Method for preparing high-strengthalpha-semihydratetitanium gypsum with industrial wastedihydratetitanium gypsum

A technology for industrial waste and titanium gypsum is applied in the field of preparing high-strength α-hemihydrate titanium gypsum, which can solve the problems affecting the crystallization process of α-hemihydrate titanium gypsum, low purity of dihydrate titanium gypsum, and small crystal size, etc. Eliminate the possibility of secondary hydration, promote comprehensive utilization of high value and high volume, and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

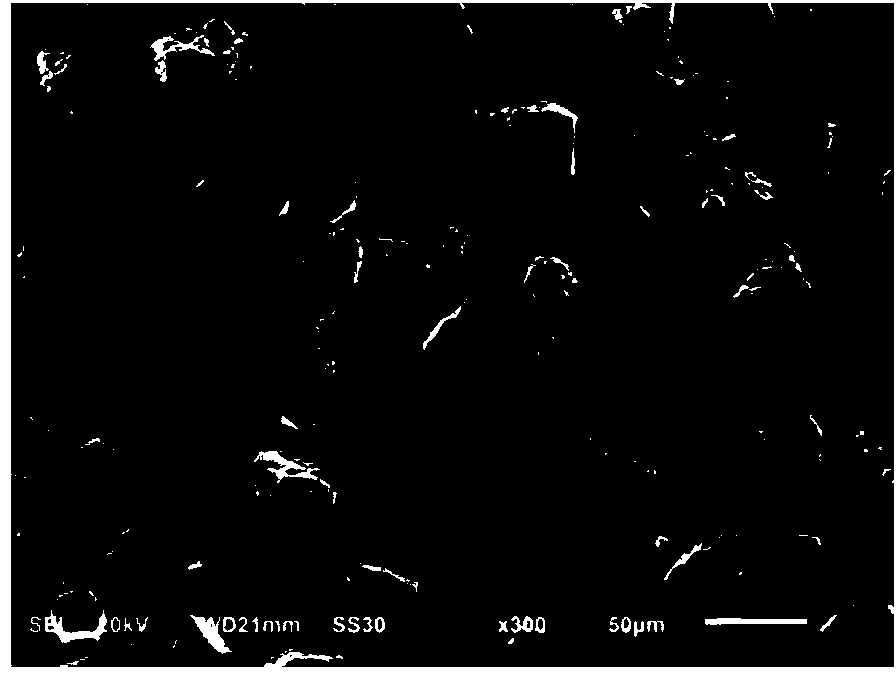

[0043] Example 1. Put the dihydrate titanium gypsum in an oven at 80°C and dry it to constant weight, take it out and grind it finely, pass it through a 200-mesh sieve, take 1000 parts and add it to a high-pressure reactor, add an appropriate amount of water, and make the mass percentage concentration of 50% dihydrate titanium gypsum slurry, add 1.1% crystal modifier of dihydrate titanium gypsum weight, wherein 1 part of sodium citrate, 10 parts of aluminum sulfate, and adjust it with 2mol / L hydrochloric acid or 2mol / L sodium hydroxide solution When the pH is 4.5, stir and feed 0.4MPa nitrogen, then heat up to 140°C, stir at 60 rpm, dehydrate and crystallize at constant temperature and pressure for 3 hours, open the vent valve to release the pressure to within 0.1MPa, continue heating, keep The temperature in the kettle is 100°C, after complete drying, short hexagonal prism crystals such as figure 1 As shown, after grinding to 10-50μm, 10-20μm accounts for 25%, 20-40μm account...

Embodiment 2

[0044] Example 2: Put the dihydrate titanium gypsum in an oven at 80°C and dry it to constant weight, take it out and grind it finely, pass it through a 200-mesh sieve, take 1000 parts and add it to the high-pressure reactor, add an appropriate amount of water, and make the mass percentage concentration of 50% dihydrate titanium gypsum slurry, add 1.1% crystal modifier of dihydrate titanium gypsum weight, wherein 1 part of sodium citrate, 10 parts of aluminum sulfate, with 2mol / L hydrochloric acid or 2mol / L sodium hydroxide solution to adjust its When the pH is 1.0, stir and feed 0.5MPa nitrogen, then raise the temperature to 140°C, the stirring speed is 60 rpm, dehydrate and crystallize at constant temperature and pressure for 3 hours, open the vent valve to release the pressure to within 0.1MPa, continue heating, keep The temperature in the kettle is 110°C. After complete drying, grind to 10-50μm, 10-20μm accounts for 25%, 20-40μm accounts for 60%, and 40-50μm accounts for 15...

Embodiment 3

[0045] Example 3: Put the dihydrate titanium gypsum in an oven at 80°C and dry it to constant weight, take it out and grind it finely, pass it through a 200-mesh sieve, take 1000 parts and add it to the high-pressure reactor, add an appropriate amount of water, and make the mass percentage concentration of 50% dihydrate titanium gypsum slurry, add 1.1% crystal modifier of dihydrate titanium gypsum weight, wherein 1 part of sodium citrate, 10 parts of aluminum sulfate, and adjust it with 2mol / L hydrochloric acid or 2mol / L sodium hydroxide solution The pH is 4.5, stir and feed 0.4MPa nitrogen, then raise the temperature to 140°C, the stirring speed is 60 rpm, dehydrate and crystallize at constant temperature and pressure for 3 hours, open the vent valve to release the pressure to below 0.1MPa, and continue heating. Keep the temperature in the kettle at 120°C, after complete drying, grind to 10-50μm, 10-20μm accounts for 25%, 20-40μm accounts for 60%, and 40-50μm accounts for 15%....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com