Preparation method of super-hydrophobic micro-nano structure on titanium alloy surface

A micro-nano structure, titanium alloy technology, applied in the field of material surface treatment, can solve the problems of complicated procedures, short life, expensive equipment, etc., achieve good fatigue strength and crack growth resistance, high specific strength and specific fracture toughness, high resistance to excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

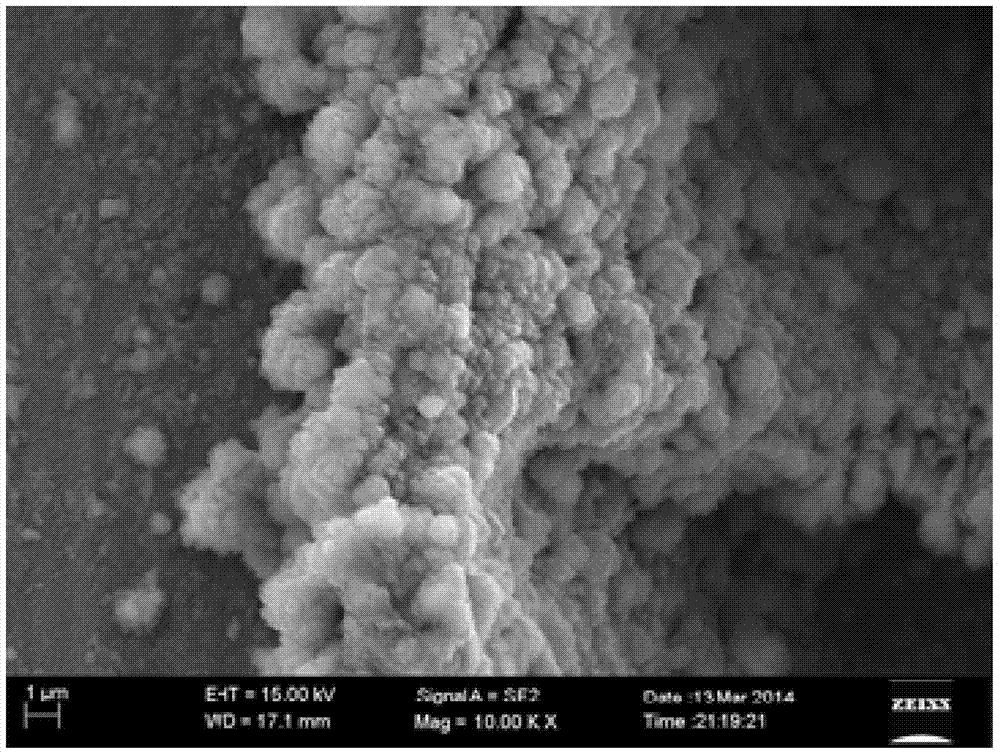

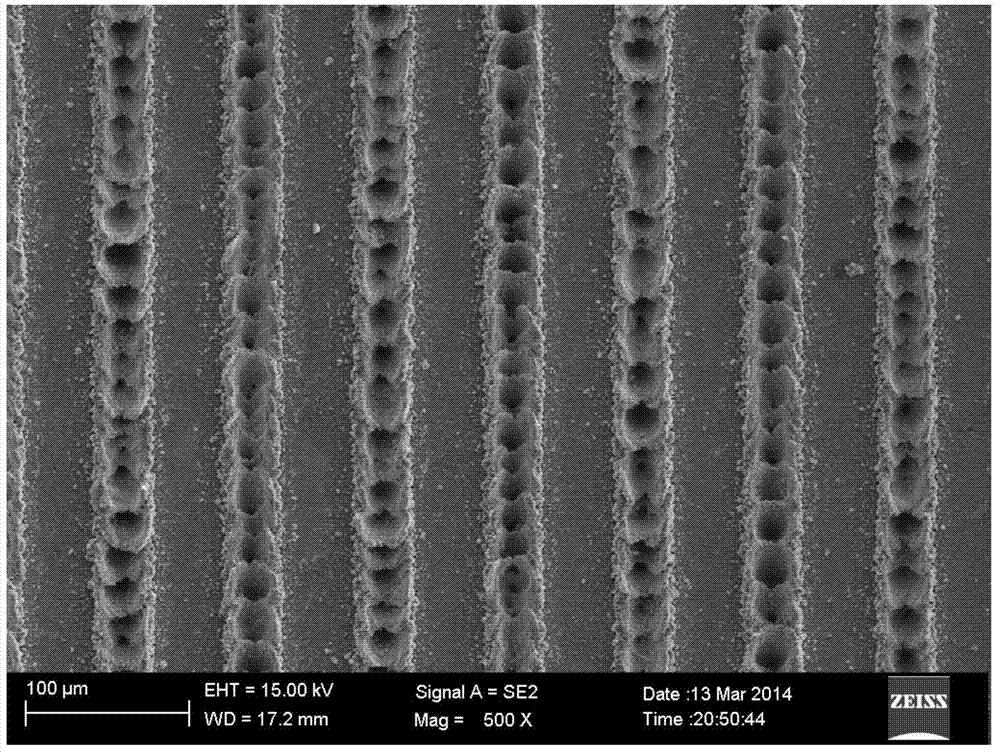

[0034] This embodiment provides a method for preparing a super-hydrophobic micro-nano structure on the surface of a titanium alloy, which can prepare a super-hydrophobic micro-nano structure on the surface of a parallel grating titanium alloy, including the following steps:

[0035] Ultrasonic cleaning was performed on the surface of the titanium alloy sample with acetone and absolute alcohol respectively to obtain a clean surface of the titanium alloy sample;

[0036] Perform femtosecond laser lithography processing on the clean titanium alloy sample surface to obtain super-hydrophobic micro-nano structure on the surface of parallel grating titanium alloy in one step;

[0037] Among them, the femtosecond laser beam is fixed and perpendicular to the surface of the material to be processed. The single pulse energy of the femtosecond laser beam is 120μJ, the pulse width is 300fs, the center wavelength is 800nm, and the repetition frequency is 1kHz. The etching spot of the femtose...

Embodiment 2

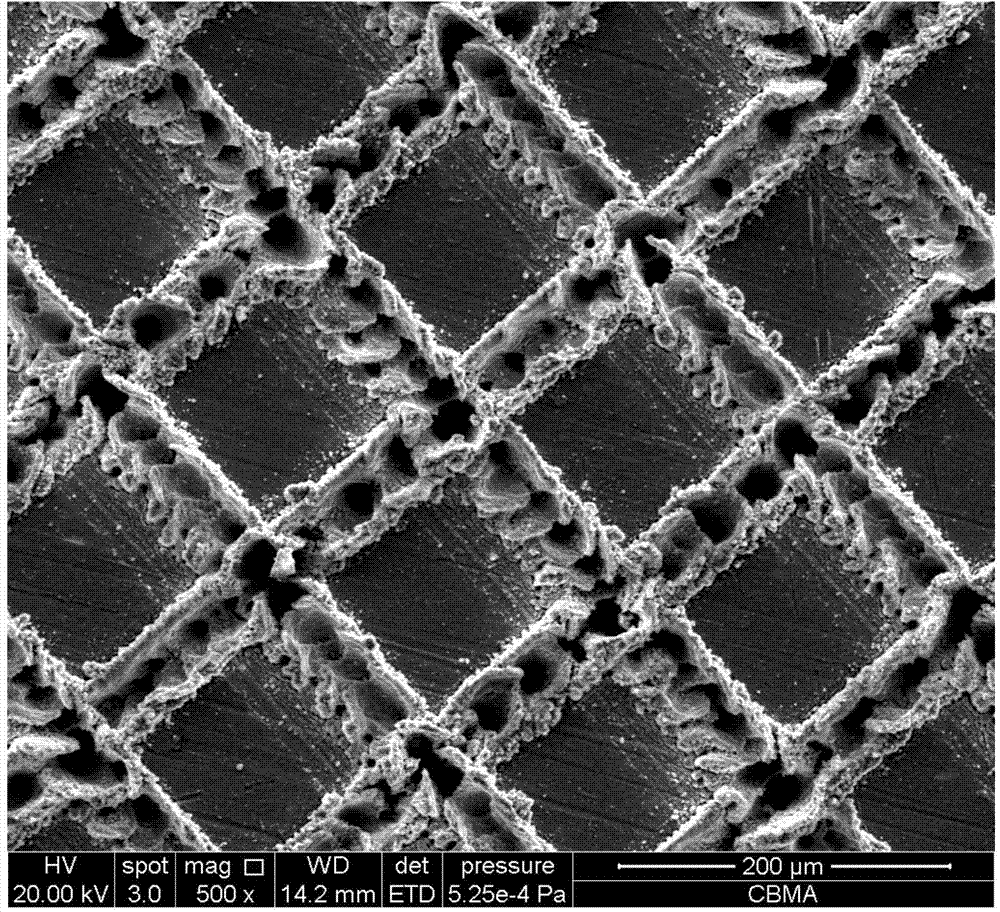

[0042] This embodiment provides a method for preparing a super-hydrophobic micro-nano structure on the surface of a titanium alloy, which can prepare a super-hydrophobic micro-nano structure on the surface of a well-shaped titanium alloy, including the following steps:

[0043] Ultrasonic cleaning was performed on the surface of the titanium alloy sample with acetone and absolute alcohol respectively to obtain a clean surface of the titanium alloy sample;

[0044] Femtosecond laser lithography processing is performed on the surface of a clean titanium alloy sample to obtain a super-hydrophobic micro-nano structure on the surface of a well-shaped titanium alloy;

[0045] Among them, the femtosecond laser beam is fixed and perpendicular to the surface of the material to be processed. The single pulse energy of the femtosecond laser beam is 120μJ, the pulse width is 300fs, the center wavelength is 800nm, and the repetition frequency is 1kHz. The etching spot of the femtosecond las...

Embodiment 3

[0049] This embodiment provides a method for preparing a super-hydrophobic micro-nano structure on the surface of a titanium alloy, which can prepare a super-hydrophobic micro-nano structure on the surface of a circular blind-hole titanium alloy, including the following steps:

[0050] Ultrasonic cleaning was performed on the surface of the titanium alloy sample with acetone and absolute alcohol respectively to obtain a clean surface of the titanium alloy sample;

[0051] Femtosecond laser lithography processing is performed on the surface of a clean titanium alloy sample to obtain a superhydrophobic micro-nano structure on the surface of a circular blind-hole titanium alloy in one step;

[0052] Among them, the femtosecond laser beam is fixed and perpendicular to the surface of the material to be processed. The single pulse energy of the femtosecond laser beam is 120μJ, the pulse width is 300fs, the center wavelength is 800nm, and the repetition frequency is 1kHz. The etching ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com