Selective solar energy absorbing film system and preparation method thereof

A selective, absorbing film technology, applied in the field of solar thermal conversion, can solve the problems of not adapting to the requirements of solar collectors, short service life, unable to bear pressure, etc., to improve the anti-reflection effect, improve service life, and not easy to fall off Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

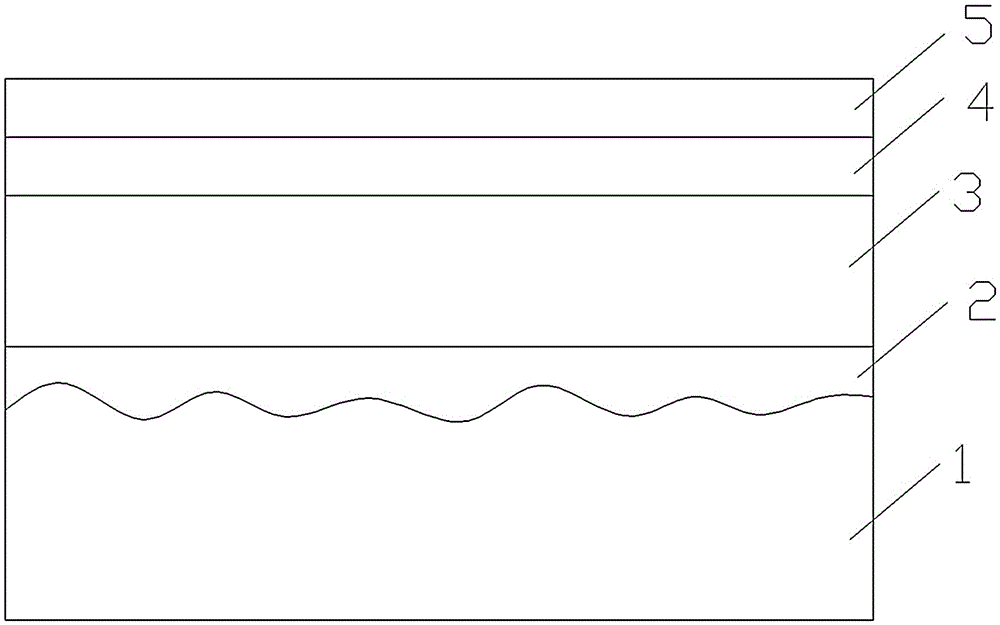

[0021] Such as figure 1 As shown, the present invention provides a solar selective absorption film system, including a metal substrate 1, the top surface of the metal substrate 1 is a rough microstructure, and the top surface of the metal substrate 1 is deposited with a TiAlN absorption barrier layer 2, TiAlN A TiNxOy absorber layer 3 is deposited on the absorber barrier layer 2, and SiO is deposited on the TiNxOy absorber layer 2 AR layer 4, SiO 2 An AlN antireflection protection layer 5 is deposited on the antireflection layer 4 .

[0022] The metal base 1 can be silver foil, Cu foil or Al foil with a thickness of 0.3 mm, or a layer of Ag film, Cu film or Al film can be deposited on the stainless steel foil as the metal base 1; the TiAlN absorbs The barrier layer 2 has a thickness of 30-50 nm, the TiNxOy absorbing layer 3 has a thickness of 100-150 nm, and the SiO 2 The thickness of the anti-reflection layer 4 is 30-50 nm, and the thickness of the AlN anti-reflection prot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com