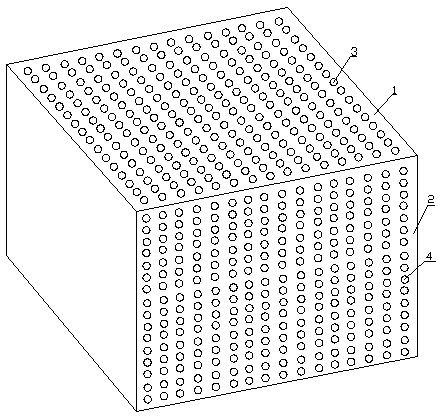

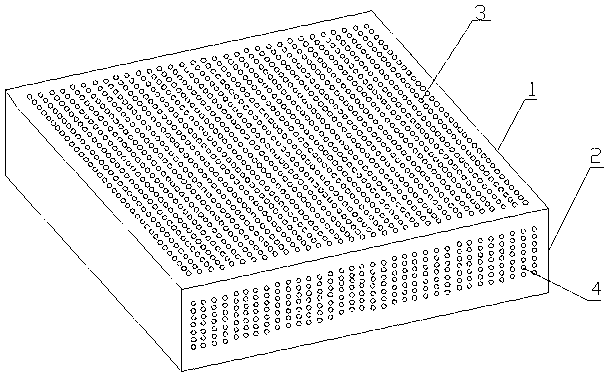

Heat exchanging component made of ceramic materials and preparation method thereof

A technology of heat exchange elements and ceramic materials, applied in the field of heat exchange elements and their preparation, can solve the problems affecting the life of the heat exchanger in continuous operation of the production process, restricting the use range and application effect of the heat exchanger, fluid flow rate, flow rate, temperature, etc. Improper parameters and other problems, to achieve the effect of improving stability and equipment safety, reducing exhaust emission pollution, and small thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: the preparation method of ceramic material and ceramic heat exchange element

[0051] Including raw material mixing - mixed grinding pulping - pouring molding - trimming blank - sintering into the furnace - sintering out of the furnace - inspection and warehousing steps.

[0052] (1) Mixing of raw materials:

[0053] The raw material ratio that present embodiment adopts is:

[0054] Silicon carbide (SiC) 72kg,

[0055] Silicon nitride (Si 3 N 4 ) 3 kg,

[0056] β-phase sialon (sialon) 3 kg,

[0057] Aluminum nitride (AlN) 3 kg,

[0058] Flux 3 kg (including magnesium oxide (MgO) 1kg, silicon (Si) powder 2kg),

[0059] Adhesive 15 kg (including 10 kg of clay, 1.5 kg of methyl cellulose, 2 kg of tung oil, 1.5 kg of paraffin),

[0060] The molding aid uses 1kg of alum.

[0061] (2) Mixed grinding and pulping:

[0062] Add the above raw materials and 40 kg of water into a ball mill, and mix and grind in the ball mill for 24 hours to make a mud slurry...

Embodiment 2

[0073] Embodiment 2: the preparation method of ceramic material and ceramic heat exchange element

[0074] Concrete operation process flow is with embodiment 1.

[0075] The ratio of raw materials selected in this embodiment is:

[0076] Silicon carbide (SiC) 80kg,

[0077] Silicon nitride (Si 3 N 4 ) 1 kg,

[0078] β-phase sialon (sialon) 1 kg,

[0079] Aluminum nitride (AlN) 1 kg,

[0080] Flux 1kg (including magnesium oxide (MgO) 0.5kg, silicon (Si) powder 0.5kg),

[0081] Adhesive 15 kg (including 10 kg of clay, 1.5 kg of polyvinyl alcohol, 2 kg of tung oil, 1.5 kg of paraffin),

[0082] The molding aid is 1kg of liquid silica gel.

[0083] The firing operation process of this embodiment is as follows: the blower blows air on the shell of the electric furnace until the temperature inside the electric furnace drops below 300°C, then opens the furnace door, continues to cool down naturally to a temperature that can be handled by workers, and then sends it out for in...

Embodiment 3

[0085] Embodiment 3: the preparation method of ceramic material and ceramic heat exchange element

[0086] Concrete operation steps are with embodiment 1.

[0087] The proportion of raw materials selected in this embodiment is: silicon carbide (SiC) 85kg,

[0088] Flux 1kg (including magnesia (MgO) 0.3kg, silicon (Si) powder 0.7kg),

[0089] Adhesive 14kg (including 9kg of Shuo soil, 1.5kg of polyvinyl alcohol, 2 kg of tung oil, 1.5 kg of paraffin wax),

[0090] In this example, a natural gas furnace is selected for sintering, and the trimmed blank is placed in a natural gas furnace, and the temperature is raised slowly and evenly to 800°C for 4 hours using a reducing flame, with a heating rate of 3.33°C / min, and after maintaining a constant temperature of 800°C for 2-3 hours Heating, using an oxidizing flame for firing, it is required to gradually and evenly raise the temperature to 1400°C within 5 hours of firing, the heating rate is 2°C / min, and the furnace is shut down ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com