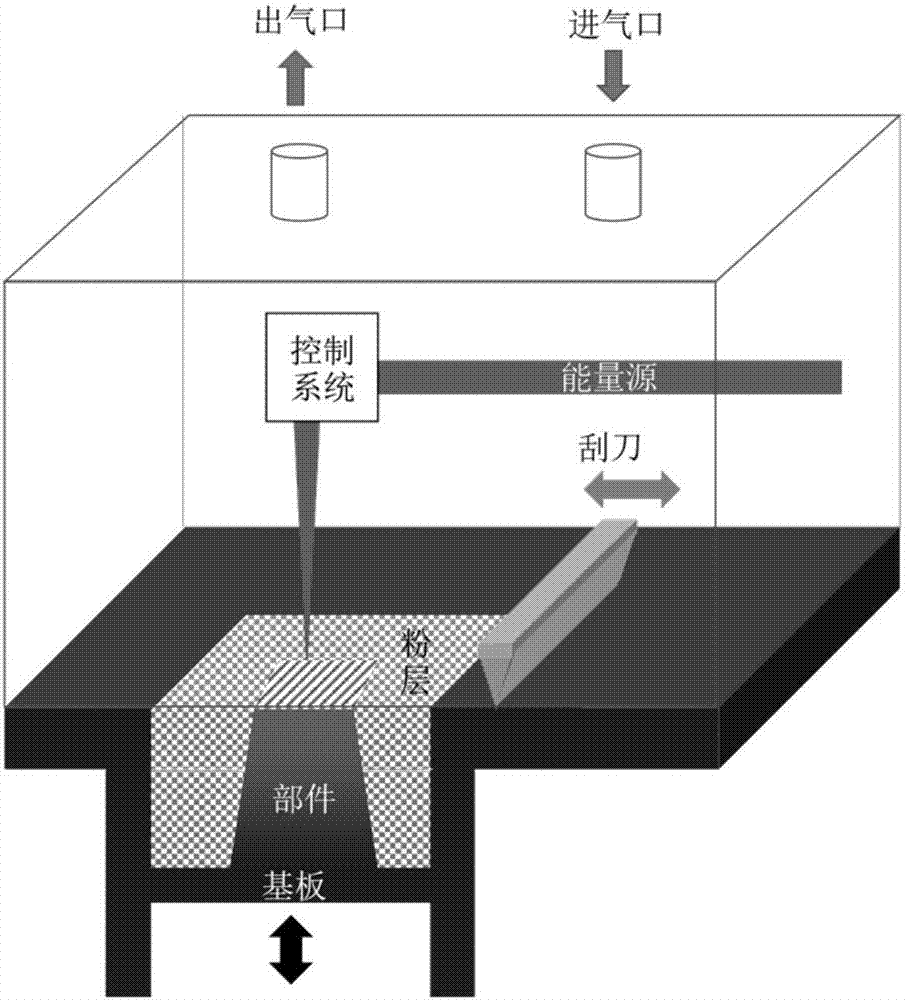

[0048] Mount the metal substrate on the working platform of the fiber laser (see figure 1 ), and at the same time control the gap between the powder spreading scraper and the metal substrate to be 30 μm, take polygonal tungsten powder particles with no impurities and oxygen adsorption on the surface, and the particle size of the tungsten powder is 36 μm.

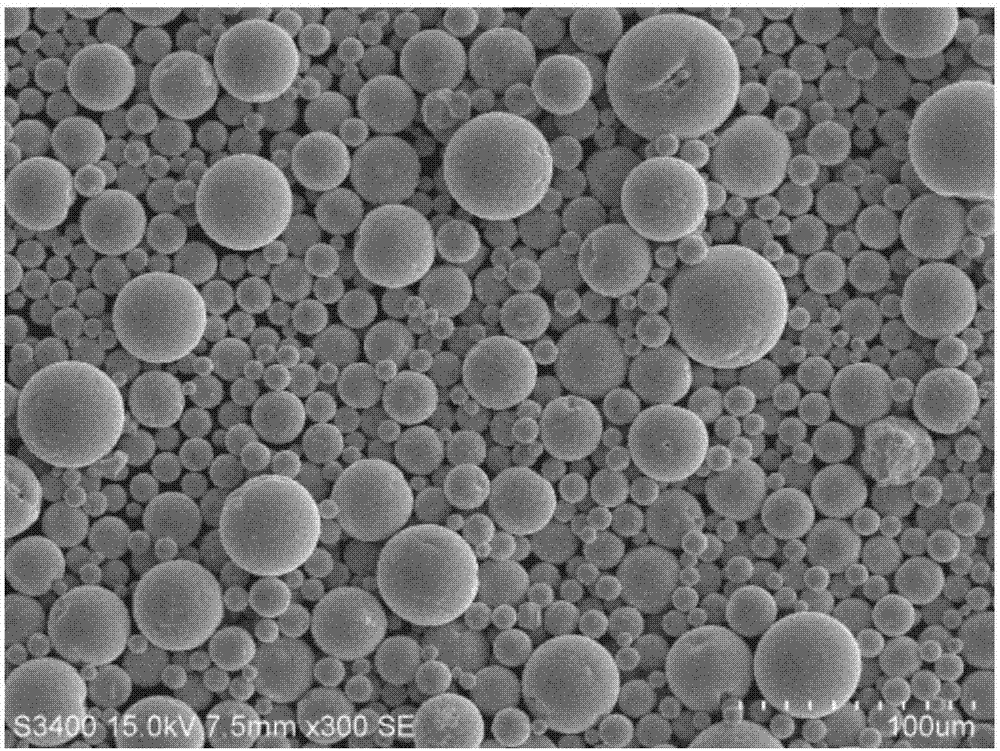

[0049] Use the induction plasma spheroidization equipment to spheroidize the tungsten powder, the voltage is 8.5kV, the current is 4.5A, the spheroidization power is 35kW, the powder feeding speed is 1rpm, the spherical powder see figure 2 , The spherical powder particle size is 28μm.

[0050] take as figure 2 The spherical tungsten powder shown is to which 6% by weight of tantalum is added as an alloying element, and the two powders are mechanically mixed to obtain tungsten alloy powder. Fill the mixed tungsten alloy powder into the powder silo.

[0051] Seal the forming cavity, evacuate to a relative vacuum of -90KPa,...

Embodiment 2

[0055] Mount the metal substrate on the working platform of the fiber laser (see figure 1 ), and at the same time control the gap between the powder spreading scraper and the metal substrate to be 60 μm, take polygonal tungsten powder particles with no impurities and oxygen adsorption on the surface, and the particle size of the tungsten powder is 40 μm.

[0056] The powder is spheroidized by induction plasma spheroidization equipment, the voltage is 10kV, the current is 4.5A, the spheroidization power is 38kW, the powder feeding speed is 1.5rpm, the spheroidized powder has a particle size of 25μm.

[0057] Spherical tungsten powder is taken, 10% by weight of molybdenum is added thereto as an alloying element, and the two powders are mechanically mixed to obtain tungsten alloy powder. Fill the tungsten alloy powder into the powder silo.

[0058] Seal the forming cavity, evacuate to a relative vacuum of -100KPa, and input protective gas argon into the forming cavity; repeatedl...

Embodiment 3

[0062] Mount the metal substrate on the working platform of the fiber laser (see figure 1 ), and at the same time control the gap between the powder spreading scraper and the metal substrate to be 80 μm, take polygonal tungsten powder particles with no impurities and oxygen adsorption on the surface, and the particle size of the tungsten powder is 45 μm.

[0063] The powder is spheroidized by induction plasma spheroidization equipment, the voltage is 9.5kV, the current is 6A, the spheroidization power is 36kW, the powder feeding speed is 2rpm, the spheroidized powder has a particle size of 20μm.

[0064] Spherical tungsten powder is taken, 10% by weight of niobium is added thereto as an alloying element, and the two powders are mechanically mixed to obtain tungsten alloy powder. Fill the tungsten alloy powder into the powder silo.

[0065] Seal the forming cavity, evacuate to a relative vacuum of -80KPa, and input protective gas argon into the forming cavity; repeatedly vacuu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molding density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com