Bulk metal glass composite material with stretching plasticity and work hardening capacity

A work hardening, bulk metal technology, applied in the field of bulk metal glass composite materials, can solve the problems of inability to obtain engineering applications, no bearing capacity, strain softening, etc., and achieve the effects of safe use, convenient preparation, and large plastic deformation capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

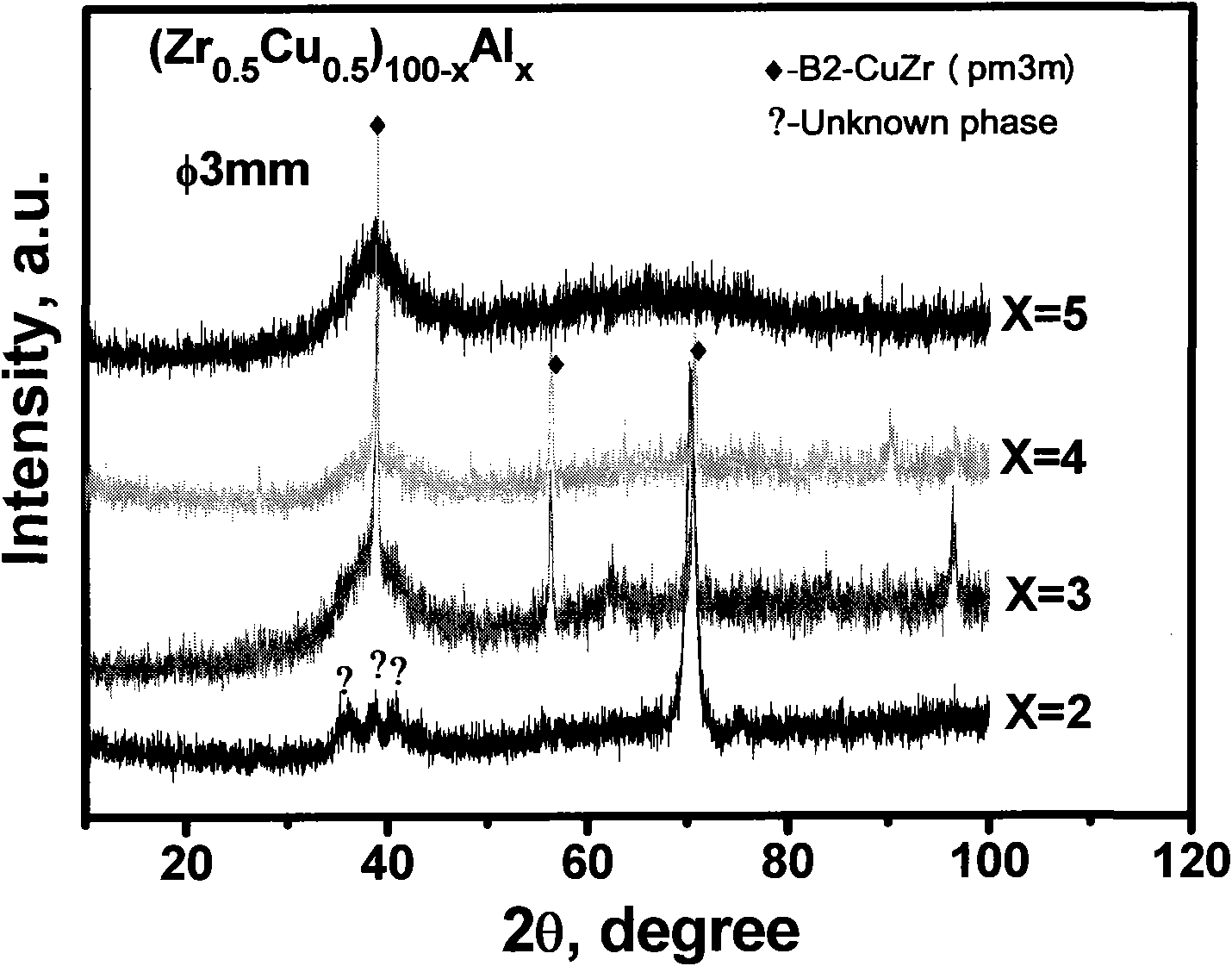

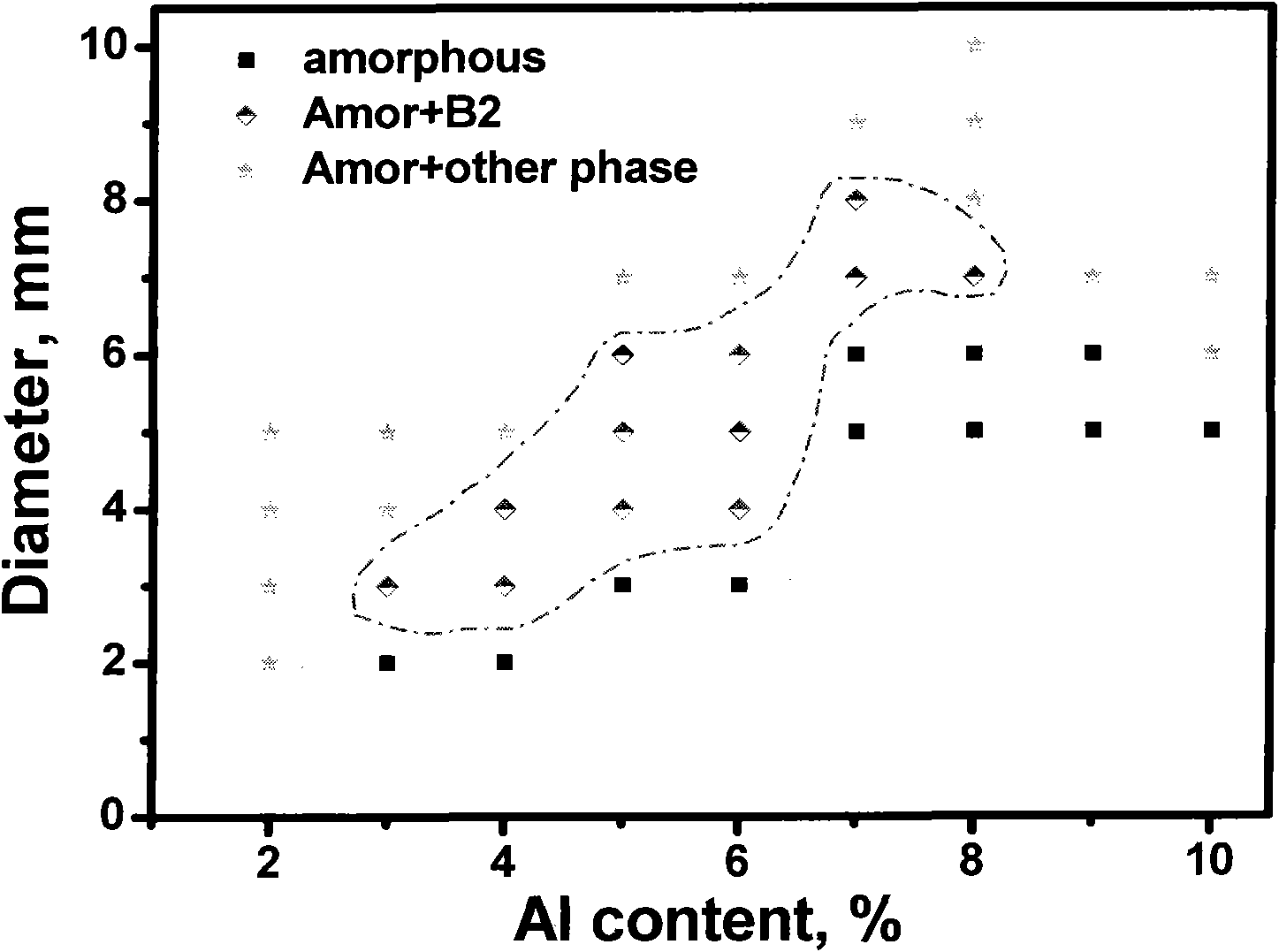

[0040] Preparation (Zr 0.5 Cu 0.5 ) 100-x al x Ternary Metallic Glass Composites

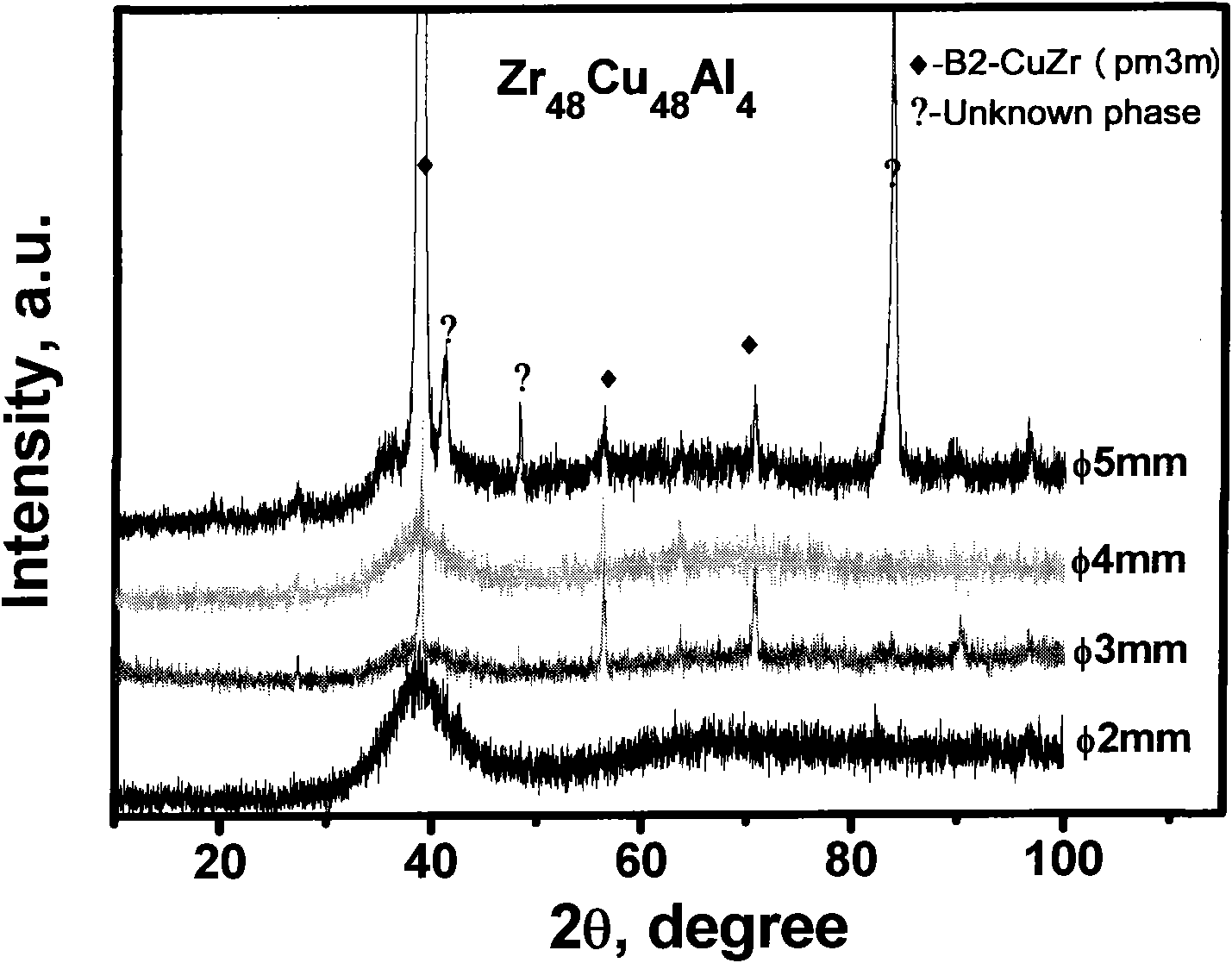

[0041] Adopt commercially available purity to be higher than 99.9% (percentage by weight) common pure metal Zr, Cu, Al press composition formula (Zr 0.5 Cu 0.5 ) 100-x al x (Atomic molar ratio, 0≤x≤10) ratio is well matched, and test rods with different diameters are suction-cast. With the change of Al content, the amorphous forming ability of the alloy will change, and the cooling rate of the prepared sample is different with the different suction casting diameter. figure 1 is Zr 48 Cu 48 al 4 X-ray diffraction patterns of alloy samples with different suction casting diameters. It can be seen that when the suction casting diameter is small, that is, when the cooling rate is high, the obtained sample structure is a fully amorphous structure; as the suction casting diameter increases, that is, the cooling rate decreases, the amorphous matrix begins to The body-centered cubic B2-CuZr p...

Embodiment 2

[0044] (Zr 0.5 Cu 0.5 ) 100-x al x Influence of Adding Doping Elements in Ternary Alloy System

[0045] In the alloy system provided by the present invention, the doping of other elements will significantly change the structure and properties of the alloy. Figure 5 is Zr 48 Cu 48 al 4 The X-ray diffraction pattern of the 3mm test rod doped with different contents of Fe in the medium, wherein, the abscissa is the 2θ angle; the ordinate is the diffraction intensity (arbitrary unit), and the structure of the 3mm test rod compared with the suction casting can be It can be seen that after the addition of 0.5% Fe element, the B2-CuZr phase in the test bar is reduced, and it is close to a completely amorphous structure, indicating that the amorphous forming ability of the alloy has increased. When the addition of Fe element reaches 1%, the B2-CuZr phase in the test bar increases, indicating that the amorphous formation ability of the alloy is reduced compared with that of 0.5...

Embodiment 3

[0047] Preparation of Zr with crystal phase volume fraction of 30% 48 Cu 47.5 al 4 co 0.5 Amorphous composite material

[0048] Commercially available pure metals Zr, Cu, Al, and Co with a purity higher than 99.9% (weight percent) are prepared in an atomic ratio of 48:47.5:4:0.5, and firstly arc smelted under an argon atmosphere protected by a titanium ingot , each alloy ingot needs to be smelted more than 5 times to ensure that the composition of the master alloy is uniform. Then take an appropriate amount of master alloy material and place it on the top of the water-cooled copper mold, re-melt the alloy melt by electric arc under the argon or helium atmosphere, and suck and cast the alloy melt into the lower water-cooled copper mold. The inner cavity diameter of the copper mold is 3mm. Figure 7 It is Zr with copper mold suction casting diameter of 3mm 48 Cu 48 al 4 、Zr 48 Cu 47.5 al 4 co 0.5 Alloy and Zr with a diameter of 5mm 47 Cu 47 al 6 The cross-sectiona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com