Lamella catalyst for preparing petroleum naphtha and diesel oil, preparation method and application thereof

A catalyst and naphtha technology, applied in the field of shell catalysts, can solve the problems of falling off of active component powder and reducing the utilization efficiency of active components, and achieve the effects of uniform shell layer, easy control of preparation process and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043]According to the method for preparing a catalyst provided by the present invention, the catalytically active component can be any element and its compound known to have catalytic activity. The additive component can be any element and its compound known to have a promoting effect on reaction activity, product selectivity or catalyst stability. The supported component contained in the solution used for spraying the carrier may be a catalytic active component, or an auxiliary component, or simultaneously include a catalytic active component and an auxiliary component. When two or more loaded components are loaded by the method of spraying, different loaded components may be loaded at the same time, or not at the same time. When the catalytic active component and the auxiliary component are not loaded at the same time, the auxiliary component can be loaded first, and then the catalytic active component, or the catalytic active component can be loaded first, and then the aux...

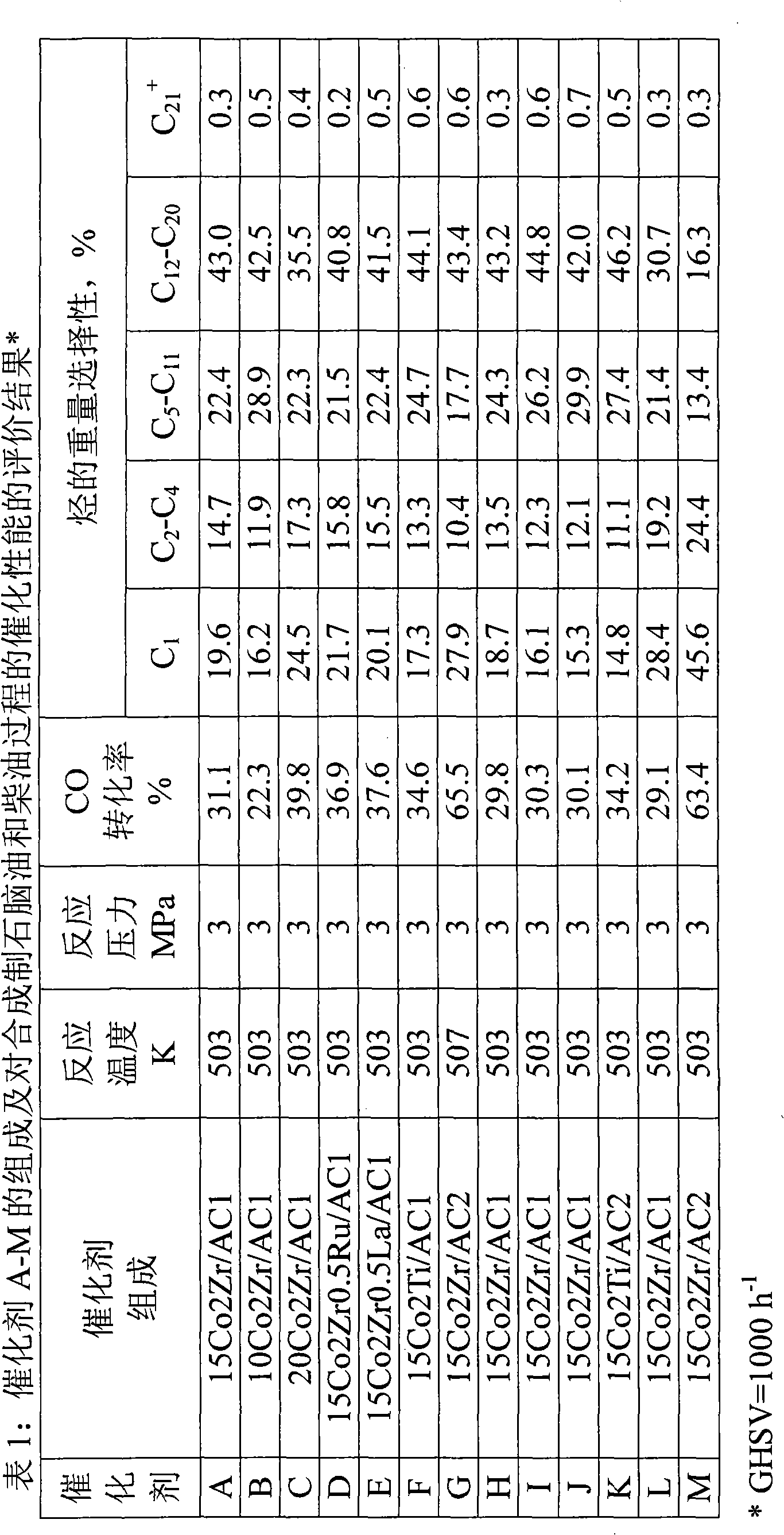

Embodiment 1

[0061] The supporting components of catalyst A are Co and Zr, and the activated carbon AC1 (AC represents activated carbon, 1 is the type of activated carbon, 1 is apricot kernel charcoal, and 2 is coconut shell charcoal) is used as the carrier, and the particle size is 1.5-2.5mm. 15Co2Zr / AC1 catalyst is prepared according to the following steps:

[0062]10,000 grams of apricot kernel charcoal carrier is washed three times with boiling deionized water (about 373K), and dried at 393K for 8 hours. Weigh 183.2 grams of zirconyl nitrate and dissolve it in 5000ml deionized water to make a solution and place it in a separatory funnel, weigh 3.00 kilograms of activated carbon and place it in a suction filter bottle, and use a rubber stopper with a suitable small hole in the middle to close the separatory funnel. Seal with the suction filter bottle, first treat the activated carbon under vacuum (0.01Mpa) for half an hour, open the piston on the separatory funnel, quickly flow the abov...

Embodiment 2

[0064] The supporting components of catalyst B are Co and Zr, except that 169.0 grams of zirconyl nitrate and 1646.1 grams of cobalt nitrate are weighed, the preparation method of catalyst B 10Co2Zr / AC1 is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com