Dealuminzation method of hydrogenous and ammonic Y,ZSM-5,beta and SAPO-34 molecular sieves

A ZSM-5, molecular sieve technology, applied in the direction of molecular sieve characteristic silicoaluminophosphate, molecular sieve and alkali-exchanged phosphate, crystalline aluminosilicate zeolite, etc., can solve the problems of complicated preparation process and uneven degree of molecular sieve dealumination. , to achieve the effect of easy control of the degree of dealumination and a wide range of dealumination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

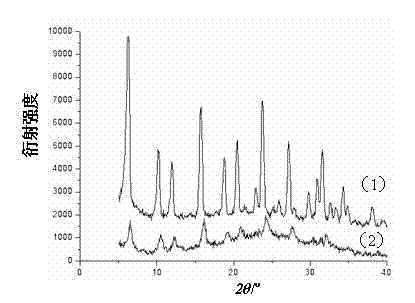

[0046] Put 1 g of hydrogen-type Y molecular sieve (HY, SiO2 / Al2O3=5) (pressed and sieved into 20-40 mesh) in a quartz fixed-bed reactor, and feed pure N2 at 500 °C to pretreat the zeolite for 40 min to remove the moisture. Lower the bed temperature to 250 ° C, at this temperature, the CCl4 concentration of 5% CCl4 / N2 mixed gas is passed into the reactor at a flow rate of 300 ml / min to dealuminate the hydrogen-type Y molecular sieve12 min. Then the above mixed gas was switched to pure N2, the bed temperature was raised from 250 °C to 400 °C, and the sample was purged at a flow rate of 300 ml / min for 40 min. The XRD pattern of the molecular sieve after the gained dealumination and the original parent hydrogen type Y molecular sieve is as follows: figure 1 shown. It is measured that the dealumination process results in a dealumination amount of the hydrogen-type Y molecular sieve of 173.5 mg (calculated as Al2O3).

example 2

[0048] Repeat example 1, but the mixed gas that will be used for the dealumination of hydrogen type Y molecular sieve is that the CCl4 / N2 of 5% is changed to the CHCl3 / N2 that the concentration of CHCl3 is 300 ppm by the concentration of CCl4 for the dealumination of hydrogen type Y molecular sieve, meanwhile, the flow rate of mixed gas is changed to 600 ml / min, the dealumination time was extended from 12 min to 1 h. The XRD pattern of the obtained molecular sieve after dealumination is similar to that of the original parent hydrogen type Y molecular sieve. It was measured that the dealumination process resulted in a dealumination amount of hydrogen type Y molecular sieve of 8.9 mg (calculated as Al2O3).

example 3

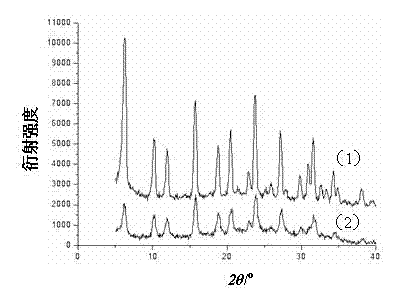

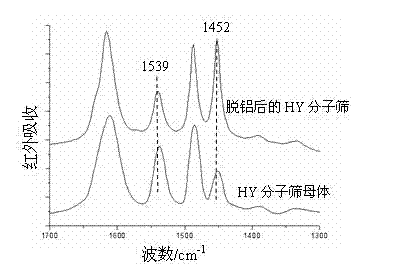

[0050] Repeat Example 1, but shorten the dealumination treatment time of hydrogen type Y molecular sieve from 12 min to 4 min. It was measured that the dealumination process resulted in a dealumination amount of hydrogen type Y molecular sieve of 62.8 mg (calculated as Al2O3). The XRD pattern of the molecular sieve after the gained dealumination and the original parent hydrogen type Y molecular sieve is as follows: figure 2 shown. The obtained dealuminated molecular sieve samples and the original parent hydrogen-type Y molecular sieve samples were measured by pyridine adsorption infrared spectrum at 400 ℃. Depend on image 3 It can be seen that the infrared absorption of the dealuminated molecular sieve by this method is nearly 3 times that of the dealuminated molecular sieve at 1452 cm-1, which indicates that the strong Lewis acid content of the dealuminated molecular sieve by this method is nearly 3 times that of the original parent hydrogen-type Y molecular sieve. times...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com