Novel rubber powder composite modified asphalt and preparation method thereof

A technology of compound modified asphalt and rubber powder, applied in building components, building insulation materials, buildings, etc., can solve problems such as poor storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

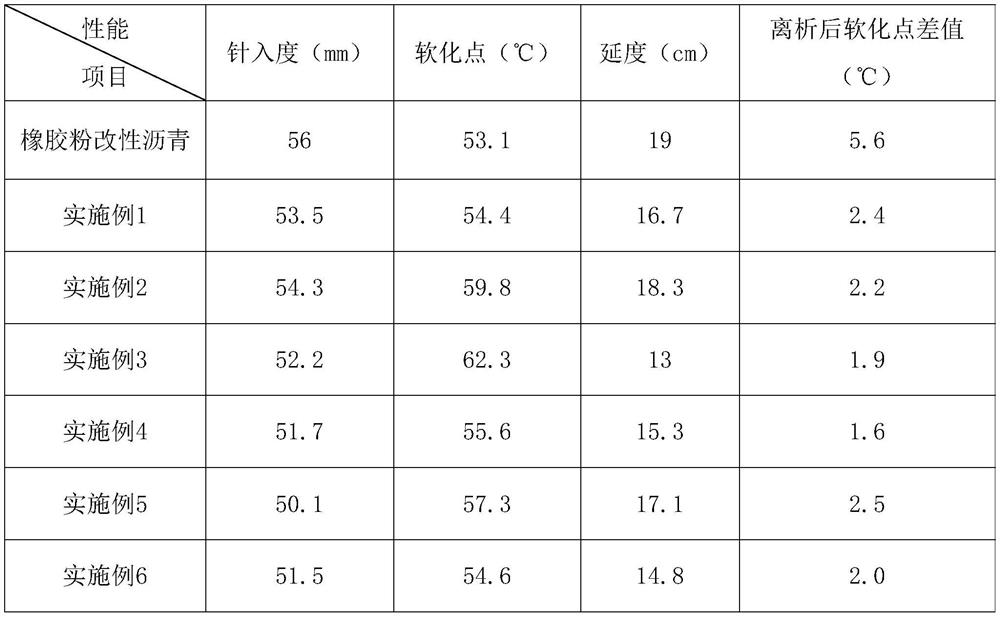

Examples

preparation example Construction

[0028] A kind of preparation method of novel rubber powder composite modified asphalt provided by the invention comprises the following steps:

[0029] Step 1, heating the base asphalt in an oven at 140°C to a molten state to obtain molten base asphalt; take it out for later use;

[0030] Step 2, adding waste tire rubber powder to the molten matrix asphalt obtained in step 1 at a temperature of 180-190°C, performing high-speed shearing, the shearing rate is 4500-5500r / min, and the shearing time is 45-60min. After the cutting is completed, it will be a thick mixture, and then fully swell for 20-30 minutes; wherein, the mass ratio of molten matrix asphalt and waste tire rubber powder is (80-86): (12-18);

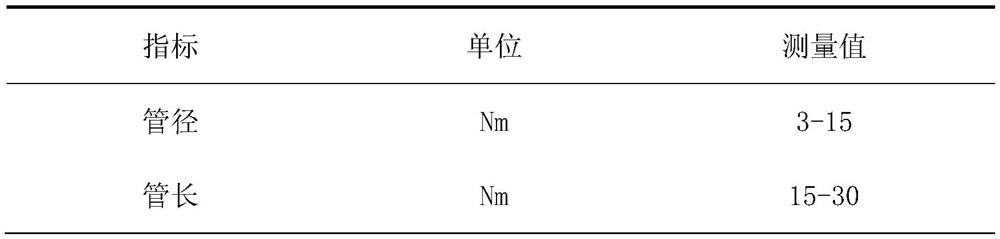

[0031] Step 3, using an ultrasonic disperser, adding the nanomaterial modifier to the thick mixture obtained in step 2 to disperse for 20-30min to obtain a dispersed mixture; wherein, the amount of the nanomaterial modifier is the same as that added in step 2 The mass ratio o...

Embodiment 1

[0039] Step 1, heat the base asphalt in an oven at 140°C to a molten state, and take it out for later use;

[0040] Step 2: Add waste tire rubber powder to the molten matrix asphalt obtained in Step 1 at a temperature of 190°C, perform high-speed shearing, the shearing rate is 4500r / min, the shearing time is 45min, and fully swell for 20min after shearing ; Wherein, the mass ratio of molten matrix asphalt and waste tire rubber powder is 80:15;

[0041] Step 3, using an ultrasonic disperser, adding the nanomaterial modifier to the thick mixture obtained in step 2 and dispersing for 20 minutes to obtain a dispersed mixture; wherein, the amount of the nanomaterial modifier and the waste added in step 2 The mass ratio of rubber powder is 5:15;

[0042] Step 4: Heat the dispersion mixture to 160°C in an electric furnace, shear the asphalt at a high speed for 30 minutes, and use a shear rate of 3000r / min to obtain a new type of rubber powder composite modified asphalt.

Embodiment 2

[0044] Step 1, heat the base asphalt in an oven at 140°C to a molten state, and take it out for later use;

[0045] Step 2: Add waste tire rubber powder to the molten matrix asphalt obtained in Step 1 at a temperature of 190°C, perform high-speed shearing, the shearing rate is 5500r / min, the shearing time is 60min, and fully swell for 30min after shearing ; Wherein, the mass ratio of molten matrix asphalt and waste tire rubber powder is 86:12;

[0046] Step 3, using an ultrasonic disperser, adding the nanomaterial modifier to the thick mixture obtained in step 2 to disperse for 30 minutes to obtain a dispersed mixture; wherein, the amount of the nanomaterial modifier and the waste added in step 2 The mass ratio of rubber powder is 2:12;

[0047] Step 4: Heat the dispersion mixture to 163°C in an electric furnace, shear the asphalt at a high speed for 45 minutes, and use a shear rate of 4000r / min to obtain a new type of rubber powder composite modified asphalt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com