Method for preparing catalyst and application thereof

A catalyst and catalytic activity technology, applied in catalyst carriers, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of powder falling off of active components, reducing the utilization efficiency of active components, etc., to achieve uniform shell layer, preparation of The process is easy to control and the operation is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

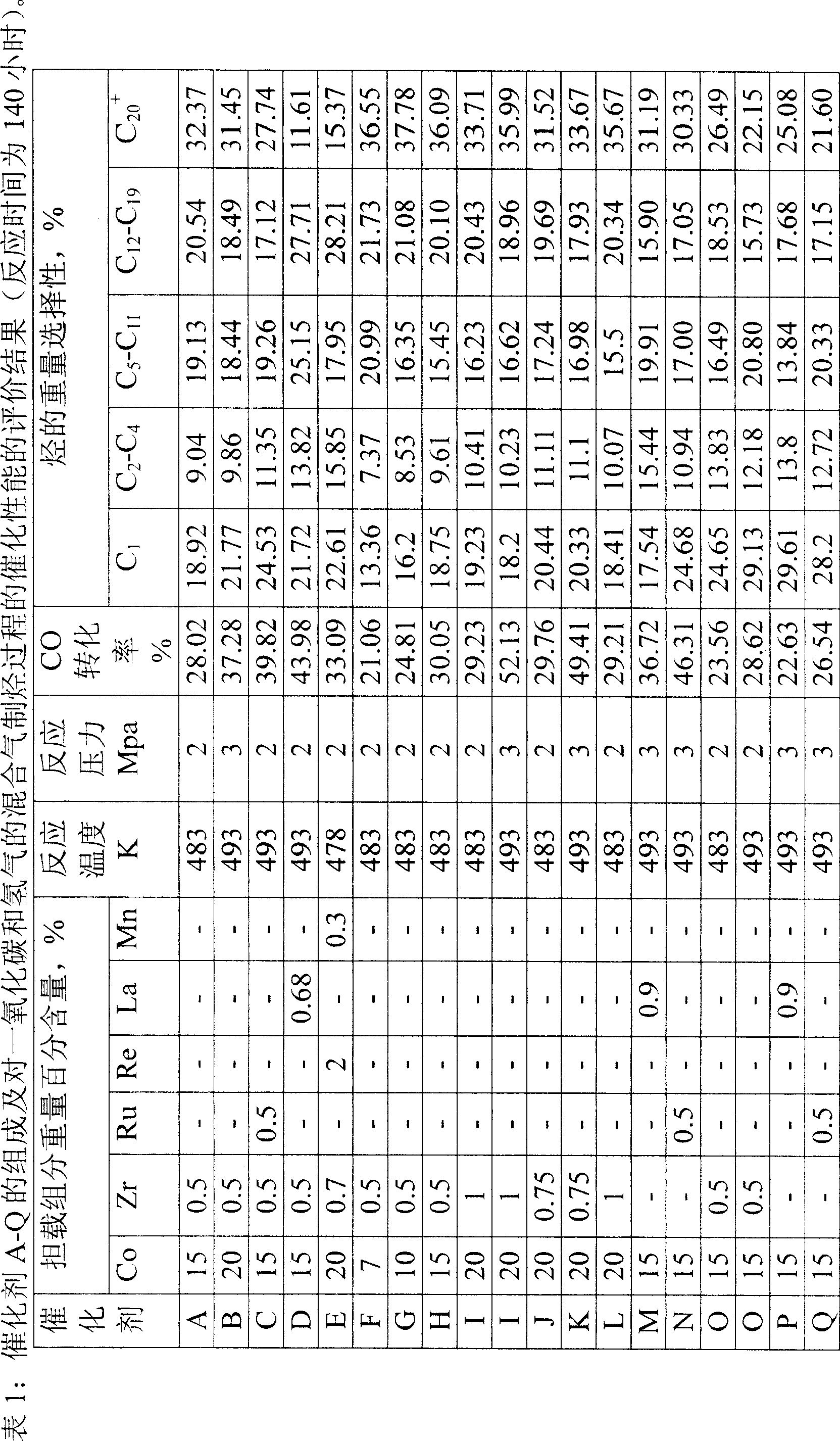

Examples

Embodiment 1

[0053] The supporting components of catalyst A are Co and Zr, with spherical SiO 2 As a carrier, the particle size is 1.5-3mm. Catalyst is prepared according to the following steps:

[0054] a) The required amount of zirconium nitrate is loaded on the carrier by a conventional impregnation method, then dried at 383K for 6 hours, and calcined at 573K for 6 hours;

[0055] b) Dissolving the required amount of cobalt nitrate in water to make a solution, the weight ratio of the solution to the carrier is 3:1;

[0056] c) spraying the solution prepared in step b) onto a rolling carrier pre-loaded with Zr components, and the spraying speed of the solution is 1 kg of solution per kg of carrier per hour. The rolling of the carrier during the spraying process is carried out in a rotating container. The angle between the rotation plane of the container and the horizontal plane is 60 degrees. The rotational speed of the container was 30 revolutions per minute. The carrier temperatur...

Embodiment 2

[0059] The supporting components of catalyst B are Co and Zr, and the carrier and preparation process used are the same as catalyst A.

Embodiment 3

[0061] The supporting components of the catalyst C are Co, Ru and Zr, the spherical SiO2 is used as the carrier, and the particle size is 1.5-3 mm. Catalyst is prepared according to the following steps:

[0062] a) Load the required amount of zirconium nitrate on the carrier by conventional impregnation method, then dry at 353K for 6 hours, and bake at 573°C for 6 hours;

[0063] b) the required amount of cobalt nitrate and RuCl 3 Dissolve in water to make a solution, the weight ratio of the solution to the carrier is 3:1;

[0064] c) spraying the solution prepared in step b) onto a rolling carrier pre-loaded with Zr components, and the spraying speed of the solution is 1 kg of solution per kg of carrier per hour. The rolling of the carrier during the spraying process is carried out in a rotating container. The angle between the rotation plane of the container and the horizontal plane is 60 degrees. The rotational speed of the container was 30 revolutions per minute. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com