Method for corrosion repair and long-term protection of ship propeller

A technology for propellers and ships, applied in the field of corrosion repair and long-term protection of ship propellers, can solve the problems of ship propeller corrosion, complex process operation, deformation of propeller blades, etc., and achieves good anti-cavitation corrosion performance, low maintenance risk, and thermal impact. small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

[0041] refer to Figure 1-13 , is an embodiment of a method for corrosion repair and long-term protection of ship propellers.

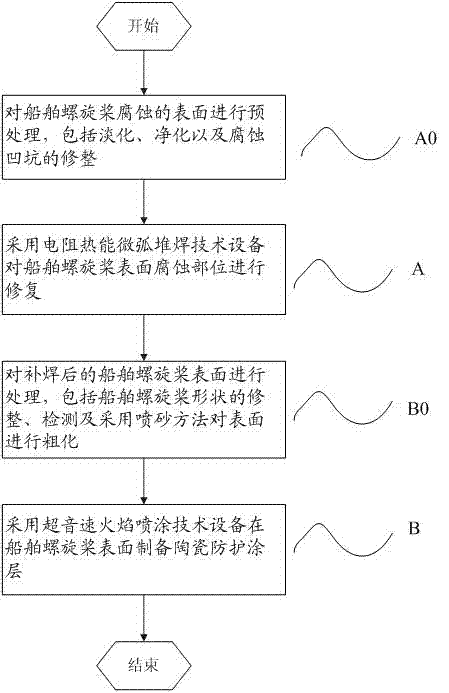

[0042] A method for corrosion repair and long-term protection of ship propellers, comprising the steps of:

[0043] A. Use resistance thermal micro-arc surfacing equipment to repair the corroded parts on the surface of ship propellers;

[0044] B. Use supersonic flame spraying equipment to prepare ceramic protective coatings on the surface of ship propellers.

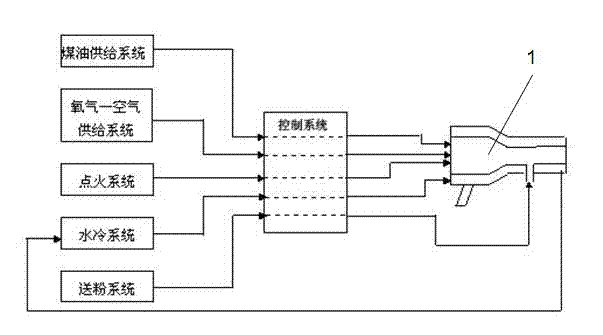

[0045] Among them, the resistance thermal energy micro-arc surfacing equipment includes pulse precision welding repair system and electric spark ion micro-arc surfacing syste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com