Method for preparing high-strength α-titanium gypsum from industrial waste titanium dioxide waste residue

A technology of industrial waste and titanium dioxide, applied in the direction of calcium/strontium/barium sulfate, etc., can solve the problems affecting the crystallization process of high-strength α-titanium gypsum, the small crystal size of the product, and the low purity of dihydrate gypsum, so as to promote High-value and high-volume comprehensive utilization, excellent product quality, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

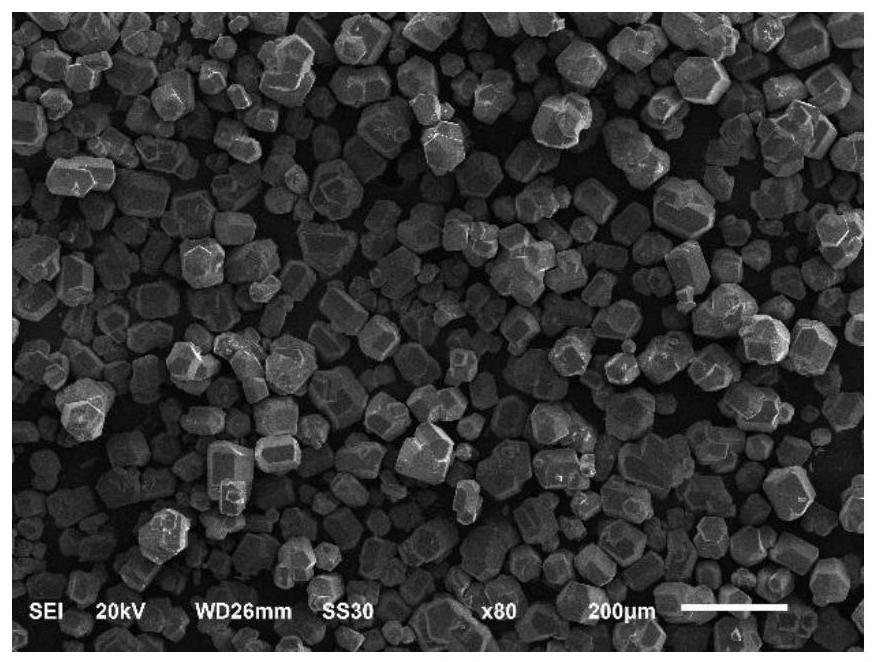

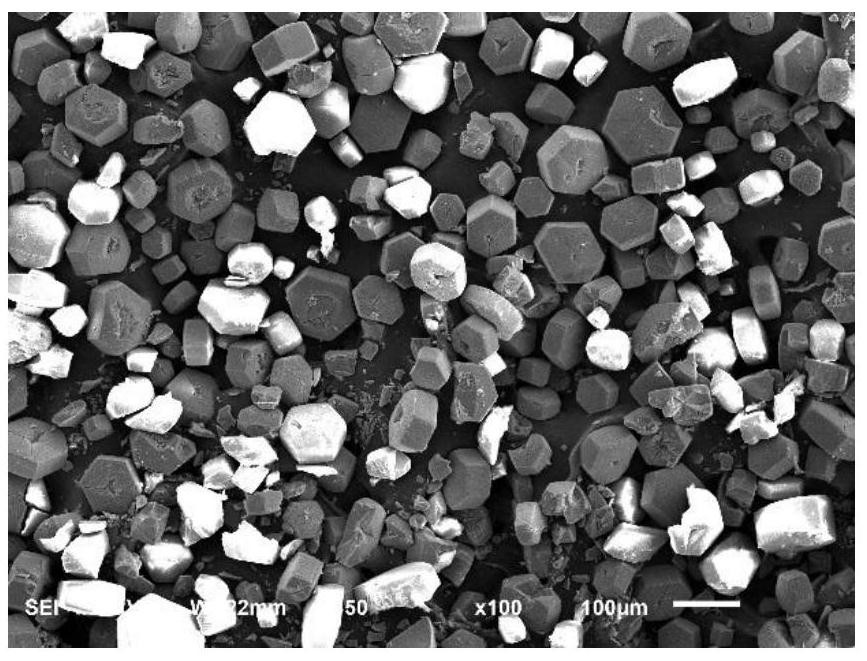

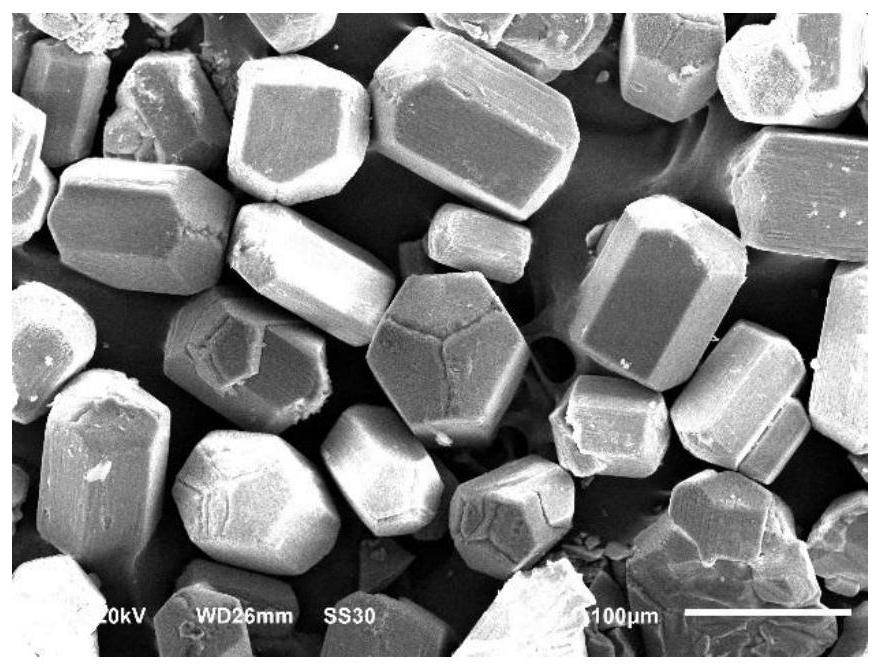

Image

Examples

Embodiment 1

[0037] The method for preparing high-strength α-titanium gypsum by using industrial waste titanium dioxide waste slag of the present invention, the specific steps are as follows:

[0038] The titanium dioxide waste residue used is produced by the acid method and contains a certain amount of Fe after being treated with calcium hydroxide. 2 o 3 Impurities and a large amount of free water, the appearance is dark red and very viscous solid waste.

[0039] (1) Add water to the titanium dioxide waste residue that has been ground to a particle size of less than 270 meshes to prepare a slurry with a concentration of 10% by mass.

[0040](2) Add a composite nucleating agent to the slurry prepared in step (1), the composite nucleating agent is compounded by nucleating agent A and nucleating agent B in a weight ratio of 1:1, and the composite nucleating agent is formed The addition amount of the nucleating agent is 0.5% of the weight of the titanium dioxide waste residue, the nucleatin...

Embodiment 2

[0046] The method for preparing high-strength α-titanium gypsum by using industrial waste titanium dioxide waste slag of the present invention, the specific steps are as follows:

[0047] The titanium dioxide waste residue used is produced by the acid method and contains a certain amount of Fe after being treated with calcium hydroxide. 2 o 3 Impurities and a large amount of free water, the appearance is dark red and very viscous solid waste.

[0048] (1) Add water to the titanium dioxide waste residue that has been ground to a particle size of less than 270 meshes to prepare a slurry with a concentration of 50% by mass.

[0049] (2) Add a composite nucleating agent to the slurry prepared in step (1), the composite nucleating agent is compounded by nucleating agent A and nucleating agent B in a weight ratio of 1:10, and the composite nucleating agent is formed The addition amount of the nucleating agent is 3.0% of the weight of the titanium dioxide waste residue, the nucleat...

Embodiment 3

[0055] The method for preparing high-strength α-titanium gypsum by using industrial waste titanium dioxide waste slag of the present invention, the specific steps are as follows:

[0056] The titanium dioxide waste residue used is produced by the acid method and contains a certain amount of Fe after being treated with calcium hydroxide. 2 o 3 Impurities and a large amount of free water, the appearance is dark red and very viscous solid waste.

[0057] (1) Add water to the titanium dioxide waste slag that has been ground to a particle size of less than 270 meshes to prepare a slurry with a concentration of 30% by mass.

[0058] (2) Add a composite nucleating agent to the slurry prepared in step (1), the composite nucleating agent is compounded by nucleating agent A and nucleating agent B in a weight ratio of 1:5, and the composite nucleating agent is formed The addition amount of the nucleating agent is 1.0% of the weight of the titanium dioxide waste residue, the nucleating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com