Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

86 results about "Pulse field" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

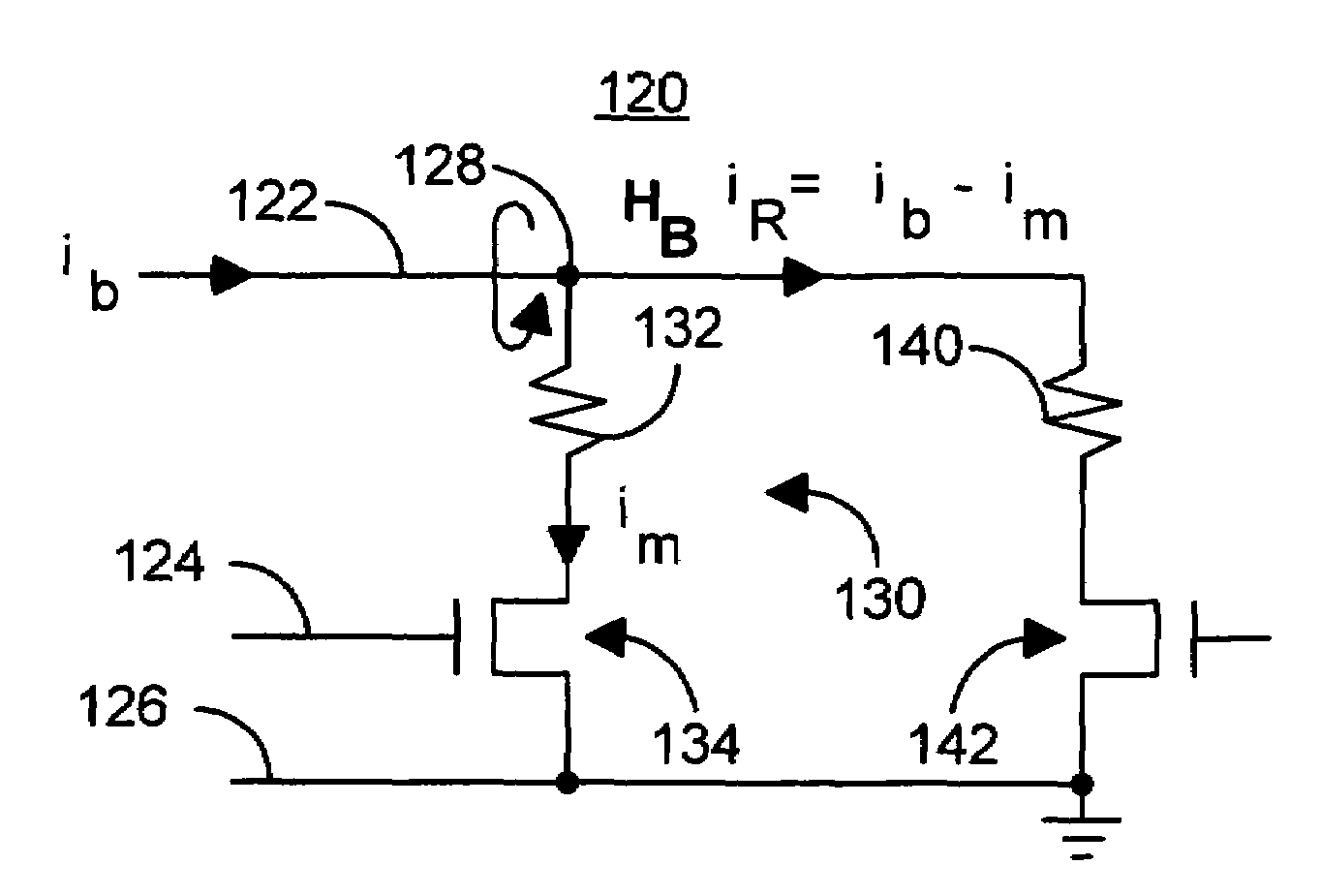

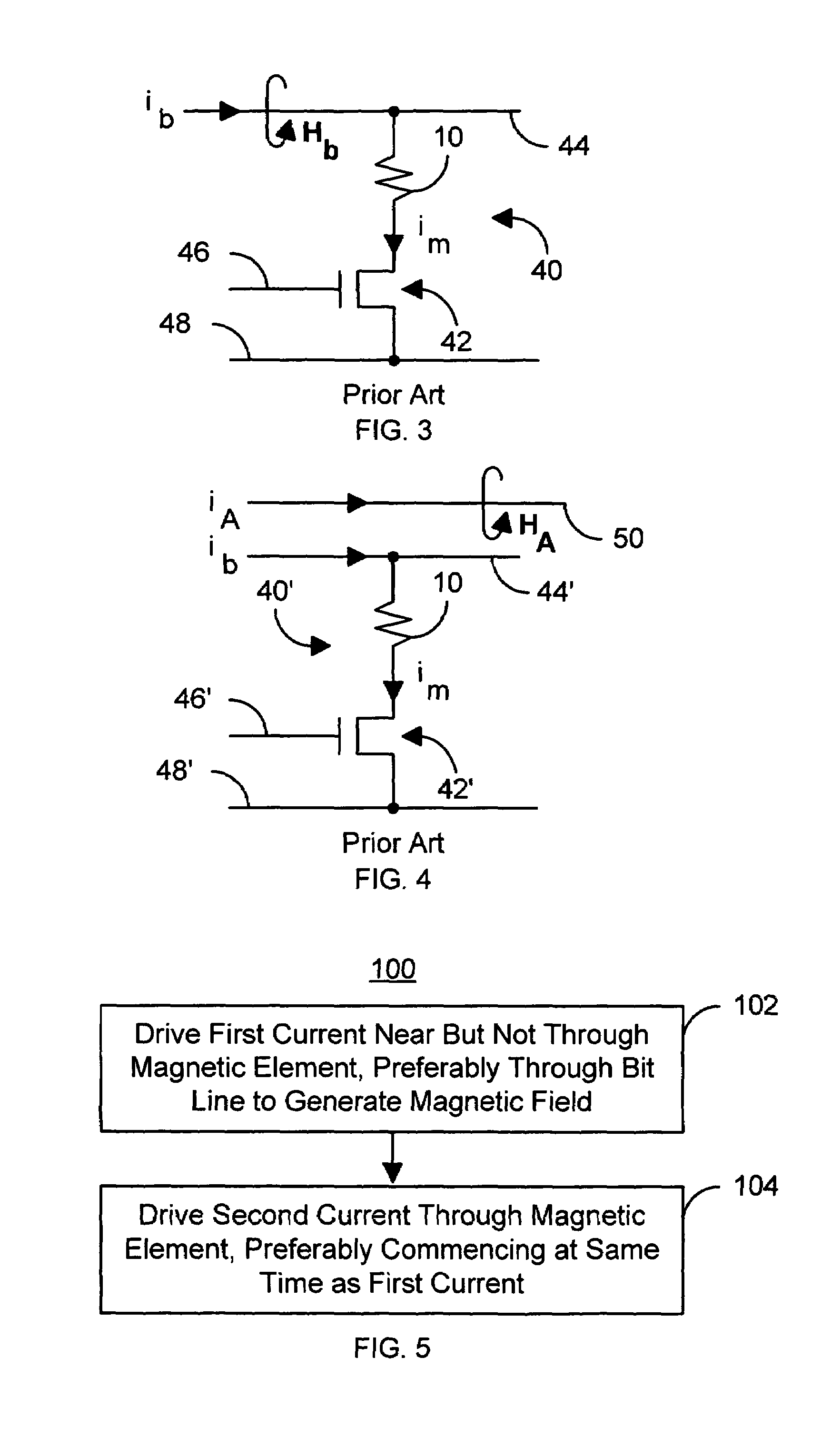

Method and system for using a pulsed field to assist spin transfer induced switching of magnetic memory elements

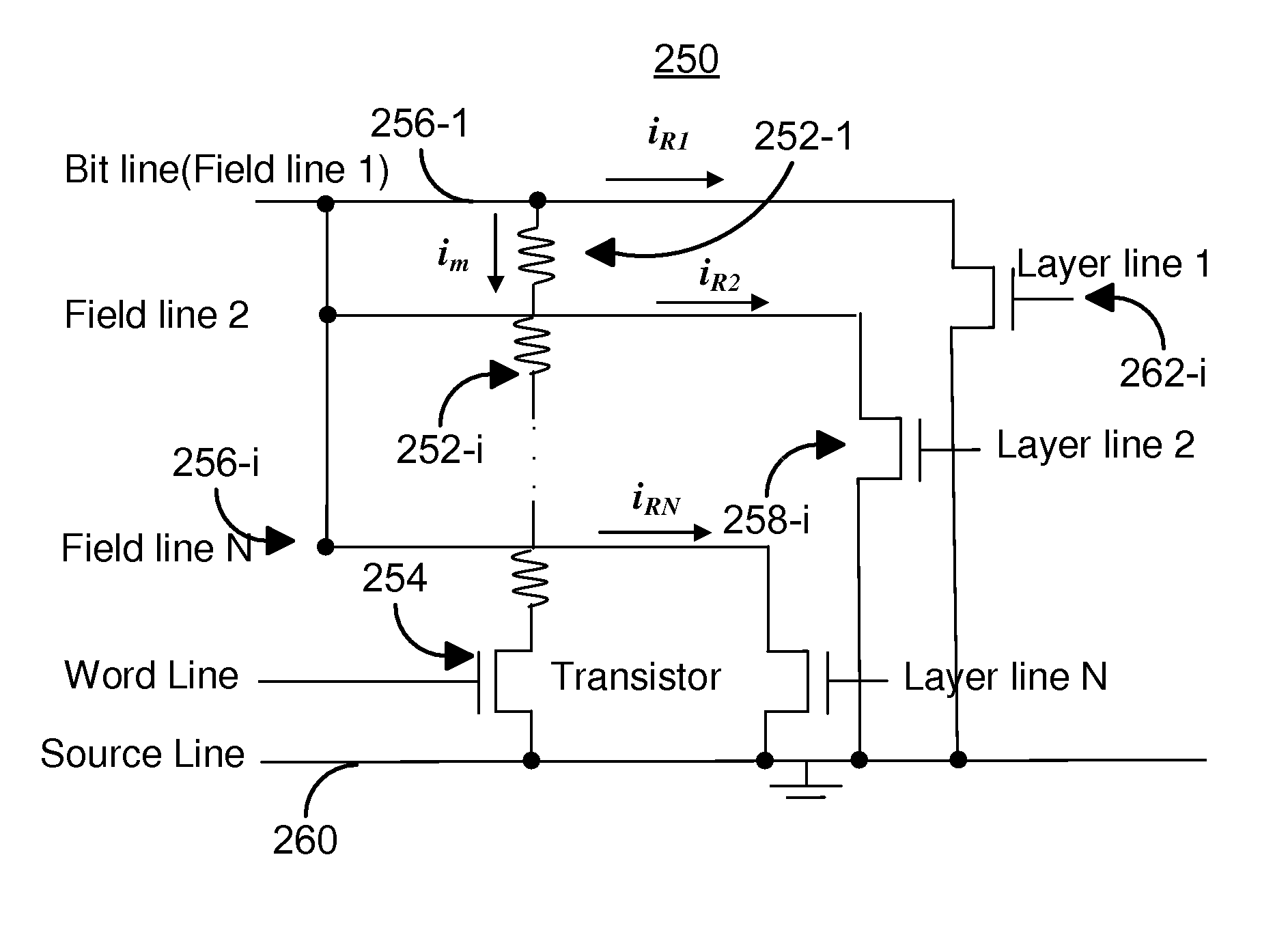

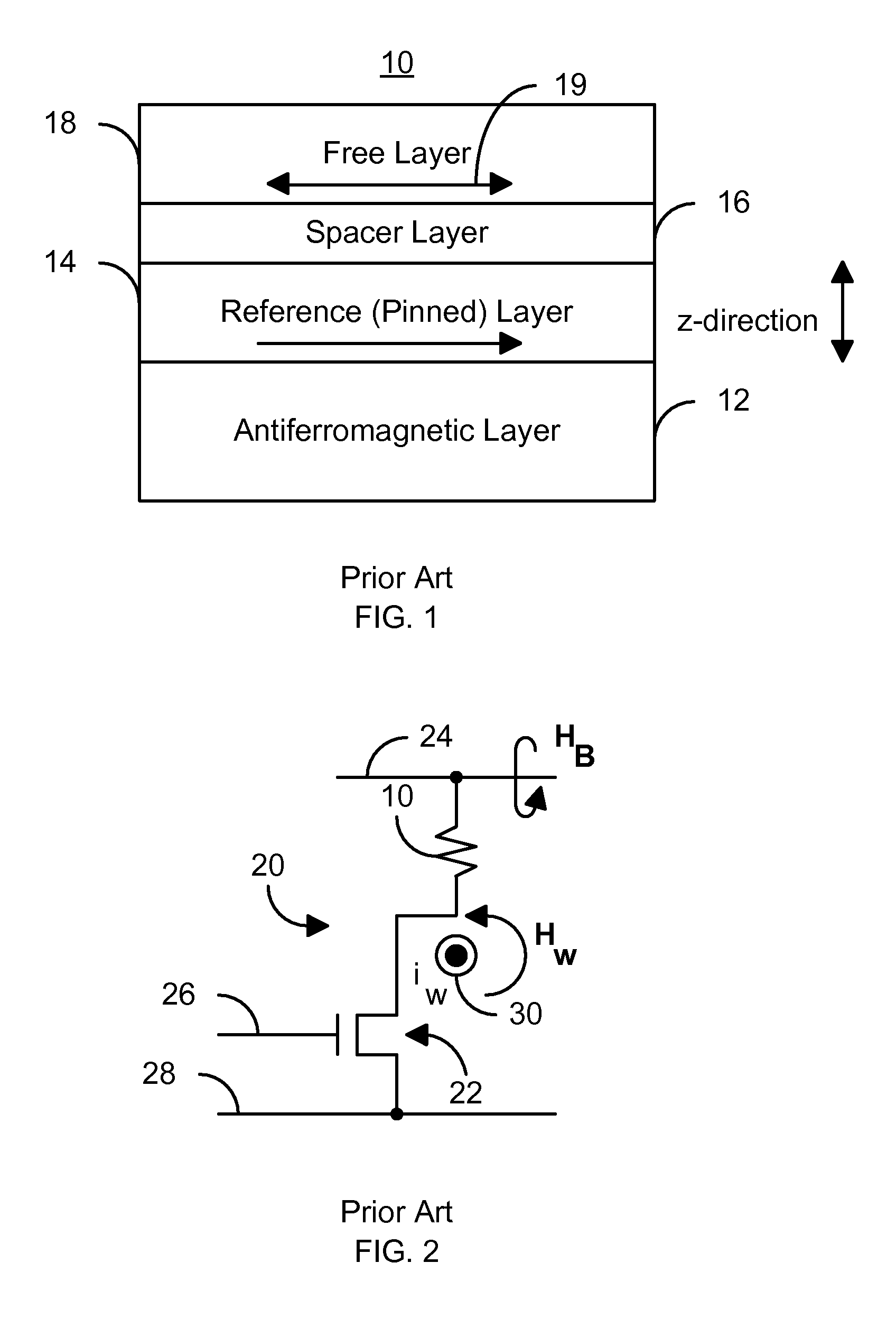

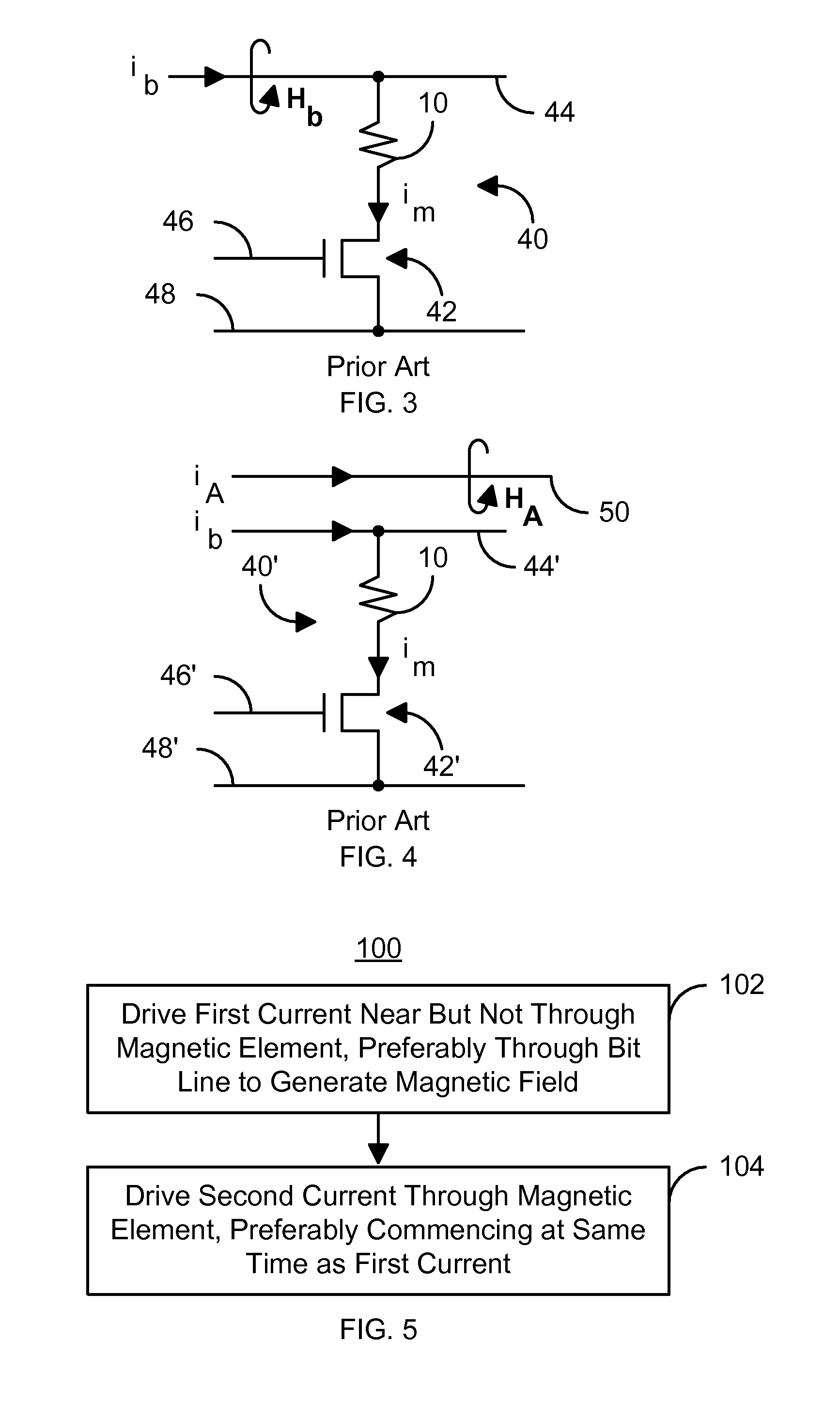

A method and system for providing and utilizing a magnetic memory are described. The magnetic memory includes a plurality of magnetic storage cells. Each magnetic storage cell includes magnetic element(s) programmable due to spin transfer when a write current is passed through the magnetic element(s) and selection device(s). The method and system include driving a first current in proximity to but not through the magnetic element(s) of a portion of the magnetic storage cells. The first current generates a magnetic field. The method and system also include driving a second current through the magnetic element(s) of the portion of the magnetic storage cells. The first and second currents are preferably both driven through bit line(s) coupled with the magnetic element(s). The first and second currents are turned on at a start time. The second current and the magnetic field are sufficient to program the magnetic element(s).

Owner:RENESAS ELECTRONICS CORP +1

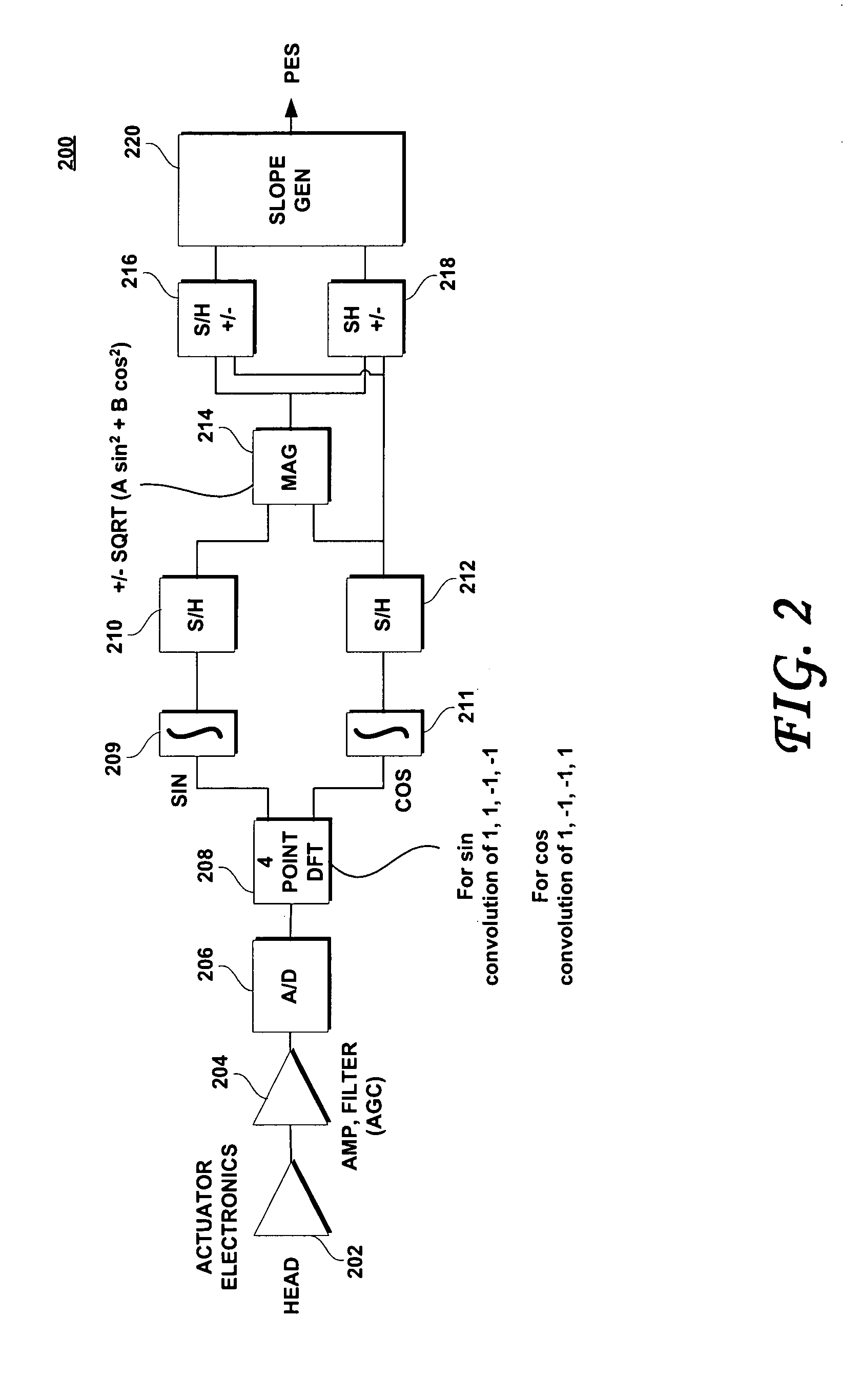

Disk drive having a disk including a servo burst pattern that improves the signal to noise ratio during track following for writing

InactiveUS7023637B1Record information storageAlignment for track following on disksSignal-to-noise ratio (imaging)Engineering

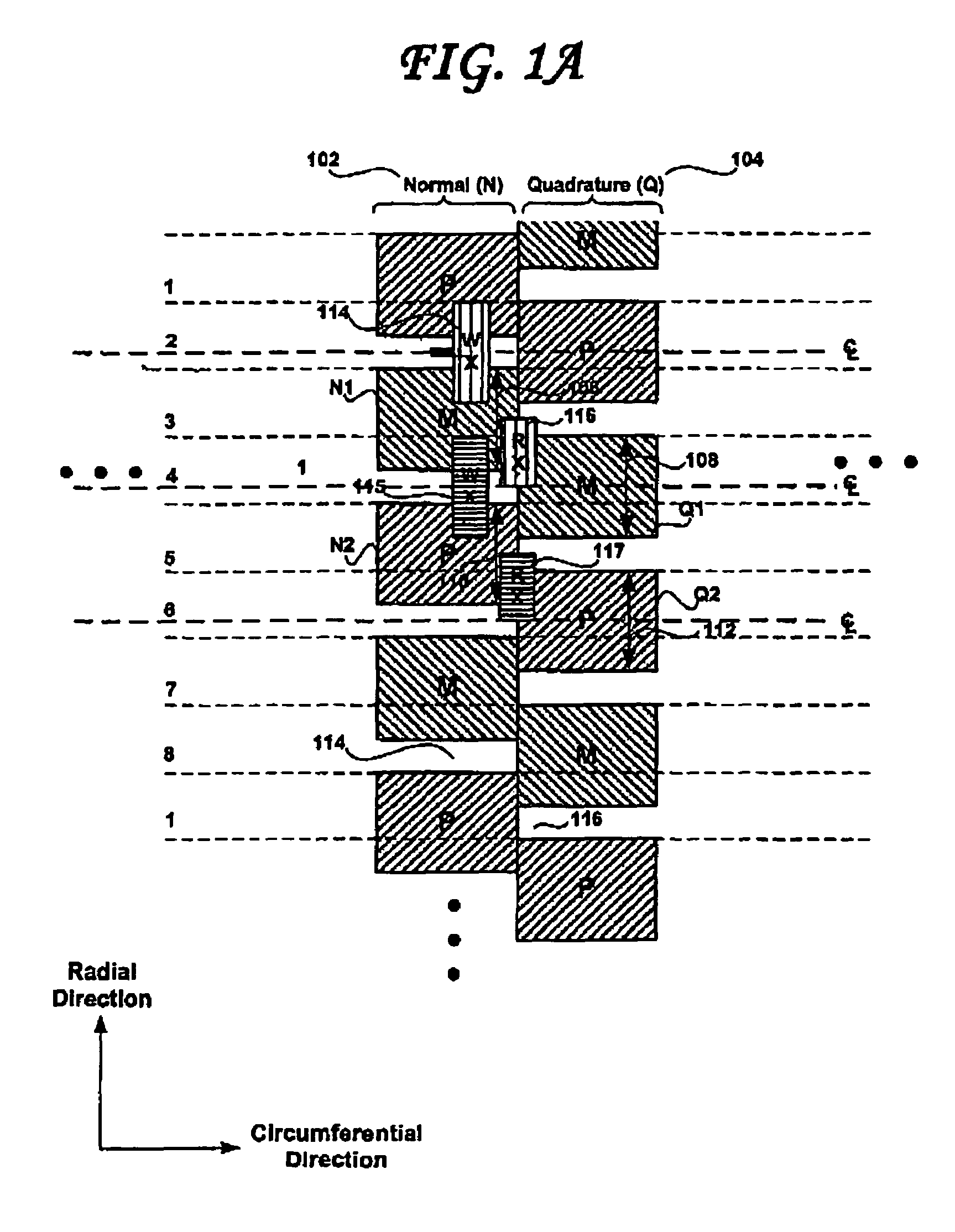

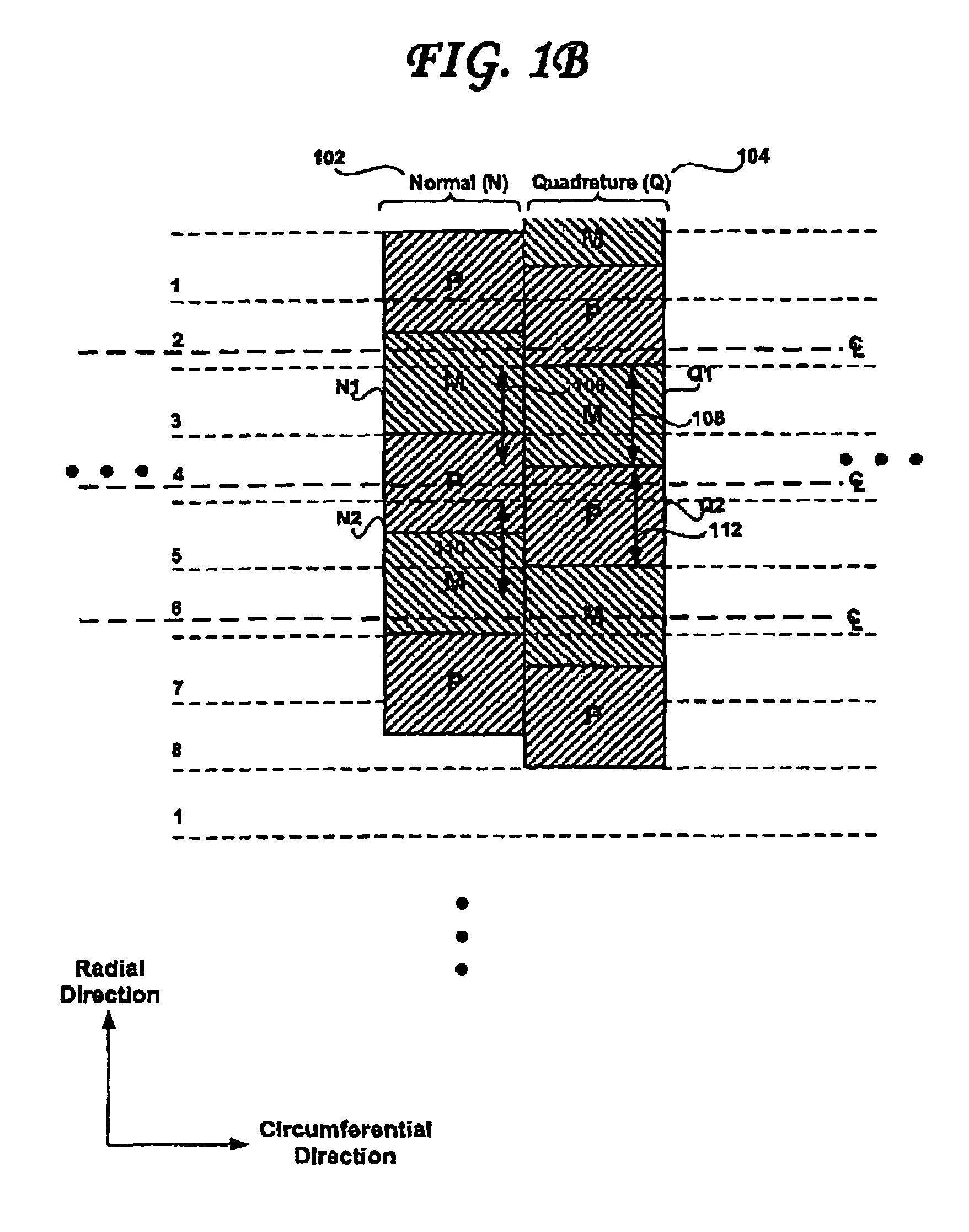

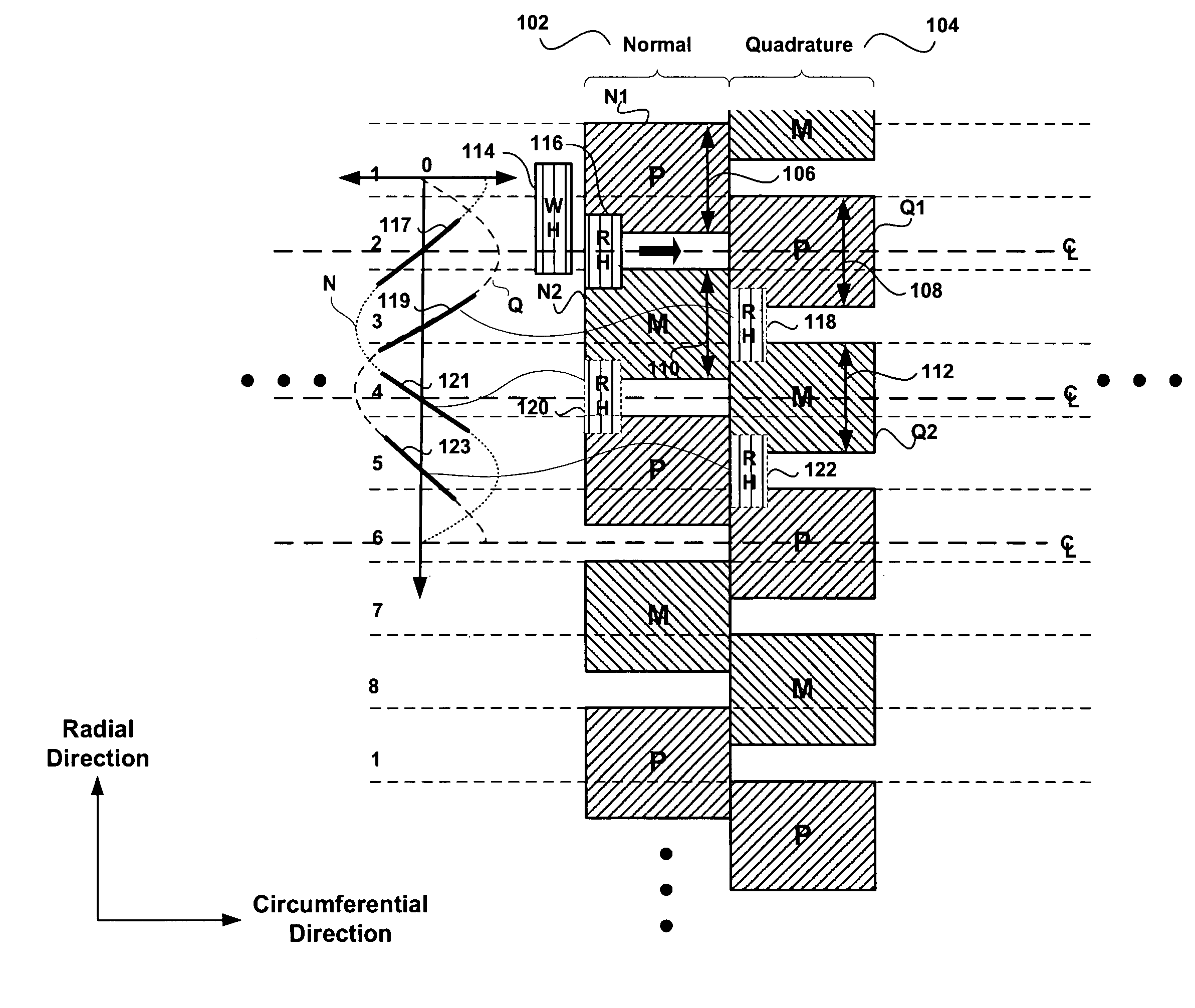

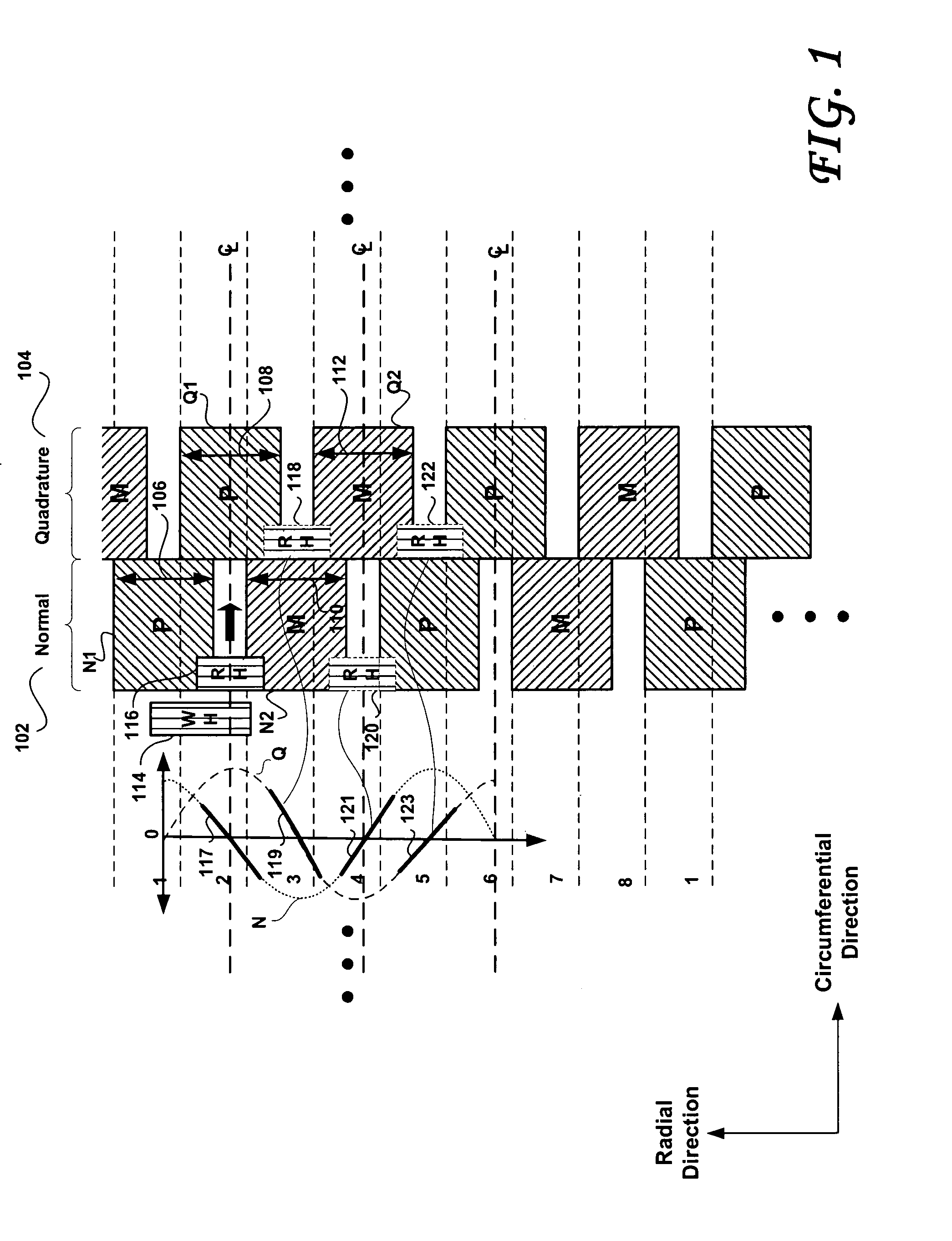

A disk drive has a sampled servo system controller and a disk. The disk has a plurality a plurality servo burst fields, the plurality of servo burst field including first and second normal burst fields, and first and second quadrature burst fields. A portion of the first quadrature burst field is circumferentially contiguous with the first normal burst field and spans a portion of a radial extent of the first normal burst field. The second normal burst field is radially aligned with and away from the first normal burst field and spans a portion of a radial extent of the first quadrature burst field. The second quadrature burst field is radially aligned with and away from the first quadrature burst field and spans a portion of a radial extent of the second normal burst field. The first normal burst field and the first quadrature burst field have a same first phase and the second normal burst field and the first quadrature burst field have a same second phase. The first phase is different than the second phase.

Owner:WESTERN DIGITAL TECH INC

Disk drive having a disk including a servo burst pattern having a normal servo burst field and a quadrature servo burst field

InactiveUS6980389B1Record information storageAlignment for track following on disksEngineeringControl theory

A disk drive has a sampled servo system controller and a disk. The disk has a plurality a plurality servo burst fields, the plurality of servo burst field including first and second normal burst fields, and first and second quadrature burst fields. A portion of the first quadrature burst field is circumferentially contiguous with the first normal burst field and spans a portion of a radial extent of the first normal burst field. The second normal burst field is radially aligned with and away from the first normal burst field and spans a portion of a radial extent of the first quadrature burst field. The second quadrature burst field is radially aligned with and away from the first quadrature burst field and spans a portion of a radial extent of the second normal burst field. The first normal burst field and the first quadrature burst field have a same first phase and the second normal burst field and the first quadrature burst field have a same second phase. The first phase is different than the second phase.

Owner:WESTERN DIGITAL TECH INC

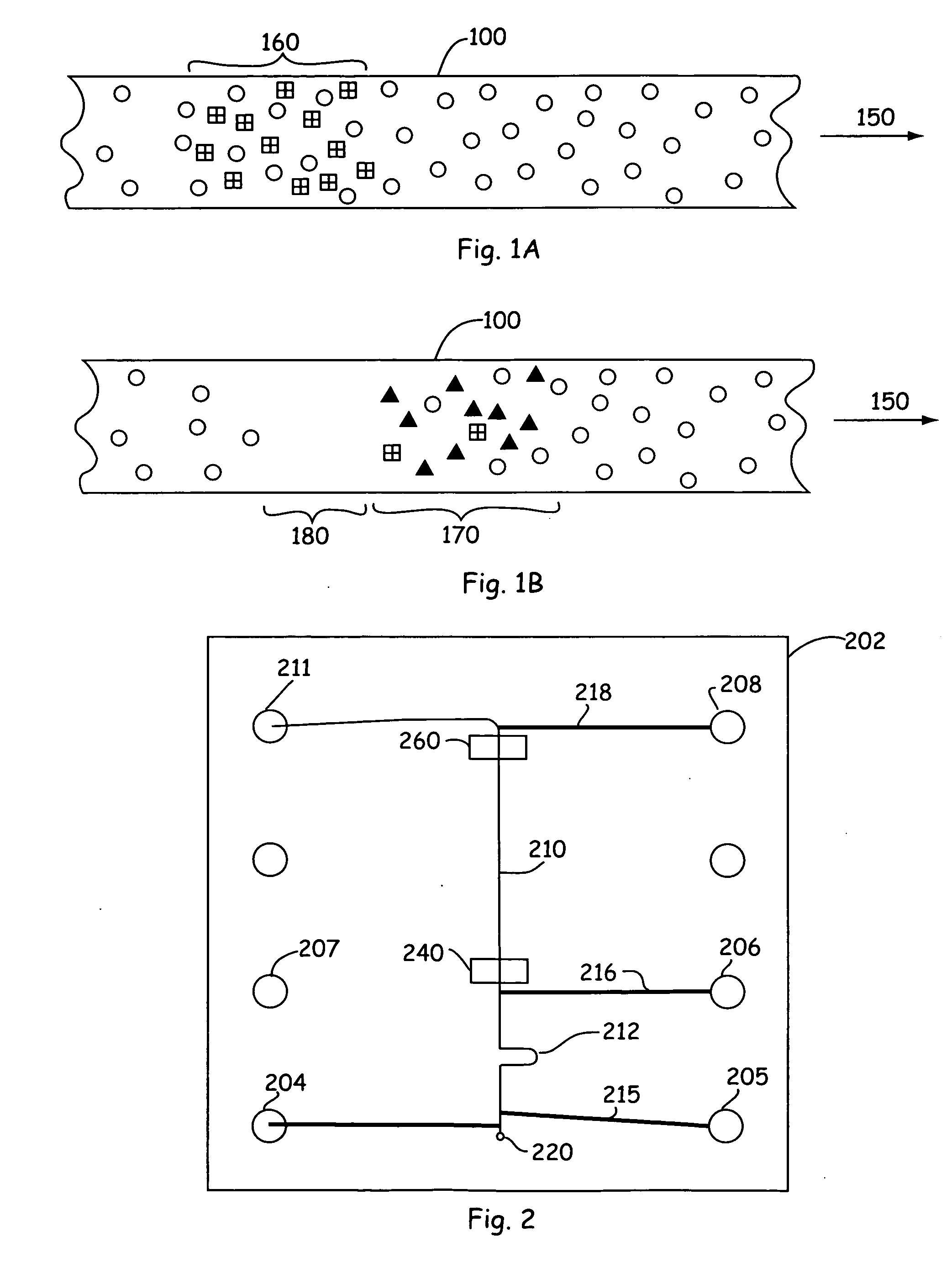

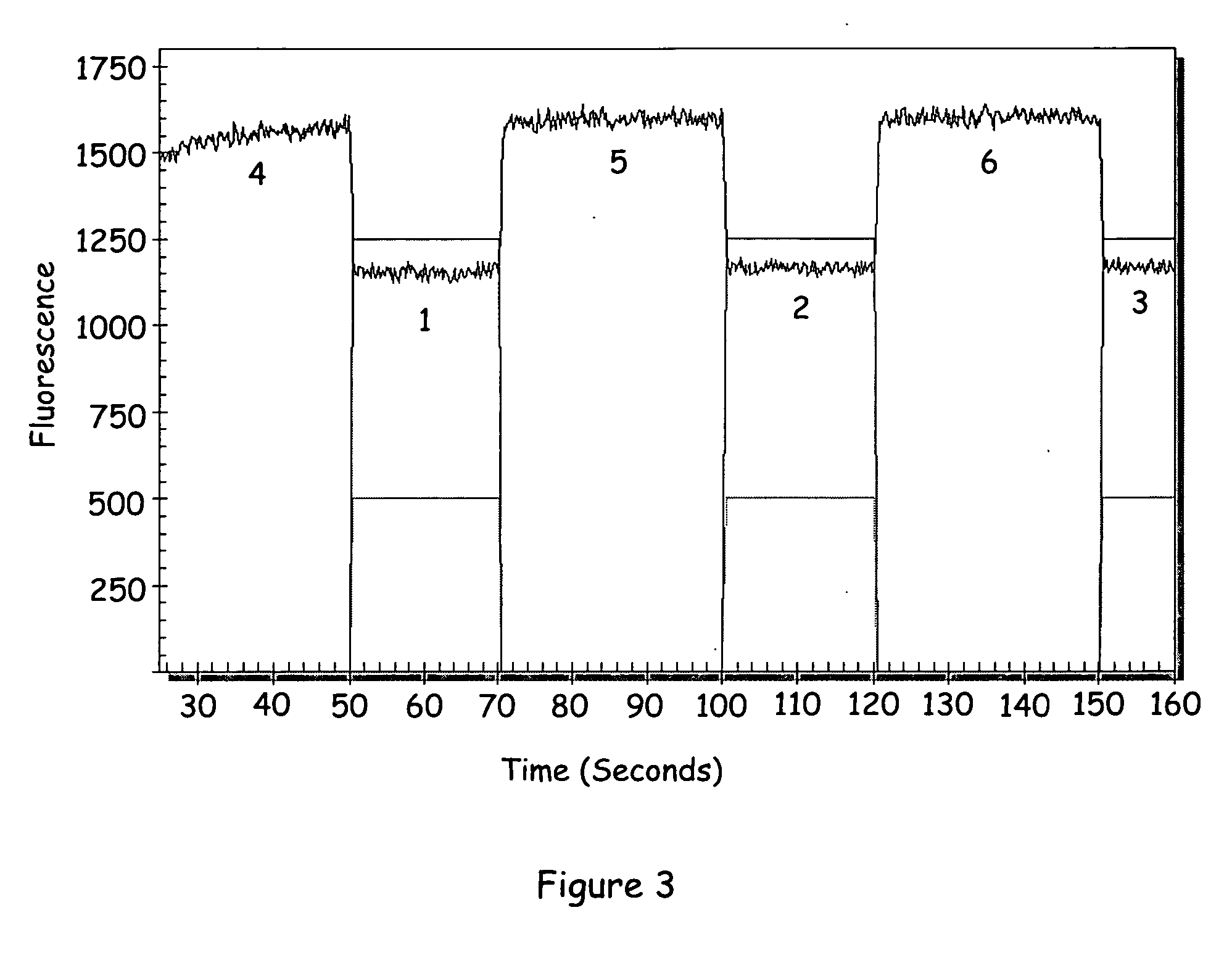

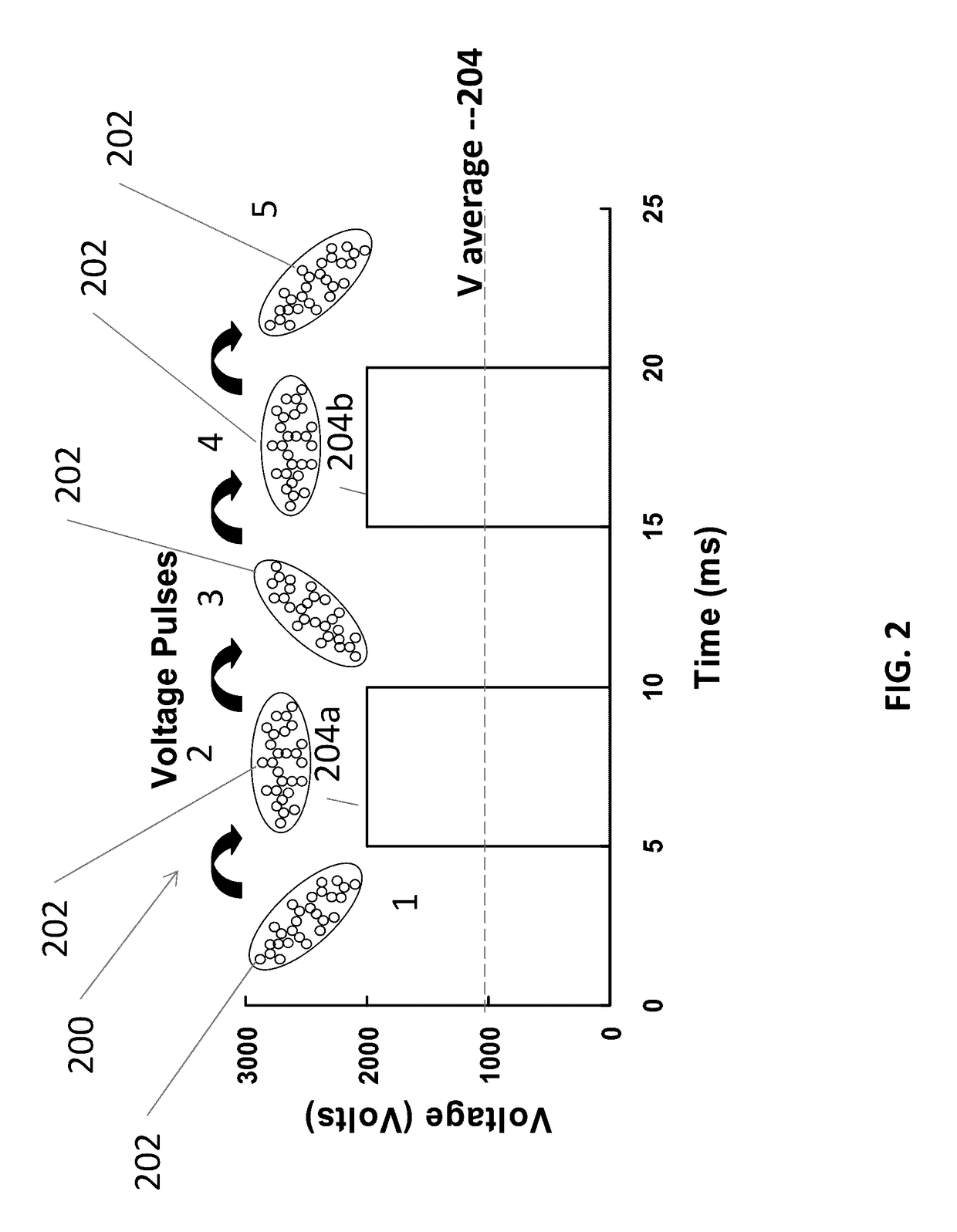

High throughput mobility shift

ActiveUS20070099200A1High detection sensitivityMaximizing and increasing differenceBioreactor/fermenter combinationsHeating or cooling apparatusEngineeringReagent

The present invention provides novel microfluidic devices and methods for performing pulsed field mobility shift assays in microfluidic devices. In particular the devices and methods of the invention utilize differences between electrophoretic mobilities (e.g., as between reactants and products, especially in non-fluorogenic reactions) in order to separate the species and thus analyze the reaction.

Owner:CAPLIPER LIFE SCI INC

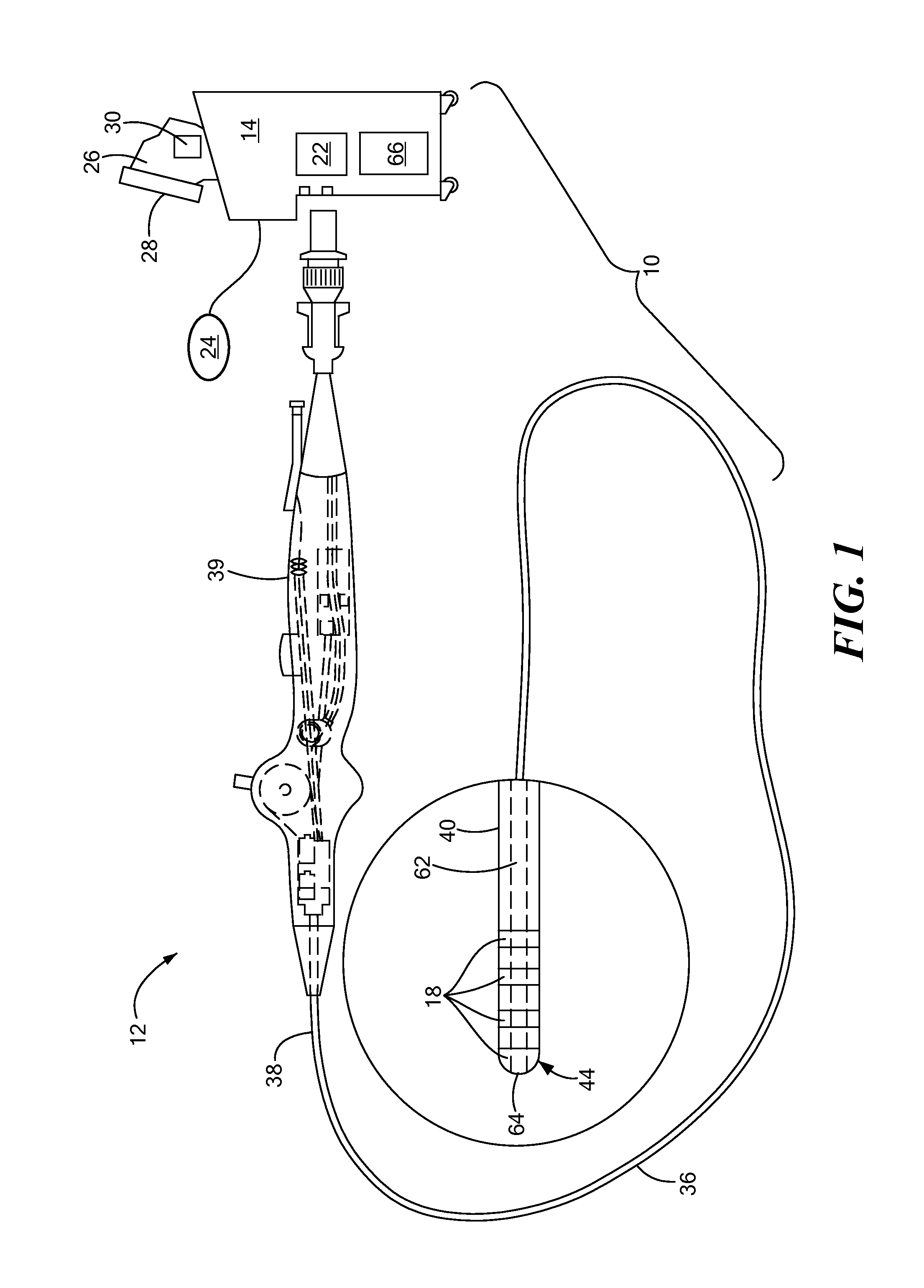

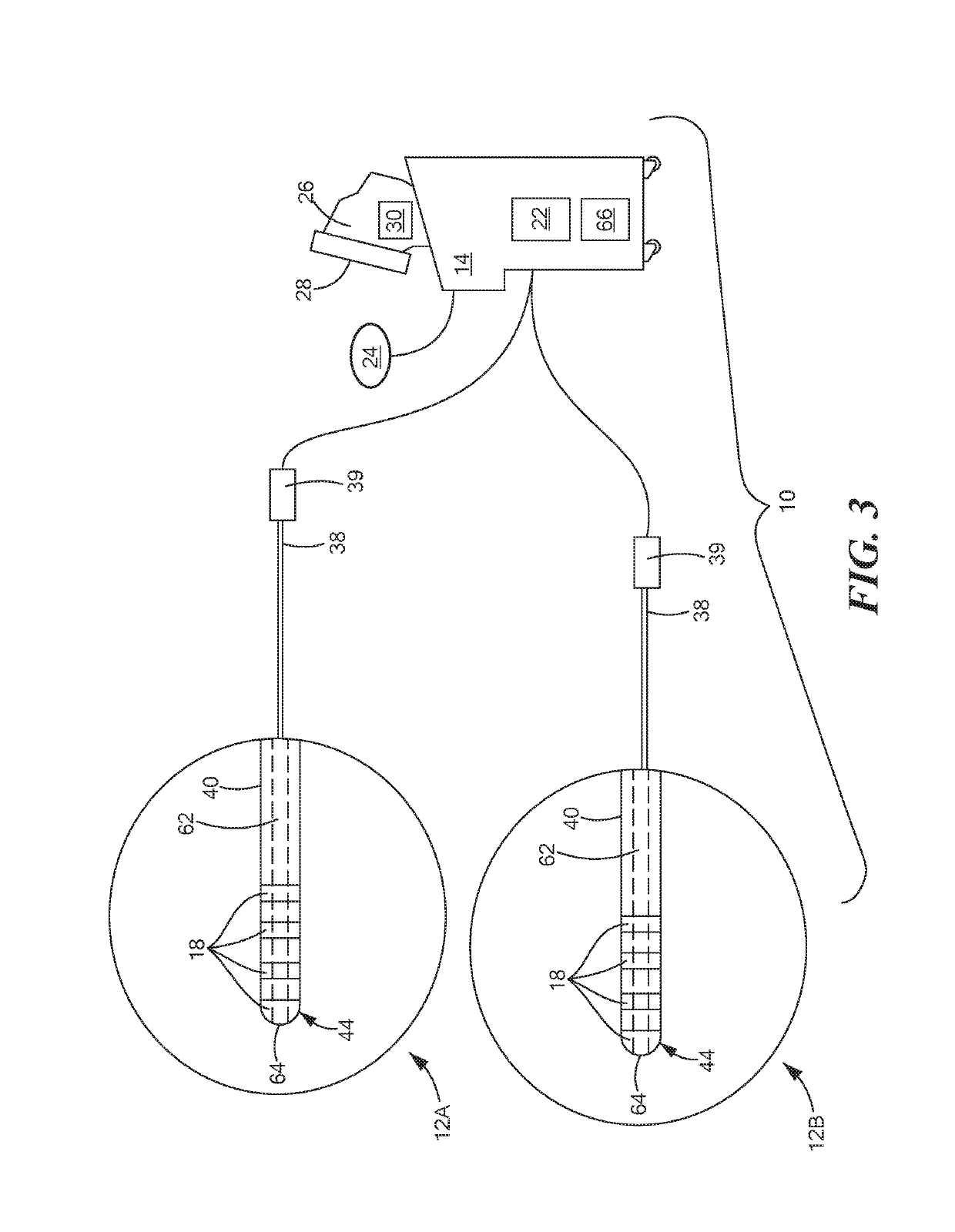

Timed energy delivery

A method and system for mapping tissue and producing lesions for the treatment of cardiac arrhythmias in a non-thermal and optimal manner, minimizing the amount of energy required to selectively stun or ablate the target tissues. Energy may be delivered only at the moment(s) of best device position and proximity of an electrode to target tissue, and only during a time in the cardiac cycle determined to be optimal for reversible or irreversible effects. A method may include determining timing of the cardiac cycle and an optimal time within the cardiac cycle for energy delivery, evaluating proximity between at least one energy delivery electrode and the target tissue, and delivering pulsed field energy from the at least one energy delivery electrode to the target tissue when, during the optimal time for energy delivery, the at least one energy delivery electrode is in close proximity with the target tissue.

Owner:MEDTRONIC ABLATION FRONTIERS

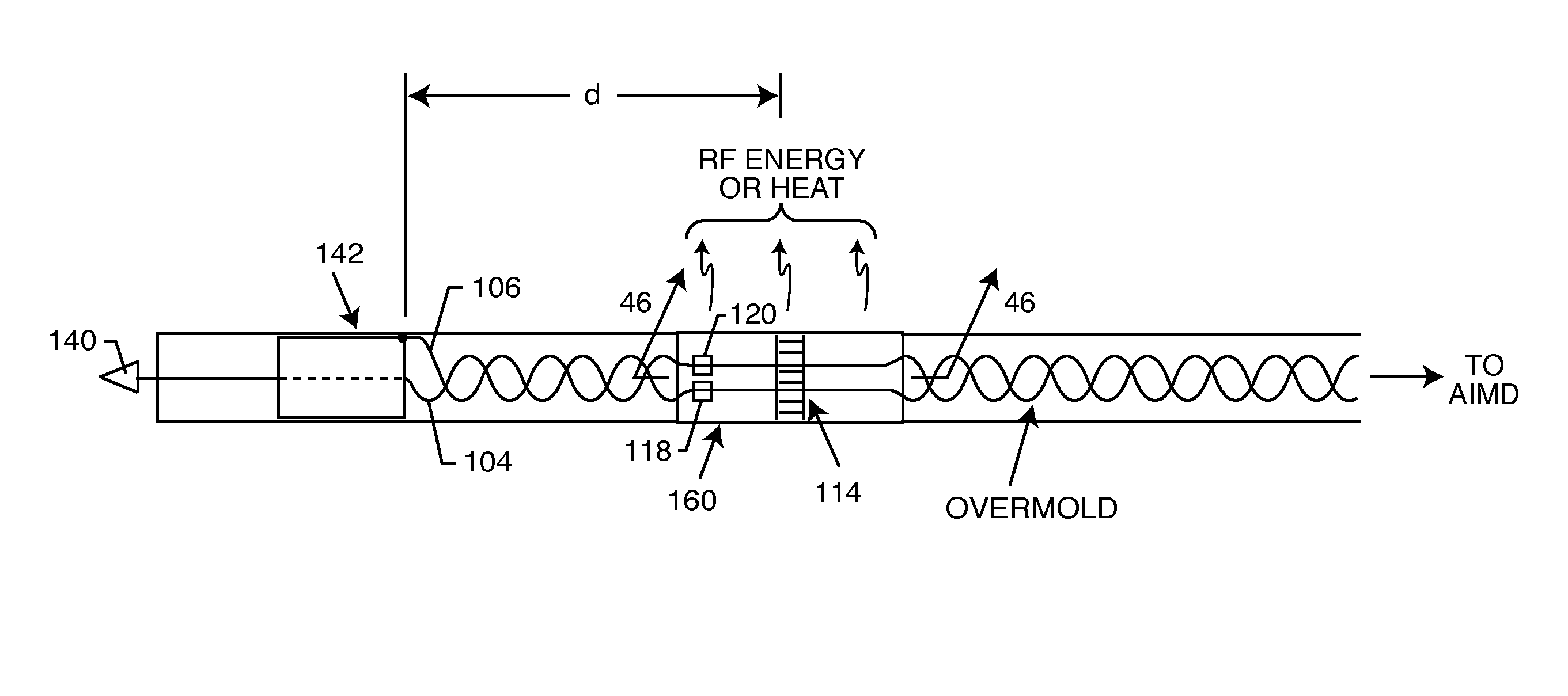

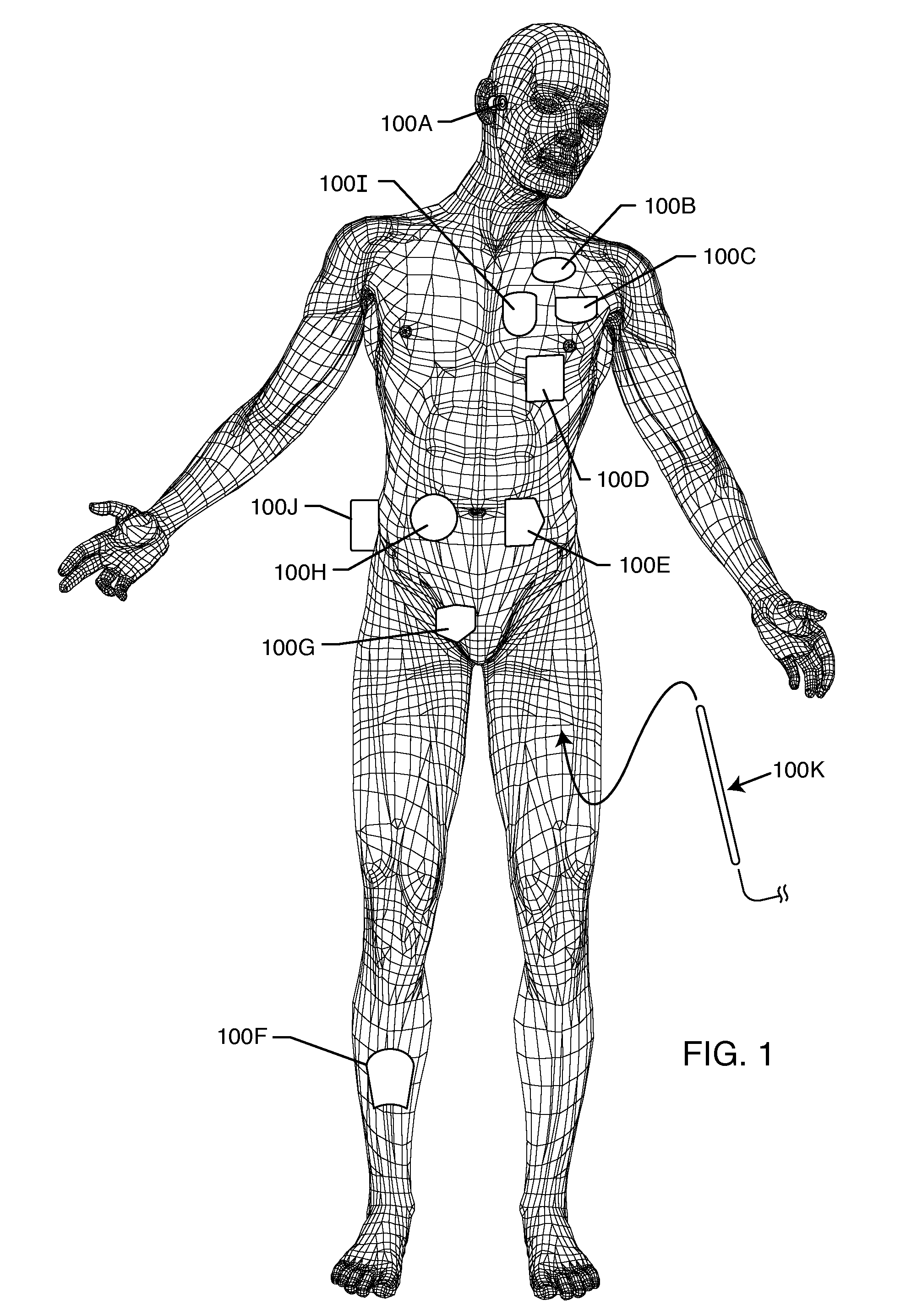

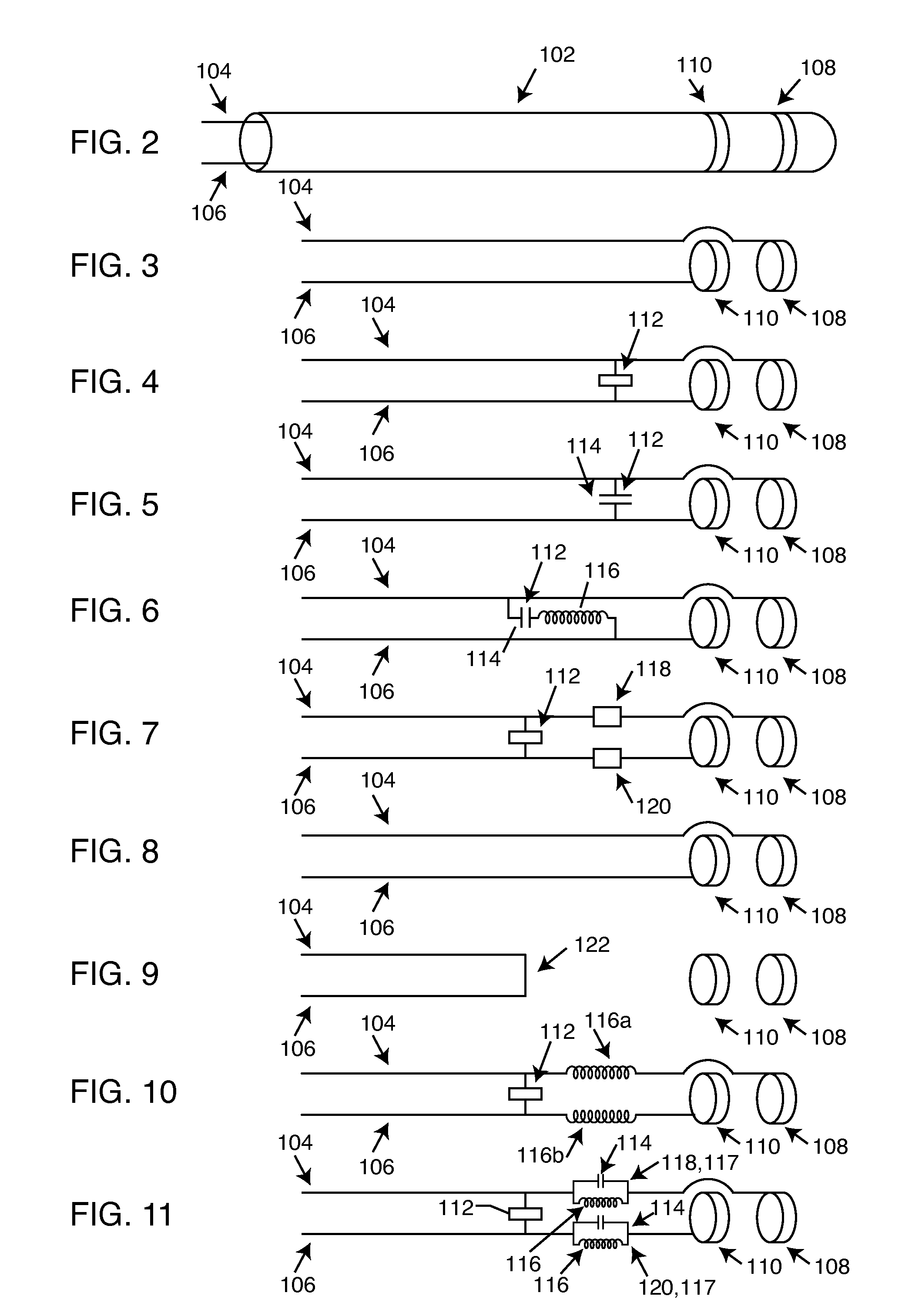

Frequency selective passive component networks for active implantable medical devices utilizing an energy dissipating surface

InactiveUS8219208B2Direct contact guaranteeMultiple-port networksElectrocardiographyEnergy transferMedical device

Decoupling circuits are provided which transfer energy induced from an MRI pulsed RF field to the housing for an active implantable medical device (AIMD) which serves as an energy dissipating surface. This is accomplished through broadband filtering or by resonant filtering. In a passive component network for an AIMD, a frequency selective energy diversion circuit is provided for diverting high-frequency energy away from an AIMD lead to the AIMD housing for dissipation of said high-frequency energy.

Owner:WILSON GREATBATCH LTD

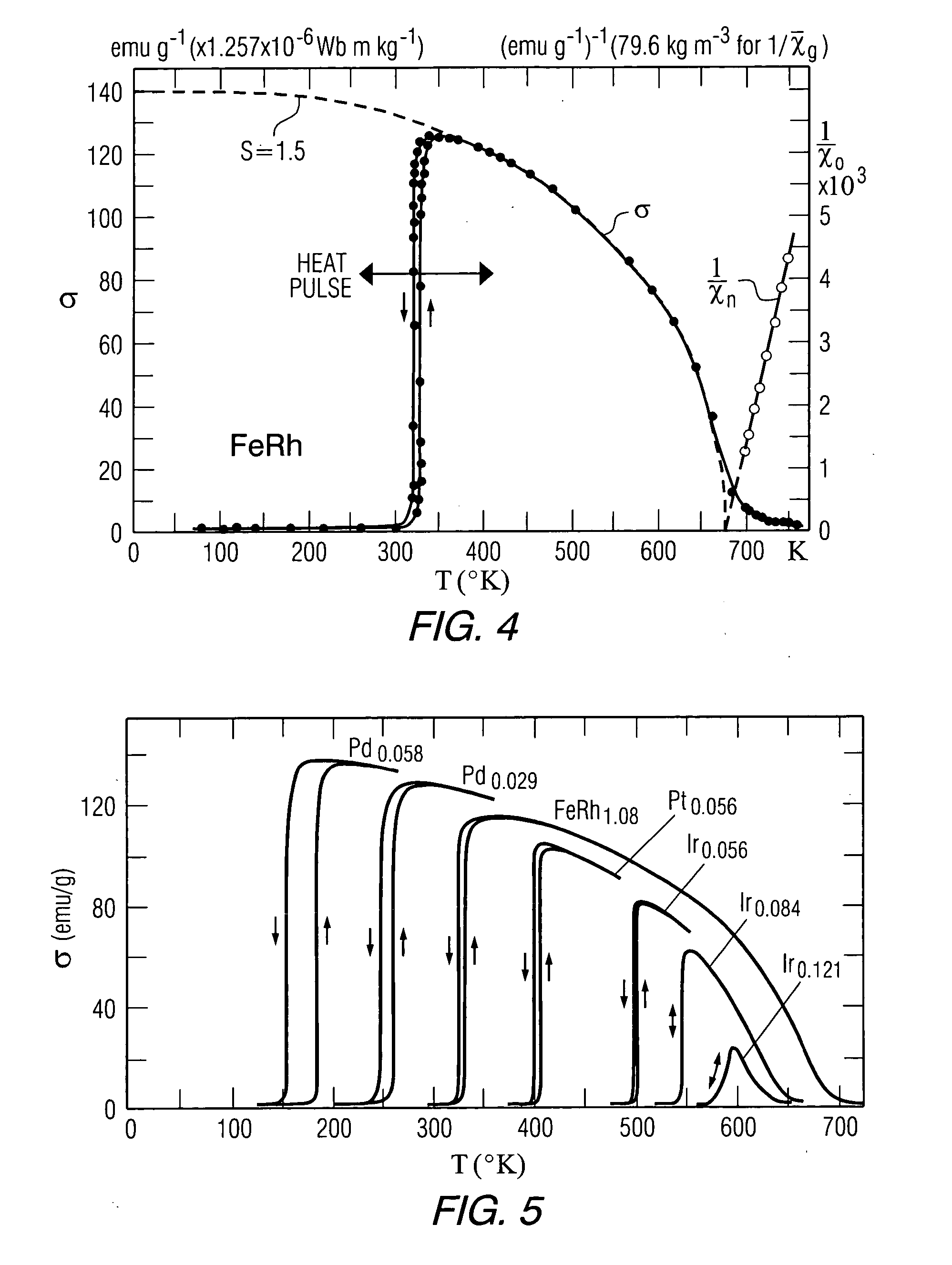

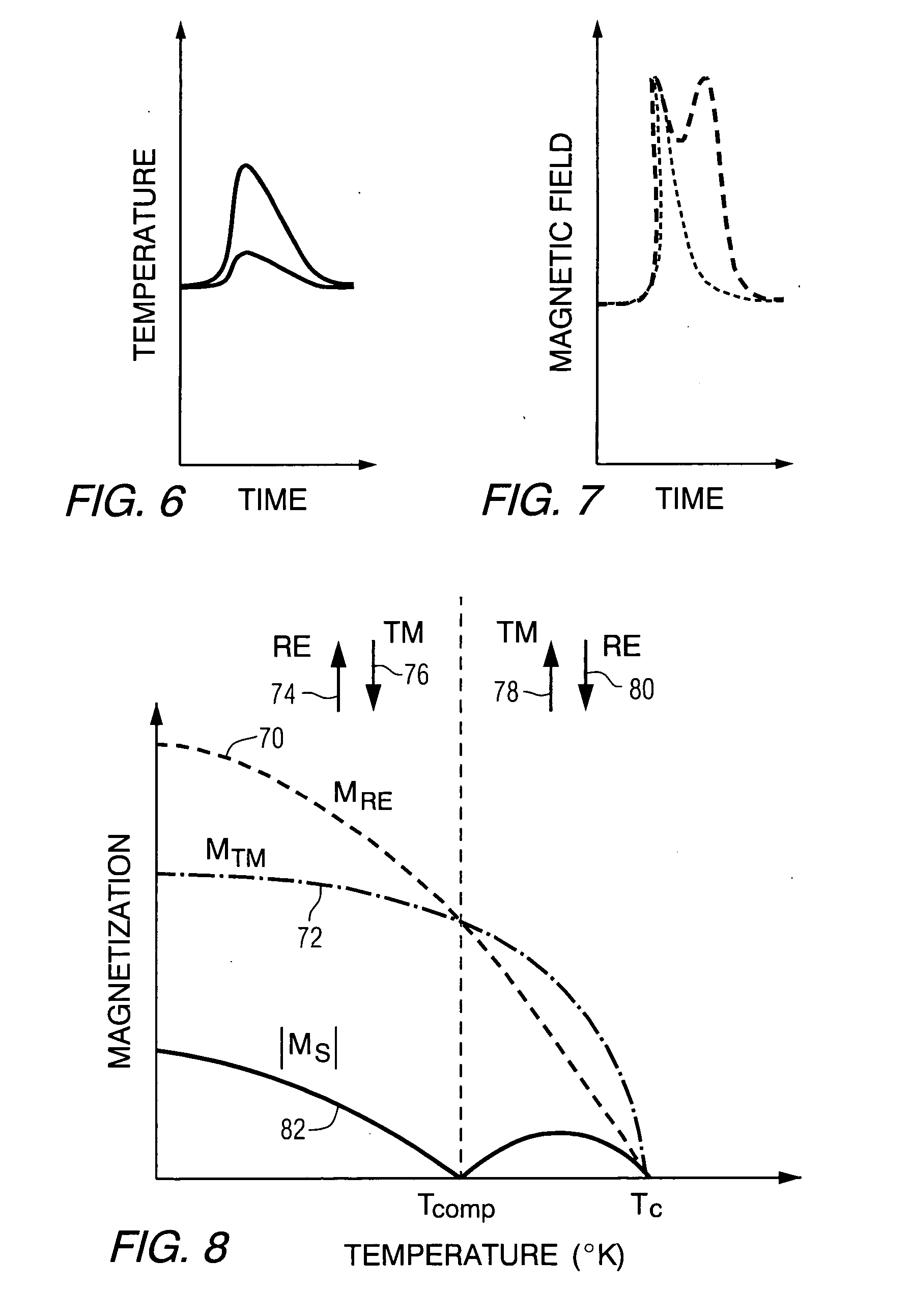

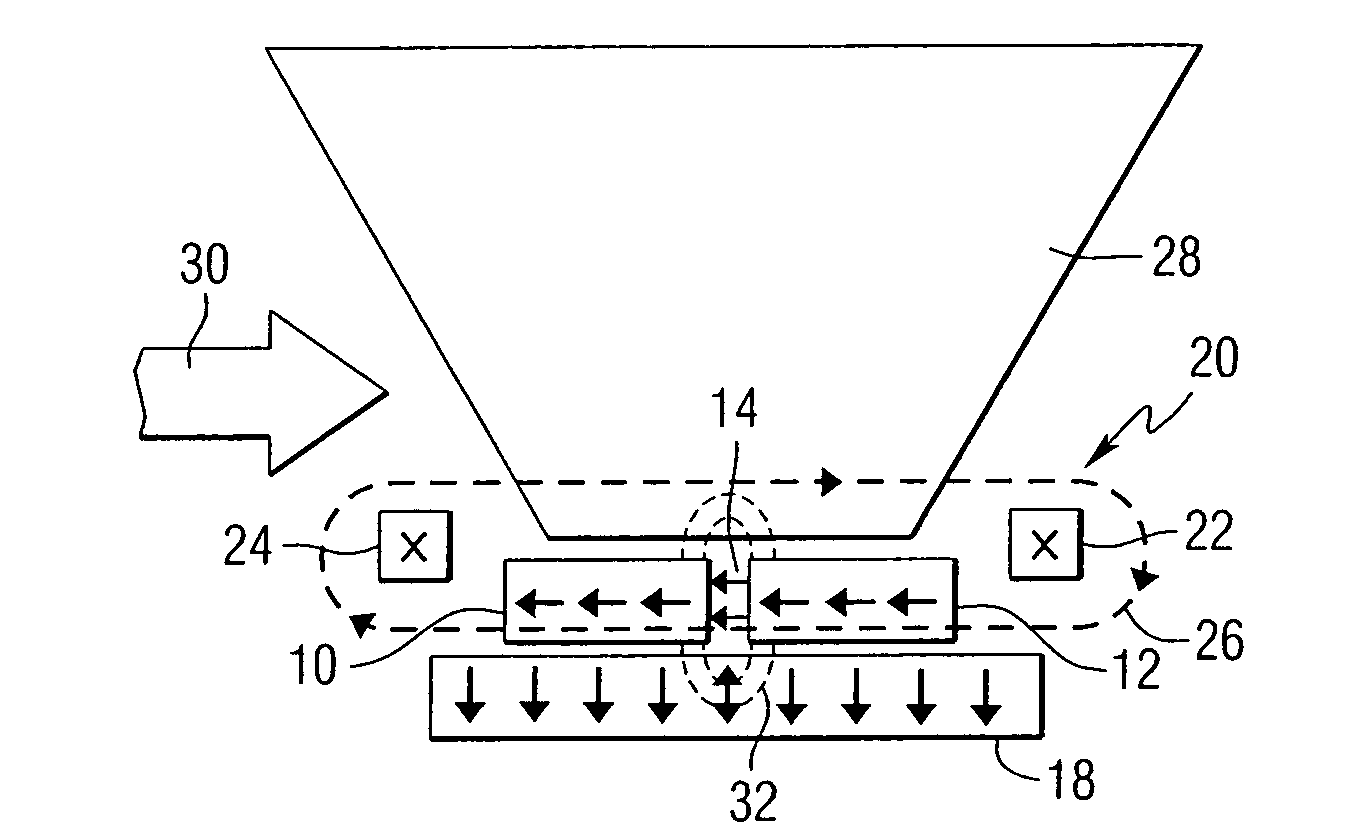

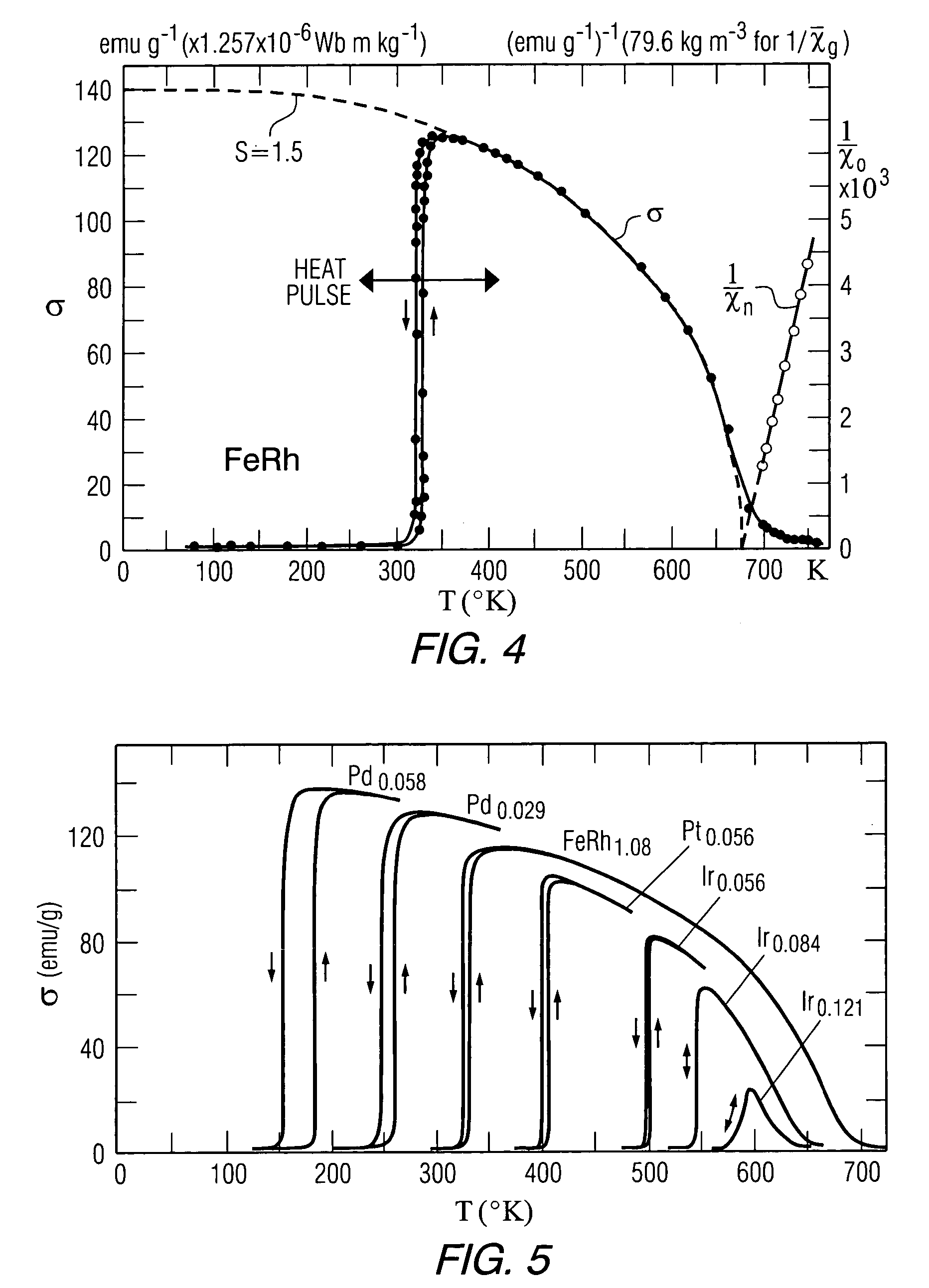

Ultrafast pulse field source utilizing optically induced magnetic transformation

A magnetic field transducer includes a phase transition material exhibiting a change from an antiferromagnetic phase to a ferromagnetic phase when heated above a critical temperature, means for applying a magnetic bias field to the phase transition material, and means for heating the phase transition material above the critical temperature. Magnetic recording heads that include the transducer and magnetic disc drives that include the magnetic recording heads are also described. A method of producing a magnetic field pulse including applying a magnetic bias field to a phase transition material, and heating the phase transition material to cause the phase transition material to change from an antiferromagnetic phase to a ferromagnetic phase, is also provided. The phase transition material can comprise a rare earth-transition metal alloy, where the alloy is heated above a compensation temperature.

Owner:SEAGATE TECH LLC

Method and system for using a pulsed field to assist spin transfer induced switching of magnetic memory elements

A method and system for providing and utilizing a magnetic memory are described. The magnetic memory includes a plurality of magnetic storage cells. Each magnetic storage cell includes magnetic element(s) programmable due to spin transfer when a write current is passed through the magnetic element(s) and selection device(s). The method and system include driving a first current in proximity to but not through the magnetic element(s) of a portion of the magnetic storage cells. The first current generates a magnetic field. The method and system also include driving a second current through the magnetic element(s) of the portion of the magnetic storage cells. The first and second currents are preferably both driven through bit line(s) coupled with the magnetic element(s). The first and second currents are turned on at a start time. The second current and the magnetic field are sufficient to program the magnetic element(s).

Owner:RENESAS ELECTRONICS CORP +1

Cardiac pulsed field ablation

A method for ablating tissue by applying at least one pulse train of pulsed-field energy. The method includes delivering a pulse train of energy having a predetermined frequency to cardiac tissue, thepulse train including at least 60 pulses, an inter-phase delay between 0 mus and 5 mus, an inter-pulse delay of at least 5 mus, and a pulse width of 5 mus.

Owner:MEDTRONIC INC

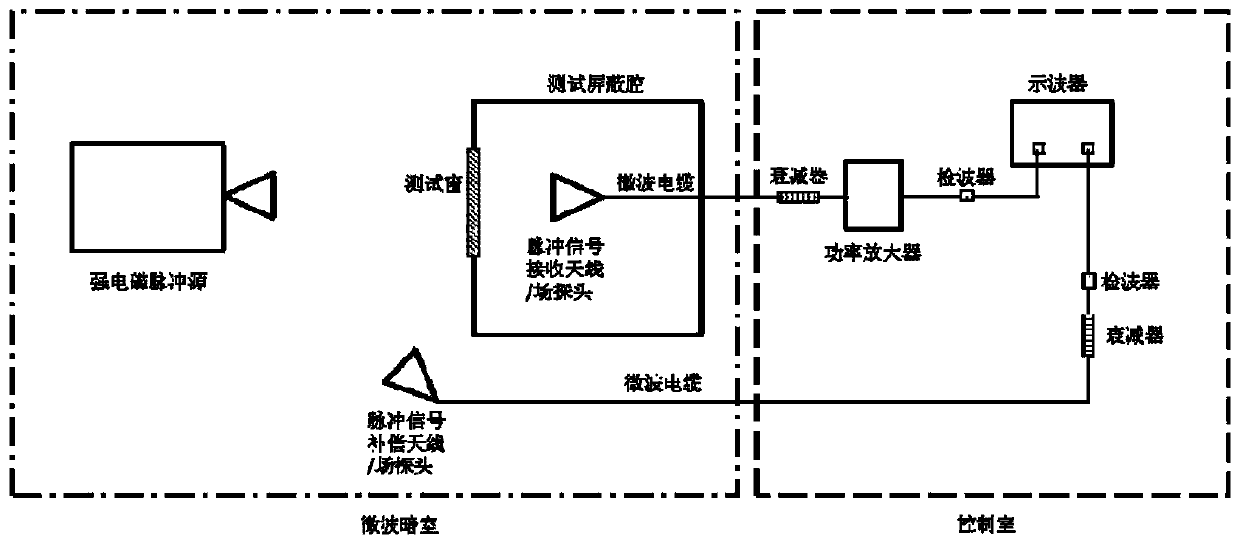

Strong electromagnetic pulse shielding effectiveness test system and method

ActiveCN110702999ASolve the problem that the microwave pulse signal cannot be obtainedImprove dynamic rangeElectromagentic field characteristicsMicrowaveDisplay device

The invention discloses a strong electromagnetic pulse shielding effectiveness test system which comprises a strong electromagnetic pulse source, a test shielding cavity, a pulse field signal receiving loop and a pulse field signal compensation loop; the strong electromagnetic pulse source generates a strong electromagnetic pulse field in an anechoic chamber, a test window is formed in the side surface of the test shielding cavity, the shielding cavity is arranged in the anechoic chamber, and the side with the test window of the shielding cavity faces the incoming wave direction; each of the pulse field signal receiving loop and the pulse field signal compensation loop comprise receiving antenna / field probes, signal transmission loops and a signal display device; and each receiving antenna / field probe is connected with the signal display device through the first signal transmission loop or the second signal transmission loop. In addition, the invention further discloses a method corresponding to the system. Blanks in the field of strong electromagnetic pulse shielding effectiveness test system and the method are filled. The system is wide in the dynamic range, and a test result isextremely high in accuracy.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

Method of fabricating two-dimensional ferroelectric nonlinear crystals with periodically inverted domains

ActiveUS6926770B2Easy to separatePolycrystalline material growthAfter-treatment detailsPhotonicsEngineering

The present invention relates to a method to control the nucleation and transverse motion of 180° inverted domains in ferroelectric nonlinear crystals. It includes a process composing of a high temperature oxidation of the first metal layer and a pulsed field poling of the second electrodes. The main object of present invention is to provide domain inversion of ferroelectric nonlinear crystals with field control the nucleation and transverse motion of inverted domains and two-dimension nonlinear photonic crystals for time-domain multiple-wave simultaneous lasers and space filter function. Another object of present invention is to provide space-charge effect for screened edge field beneath the metal electrode, The other object of present invention is to provide the constraint of inverted domain nucleation in the oxidized electrode for arbitrarily geometrical form of 2D ferroelectric lattice structure.

Owner:NAT TAIWAN UNIV

Ultrafast pulse field source utilizing optically induced magnetic transformation

A magnetic field transducer includes a phase transition material exhibiting a change from an antiferromagnetic phase to a ferromagnetic phase when heated above a critical temperature, means for applying a magnetic bias field to the phase transition material, and means for heating the phase transition material above the critical temperature. Magnetic recording heads that include the transducer and magnetic disc drives that include the magnetic recording heads are also described. A method of producing a magnetic field pulse including applying a magnetic bias field to a phase transition material, and heating the phase transition material to cause the phase transition material to change from an antiferromagnetic phase to a ferromagnetic phase, is also provided. The phase transition material can comprise a rare earth-transition metal alloy, where the alloy is heated above a compensation temperature.

Owner:SEAGATE TECH LLC

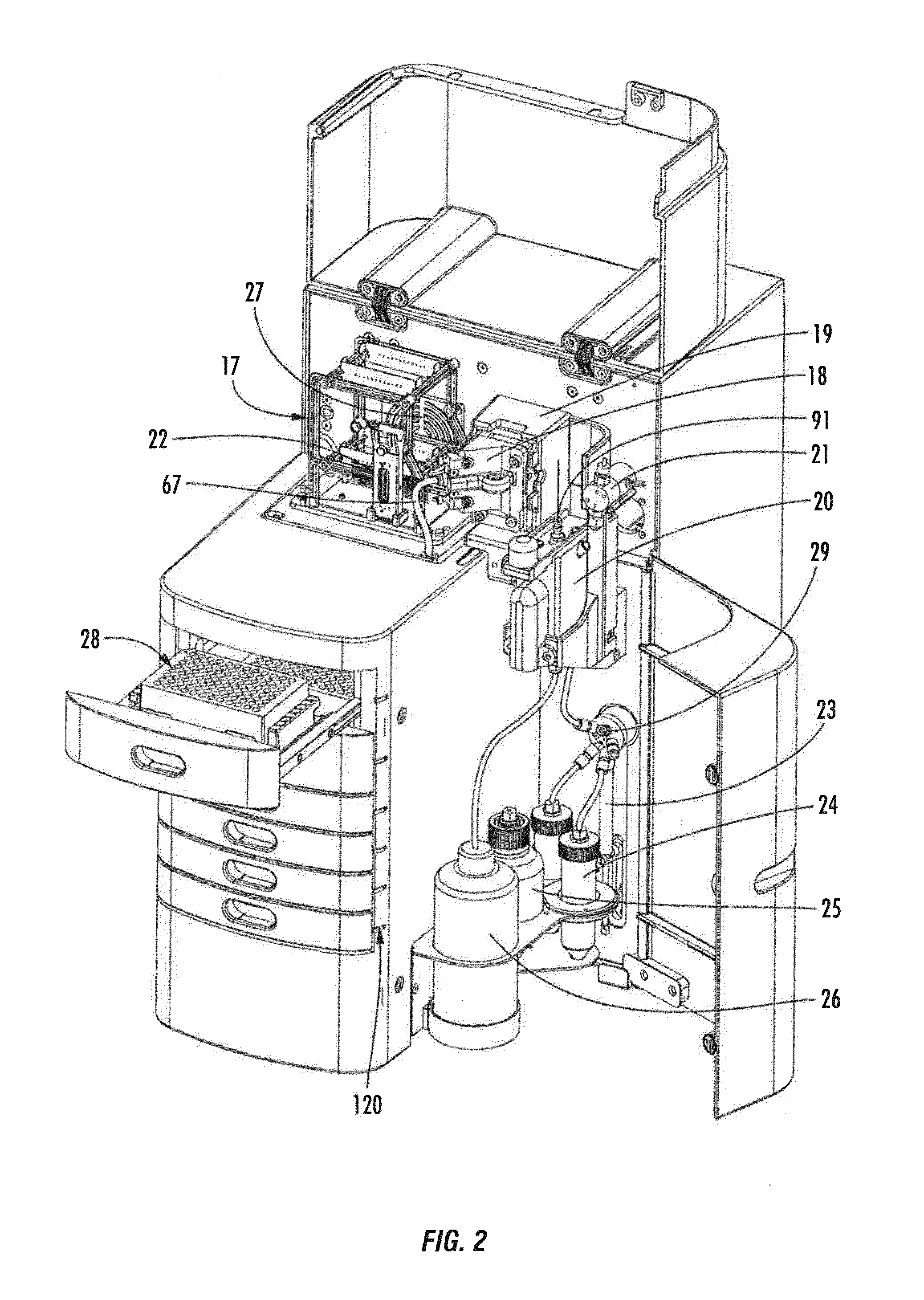

Pulse-field multiplex capillary electrophoresis system

InactiveUS20160109406A1Accurate measurementImprove handlingMaterial analysis by electric/magnetic meansLibraries apparatusCapillary electrophoresisElectrophoresis

The invention is a multiplex, pulsed-field capillary electrophoresis instrument with the ability to analyze DNA fragments with sizes greater than 50,000 bp, greater than 100,000 bp and even granter than 150,000 base pairs. The parallel capillary electrophoresis system allows for the simultaneous analysis of at least 12 samples while applying a pulse or varying electric field for separation.

Owner:AGILENT TECH INC

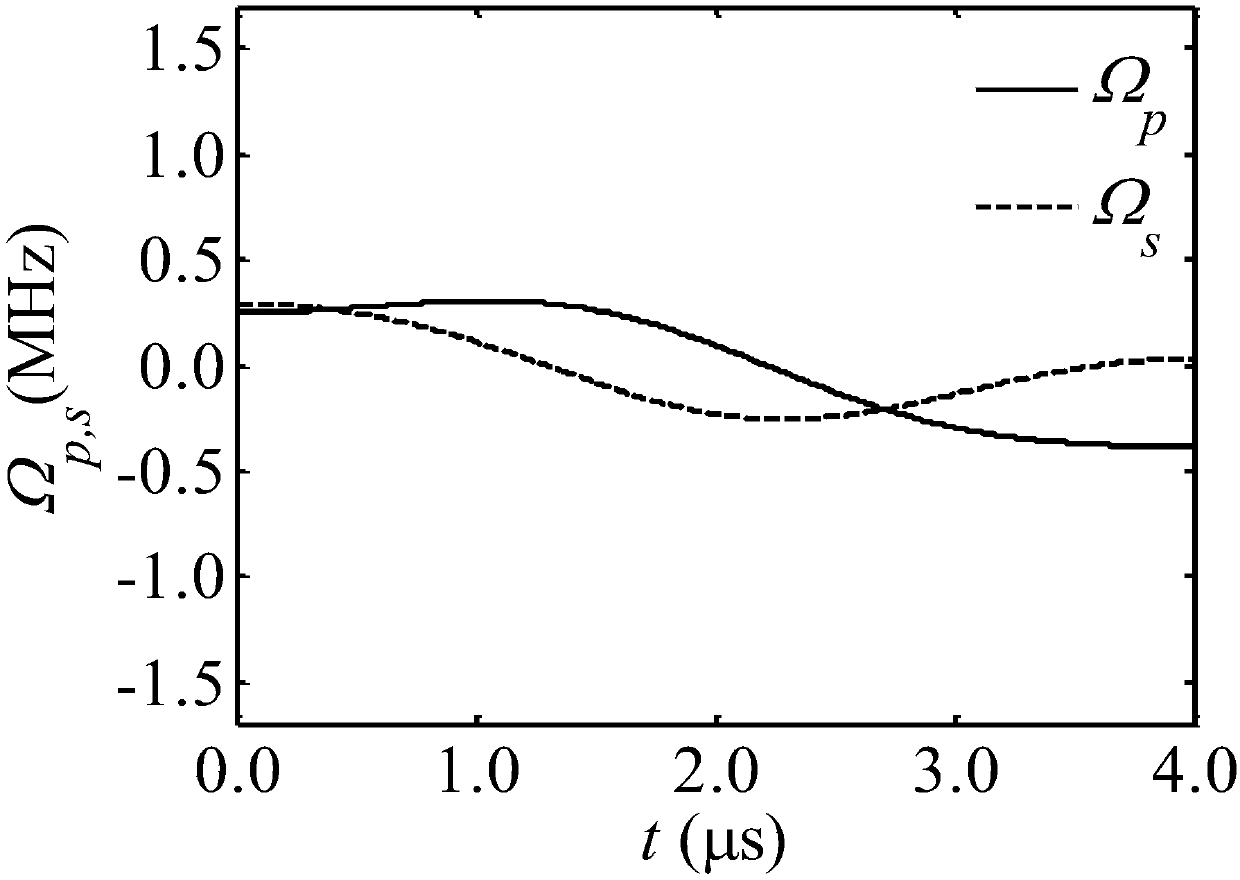

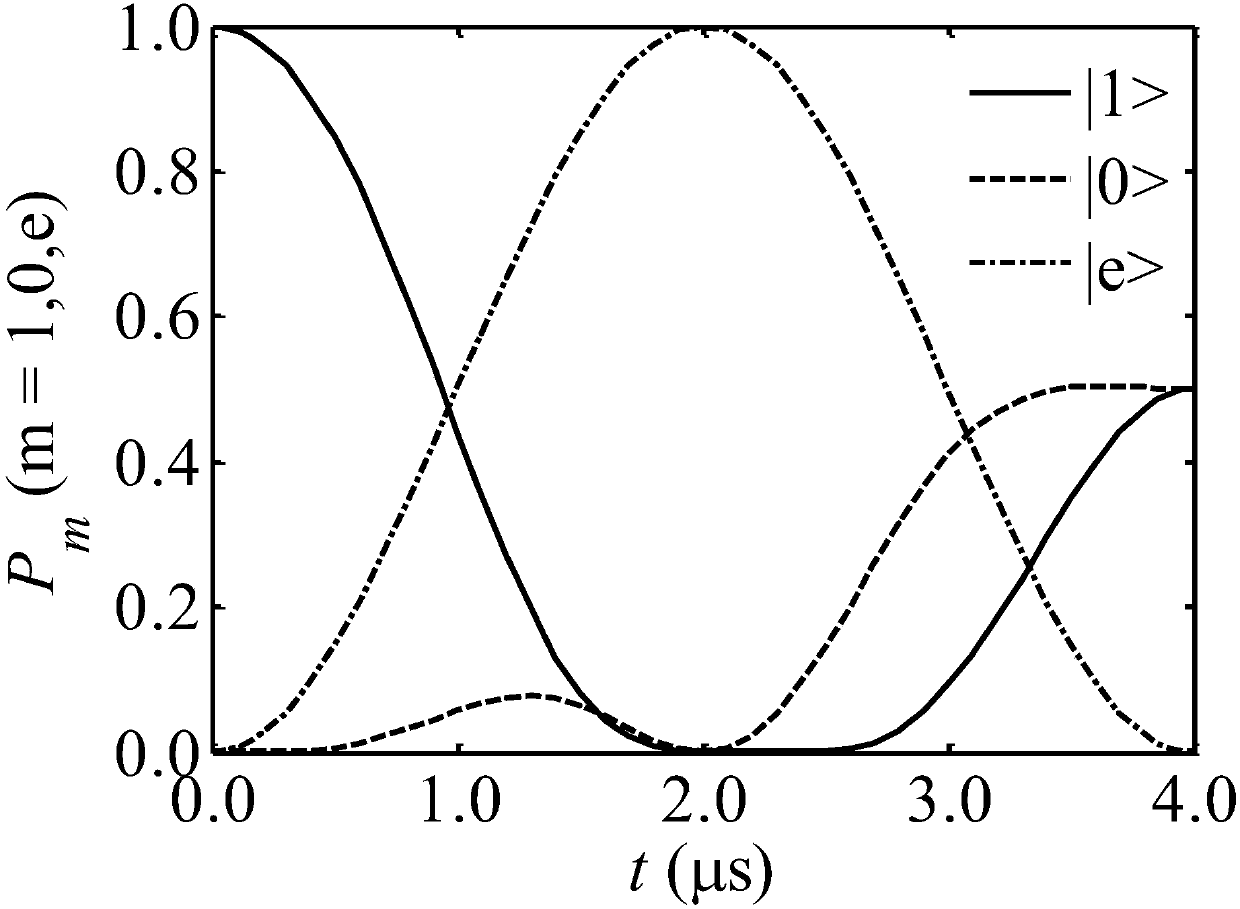

Optical pulse generating method capable of creating three-energy-level system quantum bit random superposition state

The invention discloses an optical pulse generating method capable of creating the three-energy-level system quantum bit random superposition state. An invariant theory is adopted to reversely solve atime-dependent Schrodinger equation of a three-energy-level system, field intensity information of a group of polychromatic optical pulses capable of generating the quantum bit random superposition state is constructed, an arbitrary wave generator and an acoustic and optical modulator are utilized to generate the polychromatic optical pulses, the extra degree of freedom in the polychromatic optical pulse field intensity is utilized to optimize the shape of the pulses, so that the pulses show robustness to the frequency detuning amount existing in the system, and have small-enough non-resonance excitation of background ions existing in the system, and thus the quantum bit random superposition state is created with the fidelity within a short acting time. By means of the optical pulse generating method, the optical pulses can generate the quantum bit random superposition state within the acting time of 4 microseconds, the fidelity within the frequency detuning amount range of + / -340 kHzis not lower than 99.5%, and the non-resonance excitation of the background ions does not exceed 2%.

Owner:SUZHOU UNIV +1

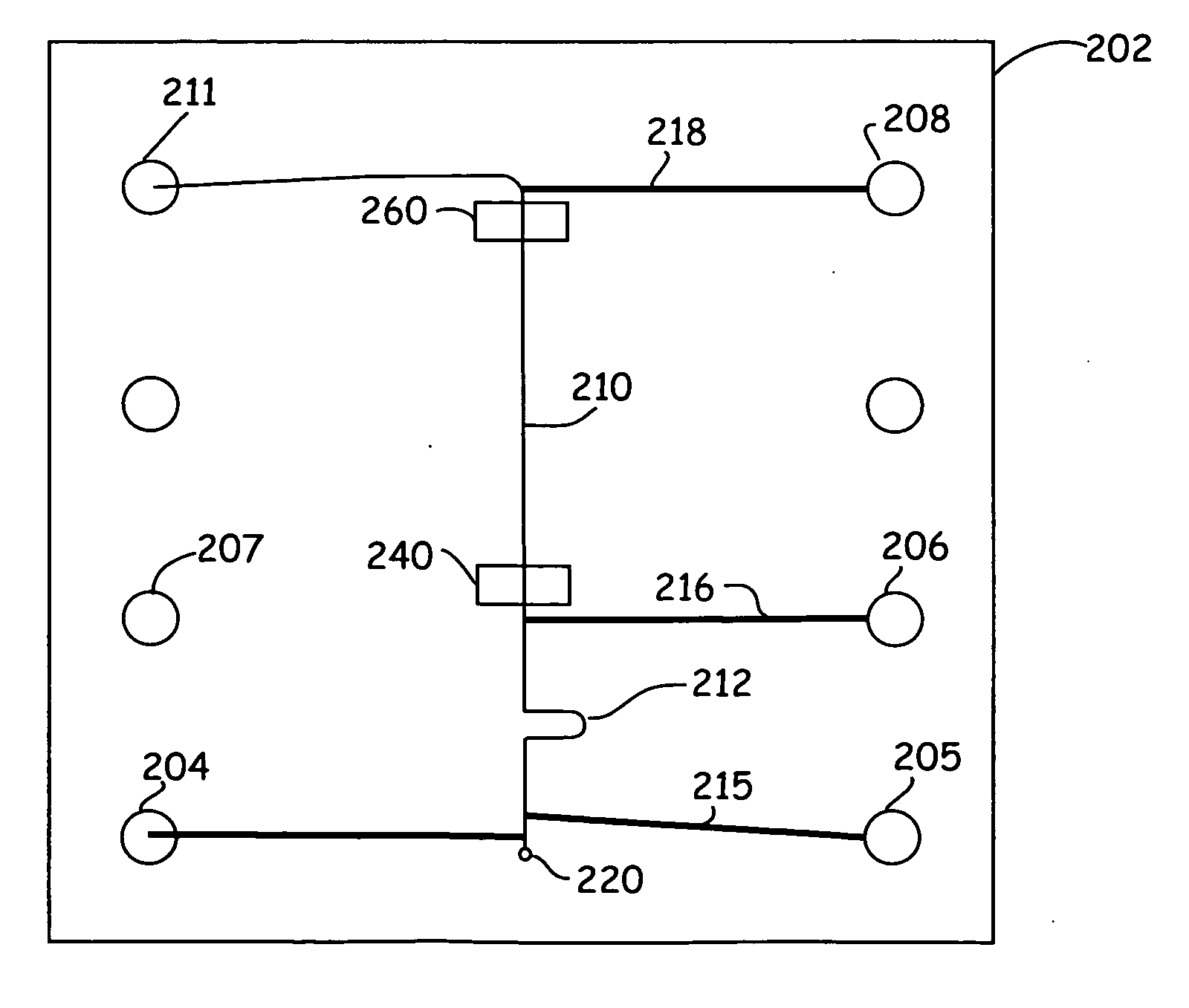

Pulse field assisted spin momentum transfer MRAM design

An MRAM array structure and a method of its operation that is not subject to accidental writing on half-selected elements. Each element of the MRAM is an MTJ (magnetic tunneling junction) cell operating in accord with an STT (spin torque transfer) scheme for changing its free layer magnetization state and each cell is patterned to have a C-shape in the horizontal plane. The cell thereby operates by C-mode switching to provide stability against accidental writing by half-selection. During operation, switching of a cell's magnetization is accomplished with the assist of the pulsed magnetic fields of additional word lines that are formed either orthogonal to or parallel to the existing bit lines and that can carry currents in either direction as required to provide the assist.

Owner:TAIWAN SEMICON MFG CO LTD

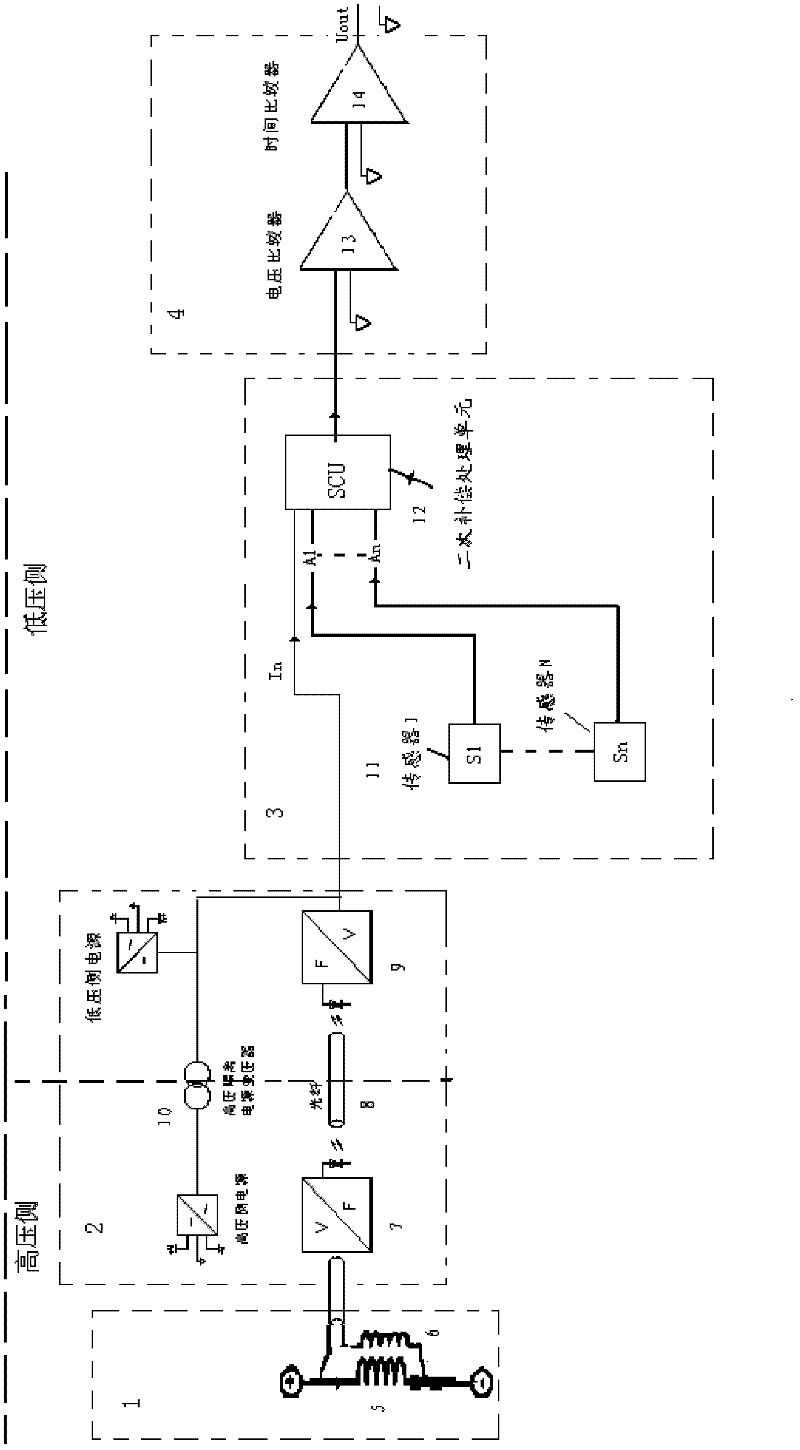

Quenching detection system used in superconducting magnet under pulsed field and method thereof

ActiveCN102346239ASolving Quench Detection ChallengesMagnetic property measurementsFiberCurrent sensor

The invention discloses a quenching detection system and a method which are suitable for being used under a rapidly alternating magnetic field. The system comprises: a quenching detection sensor, a fiber optic isolator, a secondary compensation processing unit and a quenching detector. The quenching detection sensor is connected with the quenching detector through the fiber optic isolator and the secondary compensation processing unit successively. The secondary compensation unit is externally connected with a plurality of current sensors which are installed on an alternating power supply. The quenching detection sensor sends an obtained detection voltage signal to the secondary compensation processing unit after the signal is passed through the fiber optic isolator. The detection voltage signal is accumulated with the detection voltage signal which is sent to the secondary compensation processing unit and is acquired by the current sensors installed on the alternating power supply so as to obtain the effective detection voltage signal. And then the effective detection voltage signal is discriminated by the quenching detector. By using the system and the method of the invention, a large superconducting magnet can perform reliable quenching detection under the condition of rapid changes of working current and the magnetic field.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

Timed energy delivery

A method and system for mapping tissue and producing lesions for the treatment of cardiac arrhythmias in a non-thermal and optimal manner, minimizing the amount of energy required to selectively stun or ablate the target tissues. Energy may be delivered only at the moment(s) of best device position and proximity of an electrode to target tissue, and only during a time in the cardiac cycle determined to be optimal for reversible or irreversible effects. A method may include determining timing of the cardiac cycle and an optimal time within the cardiac cycle for energy delivery, evaluating proximity between at least one energy delivery electrode and the target tissue, and delivering pulsed field energy from the at least one energy delivery electrode to the target tissue when, during the optimal time for energy delivery, the at least one energy delivery electrode is in close proximity with the target tissue.

Owner:MEDTRONIC ABLATION FRONTIERS

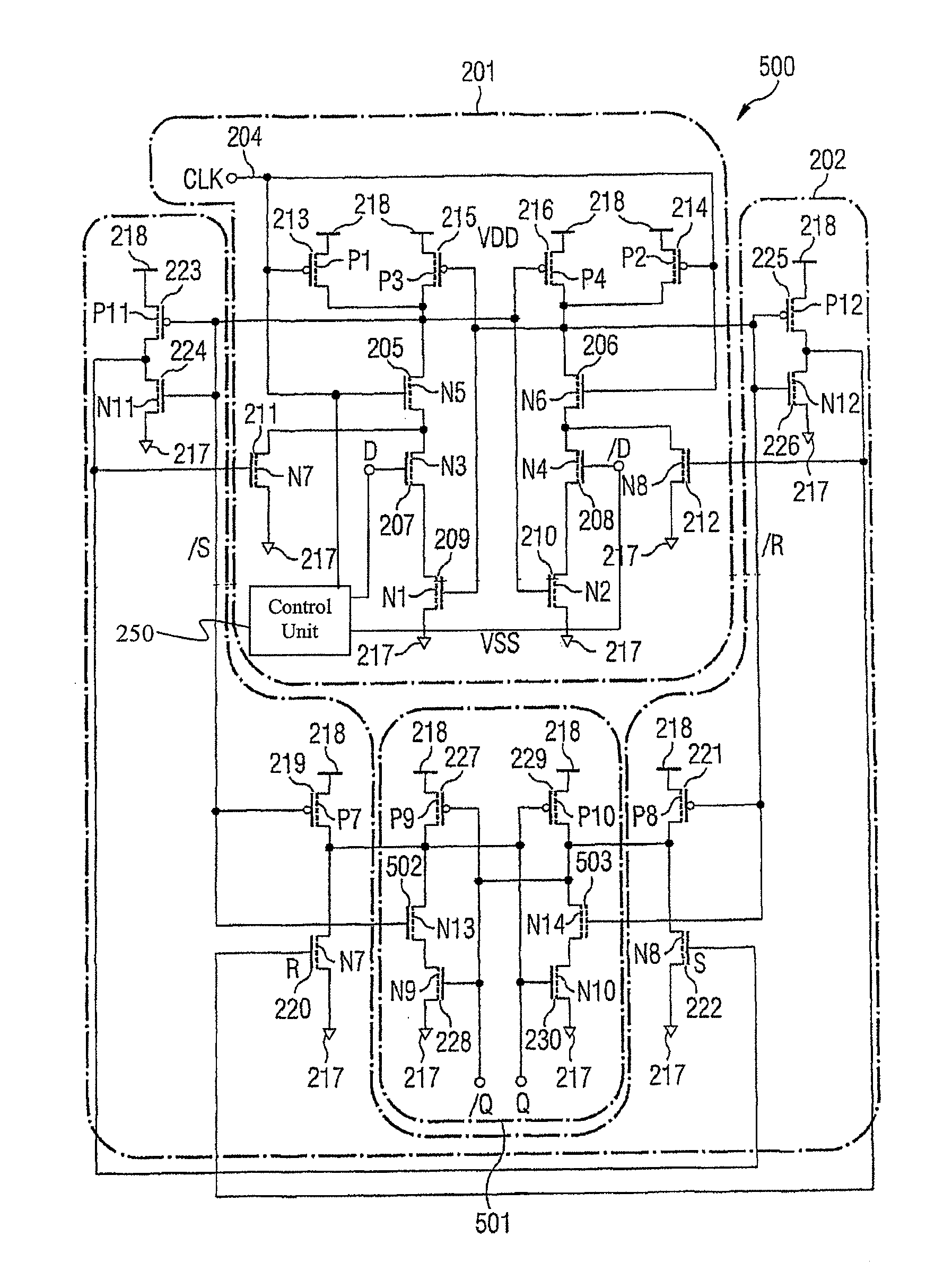

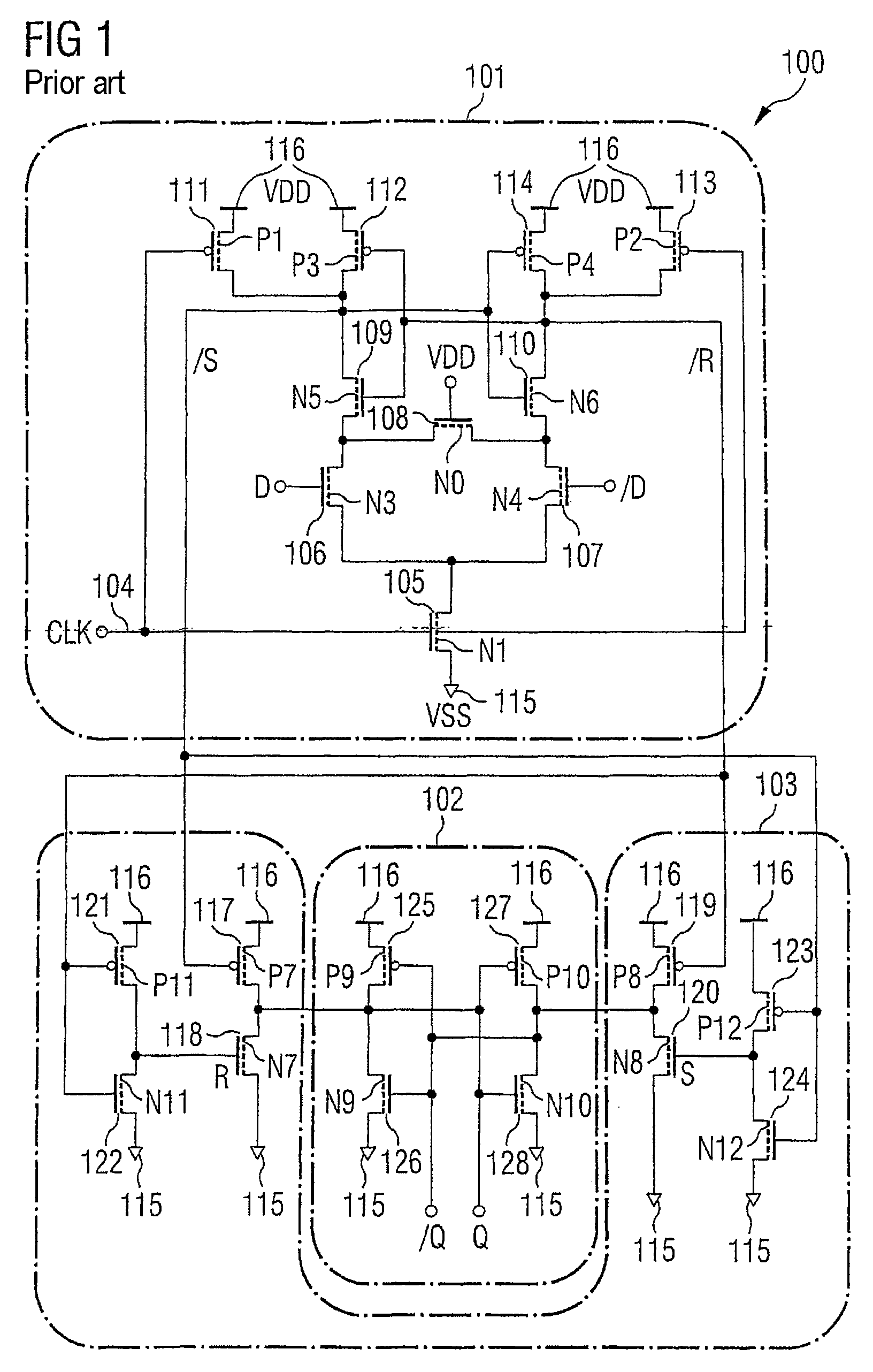

Pulse-generator circuit and circuit arrangement

Pulse-generator circuit for generating an input signal for a flip-flop circuit from a clock-pulse signal and a data signal. The circuit includes a control unit for controlling a clock-pulse field effect transistor, a logic field effect transistor and a feedback field effect transistor. To generate the input signal, the control unit is configured in such a way that the clock-pulse field effect transistor is controlled chronologically after the logic field effect transistor and the feedback field effect transistor, thus generating the flip-flop signal.

Owner:INFINEON TECH AG

Claw-pole electric machine with actively controlled switches

InactiveUS20060052976A1Digital computer detailsSpeed measurement using gyroscopic effectsElectric machinePosition angle

A system, for determining a starting position angle of an electric motor, includes a plurality of windings, a circuit, a processor, and at least one voltage sensor. The circuit is configured to create a pulse current field in at least one of the plurality of windings. The sensor is configured to sense a pulse current field response in a corresponding winding of the plurality of windings. The processor is in communication with the voltage sensor and is configured to determine the position angle of the rotor based on the pulse field response.

Owner:VISTEON GLOBAL TECH INC

Water mist collector of cooling tower

The present invention discloses a water mist collector of a cooling tower, which belongs to the field of water mist collection. The water mist collector is formed by installing two layers of wire mesh screens in the cooling tower. One end of a corona wire is hanged in the cooling tower, and the other end of the corona wire is connected with a power supply unit. A fixing frame is arranged between the two wire mesh screens to fix the corona wire, and a high-frequency ultrasonic generator is arranged on the fixing frame and is connected with a power supply; and a high-voltage electrostatic fieldis formed in the tower when the corona wire is connected with power supply equipment, corona discharges and the outer wall of the cooling tower is grounded. The high-frequency ultrasonic generator can generate ultrasonic waves after being powered up, so as to facilitate water mist condensation. A pulse electrode is arranged to form a pulse field in the tower to further facilitate the water mist condensation. The device combines the electrostatic field, the pulse field and the ultrasonic field to process water in the cooling tower, the water can be condensed more effectively and fall into the water collector, and thus the utilization rate of water resources is increased.

Owner:BEIJING JIAOTONG UNIV

High-power pulse field strength calibration system and high-power pulse field strength calibration method

PendingCN109164405AMeet the needs of measurement assuranceIncrease calibration rangeElectrical measurementsElectric field sensorDark chamber

Embodiments of the application disclose a high-power pulse field strength calibration system and a high-power pulse field strength calibration method. The system comprises: a horn antenna and an integrated optical electric field sensor disposed opposite in a microwave dark chamber, and an analysis module, wherein the horn antenna emits a pulse field with a fixed duty cycle in the microwave dark chamber, the integrated optical electric field sensor induces a pulse field strength to generate an induced voltage, and the analysis module obtains calibration data of the pulse field strength based onparameters of the pulse signal source and the induced voltage. The technical solution described in the application can accurately perform the calibration of high-power pulse field strength, and can meet the measurement guarantee requirements of high-power pulse field strength. The calibration range is up to 3000V / m, which is a significant improvement over the calibration range of the existing conventional methods (up to 1000V / m). The scheme can also calibrate time domain parameters such as pulse field strength repetition frequency, pulse width, and rise / fall time as needed.

Owner:BEIJING INST OF RADIO METROLOGY & MEASUREMENT

Electromagnetic action device improving high-field large-current electromagnetic launch force and being used for body to be launched

InactiveCN102075064ASolve the technical problems of material magnetizationIncrease field strengthMagnetic circuit rotating partsLaunching/towing gearElectromagnetic launchHigh-temperature superconductivity

The invention discloses an electromagnetic action device improving high-field large-current electromagnetic launch force and being used for a body to be launched, namely a high temperature superconducting launch rotor mechanism. The electromagnetic action device comprises the following materials and components: a high temperature bulk superconductor magnet, high temperature superconducting coils,a low temperature cabinet, refrigerating fluid and large-current electrodes. The electromagnetic action device is characterized in that via the high temperature superconducting coil magnets, the hightemperature bulk superconductor can be magnetized by adopting a stable impressed field cooling or zero pulsed field cooling magnetizing scheme; and the prepared rotor and an electromagnetic rotor actto generate greater electromagnetic thrust to implement launch. Through the electromagnetic action device, the technical difficulty of magnetizing the high temperature bulk superconductor magnet usedin the above scheme is effectively overcome and the magnetizing effect is obviously improved. The high temperature bulk superconductor and the high temperature superconducting coils form a whole in the design, so on the one hand, the intensity of the trapped field of the high temperature bulk superconductor is structurally improved, and on the other hand, the intensity of the magnetic field is improved from the current density of the high temperature superconducting material, thus greatly improving the effective field intensity.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Nanosecond-level rising edge high voltage pulse generation device in rydberg state field ionization experiment

ActiveCN103560770ASimple structureEasy to operateElectric pulse generator circuitsLoad circuitCapacitance

The invention discloses a nanosecond-level rising edge high voltage pulse generation device in a rydberg state field ionization experiment. The nanosecond-level rising edge high voltage pulse generation device comprises a power supply module, a switch module and an output load circuit, wherein the power supply module is connected with the switch module, and the switch module is connected with the output load circuit. The power supply module comprises a direct current stabilized power supply and an R1C1 filter circuit, and a number I power supply supplies power to the direct current stabilized power supply. The switch module comprises a quick high voltage pulse switch and an external trigger signal source, and a number II power supply supplies power to the quick high voltage pulse switch. The output load circuit is composed of a damping resistor R2, a discharge resistor R3 and a test capacitor C2. The nanosecond-level rising edge high voltage pulse generation device is simple in structure, convenient to operate and good in stability; besides, rising edges are fast, and frequency and the duty ratio can be modulated. In the fields of laser ionization spectroscopy, laser mass-spectrometric technique and the like, a pulse field of nanosecond-level rising edges can be provided for a rydberg state field ionization process, and therefore a high ionization rate can be realized in the rydberg state field ionization process.

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

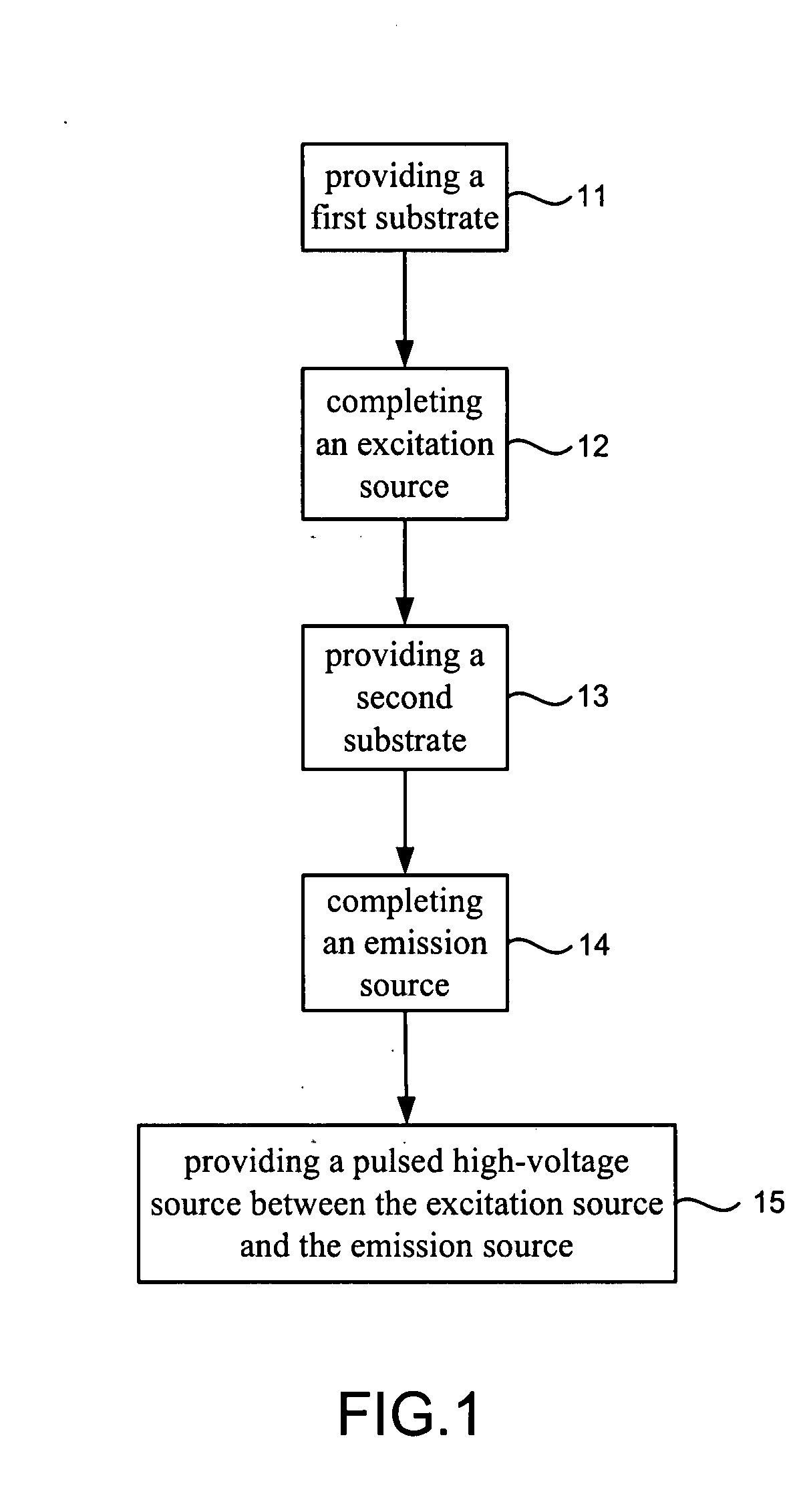

Pulsed high-voltage silicon quantum dot fluorescent lamp

InactiveUS20100216266A1Semiconductor/solid-state device manufacturingLuminescent screen lampsFluorescenceTitanium nitride

In a method for making a pulsed high-voltage silicon quantum dot fluorescent lamp, an excitation source is made by providing a first substrate, coating the first substrate with a buffer layer of titanium, coating the buffer layer with a catalytic layer of a material selected from a group consisting of nickel, aluminum and platinum and providing a plurality of nanometer discharging elements one the catalytic layer. An emission source is made by providing a second substrate, coating the second substrate with a transparent electrode film of titanium nitride and coating the transparent electrode film with a silicon quantum dot fluorescent film comprising silicon quantum dots. A pulsed high-voltage source is provided between the excitation source and the emission source to generate a pulsed field-effect electric field to cause the nanometer discharging elements to release electrons and accelerate the electrons to excite the silicon quantum dots to emit pulsed visible light.

Owner:INST NUCLEAR ENERGY RES ROCAEC

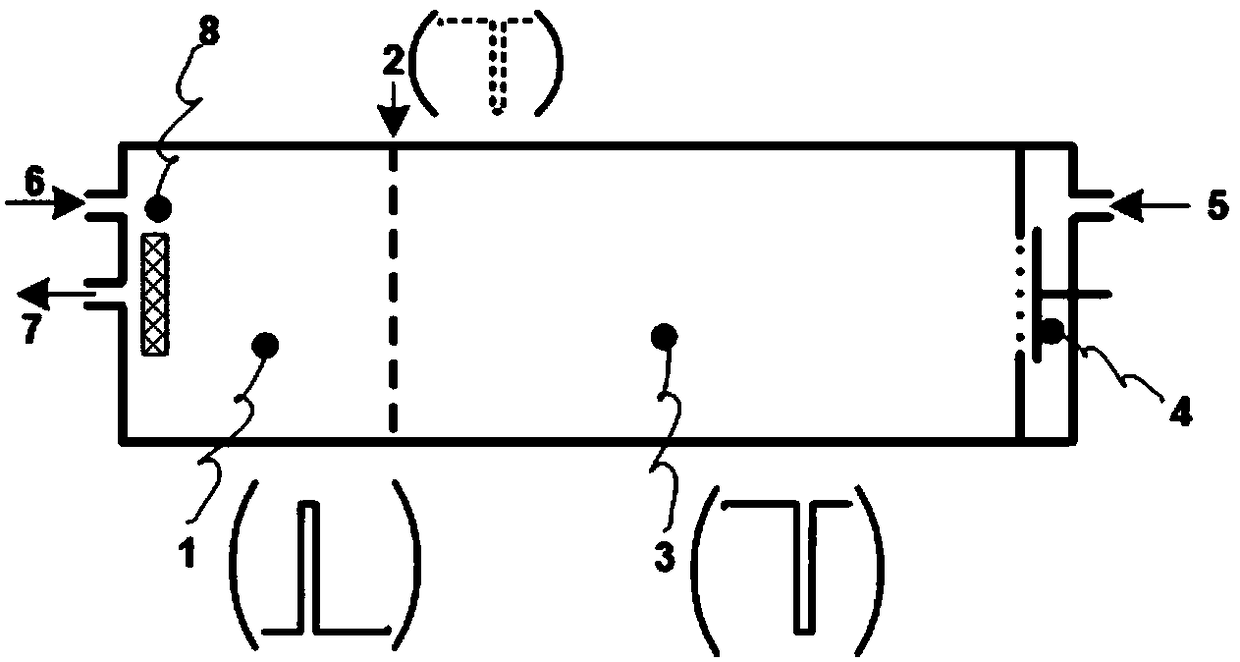

Pulse field enrichment ion migration tube

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method and device for electromagnetic continuous casting of bimetallic multilayer round billet

The invention relates to a method and a device for electromagnetic continuous casting of bimetallic multilayer round billets. The method comprises the following steps: sending a dummy ingot device into an outer crystallizer to tightly contact with the bottom end of an inner crystallizer, pouring outer layer molten metal to an annular space formed by the inner crystallizer and the outer crystallizer, the outer layer molten metal being cooled by the outer crystallizer, and forming a semi-solid support layer after contacting with the outer circular side wall of the inner crystallizer, the outer circular side wall being bare outside, the dummy ingot device beginning to move downward, casting inner layer molten metal to the inner crystallizer, the inner layer molten metal being cooled by the inner crystallizer and contacting and combining with the semi-solid support layer of the outer layer molten metal to form a compound interface, when a continuous casting process enters a stabilizing stage, switching on a pulse power supply and an intermediate frequency power generator, a pulse field coil applying a pulse electromagnetic field in the inner crystallizer, and an intermediate frequency field coil applying an intermediate frequency electromagnetic field in the outer crystallizer. The method is simple in process technology, an inner layer metal solidification structure and an outer layer metal solidification structure of a manufactured product are refined, surface quality of the outer layer metal is high, and the compound interface is clear and stable.

Owner:锦州博锐源创新科技有限公司

Correction method for large-sized coaxial-cable insulation space charge measurement

ActiveCN104698297AEliminate the effects ofAccurate and reliable measurement signalElectrical measurementsCoaxial cableSound wave

The invention relates to a correction method for large-sized coaxial-cable insulation space charge measurement. The correction method specifically comprises the steps of obtaining an exciting pulse field intensity compensation factor, obtaining a sound wave strength compensation factor, correcting geometrical factors of measurement signals and the like. The correction method is applicable to the processing process of the space charge measurement signals of a large-sized coaxial cable sample, by means of a pulse electroacoustic method, the correction factors of the geometrical factors are quantitatively calculated, the geometrical factors of the space charge measurement signals are corrected to eliminate the influence of a coaxial columnar structure of the measured cable sample to the space charge measurement signals and obtain high-accuracy space charge measurement results.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD

Automatically on-line cleaning and water treatment for pipeline system

InactiveCN1895800ABactericidalPlay the role of descaling and antirustHollow article cleaningWater/sewage treatment by magnetic/electric fieldsRustPulse field

A method for in-line automatic cleaning pipeline system and treating water in order to remove dirt and rust, and killing bacteria and algia features that said pipeline system is treated by an alternative digital pulse field generated under the control of PC and the cleaning ball with a diameter slightly greater than the internal diameter of pipeline comes in said pipeline system for cleaning the pipeline and filtering water.

Owner:熊江岳

Pulsed-field differential mobility analyzer system and method for separating particles and measuring shape parameters for non-spherical particles

ActiveUS9677984B2Fall fastRapid riseParticle separator tubesParticle size analysisDifferential mobility analyzerStreamflow

A method for extracting shape information for particles with similar shape and corresponding system of a tandem differential mobility analyzer (DMA) and pulse field differential mobility analyzer (PFDMA) system, that executes at least generating a steady state aerosol concentration; passing aerosol flow from the aerosol concentration thru a bipolar charger to produce a known charge distribution; passing aerosol thru a DMA with set sheath and aerosol flows and a set voltage to generate a mono-mobility aerosol; passing mono-mobility aerosol thru a PFDMA system; and measuring mobility as a function of electric field by varying the duty cycle of the pulse in the PFDMA system. Alternatively, the method and system relate to separating particles with different shapes by adjusting the duty cycle of the pulse to reach a higher or lower electric field than in the DMA in which the mono-mobility aerosol was generated; and separating particles based on shape.

Owner:UNIV OF MARYLAND

Pulse field ion migration tube

ActiveCN108091536AImprove resolutionImprove utilization efficiencyParticle spectrometer methodsUltimate tensile strengthIonization

The invention provides a new technology for enhancing the ion utilization efficiency in the ion migration tube ionization region, and particularly provides a pulse field ion migration tube. A pulse varying electric field is applied to the ionization region and the migration region of the ion migration tube so that the electric field in the ionization region can be enhanced and the electric field in the migration region can be reduced at the moment of opening of the ion gate, all the ions in the ionization region can be injected into the migration region and spatial focusing compression is performed on the ion groups by using the difference of the electric field intensity of the ionization region and the migration region and thus the sensitivity of the ion migration tube can be greatly enhanced and the ion migration tube is enabled to have great resolution capacity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com