Special material for silicane grafted PPR (polypropylene random) pipe and preparation method thereof

A special material for pipes and a silane grafting technology are applied in the field of special materials for silane grafted PPR pipes and their preparation, which can solve the problems of adverse effects on the mechanical properties of pipes and improve PPR performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

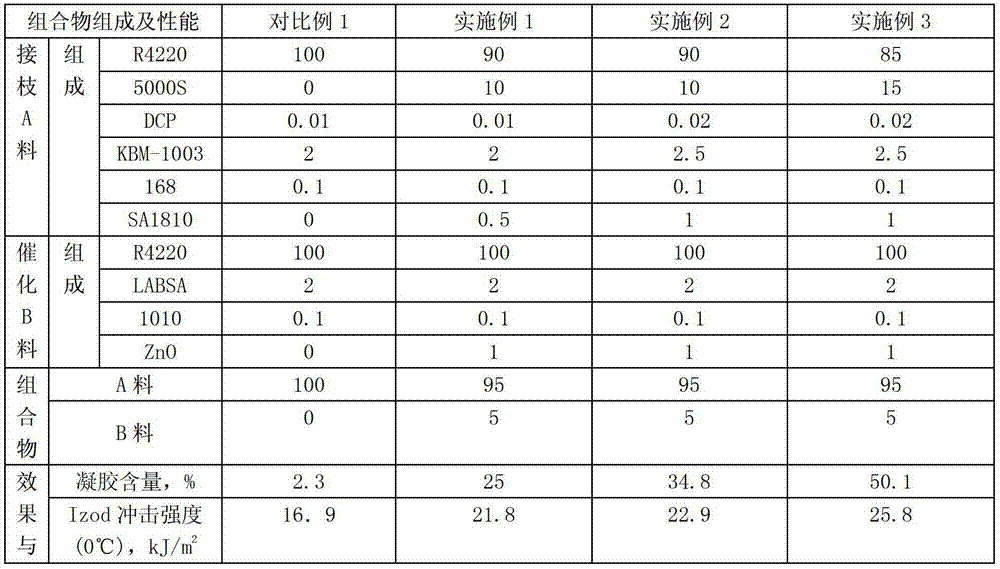

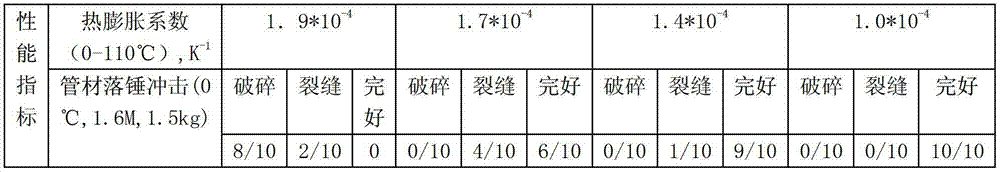

[0039] The present invention will be further described below through embodiment.

[0040] The preparation method of each embodiment in the embodiment of the present invention is as follows:

[0041] Both adopt a two-step preparation process route. That is, the silane-grafted PPR material (material A) and the silane crosslinking catalyzed PPR material (material B) were prepared respectively by two-step method.

[0042] Preparation method of material A:

[0043] After weighing the unsaturated silane and the initiator in proportion, they are fully stirred and mixed in a closed stainless steel mixer for about 5-10 minutes. The temperature of the mixer is controlled between 23-27°C, and the mixture is uniform before use.

[0044] Weigh PPR, high-density polyethylene, antioxidant and auxiliary crosslinking agent in proportion and put them into a high-speed mixer. The speed of the high-speed mixer is controlled at 50-100 rpm, and stirred for 8-10 minutes. Then gradually add the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com