800MPa-grade high-strength steel for engineering machinery and production method of 800MPa-grade high-strength steel

A technology for construction machinery and production methods, which is applied in the field of high-strength steel for construction machinery of 800MPa and its production field, can solve the problems of relatively few studies on the microstructure and properties of ultra-high-strength steel, and achieve the effect of improving plasticity and toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with embodiment.

[0056] The production process flow of the high-strength steel in the present invention is: smelting, casting→heating→rolling→cooling→heat treatment.

[0057] The specific components and process parameters are shown in Table 1 and Table 2, and the properties of the steel plates of each embodiment are shown in Table 3.

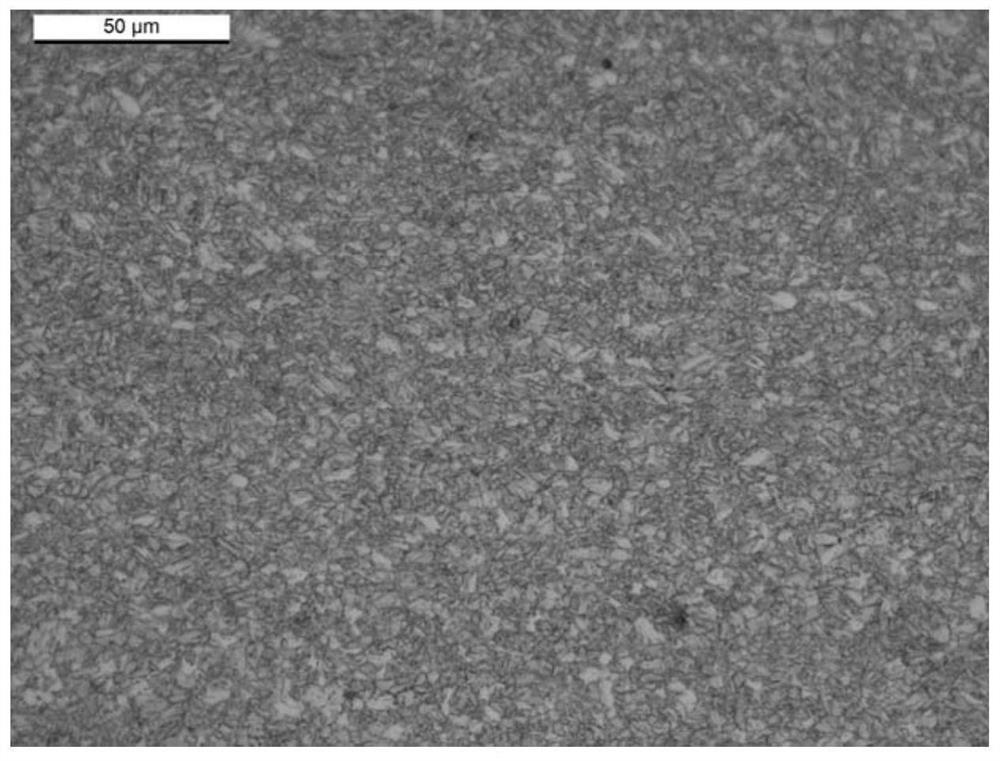

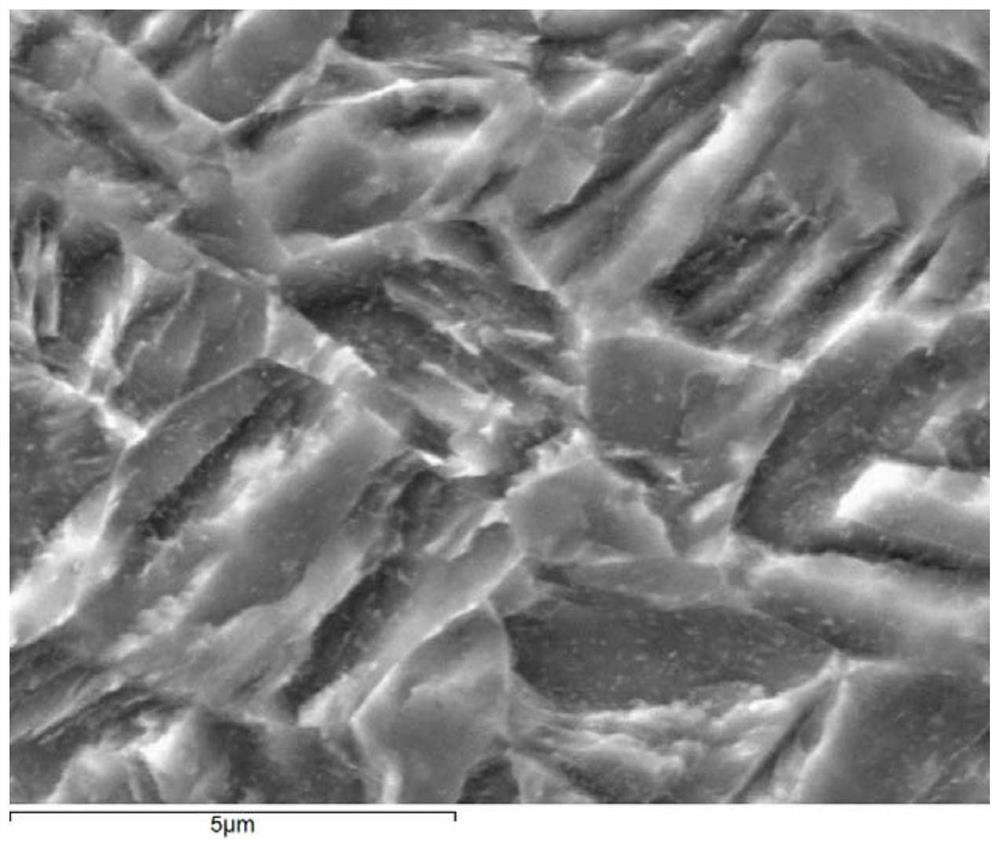

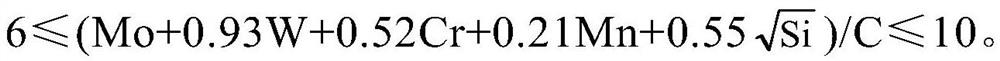

[0058] figure 1 and figure 2 The metallographic structure photos of the steel in Example 3 and the metallographic structure photos of the scanning electron microscope are given respectively. From figure 1 It can be seen that the metallographic structure of the finished steel plate is tempered sorbite, and the structure is fine and dense, the tempered sorbite grain size is 3-5 microns, and the tempered sorbite sheet width is 30-90 nanometers, the same Composition According to the conventional heat treatment process, the tempered sorbite grain size is about 15-20 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com